Abstract

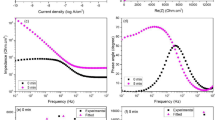

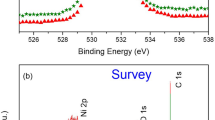

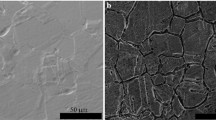

The passive film mainly consists of oxides and hydroxide and is a key for corrosion protection of metallic materials. It increases the durability and performance of engineering components by spontaneous formation of effective, adherent barrier between the corrosive environment and a substrate. Herein, influence of plastic strain and after heat treatment on austenitic stainless steels was compared with the focus on stability of the passive film. The following materials were used in this study: Sanicro 28™, AISI 316 L, and AISI 304 L. These specimens were subjected to a true strain of 0.58. The conventional three-electrode cell was used to record the anodic potentiodynamic polarization curves. The grain size and other misorientation parameters were extracted using electron backscattered diffraction (EBSD). Fourier transform infrared spectroscopy (FTIR)-imaging was used for capturing chromium oxide (Cr2O3) peaks for all specimens. The average area of Cr2O3 peaks was compared with deformed and after heat treatment of 700 °C 30 min specimens. It was found that heat-treated specimens exhibited slightly higher average area of Cr2O3 than deformed.

Similar content being viewed by others

References

Oh YJ, Hong JH (2000) Nitrogen effect on precipitation and sensitization in cold-worked type 316L(N) stainless steels. J Nucl Mater 278:242–250

Jones R, Randle V, Owen G (2008) Carbide precipitation and grain boundary plane selection in overaged type 316 austenitic stainless steel. Mater Sci Eng A 496:256–261

Hong S, Kim M, Min D, Lee K, Shim J, Kim D, Suh J, Jung W, Choi I (2014) Unraveling the origin of strain-induced precipitation of M 23 C 6 in the plastically deformed 347 austenite stainless steel. Mater Charact 94:7–13

Advani AH, Atteridge DG, Murr LE (1991) Solution annealing effects on sensitization of 316 stainless steels. ScriptaMetallurgica Mater 25:2221–2226

Pradhan SK, Prithiv TS, Mandal S (2017) Through-thickness microstructural evolution during grain boundary engineering type thermomechanical processing and its implication on sensitization behavior in austenitic stainless steel. Mater Charact 134:134–142

Ghosh S, Kain V (2010) Effect of surface machining and cold working on the ambient temperature chloride stress corrosion cracking susceptibility of AISI 304L stainless steel. Mater Sci Eng A 527:679–683

Kumar PS, Acharyya SG, Rao SVR, Kapoor K (2017) Distinguishing effect of buffing vs. grinding, milling and turning operations on the chloride induced SCC susceptibility of 304L austenitic stainless steel. Mater Sci Eng A 687:193–199

Singh R, Chowdhury SG, Ravi Kumar B, Das SK, De PK, Chattoraj I (2007) The importance of grain size relative to grain boundary character on the sensitization of metastable austenitic stainless steel. Scr Mater 57:185–188. https://doi.org/10.1016/j.scriptamat.2007.04.017

Farahat AIZ, El-Bitar TA (2010) Effect of Nb, Ti and cold deformation on microstructure and mechanical properties of austenitic stainless steels. Mat Sci Eng A 527:3662–3669

Hamdy AS, El-Shenawy E, El-Bitar T (2007) The corrosion behavior of niobium bearing cold deformed austenitic stainless steels in 3.5% NaCl solution. Mater Lett 61:2827–2832

Malki B, Le Bacq O, Pasturel A, Baroux B (2014) Ab initio study of water related defects in Cr2O3 and the consequences for the stability of passive films of stainless steels. J Electrochem Soc 161:486–493. https://doi.org/10.1149/2.0701410jes

