Highlights

-

Bi2S3 is proposed as a promising cathode material for rechargeable aqueous Zn ion battery.

-

The Zn/Bi2S3 battery shows a reversible capacity of 161 mAh g−1 at 0.2 A g−1 and good cyclic stability of up to 100 cycles with ca. 100% retention.

-

The storage mechanism in the Bi2S3 cathode is related to the reversible Zn ion intercalation/extraction reactions and the capacitive contribution.

Abstract

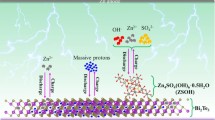

Aqueous Zn ion batteries (ZIBs) are promising in energy storage due to the low cost, high safety, and material abundance. The development of metal oxides as the cathode for ZIBs is limited by the strong electrostatic forces between O2− and Zn2+ which leads to poor cyclic stability. Herein, Bi2S3 is proposed as a promising cathode material for rechargeable aqueous ZIBs. Improved cyclic stability and fast diffusion of Zn2+ is observed. Also, the layered structure of Bi2S3 with the weak van der Waals interaction between layers offers paths for diffusion and occupancy of Zn2+. As a result, the Zn/Bi2S3 battery delivers high capacity of 161 mAh g−1 at 0.2 A g−1 and good cycling stability up to 100 cycles with ca. 100% retention. The battery also demonstrates good cyclic performance of ca. 80.3% over 2000 cycles at 1 A g−1. The storage mechanism in the Bi2S3 cathode is related to the reversible Zn ion intercalation/extraction reactions and the capacitive contribution. This work indicates that Bi2S3 shows great potential as the cathode of ZIBs with good performance and stability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Energy storage devices are in great demands for the integration of renewable energy and electrical energy infrastructures due to the energy crisis and environmental pollution [1,2,3,4]. Poised as the most successful commercial energy storage devices, lithium-ion batteries (LIB) are widely used due to their rechargeability and high energy density [5,6,7]. However, as the usage of LIB increases, there are growing concerns regarding the safety issues of flammable organic electrolytes and the availability of lithium resources [8, 9]. To reduce such heavy reliance on LIB, there is a renewed interest in alternative energy storage devices, especially those that utilize aqueous electrolyte, i.e., aqueous rechargeable battery (ARB) [10,11,12,13]. Among these ARBs, zinc ion batteries (ZIBs) are particularly attractive as zinc displays water compatibility, natural abundance, relatively low redox potential (− 0.76 V vs. SHE) and high theoretical capacity (820 mAh g−1) [14,15,16]. Despite these numerous advantages, cathode material selection is highly stringent which poses significant difficulties in developing advanced cathode materials that show both high energy density and long cycling stability.

The most widely studied ZIBs cathode materials remain to be metal oxides such as vanadium-based oxides and manganese-based oxides [17,18,19,20,21]. Despite many successful demonstrations of vanadium-based and manganese-based oxides in ZIBs application, one main concern for these materials is the presence of high negative charge density O2− from M–O where M = Mn or V. Such concern is amplified for ZIBs as compared to LIB due to the shuttling of densely positive charged Zn2+ across the material which may lead to strong electrostatic forces between O2− and Zn2+ [16, 22]. The strongly electrostatically “glued” Zn would then be unable to be fully removed during the charging process which could eventually lead to two major issues; (1) high initial irreversible loss, and (2) poor cyclic stability. While such an issue can be alleviated with the incorporation of structural water in the interlayer spacing as an electrostatic shield, alternative strategies remain scarce [23, 24]. An alternative strategy to minimize the impact of electrostatic “adhesion” of Zn2+ onto O2− is to replace oxide in metal oxide with sulfide. Even though metal sulfides are less studied in ZIBs than metal oxide, the anion replacement from O2− to S2− may reduce the tendency of these electrostatic “adhesion” and therefore leading to improved cyclic stability and minimizing the initial irreversible capacity loss [16, 22]. Furthermore, the lack in metal sulfide studies provides excellent explorative opportunities which could potentially lead toward the development of high-performing ZIBs cathode with high cyclic stability. While there are a few reports on metal sulfides for ZIBs application such as VS2 [25], and this small material repertoire requires urgent expansion and further exploration. Bi2S3 is a semiconductor material with a narrow band gap of 1.3 eV, and high ionic conductivity which have attracted significant attention in electrochemistry application. In particular, the highly anisotropic Bi4S6 layers that are held together by weak van der Waals interaction provides sufficient pathway for foreign ions to intercalate into. As such, it has been studied as lithium-ion battery, and sodium ion battery cathodes [26, 27]. Such layered structure presents exciting opportunity for ion intercalation which may provide possible Zn2+ storage.

