Abstract

How does Italy position inside the European structure of trade relationships? How labour bilateral flows have changed over time? Which type of employment activity has been outsourced? Which insourced? Focusing on a three-country perspective, what are the employment bilateral relationships between Italy-Germany-Poland (descending periphery-core-ascending periphery)? To address these questions we develop a novel set of bilateral labour dependence indicators inside I-O production networks. Overall, we provide evidence of the reconfiguration of Italy as falling into the trap of GVC downgrading, with an increasing number of trade relationships in employment requirements, particularly in the most strategic productions, as insourced from abroad. The offshoring strategy conducted so far has resulted in a weakening of its internal production capacity and employment absorption, even more harshly when compared to other European countries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

This work proposes a novel analytical and measurement framework to investigate the bilateral positioning of Italy in the European production network. Differently from the extant literature, we look at employment flows rather than production flows inside input–output relationships, with the aim of detecting the ensuing division of labour. We develop an analytical and measurement framework in order to take into account the asymmetric positioning of countries in providing or sourcing labour to and from specific trade partners. In this respect, we make use of employment multipliers matrices. Our starting point of analysis rests on the fact that labour inputs, beyond the sheer number of employees embedded in the intermediary goods delivered, embody collective knowledge and capabilities, that is the set of know-how, tacit rules and accumulated capabilities that are needed in order to operate a given factory and the ensuing production. Therefore, once destined for abroad production, offshoring implies the loss of internal capabilities (Cimoli et al. 2009; Cresti and Virgillito 2023). Granted this perspective, we build indicators measuring countries’ positioning rather than participation in Global Value Chains (GVCs) in order to encompass the asymmetric loss of productive capabilities that has taken place in the last thirty years in many mature economies, due to the combined interaction of deindustrialization and relocation abroad of manufacturing productions, with some losing and some winning countries.

The extant literature, indeed, tends to consider unconditional benefits from GVC participation, with gains from cost reduction and specialisation in high productive activities for production outflows countries, and gains from spillovers and knowledge complementarities for production inflows countries (Formai and Vergara Caffarelli 2016; Taglioni and Winkler 2016; Criscuolo and Timmis 2017; Jona-Lasinio and Meliciani 2019; Constantinescu et al. 2019; Pahl and Timmer 2020; Battiati et al. 2020; World Development Report 2020). Differently, we argue that being a net provider versus being a net sourcing country asymmetrically affects the nature of positioning in terms of the overall division of labour. In addition, we deem to characterise the quality of production, distinguishing into hierarchical contents of goods sourced/demanded, given that outsourcing micro-chips is not equivalent to outsourcing potato-chips (Dosi et al. 2021).

Such trade relationships took place inside a European production network that has seen in the last twenty years the emergence of a dominant core (Germany and other central European economies) and two peripheries (the Mediterranean and the eastern ones). However, the latter peripheries are quite diverse: one, the Mediterranean, which progressively eroded its dominant position; the other, the Eastern, progressively ameliorated its positioning in manufacturing production. How does Italy position inside the European structure of trade relationships? How labour bilateral flows have changed over time? Which type of employment activity has been outsourced? Which insourced? Focusing on a three-country perspective, what are the employment bilateral relationships between Italy-Germany-Poland (descending periphery-core-ascending periphery)?

We address the latter questions by taking advantage of evolutionary (Dosi 1982; Nelson and Winter 1982; Pavitt 1984), structuralist (Pasinetti 1981; Landesmann and Scazzieri 1996; Andreoni and Scazzieri 2014) and dependency theories (Prebisch 1950; Santos 1970; Gereffi and Korzeniewicz 1994). We contribute both to the literature on the fragmentation of labour inside GVCs (Garbellini and Wirkierman 2014; Baldwin and Lopez-Gonzalez 2015; Foster-McGregor et al. 2016; Pahl et al. 2019; Bontadini et al. 2022; Fana and Villani 2022; Wirkierman 2022; Cresti and Virgillito 2022) and to the one on the positioning of countries and sectors along GVCs (Koopman et al. 2010; Baldwin and Freeman 2022).