Taveira LV, Montemor MF, Da Cunha Belo M, Ferreira MG, Dick LFP (2010) Influence of incorporated Mo and Nb on the Mott-Schottky behaviour of anodic films formed on AISI 304L. Corros Sci 52:2813–2818

Bai G, Lu S, Li D, Li Y (2016) Influences of niobium and solution treatment temperature on pitting corrosion behaviour of stabilised austenitic stainless steels. Corros Sci 108:111–124. https://doi.org/10.1016/j.corsci.2016.03.009

Srinivasan N, Senthil Kumaran S (2019) Role of alloy chemistry on stability of passive films in austenitic stainless steel grades. J MaterEng Perform 28:3695–3703

Peguet L, Malki B, Baroux B (2007) Influence of cold working on the pitting corrosion resistance of stainless steels. Corros Sci 49:1933–1948

Zhang B, Wang J, Wu B, Guo XW, Wang YJ, Chen D, Zhang YC, Du K, Oguzie EE, Ma XL (2018) Unmasking chloride attack on the passive film of metals. Nat Commun 9:1–9. https://doi.org/10.1038/s41467-018-04942-x

Ogunsanya IG, Hansson CM (2019) The semiconductor properties of passive films and corrosion behavior of stainless steel reinforcing bars in simulated concrete pore solution. Materialia 6:100321. https://doi.org/10.1016/j.mtla.2019.100321

Zhang B, Wei XX, Wu B, Wang J, Shao XH, Yang LX, Zheng SJ, Zhou YT, Jin QQ, Oguzie EE, Ma XL (2019) Chloride attack on the passive film of duplex alloy. Corros Sci 154:123–128. https://doi.org/10.1016/j.corsci.2019.04.012

Massoud T, Maurice V, Klein LH, Seyeux A, Marcus P (2014) Nanostructure and local properties of oxide layers grown on stainless steel in simulated pressurized water reactor environment. Corros Sci 84:198–203. https://doi.org/10.1016/j.corsci.2014.03.030

Jinlong L, Tongxiang L, Chen W, Limin D (2015) Comparison of corrosion properties of passive films formed on coarse grained and ultrafine grained AISI 2205 duplex stainless steels. J Electroanal Chem 757:263–269. https://doi.org/10.1016/j.jelechem.2015.09.036

Jinlong L, Hongyun L (2013) Comparison of corrosion properties of passive films formed on phase reversion induced nano/ultrafine-grained 321 stainless steel. Appl Surf Sci 280:124–131

Jinlong L, Tongxiang L, Chen W, Ting G (2016) Effect of in site strain on passivated property of the 316L stainless steels. Mater Sci Eng C 61:32–36. https://doi.org/10.1016/j.msec.2015.12.010

Jinlong L, Hongyun L (2012) Electrochemical investigation of passive film in pre-deformation AISI 304 stainless steels. Appl Surf Sci 263:29–37

Phadnis SV, Satpati AK, Muthe KP, Vyas JC, Sundaresan RI (2003) Comparison of rolled and heat treated SS304 in chloride solution using electrochemical and XPS techniques. Corros Sci 45:2467–2483

Rangel CM, Silva TM, Belo M d C (2005) Semiconductor electrochemistry approach to passivity and stress corrosion cracking susceptibility of stainless steels. Electrochim Acta 50:5076–5082

Gaffney JS, Marley NA, Jones DE (2012) Fourier transform infrared (FTIR) spectrscopy. In: Kaufmann EN (ed) Charact Mater. John Wiley & Sons, Ltd, pp 1104–1135

Wang M, Zhou Z, Wang Q, Wang Z, Zhang X, Liu Y (2019) Role of passive film in dominating the electrochemical corrosion behavior of FeCrMoCBY amorphous coating. J Alloys Compd 811:151962. https://doi.org/10.1016/j.jallcom.2019.151962

Örnek C, Leygraf C, Pan J (2019) Author correction: passive film characterisation of duplex stainless steel using scanning kelvin probe force microscopy in combination with electrochemical measurements. Npj Mater Degrad 3:1–8. https://doi.org/10.1038/s41529-019-0077-2