Hence, motivated by this phenomenon, Bi2S3 is investigated as ZIBs cathode in this work. Bi2S3 nanoparticles were synthesized using a facile chemical method followed by calcining. Bi2S3 with layered structure offers paths for fast diffusion and occupancy of Zn2+, and also shows good cyclic stability. The as-prepared Bi2S3 delivers a high capacity of 161 mAh g−1 at a current density of 0.2 A g−1 and exhibits enhanced cyclic stability (100% retention after 100 cycles at 0.2 A g−1) as the cathode for ZIBs. The energy storage mechanism of the Bi2S3 electrode is revealed by a series of measurements. Results demonstrate that the capacitive process and the intercalation/deintercalation of Zn2+ in the Bi2S3 interlayer occur during discharging/charging processes. Our finding shows that Bi2S3 is a promising cathode material with high capacity and good stability for the development of high-performance aqueous Zn ion battery system.

2 Experimental Section

2.1 Chemicals

Na2S, Bi(NO3)3·5H2O, and ZnSO4·7H2O were purchased from Sigma-Aldrich. Acetic acid was purchased from Fluka. Carbon paper (0.18 mm, 77% porosity) was purchased from Ce-Tech Co. Ltd.

2.2 Synthesis of Bi2S3 Nanoparticles

Bi2S3 nanoparticles were synthesized by a simple chemical reaction followed by a simple calcining method. Typically, 0.97 g of Bi(NO3)3·5H2O was dissolved into 100 mL H2O containing 9 mL acetic acid. Then, 30 mL of Na2S solution (0.003 mol) was added into the above solution and kept for stirring 2 h. The solid were collected by centrifugation, washed with ethanol and distilled water for three times, and then dried at 60 °C. The dried solid was then heat-treated in a vacuum oven at 200 °C for 3 h to yield crystallized Bi2S3 nanoparticles.

2.3 Characterization

The powder X-ray diffraction (XRD) pattern was measured by a powder diffractometer (Bruker D8 Advanced Diffractometer System) with a Cu Kα (1.5418 Å) source. Scanning electron microscopy (SEM) images were recorded on a ZEISS SEM Supra 40 (5 kV). Transmission electron microscopy (TEM) was performed on a JEOL-3010 (300 kV acceleration voltage). TEM samples were prepared by dripping the sample solutions onto a copper grid. Surface composition was studied by X-ray photoelectron spectroscopy (XPS) using a Kratos Analytical Axis UltraDLD UHV spectrometer with a monochromatized Al Ka X-ray source (1486.6 eV) scanning a spot size of 700 µm by 300 µm.

2.4 Electrochemical Measurements

All electrochemical tests were tested using an electrochemical station (Bio-logic VMP 3) at room temperature. A CR2025-type coin cell was constructed to evaluate the electrochemical performance. The as-prepared Bi2S3 nanoparticles were mixed with carbon black and polyvinyl difluoride in a 7:2:1 weight ratio with N-methyl-2-pyrrolidone. The mixture was hand-grinded and then coated onto the carbon paper, and finally dried at 80 °C for further use as cathode. Zn foil was used as the anode and filter paper was applied as the separator. 2 M of ZnSO4 was employed as the electrolyte. For both cyclic voltammetry and charge/discharge tests, the voltage was measured in the range of 0.4–1.2 V. The current densities of 0.2, 0.3, 0.4, 0.5, 0.6, 0.8, 1, 2, 3, 4, 5, 6, 8, and 10 A g−1 were selected for charge/discharge test. Electrochemical impedance spectroscopy was tested in the frequency range from 0.01 to 105 Hz. Specific capacity, energy density, and power density were determined using the mass of the active material from the cathode. The mass of the active material is about 1 mg, pasted onto a 1.2 cm in diameter carbon paper.

