Abstract

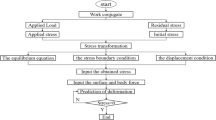

A new straightforward method for residual stress measurement is presented. A specimen is cut in half along its diagonal by using electric discharge machining, and the deformation benchmarks are measured to determine the displacements caused by release of the residual stresses. Analytically, to verify calculation accuracy of the new method, the known stresses are applied in finite element model as an initial condition. By using the series expansion approach, the inverse calculation based on displacements gives the original longitudinal residual stress of the specimen. This “wedge method” is more straightforward than other relaxation methods because it measures fewer data. Its data processing is simpler, yet its result is found to be in good agreement with other methods. The new method is first outlined for a three-dimensional (3-D) body and the accuracy of the methodology is demonstrated for a representative case using a numerical experiment. Then measurements are performed on a block specimen of AA6061-T6 to show that the approach is valid under real experimental conditions.

Similar content being viewed by others

References

Bains, T., 1st International Non-Ferrous Processing and Technology Conference, ASM International, St. Louis, MO, pp. 221–231 (1997).

Nickola, W.E., “Residual Stress Alterations via Cold Rolling and Stretching of an Aluminum Alloy,” Mordfin, L., (ed), Mechanical Relaxation of Residual Stresses, ASTM STP 993, American Society for Testing and Materials, Philadelphia, PA, pp. 7–18 (1988).

Myer, R.T., Kilpatrick, S.A., and Backus, W.E., “Stress relief of aluminium for aircraft,” Metal Progress 3: 112–115 (1959).

Robinsona, J.S., Hossain, S., Truman, C.E., et al, “Residual Stress in 7449 Aluminium Alloy Forgings,” Materials Science and Engineering A 527: 2603–2612 (2010).

Prime, M.B., “Residual Stress Measurement by Successive Extension of a Slot: The Crack Compliance Method,” Applied Mechanics Reviews 52(2): 75–96 (1999).

Lu, J., James, M., and Roy, G. (eds), Handbook of Measurement of Residual Stresses, The Fairmont Press Inc., Lilburn, GA (1996).

Hosseinzadeh, F., Toparli, M.B., and Bouchard, P.J., “Slitting and Contour Method Residual Stress Measurements in an Edge Welded Beam,” Journal of Pressure Vessel Technology 134(1): 011402 (2012).

Mahmoudi, A.H., Hossain, S., Truman, C.E., Smith, D.J., and Pavier, M.J., “A New Procedure to Measure Near Yield Residual Stresses using the Deep Hole Drilling Technique,” Experimental Mechanics 49: 595–604 (2009).

Prime, M.B., and Hill, M.R., “Residual Stress, Stress Relief, and in Homogeneity in Aluminum Plate,” Scripata Materialia 46: 77–82 (2002).

Prime, M.B., “Residual Stresses Measured in Quenched HSLA-100 Steel Plate,” 2005 SEM Annual Conference and Exposition on Experimental and Applied Mechanics, Portland, OR; June 7–9, 2005, paper number 52.

DeWald, A.T., and Hill, M.R., “Multi-Axial Contour Method for Mapping Residual Stresses in Continuously Process Bodies,” Experimental Mechanics 46: 473–490 (2006).

Cheng, W., and Finnie, I., Residual Stress Measurement and the Slitting Method, Chapter 5, Springer Science+Business Media, LLC, New York, NY (2007).

ABAQUS Inc., Abaqus Analysis User’s Manual, Version 6.11, Section 32.2.1, ABAQUS Inc., Pawtucket, RI (2012).

Pagliaro, P., Mapping Multiple Residual Stress using the Contour Method and Superposition, Ph.D. Dissertation, Univesita degli Studi di Palermo (2008).

Timoshenko, S.P., and Goodier, J.N., Theory of Elasticity, 3rd Edition, McGraw-Hill Article 17, New York, NY (1970).

Prime, M.B., Sebring, R.J., Edwards, J.M., Hughes, D.J., and Webster, P.J., “Laser Surface Contouring and Spline Data-Smoothing for Residual Stress Measurement,” Experimental Mechanics 44(2): 176–184 (2004).

Johnson G., Residual Stress Measurements using the Contour Method, Ph.D. Dissertation, University of Manchester (2008).

Trummer, V.R., Koch, D., Witte, A., dos Santos, J.F., and de Castro, P.M.S.T., “Methodology for Prediction of Distortion of Workpiece Manufactured by High Speed Machining based on an Accurate Through-the-thickness Residual Stress Determination,” The International Journal of Advanced Manufacturing Technology 68: 2271–2281 (2013).

Shu-hong, W., Dun-wen, Z., Min, W., and Zong-rong, W., “Modified Layer Removal Method For Measurement of Residual Stress Distribution in Thick Pre-Stretched Aluminum Plate,” Transaction of Nanjing University of Aeronautics & Astronautics 24(4): 286–289 (2004).

Schindler, H.J., and Bertschinger, P., “Some Steps towards Automation of the Crack Compliance Method to Measure Residual Stress Distributions,” Proceedings of the 5th International Conference on Residual Stress 1: 682–687 (1997).

Prime, M.B., “Cross Sectional Mapping of Residual Stresses by Measuring the Surface Contour after Cut,” Journal of Engineering Material and Technology 123: 162–168 (2001).

Prime, M.B., and Kastengren, A.L., “The Contour Method Cutting Assumption: Error Minimization and Correction,” Proulx, T., (ed), Experimental and Applied Mechanics, Volume 6, Springer, New York, NY, pp. 233–250 (2010).

Withers, P.J., and Bhadeshia, H.K.D.H., “Residual Stress: Part 1 - Measurement Techniques,” Material Science and Technology 17: 355–365 (2000).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Z., Li, L., Yang, Y. et al. Residual Stress Calculation by Measuring Deformation After a Diagonal Cut. Exp Tech 40, 583–595 (2016). https://doi.org/10.1007/s40799-016-0059-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-016-0059-z