Örnek C, Engelberg DL (2015) SKPFM measured Volta potential correlated with strain localisation in microstructure to understand corrosion susceptibility of cold-rolled grade 2205 duplex stainless steel. Corros Sci:4–11

Panchanadeeswaran S, Doherty RD, Becker R (1996) Direct observation of orientation change by channel die compression of polycrystalline aluminum - use of a split sample. Acta Mater 44:1233–1262

Srinivasan N, Kain V, Samajdar I, Krishna KVM, Sivaprasad PV (2017) Plane strain compression testing of Sanicro 28 by channel-die compression test: a direct microstructural observation. Mater Today Proc 4:9888–9892

Chapelle D, Darrieulat M (2003) The occurence of shear banding in a millimeter scale (1̄2̄3)[634] grain of an Al-4.5% mg alloy during plane strain compression. Mater Sci Eng A 347:32–41. https://doi.org/10.1016/S0921-5093(02)00556-7

Srinivasan N, Kain V, Birbilis N, Kumar BS, Gandhi MN, Sivaprasad PV, Chai G, Lodh A, Ahmedabadi PM, Samajdar I (2016) Plastic deformation and corrosion in austenitic stainless steel: a novel approach through microtexture and infrared spectroscopy. Corros Sci 111:404–413

Srinivasan N, Kumaran SS, Venkateswarlu D (2018) Effects of plastic strains on passivation behavior of different austenitic stainless steel grades. Mater Res Express 6:026504. https://doi.org/10.1088/2053-1591/aaea2d

Wells DB, Williams DE (1991) Initiation events for pitting corrosion of stainless steel. Corr Sci 32:1307–1313

Al Saadi S, Yi Y, Cho P, Jang C, Beeley P (2016) Passivity breakdown of 316L stainless steel during potentiodynamic polarization in NaCl solution. Corros Sci 111:720–727

Elayaperumal K, De PK, Balachandra J (1972) Passivity of type 304 stainless steel–effect of plastic deformation. Corrosion 28:269–273

Alvarez SM, Bautista A, Velasco F (2013) Influence of strain-induced martensite in the anodic dissolution of austenitic stainless steels in acid medium. Corros Sci 69:130–138

Srinivasan NR, Bandyopadhyaya R (2016) SnxTi1−xO2 solid-solution-nanoparticle embedded mesoporous silica (SBA-15) hybrid as an engineered photocatalyst with enhanced activity. Faraday Discuss 186. https://doi.org/10.1039/c5fd00126a

Hamada AS, Karjalainen LP, Somani MC (2006) Electrochemical corrosion behaviour of a novel submicron-grained austenitic stainless steel in an acidic NaCl solution. MatSciEng A 431:211–217

Peguet L, Malki B, Baroux B (2009) Effect of austenite stability on the pitting corrosion resistance of cold worked stainless steels. Corros Sci 51:493–498

Barbucci A, Delucchi M, Panizza M, Sacco M, Cerisola G (2001) Electrochemical and corrosion behaviour of cold rolled AISI 301 in 1 M H2SO4. J Alloys Compd 317–318:607–611

Barbucci A, Cerisola G, Cabot PL (2002) Effect of cold-working in the passive behavior of 304 stainless steel in sulfate media. J Electrochem Soc 149:B534–B542

LvJinlong L (2014) Hongyun, effects of strain and strain-induced α′-martensite on passive films in AISI 304 austenitic stainless steel. Mater Sci Eng C 34:484–490

Jinlong L, Zhuqing W (2019) Sensitization evaluation of the AISI 2205 duplex stainless steel by the IQ value in EBSD technique. Eng Fail Anal 105:65–69. https://doi.org/10.1016/J.ENGFAILANAL.2019.07.001

Saraf L (2011) Kernel average misorientation confidence index correlation from FIB sliced Ni-Fe-Cr alloy surface. Microsc Microanal 17:424–425