3 Results and Discussion

The Bi2S3 nanoparticles were synthesized via a simple chemical reaction followed by calcination. The XRD pattern of the obtained Bi2S3 nanoparticles displays a high degree of crystallization. All the diffraction peaks of the obtained sample can be indexed to orthorhombic Bi2S3 (JCPDS No. 17-0320) (Fig. 1a). The crystal structure of Bi2S3 is shown in Fig. 1b, which consisted of sheets of atoms parallel to the z-axis with each S surrounded by three Bi atoms and each Bi atom surrounded by three S atoms [28]. Also, sufficient interlayer spacing in the layers offers paths for diffusion and occupancy of foreign ions to storage energy. XPS spectrum in Fig. 1c confirms that the synthesized material is mainly composed of S and Bi elements (C and O signals come from the reference sample and absorbed oxygen).

TEM images show that the Bi2S3 exhibits nanoparticle-like morphology (Fig. 1d, e). The size of the nanoparticles is in the range of 10–50 nm, and the nanosized structure could suppress volume expansions during intercalation and deintercalation of ions [29]. The lattice distance of 0.503 nm corresponds to the (120) crystal plane of Bi2S3 in high-resolution TEM image (Fig. 1f). The SAED in the inset of Fig. 1f confirms the polycrystalline nature of the synthesized Bi2S3 nanoparticles. Further microstructural features of the synthesized Bi2S3 samples were investigated by N2 adsorption–desorption isotherms as shown in Fig. S1a. The type IV isotherm (IUPAC definition) is obtained with a Brunauer–Emmett–Teller surface area of 16 m2 g−1, and the H1 hysteresis loop demonstrates the presence of mesopores [30]. The pore size distribution (Fig. S1b) shows the mesopores centered at 28 nm, formed by the aggregated nanoparticles. Originating from the high crystallinity, nanosized structure and mesopores, the synthesized Bi2S3 is expected to show good electrochemical performance.

The electrochemical performance of the material was assessed by assembling a Zn/Bi2S3 cell using Bi2S3 as cathode and Zn foil as anode in an aqueous solution of 2 M ZnSO4. Figure 2a shows the cyclic voltammetry (CV) curve of Zn/Bi2S3 cell at scan rate of 0.5 mV s−1 in the voltage window of 0.4–1.2 V. Obvious redox peaks could be observed, which may be related to the interaction between Bi2S3 and Zn ions. In addition, galvanostatic discharge/charge (GCD) profiles are in accordance with the CV curves, which show one plateau around 0.6 V (Fig. 2b). Zn/Bi2S3 cell shows a high discharge capacity of 161 mA h g−1 at 0.2 A g−1. It also shows excellent rate performance, demonstrating high capacities of 143, 132, 121, 113, and 101 mAh g−1 at 0.3, 0.4, 0.5, 0.6, and 0.8 A g−1, respectively (Fig. 2c).

The energy and power densities of the Zn/Bi2S3 battery are calculated as shown in Fig. 2d. It can be seen that the assembled battery shows a maximum energy density of 105 Wh kg−1, and also it delivers a maximum power density of 1455 W kg−1. For the long-term cycling stability, the Zn/Bi2S3 cell obtains a cyclic retention of 100% up to 100 cycles at a low current density of 0.2 A g−1, with the corresponding columbic efficiency approaching 100% (Fig. 2e). The capacity remains 80.3% after 2000 cycles at current density of 1 A g−1 (Fig. 2f). Also, we tested the XRD of the cycled Bi2S3, and the result shows that the sample is stable because it shows similar XRD pattern to the fresh one (Fig. S2). The good stability indicates that the Bi2S3 is a promising material for Zn ion battery application.

Electrochemical impedance spectroscopy (EIS) measurements are performed on the Zn/Bi2S3 battery to study the detailed reaction kinetics. Figure 3a exhibits the Nyquist plots with a semicircle (at high frequency) involved with charge transfer and a sloped line associated with ion diffusion (at low frequency) [31]. In the equivalent circuit, by fitting, Bi2S3 shows low resistance of Rs (equivalent series resistance, 5.02 OhΩ), RCT (charge transfer resistance, 4.1 OhΩ), and ZW (936.2 OhΩ), illustrating the fast reaction kinetics. The fast reaction kinetics could be attributed to the reduced electrostatic “adhesion” of Zn2+ onto anion S2− which leads to fast diffusion of Zn2+. To reveal the electrochemical kinetics of the Bi2S3 electrode, CV curves at different scan rates from 0.1 to 0.5 mV s−1 are studied in Fig. 3b. In each curve, three peaks were observed. An equation for analyzing the electrochemical kinetics processes, based on the peak currents (i) and scan rates (v) is shown as Eq. 1 [32, 33]:

which can be equally written as Eq. 2

where b is defined as the slope of log(i) versus log(v) curve. Typically, the value of b (0.5–1) is related to the type of electrochemical process. When b value reaches 0.5, it indicates that the electrochemical kinetics process is dominated by ionic diffusion. Surface capacitive effects become dominant as the b value is 1. From Fig. 3c, the b values for peak 1, 2, and 3 are determined to be 0.81, 0.91, and 0.97, separately. These b values hint that the ionic diffusion along with surface capacitive effects would control the electrochemical kinetics reaction for Zn/Bi2S3 cell. The contribution from capacitor-like and diffusion-controlled processes can further be determined by Eq. 3 [34, 35]:

which can be rewritten in Eq. 4

where i is related to the total current response, k1v represents current from surface capacitive effects, and k2v1/2 means current because of ionic diffusion process. As k1 could be achieved via fitting i/v1/2 versus v1/2 plots, the contribution from capacitive effect is determined to be 86.5% at scan rate of 0.1 mV s−1. As scan rate increases, the percentage of capacitive contribution is up to 90.1%, 91.8%, 92.8%, and 93.5% at 0.2, 0.3, 0.4, and 0.5 mV s−1, respectively (Fig. 3d). The results suggest that the capacitive contribution is dominant, and the capacitive contribution ratios gradually increase with an increase in scan rate.

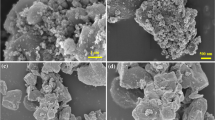

The storage mechanism is investigated by ex situ XRD, XPS spectra, SEM–EDX elemental mappings and TEM. Before charge/discharge process, we performed CV for 30 cycles to get a stable state. From the charge/discharge processes as shown in Fig. 4a, b, it indicates that ZnSO4·3Zn(OH)2·4H2O (JCPDS No. 09-0204) is successively formed during the discharge process. Subsequently, ZnSO4·3Zn(OH)2·4H2O disappears after being fully charged to 1.2 V. These results demonstrate the reversible formation/decomposition of ZnSO4·3Zn(OH)2·4H2O during the discharge/charge process. The storage mechanism was also investigated by the XPS spectra at different charge/discharge states (Fig. 4c). It should be noted that a small amount of Zn2+ ions in Bi2S3 is detected after 30 cycles, suggesting that some of Zn2+ ions were trapped into Bi2S3 (state ① in Fig. 4c). During the discharging process, two pairs of Zn2+ peaks gradually appear at 1024.1/1047.1 eV and 1024.8/1047.9 eV, which are attributed to the Zn2+ in Zn(OH)2 and ZnSO4 from ZnSO4·3Zn(OH)2·4H2O, separately [19]. Meantime, the intensity about the Zn2+ peaks at 1023.3/1046.3 eV associated with the inserted Zn2+ in Bi2S3 increases, confirming the Zn2+ insertion process.

During the charging process, the peaks associated with the Zn2+ in Zn(OH)2 and ZnSO4 from ZnSO4·3Zn(OH)2·4H2O gradually disappear, further confirming the reversible conversion of ZnSO4·3Zn(OH)2·4H2O, consistent with the XRD result. Simultaneously, the peak intensity gradually decreases for the inserted Zn2+ in Bi2S3. It indicates the continuous and reversible intercalation/extraction of Zn2+ in Bi2S3 during the electrochemical processes. SEM–EDX elemental mappings of the fully discharged Bi2S3 electrode are shown in Fig. S3. Obviously, elemental Zn is uniformly distributed in the Bi2S3 nanoparticles, which confirms the insertion mechanism of Zn ion into Bi2S3 layers.