We adopt the World Input–Output Tables and Socio and Economic Account – both from the 2016 Release of the World Input–Output Database (Timmer et al. 2015) – and construct global employment multipliers matrices for the time span 2000-2014, in the spirit of the evidence proposed by Baker and Lee (1993) and Bivens (2003, 2019) for the US economy. Such matrices contain information on the number of employees activated in every cell (i.e. country-sector) of a given column (i.e. supply chain) for the production of one unit (1 mln USD) of the corresponding column final commodity. We construct matrices for the whole manufacturing sector and matrices for each Pavitt class (Pavitt 1984). We then build a set of indicators to empirically detect the positioning in terms of the development of productive capabilities of Italian manufacturing. We present bilateral backward and forward linkages to show the amount of labour sourced and provided by each country-manufacturing (or country-macrosubsystems by Pavitt class) to each country-manufacturing, by means of bipartite employment flows networks. Secondly, we construct a synthetic measure of bilateral GVC positioning, defined as the ratio between bilateral backward and forward linkages to account for the net amount of labour sourcing. Lastly, we build a country (or Pavitt) level Bilateral Net Labour Dependence indicator (BNLD), introduced at the disaggregated 2-digit branch level in Cresti and Virgillito (2023).

After accounting for the Italian division of labour inside Europe, we compare it with Germany and Poland. We provide new evidence on the asymmetric relationships that characterise the sourcing and provision of labour (and the embodied knowledge), emerging from the bilateral interdependencies of the countries under study. The classification by Pavitt taxonomy enables the qualification of labour dependence by technological specialisation. Our results read as follows: first, we account for the deep heterogeneity of country strategic positioning in GVCs, on the basis of the type of productive activities (and the embedded capabilities) kept in-house or alternatively offshored; second, we are able to characterise Germany as a core country not only in terms of overall export activity as usually done, but in terms of the composition and partners of employment relationships. In a similar vein, the ascending East Visegrad area is turning from a weak to a strong periphery in terms of total insourcing of manufacturing activities. However, the Pavitt Taxonomy highlights that the eastern ascending periphery is acquiring a dominant positioning largely in terms of lower technological-embedding productions, while room for upgrading into specialised activities, like pharma or microprocessors, is still absent. Third, adopting a geographical perspective, dependence flows from northern countries are declining, while those from eastern countries are becoming progressively more and more important. A similar descending pattern characterises southern countries, while central countries maintained their position as relatively stable. Clearly, the massive entry of China and the recomposition of the international division of labour in the global production network is the elephant in the room. Overall, we provide evidence of the reconfiguration of Italy as falling into the trap of GVC downgrading, with an increasing number of trade relationships in employment requirements, particularly in the most strategic productions, as insourced from abroad. The offshoring strategy conducted so far has resulted in a weakening of its internal production capacity and employment absorption, even more harshly when compared to other European countries.

The remainder of the paper is structured as follows: in Sect. 2 we review the literature assessing the European fragmentation of production and dependence relationships therein, together with a focus on the Italian participation in such value chains. Section 3 proposes a novel analytical and measurement framework to address the path of participation of countries in GVCs and dependence relationships therein. Section 4 presents our results focusing on the manufacturing, while in Sect. 5 we address the role of in- and out-flows of service-based activities. Finally, in Sect. 6 we draw some concluding remarks and future extensions.

2 What is Known from the Extant Literature

2.1 European Core-Periphery Structure

The literature on Global Value Chains (GVCs) has shown that since the 1990 s, the liberalization of trade and reduction in transportation costs have led to a shift from trade in final products to trade in intermediaries, known as the so-called “globalization second unbundling” (Baldwin 2011). This paradigm shift has affected countries’ specialisation patterns in multiple ways. The increased flexibility and modularity of the production process have allowed for greater fragmentation of manufacturing, leading to far-reaching consequences not only for the geography of production, which has become increasingly dispersed (Antràs and de Gortari 2020) but also for the international division of labour (Timmer et al. 2019) and countries’ specialisation patterns therein (Bontadini et al. 2022).