Tanure L, Bakaeva A, Dubinko A, Terentyev D, Verbeken K (2019) Effect of annealing on microstructure, texture and hardness of ITER-specification tungsten analyzed by EBSD, vickers micro-hardness and nano-indentation techniques. J Nucl Mater 524:191–199. https://doi.org/10.1016/j.jnucmat.2019.07.005

Vignal V, Ba D, Zhang H, Herbst F, Le Manchet S (2013) Influence of the grain orientation spread on the pitting corrosion resistance of duplex stainless steels using electron backscatter diffraction and critical pitting temperature test at the microscale. Corros Sci 68:275–278

Rault V, Vignal V, Krawiec H, Dufour F (2015) Quantitative assessment of local misorientations and pitting corrosion behaviour of pearlitic steel using electron backscattered diffraction and microcapillary techniques. Corros Sci 100:667–671

Vignal V, Ringeval S, Thiébaut S, Tabalaiev K, Dessolin C, Heintz O, Herbst F, Chassagnon R (2014) Influence of the microstructure on the corrosion behaviour of low-carbon martensitic stainless steel after tempering treatment. Corros Sci 85:42–51

Wu J, Wray PJ, Garcia CI, Hua M, Deardo AJ (2005) Image quality analysis: a new method of characterizing microstructures. ISIJ Int 45:254–262

Schwarzer RA, Field DP, Adams BL, Kumar M, Schwartz AJ (2009) Present state of electron backscatter diffraction and prospective developments. In: Schwartz AJ, Kumar M, Adams BL, Field DP (eds) Electron backscatter Diffr. Mater. Sci. Springer Science + Business media, New York, pp 1–20

Gussev MN, Edmondson PD, Leonard KJ (2018) Beam current effect as a potential challenge in SEM-EBSD in situ tensile testing. Mater Charact 146:25–34. https://doi.org/10.1016/j.matchar.2018.09.037

Marcus P, Maurice V, Strehblow HH (2008) Localized corrosion (pitting): a model of passivity breakdown including the role of the oxide layer nanostructure. Corros Sci 50:2698–2704. https://doi.org/10.1016/j.corsci.2008.06.047

EVANS U (1927) The passivity of metals. Part I. the isolation of the protective film. J Chem Soc:1020–1040

Zhang B, Hao S, Wu J, Li X, Li C, Di X, Huang Y (2017) Direct evidence of passive film growth on 316 stainless steel in alkaline solution. Mater Charact. https://doi.org/10.1016/j.matchar.2017.05.013

Maurice V, Peng H, Klein LH, Seyeux A, Zanna S, Marcus P (2015) Effects of molybdenum on the composition and nanoscale morphology of passivated austenitic stainless steel surfaces. Faraday Discuss 180:151–170

Luo C, Zhou X, Thompson GE, Hughes AE (2012) Observations of intergranular corrosion in AA2024-T351: the influence of grain stored energy. Corros Sci 61:35–44. https://doi.org/10.1016/j.corsci.2012.04.005

Vogt MR, Nichols RJ, Magnussen OM, Behm RJ (1998) Benzotriazole adsorption and inhibition of cu(100) corrosion in HCl: a combined in situ STM and in situ FTIR spectroscopy study. J Phys Chem B 102:5859–5865

Mondal R, Bonagani SK, Lodh A, Sharma T, Sivaprasad PV, Chai G, Kain V, Samajdar I (2019) Relating general and phase specific corrosion in a super duplex stainless steel with phase specific microstructure evolution. Corrosion 75:1315–1326. https://doi.org/10.5006/3091

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author decleare that no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Srinivasan, N., Kumaran, S. The Effects of Strain on Stability of Passivation in Austenitic Stainless Steels: Comparison with Heat Treatment. Exp Tech 45, 207–216 (2021). https://doi.org/10.1007/s40799-020-00434-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-020-00434-0