The structural evolution of Bi2S3 electrode was further investigated by TEM analysis. For the Bi2S3 electrode at the fully discharged state, in Fig. 4d, e, nanoplates could be observed, and the observed lattice fringes with interplanar distances of ca. 1 nm correspond to the plane of ZnSO4·3Zn(OH)2·4H2O, indicating the generation of ZnSO4·3Zn(OH)2·4H2O during the discharge process, consistent with the XRD and XPS analysis. Also, Bi2S3 with nanoparticles structure could be observed. The lattice spacing of 0.61 nm, which was enlarged when compared with that of the fresh Bi2S3 with lattice distance of 0.503 nm, was clearly observed in the HRTEM image (Fig. 4f, g). The enlarged lattice could be attributed to the insertion of Zn2+. The layered structure of Bi2S3 with the weak van der Waals interaction between layers offers paths for diffusion and occupancy of Zn2+.

Hence, based on the collective results, the electrochemical mechanism of Zn/Bi2S3 is related to the capacitive process and the intercalation/extraction of Zn2+ into the Bi2S3 framework during discharging/charging process, which is summarized as follows: During the discharge process, ZnSO4·3Zn(OH)2·4H2O is successively formed which is confirmed by the XRD, XPS (the detected Zn2+ peaks in Zn(OH)2 and ZnSO4 from ZnSO4·3Zn(OH)2·4H2O) and TEM (the observed interplanar distances of ca. 1 nm for ZnSO4·3Zn(OH)2·4H2O) results. Meantime, Zn2+ is inserted into Bi2S3 as revealed by the XPS (enhanced Zn2+ peaks intensity of the inserted Zn2+ in Bi2S3), TEM (enlarged lattice distance of 0.61 nm for Bi2S3), and SEM–EDX elemental mappings (uniform distribution of Zn2+ in the discharged Bi2S3) results. During the charging process, ZnSO4·3Zn(OH)2·4H2O gradually disappears. These results demonstrate the reversible formation/decomposition of ZnSO4·3Zn(OH)2·4H2O during the discharge/charge process. At the same time, Zn2+ ions are extracted from Bi2S3 as demonstrated by the decreased XPS intensity of Zn2+ ions. Overall, the designed Bi2S3 electrode shows high zinc ion storage performance with faster reaction kinetics, higher capacity and better long-term cycles, presenting a potentially safe, durable, and low-cost device for large-scale energy storage.

4 Conclusions

In conclusion, we report a simple chemical method followed by calcining to synthesize Bi2S3 nanoparticles as cathodes for aqueous rechargeable ZIBs. The obtained Bi2S3 nanoparticles display high capacity of 161 mAh g−1 at current density of 0.2 A g−1. Good rate behavior is demonstrated, and the Zn/Bi2S3 cells show good cycling stability over 100 cycles. At high current density of 1 A g−1, the cell still keeps 80.3% retention after 2000 cycles. Mechanistic details of the Zn storage based on surface capacitive effects and Zn2+ ions insertion are demonstrated. The high capacity, good stability, and low cost make our battery promising for stationary energy storage applications.

References

E. Karden, S. Ploumen, B. Fricke, T. Miller, K. Snyder, Energy storage devices for future hybrid electric vehicles. J. Power Sources 168, 2–11 (2007). https://doi.org/10.1016/j.jpowsour.2006.10.090

X. Wang, X. Lu, B. Liu, D. Chen, Y. Tong, G. Shen, Flexible energy-storage devices: design consideration and recent progress. Adv. Mater. 26, 4763–4782 (2014). https://doi.org/10.1002/adma.201400910

P. Yang, P. Sun, W. Mai, Electrochromic energy storage devices. Mater. Today 19, 394–402 (2016). https://doi.org/10.1016/j.mattod.2015.11.007

J. Liu, J. Wang, C. Xu, H. Jiang, C. Li, L. Zhang, J. Lin, Z.X. Shen, Advanced energy storage devices: basic principles, analytical methods, and rational materials design. Adv. Sci. 5, 1700322 (2018). https://doi.org/10.1002/advs.201700322

M. Yoshio, R.J. Brodd, A. Kozawa, Lithium-Ion Batteries (Springer, New York, 2008), pp. 1–452

H. Li, Z. Wang, L. Chen, X. Huang, Research on advanced materials for Li-ion batteries. Adv. Mater. 21, 4593–4607 (2009). https://doi.org/10.1002/adma.200901710