These considerations become even more relevant in the European context where the expansion of a common market has accelerated fragmentation tendencies and exacerbated the effects of such integration schemes, particularly since the entry of the Visegrad countries in 2004, the ascending European factory. The relevance of the changing geography of production in the European trade network, revealing an imbalance in the integration patterns across countries has been a subject matter (Simonazzi et al. 2013; Stöllinger et al. 2013; Celi et al. 2018; Gräbner et al. 2020). Stollinger (2016) highlights that the rapid integration of eastern countries in central European GVCs has led to a growing dependence on external capital and technologies. This has resulted in the emergence of a “manufacturing divide” in Europe, where the manufacturing core benefits from GVCs’ involvement, while other peripheral European states experience an acceleration of the ongoing deindustrialization process. Indeed, on a worldwide long-term perspective, Dosi et al. (2022) show that the quality of specialisation, and especially the technological content of production, is likely to affect average growth, volatility and, most importantly, duration of growth episodes. Therefore, the very first question is how long it is sustainable a core-periphery pattern for both core and peripheral countries. It goes without saying that such core-periphery divergences might be further amplified by the Covid-19 crisis and the war in Ukraine, as the literature is already suggesting (Celi et al. 2020, 2022; Ceron and Palermo 2022).

Considering the core, Germany has leveraged its technological capabilities to gain a central position in the European trade network, benefiting from productive synergies with emerging eastern countries. This implied the outsourcing of manufacturing to emerging European countries, reorienting internal production toward specialisation in high-technology and knowledge-intensive segments, significantly reducing the internal unit labour costs and at the same time specialising in so-called “good jobs” (Lehndorff et al. 2009; Marin 2010).

The eastward expansion of European trade and productive integration has seen a contextual decline in trade flows between the core European countries and the northern and southern areas. While some southern countries, including Italy, continue to play a significant role in European value chains, some countries of the north, such as Great Britain, have experienced the sharpest decline in manufacturing integration, hampered by their long-standing hyper-deindustrialization tendency, already noted by Rowthorn (1986), resulting into a massive shift to a service-based economy well before the European monetary union.

The extent to which countries like Italy, France and the UK have changed their position in the geography of the European production network is however motivated by different productive and integration strategies. Specifically, countries such as Germany and other core European states opted for a pattern of strategic delocalisation, keeping domestically high-value added stages of production, such as conceptualization, development and marketing, maintaining control over domestic supply chains while stimulating domestic employment (Bundesbank 2011), although internally fragmented into a dual labour market characterised by an increasing fraction of low-quality jobs, even within manufacturing thanks to “opening” clauses (Jäger et al. 2022).

On the contrary, peripheral southern European countries, with Italy being the most prominent example, pursued a different integration strategy by favouring penetration from core countries’ value chains in strategic productions at the cost of relocating most of the domestic processes abroad, including high-knowledge-intensive ones (Cresti and Virgillito 2022). However, this strategy had several negative outcomes, including the inability to manage and control GVCs, particularly in sectors like automotive (Gaddi and Garbellini 2021) and pharma, increasing exposure to external shocks, and ultimately heightened cost competition due to the eastward European expansion. As a result, countries like Italy that opted for wage compression strategies and outsourcing rather than technological strategic competition (Dosi et al. 2015) lost both productive capabilities and strategic positioning into GVCs.

