Abstract

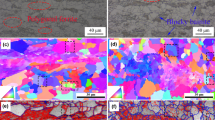

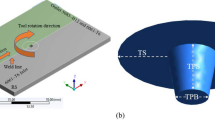

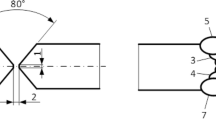

In the present investigation, fatigue crack growth threshold of the base metal, heat affected zone (HAZ), and weld metal of a steam turbine rotor’s welded joint constituents were determined by performing fatigue crack growth rate (FCGR) tests. Two types of test specimens were considered: (1) single-edge notch bend (SENB) and (2) compact tension (CT). Although a CT specimen is more appropriate for an FCGR test according to ASTM E647, in the present investigation the SENB and CT specimens were found to yield an equivalent fatigue crack growth threshold of the welded joint constituent. But, the SENB specimen provided some advantages over the CT specimen in performing the FCGR tests on the welded joints. It was also found that the fatigue crack growth threshold is a function of loading ratio rather than a single material parameter.

Similar content being viewed by others

References

Milovic, L., Vuherer, T., Radakovic, Z., et al., “Determination of Fatigue Crack Growth Parameters in Welded Joint of HSLA Steel,” Structural Integrity and Life 11(3):183–187 (2011).

Rogers, G.W., Wells, C.H., and Johnson, D.P., “Structural Integrity of Large Steam Turbine Rotors,” Proceedings of the Twelfth Turbomachinery Symposium College Station, Texas, pp. 31–44 (1983).

Assoul, Y., Bacha, N., and Semmar, D., “Probabilistic Model for Pitting Corrosion and Fatigue Life Estimation of Turbine Blades,” Structural Integrity and Life 8(1):3–12 (2008).

Lassen, T., Darcis, P., and Recho, N., “Fatigue Behavior of Welded Joints Part 1: Statistical Methods for Fatigue Life Prediction,” Welding Journal 84(Suppl):183–187 (2005).

Manjgo, M., Sedmak, A., and Grujic, B., “Fracture and Fatigue Behavior of Niomol 490 K Welded Joint,” Structural Integrity and Life 8(3):149–158 (2008).

Vuherer, T., Dunder, M., Milovic, L., Zrilic, M., and Samardzic, I., “Microstructural Investigation of the Heat Affected Zone of Simulated Welded Joint of P91 Steel,” Metalurgia 52(3):317–320 (2013).

Balasubramanian, T.S., Balasubramanian, V., and Muthumaikkam, M.A., “Effect of Welding Process on Fatigue Properties of Ti-6Al-4 V Alloy Joints,” International Journal of Mechanical and Materials Engineering 1(3):180–189 (2010).

Paris, C.P., Gomez, M.P., and Anderson, W.E., “A Rational Analytic Theory of Fatigue,” The Trend in Engineering 13: 9–14 (1961).

Beden, S.M., Abdullah, S., and Ariffin, A.K., “Review of Fatigue Crack Propagation Models for Metallic Components,” European Journal of Scientific Research 28(3):364–397 (2009).

Arora, P., Kumar, S., Singh, P.K., Bhasin, V., Singh, R.K., and Vaze, K.K., “Fatigue Crack Growth Studies on Narrow Gap Pipe Welds of Austenitic Steel Materials,” Procedia Engineering 86: 203–208 (2014).

Trudel, A., Levesque, M., and Brochu, M., “Microstructural Effects on the Fatigue Crack Growth Resistance of a Stainless Steel CA6NM Weld,” Engineering Fracture Mechanics 115: 60–72 (2014).

ASTM E647, Standard Test Method for Measurement of Fatigue Crack Growth Rates, American Society for Test and Materials, West Conshohocken, PA (2013).

ASTM E1820, Standard Test Method for Measurement of Fracture Toughness, American Society for Test and Materials, West Conshohocken, PA (2011).

Ritchie, R.O., Davidson, D.L., Boyce, B.L., Campbell, J.P., and Roder, O., “High cycle Fatigue of Ti-6Al-4 V,” Faigue and Fracture Engineering Materials and Structures 22: 621–663 (1999).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, MH.H., Akanda, S.R., Liu, X. et al. Fatigue Crack Growth Threshold Determination for Welded Joint Constituents of a Steam Turbine LP Rotor. Exp Tech 40, 1215–1220 (2016). https://doi.org/10.1007/s40799-016-0116-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-016-0116-7