N. Nitta, F. Wu, J.T. Lee, G. Yushin, Li-ion battery materials: present and future. Mater. Today 18, 252–264 (2015). https://doi.org/10.1016/j.mattod.2014.10.040

J.B. Goodenough, Y. Kim, Challenges for rechargeable Li batteries. Chem. Mater. 22, 587–603 (2010). https://doi.org/10.1021/cm901452z

V. Etacheri, R. Marom, R. Elazari, G. Salitra, D. Aurbach, Challenges in the development of advanced Li-ion batteries: a review. Energy Environ. Sci. 4, 3243–3262 (2011). https://doi.org/10.1039/C1EE01598B

F. Beck, P. Rüetschi, Rechargeable batteries with aqueous electrolytes. Electrochim. Acta 45, 2467–2482 (2000). https://doi.org/10.1016/S0013-4686(00)00344-3

D. Kundu, B.D. Adams, V. Duffort, S.H. Vajargah, L.F. Nazar, A high-capacity and long-life aqueous rechargeable zinc battery using a metal oxide intercalation cathode. Nat. Energy 1, 16119 (2016). https://doi.org/10.1038/nenergy.2016.119

L. Chen, J.L. Bao, X. Dong, D.G. Truhlar, Y. Wang, C. Wang, Y. Xia, Aqueous Mg-ion battery based on polyimide anode and prussian blue cathode. ACS Energy Lett. 2, 1115–1121 (2017). https://doi.org/10.1021/acsenergylett.7b00040

S.-W. Kim, D.-H. Seo, X. Ma, G. Ceder, K. Kang, Electrode materials for rechargeable sodium-ion batteries: potential alternatives to current lithium-ion batteries. Adv. Energy Mater. 2, 710–721 (2012). https://doi.org/10.1002/aenm.201200026

C. Xu, B. Li, H. Du, F. Kang, Energetic zinc ion chemistry: the rechargeable zinc ion battery. Angew. Chem. Int. Ed. 51, 933–935 (2012). https://doi.org/10.1002/anie.201106307

W. Xu, Y. Wang, Recent progress on zinc-ion rechargeable batteries. Nano-Micro Lett. 11, 90 (2019). https://doi.org/10.1007/s40820-019-0322-9

G. Fang, J. Zhou, A. Pan, S. Liang, Recent advances in aqueous zinc-ion batteries. ACS Energy Lett. 310, 2480–2501 (2018). https://doi.org/10.1021/acsenergylett.8b01426

H. Pan, Y. Shao, P. Yan, Y. Cheng, K.S. Han et al., Reversible aqueous zinc/manganese oxide energy storage from conversion reactions. Nat. Energy 1, 16039 (2016). https://doi.org/10.1038/nenergy.2016.39

T. Xiong, Z.G. Yu, H. Wu, Y. Du, Q. Xie et al., Defect engineering of oxygen-deficient manganese oxide to achieve high-performing aqueous zinc ion battery. Adv. Energy Mater. 9, 1803815 (2019). https://doi.org/10.1002/aenm.201803815

F. Wan, L. Zhang, X. Dai, X. Wang, Z. Niu, J. Chen, Aqueous rechargeable zinc/sodium vanadate batteries with enhanced performance from simultaneous insertion of dual carriers. Nat. Commun. 9, 1656 (2018). https://doi.org/10.1038/s41467-018-04060-8

N. Zhang, Y. Dong, M. Jia, X. Bian, Y. Wang et al., Rechargeable aqueous Zn–V2O5 battery with high energy density and long cycle life. ACS Energy Lett. 36, 1366–1372 (2018). https://doi.org/10.1021/acsenergylett.8b00565

N. Zhang, F. Cheng, Y. Liu, Q. Zhao, K. Lei, C. Chen, X. Liu, J. Chen, Cation-deficient spinel ZnMn2O4 cathode in Zn(CF3SO3)2 electrolyte for rechargeable aqueous Zn-ion battery. J. Am. Chem. Soc. 138, 12894 (2016). https://doi.org/10.1021/jacs.6b05958

L.X. Geng, G.C. Lv, X.B. Xing, J.C. Guo, Reversible electrochemical intercalation of aluminum in Mo6S8. Chem. Mater. 27, 4926–4929 (2015). https://doi.org/10.1021/acs.chemmater.5b01918