Notably, although the theory of comparative advantages would predict benefits from all trading partners, one might argue that, if not for southern countries, delocalization strategies might have played a positive effect on the eastern periphery. These countries, which are at a lower stage of specialisation, have benefited from their geographical proximity to Germany and have been able to enter German production chains and acquire more advanced technology. In addition, given their ex-ante initial conditions of development, wage compression policies might have come at cost of gaining in export-led growth. However, Riccio et al. (2022) have shown that the appropriation of benefits for workers, that is the labour share along GVCs has experienced a dramatic collapse, even harsher than the corresponding horizontal/sector level one. According to their results, GVCs have largely benefited capital, and this is even more true in emerging economies, like Visegrad countries and Mexico.

Then, who did actually benefit from the new geography of production? According to the smile curve literature, GVCs participation tends to favour task specialisation, with core countries specialising in high-value-added and knowledge-intensive segments of the production process, while developing and peripheral countries are left with more routine-intensive and low-value-added occupations (Timmer et al. 2019; Stöllinger 2021; Mudambi 2008). Advancing on this line, Riccio et al. (2022) show that such specialisation strategies, while allowing emerging countries to access advanced countries’ GVCs, impede diversification patterns and wage upgrading within GVCs, leading to negative consequences for domestic demand creation, technological capability accumulation and, ultimately, for functional income distribution. Therefore, smile curve specialisation tendencies result in short-term productive benefits for the eastern capital owners at the expense of long-term structural convergence and increased dependence on the core (Pavlínek 2020). For southern Europe, being downgraded to input suppliers has led to greater foreign dependence and to a worsening in productive specialisation, together with the quality of available jobs (Coricelli and Wörgötter 2012). Overall, the very gaining segment from GVC integration looks to be capital-owners (Riccio and Virgillito 2023).

And, on the opposite, who have been the losers from GVCs? The literature has shown that opportunities from “social upgrading”, extensively defined as “good jobs" (Milberg and Winkler 2011; Rodrik 2018), are dramatically lacking in the periphery. In a recent study, Bontadini et al. (2022) examined the evolving employment structure within European production networks and found that the integration in GVCs exacerbates pre-existing asymmetries, not only in sectoral specialisation but also in the occupational structure. These results match with an increased wage inequality between the core and peripheries, together with a widespread tendency of labour share decline along the value chain (Riccio et al. 2022). Riccio and Virgillito (2023), focusing on functional specialisation deriving from GVCs, show that across four occupational segments of the labour force (managerial, R &D, marketing and production), while the overall labour share declines, the most losing category is the one of production workers, in all countries under study.

2.2 Italy Within European GVCs

Within the European production network, Italy represents an interesting case study. Although the country still remains the second largest manufacturer in Europe after Germany, the Italian productive structure has gone through massive deindustrialization – in terms of hours worked and value added – and offshoring phenomena, resulting in declining manufacturing production, ensuing weakened employment absorption capacity, and productive capabilities losses (Gallino 2003; Confindustria 2012; Accetturo et al. 2013; Arrighetti and Ninni 2014; Lucchese et al. 2016; Cresti et al. 2020; Di Berardino and Onesti 2021; Cresti and Virgillito 2022).

From a firm-level perspective, a polarization in productivity and innovation dynamics is increasingly documented, with emerging attributes of dualism within the internal productive structure, between a few technologically advanced firms (gazelles) and the majority of less dynamic and low-tech firms (turtles) (Bugamelli et al. 2018; Costa et al. 2021; Dosi et al. 2021). Firm-level studies on Italian GVC participation (Accetturo et al. 2011; Giunta et al. 2012; Agostino et al. 2016; Accetturo and Giunta 2018) register a considerable heterogeneity in firms’ participation, in a context of overall stronger involvement when compared to Spain, France and Germany. In addition, the majority of Italian firms are suppliers (while in other countries this incidence is lower) that often operate in less profitable, intermediate stages of GVCs (Agostino et al. 2016). This is in line with the evidence connecting the “bad” positioning in GVCs and the performance gap between Italian and German firms during the recession. The low incidence of final producers displays another weakness, which is the lack of key players governing the chain through activities located at the beginning (e.g. R &D activity) or at the end (e.g. sales and after-sales services) of the production process, representing the high-value added phases according to the smile curve hypothesis (Meng et al. 2020; Baldwin and Ito 2021; Stöllinger 2021).

