Abstract

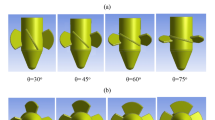

In this research, to investigate the impact of the guide vanes on the flow analysis in the axial pump, unsteady numerical turbulence field simulations with and without guide vanes are simulated using the model of standard κ–ε turbulence with the technique of sliding mesh (SM). The numerical results are firstly validated and compared with experimental outcomes. Different detailed information data regarding flow analysis, for instance, static, dynamic, total pressures, turbulent kinetic energy, shear stress, and velocity magnitude are qualitatively analysed. Then pressure at varying regions in the pump is qualitatively investigated under different operating conditions. The results have shown that the flow field and performance of the pump are highly affected by adding the guide vane to the axial impeller. The impeller with guide vane can lead to enhance the pump performance. Moreover, results show that the pressure, kinetic energy, shear stress, and velocity are increased by adding a guide vane to the axial impeller. This study will provide good information and guidance to enhance and improve the axial flow pump design operation.

Similar content being viewed by others

References

Wang, W. J., Liang, Q. H., Wang, Y., Yang, Y., Yin, G., & Shi, X. X. (2013). Performance analysis of axial flow pump on gap changing between impeller and guide vane In IOP Conference Series Materials Science and Engineering 52 3 032011 IOP Publishing.

Zhang DS, Shi WD, Chen B, Guan XF (2010) Unsteady flow analysis and experimental investigation of axial-flow pump. J Hydrodyn 22(1):35–43

Belyaev SG, Ishangaliev TS, Kariev DA, Kuklin DE (1991) Energy investigations of a pumping station with an axial-flow pump and circular feed line. Hydrotech Constr 25(11):683–685

Kochevsky A N, Kozlov S N, Aye K M, et al. 2005 Measurements of the tip clearance flow for a high-Reynolds-number axial-flow rotor-part 2 Detailed flow measurements Proc ASME FEDSM Houston USA 19–23 p 1397

Qian Z, Wang Y, Huai W, Lee Y (2010) Numerical simulation of water flow in an axial flow pump with adjustable guide vanes. J Mech Sci Technol 24(4):971–976

Yang F, Liu C, Tang FP (2015) Hydraulic interaction of flow conduits and pump in an axial-flow pump system. Rev Téc Ing Univ Zulia 38(1):25–33

Yang, F., Zhao, H. R., & Liu, C. (2016). Improvement of the efficiency of the axial-flow pump at part loads due to installing outlet guide vanes mechanism Mathematical Problems in Engineering

Wu H, Miorini RL, Katz J (2011) Measurements of the tip leakage vortex structures and turbulence in the meridional plane of an axial water-jet pump. Exp Fluids 50(4):989–1003

Wei P, Chen H, Lu W (2008) Characteristics of force acting on adjustable axial flow pump blade. Front Energy Power Eng Chin 2(4):508–513

Moazami, N., Fukamachi, K., Kobayashi, M., Smedira, N. G., Hoercher, K. J., Massiello, A., ... & Starling, R. C. (2013). Axial and centrifugal continuous-flow rotary pumps: a translation from pump mechanics to clinical practice. The Journal of heart and lung transplantation, 32(1), 1–11.

Xie C, Tang F, Zhang R, Zhou W, Zhang W, Yang F (2018) Numerical calculation of axial-flow pump’s pressure fluctuation and model test analysis. Adv Mech Eng 10(4):1687814018769775

Yang, F., & Liu, C. (2013). Numerical and Experimental Investigation of Slanted Axial-flow pumping System Journal of Engineering Science & Technology Review 6 2

Al-Obaidi, A. R., & Alhamid, J. (2023). Investigation of the Main Flow Characteristics Mechanism and Flow Dynamics Within an Axial Flow Pump Based on Different Transient Load Conditions Iranian Journal of Science and Technology Transactions of Mechanical Engineering 1–19

Li WY, Zhang XY, Shuai ZJ, Jiang CX, Li FC (2014) CFD numerical simulation of the complex turbulent flow field in an axial-flow water pump. Adv Mech Eng 6:521706

Kan, K., Xu, Z., Chen, H., Xu, H., Zheng, Y., Zhou, D., ... & Maxime, B. (2022). Energy loss mechanisms of transition from pump mode to turbine mode of an axial-flow pump under bidirectional conditions Energy 257 124630.

Kan K, Zhang Q, Xu Z, Zheng Y, Gao Q, Shen L (2022) Energy loss mechanism due to tip leakage flow of axial flow pump as turbine under various operating conditions. Energy 255:124532

Zhou Y, Kumar A, Parkash C, Vashishtha G, Tang H, Xiang J (2022) A novel entropy-based sparsity measure for prognosis of bearing defects and development of a sparsogram to select sensitive filtering band of an axial piston pump. Measurement 203:111997

Shi L, Zhang W, Jiao H, Tang F, Wang L, Sun D, Shi W (2020) Numerical simulation and experimental study on the comparison of the hydraulic characteristics of an axial-flow pump and a full tubular pump. Renewable Energy 153:1455–1464

Al-Obaidi AR, Qubian A (2022) Effect of outlet impeller diameter on performance prediction of centrifugal pump under single-phase and cavitation flow conditions. International Journal of Nonlinear Sciences and Numerical Simulation 23(7–8):1203–1229

Acknowledgements

The author in this work would like to many to the thank Mustansiriyah Universit (www.uomustansiriyah.edu.iq) Baghdad – Iraq for its support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

There is no conflict of interest in this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Al-Obaidi, A. Effect of Different Guide Vane Configurations on Flow Field Investigation and Performances of an Axial Pump Based on CFD Analysis and Vibration Investigation. Exp Tech 48, 69–88 (2024). https://doi.org/10.1007/s40799-023-00641-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-023-00641-5