J. Huang, Z. Wang, M. Hou, X. Dong, Y. Liu, Y. Wang, Y. Xia, Polyaniline-intercalated manganese dioxide nanolayers as a high-performance cathode material for an aqueous zinc-ion battery. Nat. Commun. 9, 2906 (2018). https://doi.org/10.1038/s41467-018-04949-4

M. Yan, P. He, Y. Chen, S. Wang, Q. Wei et al., Water-lubricated intercalation in V2O5·nH2O for high-capacity and high-rate aqueous rechargeable zinc batteries. Adv. Mater. 30, 1703725 (2018). https://doi.org/10.1002/adma.201703725

P. He, M. Yan, G. Zhang, R. Sun, L. Chen, Q. An, L. Ma, Layered VS2 nanosheet-based aqueous Zn ion battery cathode. Adv. Energy Mater. 7, 1601920 (2017). https://doi.org/10.1002/aenm.201601920

J. Ni, Y. Zhao, T. Liu, H. Zheng, L. Gao, C. Yan, L. Li, Strongly coupled Bi2S3@CNT hybrids for robust lithium storage. Adv. Energy Mater. 4, 1400798 (2014). https://doi.org/10.1002/aenm.201400798

H. Liang, J. Ni, L. Li, Bio-inspired engineering of Bi2S3-PPy yolk-shell composite for highly durable lithium and sodium storage. Nano Energy 33, 213–220 (2017). https://doi.org/10.1016/j.nanoen.2017.01.033

S.-Q. Zhan, H. Wan, L. Xu, W.-Q. Huang, G.-F. Huang, J.-P. Long, P. Peng, Native vacancy defects in bismuth sulfide. Int. J. Mod. Phys. B 28, 1450150 (2014). https://doi.org/10.1142/S0217979214501501

G. Qin, H. Zhang, C. Wang, Ultrasmall TiO2 nanoparticles embedded in nitrogen doped porous graphene for high rate and long life lithium ion batteries. J. Power Sources 272, 491–500 (2014). https://doi.org/10.1016/j.jpowsour.2014.08.105

K.S.W. Sing, D.H. Everett, R.A.W. Haul, L. Moscou, R.A. Pierotti, J. Rouquerol, T. Siemieniewska, Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 57, 603 (1985). https://doi.org/10.1351/pac198557040603

T. Xiong, Z.G. Yu, W.S.V. Lee, J. Xue, o-Benzenediol-functionalized carbon nanosheets as low self-discharge aqueous supercapacitors. Chemsuschem 11, 3307–3314 (2018). https://doi.org/10.1002/cssc.201801076

K. Zhang, M. Park, L. Zhou, G.-H. Lee, W. Li, Y.-M. Kang, J. Chen, Urchin-like CoSe2 as a high-performance anode material for sodium-ion batteries. Adv. Funct. Mater. 26, 6728–6735 (2016). https://doi.org/10.1002/adfm.201602608

D. Chao, C. Zhu, P. Yang, X. Xia, J. Liu et al., Array of nanosheets render ultrafast and high-capacity Na-ion storage by tunable pseudocapacitance. Nat. Commun. 7, 12122 (2016). https://doi.org/10.1038/ncomms12122

D. Chao, P. Liang, Z. Chen, L. Bai, H. Shen et al., Pseudocapacitive Na-ion storage boosts high rate and areal capacity of self-branched 2D layered metal chalcogenide nanoarrays. ACS Nano 10, 10211–10219 (2016). https://doi.org/10.1021/acsnano.6b05566

X. Xia, D. Chao, Y. Zhang, J. Zhan, Y. Zhong et al., Generic synthesis of carbon nanotube branches on metal oxide arrays exhibiting stable high-rate and long-cycle sodium-ion storage. Small 2, 3048–3058 (2016). https://doi.org/10.1002/smll.201600633

Acknowledgements

This work was supported by Singapore MOE Tier 1 funding R-284-000-162-114 and Singapore MOE Tier 2 MOE 2018-T2-1-149.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xiong, T., Wang, Y., Yin, B. et al. Bi2S3 for Aqueous Zn Ion Battery with Enhanced Cycle Stability. Nano-Micro Lett. 12, 8 (2020). https://doi.org/10.1007/s40820-019-0352-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40820-019-0352-3