From an input–output interdependence perspective, Italy has experienced a general weakening of its industrial development capacity accompanied by a rapidly evolving integration between manufacturing and services (Di Berardino 2017; Di Berardino and Onesti 2021). By taking advantage of the Pavitt Taxonomy (Pavitt 1984), Di Berardino and Onesti (2021) showed that the major contraction in employment has been recorded in Suppliers Dominated manufacturing subsystems and that countries like Italy and Spain are mainly specialised in Suppliers Dominated and Specialised Suppliers subsystems, while German and French industrial systems depend more on Scale Intensive and Science Based productions, respectively. Cresti and Virgillito (2022) confirmed the weak specialisation strategy, with a growing production concentration in low-tech industries and in services, by adopting an employment multipliers approach. They also detected a tendency of increasing offshoring of labour in Science Based productions after the 2008 crisis and dependence on high-tech inputs from abroad. In fact, overall, the Italian manufacturing sectors show a high level of GVC participation and deep integration, with many firms acting as suppliers of intermediates for Germany (Simonazzi et al. 2013; Borin and Mancini 2016; Celi et al. 2018; Gaddi and Garbellini 2016; Giovannetti and Marvasi 2021). However, Italy holds an intermediate positioning in GVCs, presenting strong linkages both upstream and downstream (Giovannetti and Marvasi 2021).

Notwithstanding eventual downgrading paths, the GVCs literature has mainly focused on purported benefits for economic upgrading of emerging countries, while less attention has been devoted to the possibility of GVC traps leading to economic downgrading for advanced countries. In the following, we provide a measurement and conceptual framework to put forward the case of Italy and the trap of GVC downgrading in which it is falling.

3 An Analytical and Measurement Framework to Assess Downgrading Traps and Dependence Relationships

The focus on employment multipliers assumes that labour requirements in production networks embody a flow of knowledge. According to the evolutionary tradition and the capability-based theory of the firm, knowledge is primarily embodied in organizational routines and problem-solving capabilities developed and accumulated by workers, thanks to learning-by-doing (or -using) processes (Rosenberg 1982; Dosi 1982; Dosi and Nelson 2010). Knowledge is not only based on individual know-how but primarily on collective organizational routines. It is therefore a hidden dimension, not easy to measure, differently from employment flows. Taking advantage of the structuralist approach on industrial interdependencies (Pasinetti 1981; Scazzieri 1990; Andreoni and Scazzieri 2014), we consider labour-embodied knowledge as a flow variable spreading throughout the production networks, both locally and globally. Knowledge flows follow the directions of the international fragmentation of production. Tracking knowledge flows incorporated into units of employees enables tracking the geography of the international division of labour, which captures the number of employees in a country-industry performing activities directed toward the production of a final good in another country-industry of the world. The division of labour might be fragmented into domestic chains or into global chains, therefore, employment multipliers allow to capture offshoring and outsourcing of labour at a 2-digit level. Input-Output analysis (Leontief 1951) allows measuring such fragmentation of production networks and division of labour considering vertically integrated sectors which resemble global supply chains.

The choice of focusing on labour was motivated by the fact that in line with the evolutionary approach to the capability accumulation (Rosenberg 1982; Cimoli et al. 2009; Dosi and Nelson 2010; Andreoni 2014), being the labour input the “learning component” of the productive structure, we consider it, given the available I-O data structure, the most appropriate empirical proxy for collective knowledge incorporated into production processes. In fact, it is mainly through learning dynamics and routine development that workers can increase the efficiency of a productive unit, while capital equipment, the opposite, except in instances of full automation, cannot be operated without labour effort. Hence, by assessing labour flows in terms of the number of employees, although not accounting for workers’ heterogeneity, we account for the disembodied knowledge component embedded into labour inputs. Our argument is in line with those scholars questioning the role of labour as a sheer productive factor and thus neglecting its (cumulative) knowledge content and the socially embedded dimension of capabilities (Barrientos et al. 2011; Andreoni et al. 2021)

It is important to clarify that knowledge derives from a multitude of sources, with the knowledge embedded in workers’ capabilities being just one facet. Other significant dimensions include the knowledge integrated into capital equipment and intangible assets. To encompass these dimensions, conventional metrics include gross fixed capital formation, as well as recent advancements in measuring intangible assets and their impact on knowledge spillovers (Corrado et al. 2017; Jona-Lasinio and Meliciani 2019). Likewise, the concept of inter-sectoral knowledge diffusion has been investigated by looking at R &D expenditure embodied in trade. However, both measures are often more closely associated with innovation dynamics within specific 2-digit sectors, rather than with the learning and development of capabilities within the productive activities of the workforce (Marengo and Sterlacchini 1990; Leoncini and Montresor 2003; Fusillo et al. 2021; Cresti et al. 2023). In this contribution, we tackle the progressive fragmentation of knowledge in GVCs due to the changing division of labour, while leaving the treatment of the role of tangible and intangible capital to future extensions.

Once we define the division of labour as the division of knowledge embodied therein, we can also assess the positioning of countries and industries into such fragmentation. Taking advantage of the dependency and world-system theories (Prebisch 1950; Santos 1970; Wallerstein 1974; Gereffi and Korzeniewicz 1990; Gereffi 1994), we study the patterns of dependence and asymmetric positioning of countries. The idea is that there is no natural way to be involved in GVCs, but it is rather a matter of strategic or non-strategic positioning, which entails an assessment of which productive activities are kept in-house and which others are offshored. Since the most important productive input is labour, as it embodies tacit knowledge, routines and learning capacities - in short, capabilities - understanding whether a country is more or less dependent on labour activities performed abroad becomes crucially important.

Finally, in order to assess the quality of knowledge flows, we merge country-subsystems into four macro-categories, according to the Pavitt (1984) taxonomy. The latter is a macro-sectoral classification that groups productive sectors into four classes characterised by different technological attributes, internal learning processes and heterogeneous positioning along value chains. Such taxonomy is distinguished into:

-

Science Based industries (e.g. Pharmaceutical), whose technological progresses are strongly linked to those of basic and applied research.

-

Specialised Suppliers (e.g. Machinery and Equipment) provide capital tools and components to a large spectrum of downstream sectors. Learning relies on innovative efforts both through formal expenditures on R &D and tacit knowledge in the design of artefacts and customization.

-

Scale Intensive (e.g. Automotive), in which innovation capabilities arise from technological adoption of capital inputs and the ability to internally develop complex products. Learning is cumulative and its effect is amplified by scale economies, also thanks to the production of basic materials, services and consumer durables.

-

Suppliers Dominated industries (e.g. Textile) in which innovation and learning depend on intermediate and capital goods purchased from other sectors.

The Pavitt Taxonomy is a widely adopted taxonomy for the manufacturing sector, with a recent attempt to include services (Bogliacino and Pianta 2016). The industry grouping is based on the nature of the innovative process taking place and on the learning regime therein. Furthermore, within the Pavitt classification, there is embedded a concept of upstreamness (Science Based and Specialised Suppliers) and downstreamness (Suppliers Dominated and Scale Intensive) in the innovation process that motivates our choice (see Dosi et al. 2021).

In the following, we shall look at the positioning of country-macrosubsystems in terms of labour dependence, disentangling the quality of knowledge flows by Pavitt Taxonomy. The joint analysis of positioning and quality of embodied knowledge flows will allow detecting patterns of upgrading or, on the opposite, downgrading.

3.1 Data and Variables

We take symmetric global industry-by-industry Input–Output tables, usually called \(\varvec{Z}\) in Input–Output Analysis, from the World Input-Output Database (WIOD) (Timmer et al. 2015), which includes, together with the World Input–Output Tables (WIOT), also the Socio and Economic Account (SEA) dataset providing variables at 2-digit level of aggregation (NACE Rev. 2 classification) as employment, value added, gross fixed capital formation, labour compensation and so on. WIOD (2016 Release) is available for the period 2000-2014, for 43 countries (plus one Rest of the World) and 56 sectors. We use the number of persons engaged as employment variable, l, gross output x and matrix \(\varvec{Z}\) transformed in the Leontief Inverse, to construct a global employment multipliers matrix, from which we exclude RoW (Rest of the World) since SEA does not contain available information on sectoral variables of interest as employment. We end up with a 2408x2408 matrix, one for each available year. In Table 1 we list the variables of interest.

3.2 Employment Multipliers and Bilateral Net Labour Dependence Measures

We take advantage of a measure of bilateral net labour dependence firstly proposed in Cresti and Virgillito (2023). The indicator relies on the construction of vertically integrated employment coefficients (Pasinetti 1973; Momigliano and Siniscalco 1982) or matrices of employment multipliers (Baker and Lee 1993; Bivens 2003), capturing the number of employees activated in every supply chain to produce one unit of the final good at the end of the chain.

Starting from the Leontief Inverse matrix, it is computed from available I-O tables after a few algebraic transformations of the initial matrix \(\varvec{Z}\) of intermediate deliveries and matrix \(\varvec{A}\) of direct inter-industry coefficients, post-multiplying \(\varvec{Z}\) by the inverse of the diagonal matrix of sectoral output \({\hat{x}}\).Footnote 1 Matrix \(\varvec{A}\) is used to solve the accounting equations, describing the economic system composed of N industries, each producing a homogeneous good, represented as a vector of gross output x which equals a vector of intermediate production \(\varvec{Z}i\) (with i as a vector of 1s) and a vector of final demand d:

Solving by x yields:

The Leontief Inverse matrix is given by:

With \(\varvec{I}\) representing the identity matrix and assuming that the inverse of \((\varvec{I}-\varvec{A})\) exists. Considering N industries with \(i,j = 1,...,N\), every \(l_{i,j}\) element of the standard Leontief matrix (\(\varvec{L} = (\varvec{I}-\varvec{A})^{-1}\)) captures the direct and indirect requirements of increased output of industry i needed to produce one additional unit of final good in industry j. These steps allow the construction of the matrix of direct and indirect contributions of labour inputs of each industry to produce one more unit of final good:

where \({\hat{l}}\) is the diagonal matrix of sectoral employment, divided by \({\hat{x}}\), the diagonal matrix of sectoral output, results in a diagonal matrix of technical labour coefficients. Each cell of matrix \(\varvec{E}\) captures the so-called employment multiplier, i.e. the number of employees activated in each country-industry of the supply chain – also known as a subsystem or vertically integrated sector – by a fixed amount of final demand (in our case 1 mln USD).

\(\varvec{E}\) is a 2408x2408 country-industry x country-subsystem matrix (56 economic branches by 43 countries), built for every year from 2000 to 2014. It represents our main source of information which can be summarised in two ways: by summing over columns (rows) we get the so-called forward (backward) linkages indicating the number of employees provided (required) in intermediate input flows. In matrix form, we can compute the backward and forward employment multipliers in each column or row of a generic matrix \(\varvec{E}\) in the following way:

Or, in alternative notation:

where (j, k) is a generic subsystem-country unit (column identifier), while (i, c) stands for the industry-country unit (row identifier).Footnote 2

After having constructed the global employment multipliers matrix, we adopt \(\varvec{E}\) to analyse bilateral industry/subsystem trade between each pair of countries, by considering only manufacturing branches.Footnote 3 In order to aggregate them for each country-industry (rows) and country-subsystem (columns), we weigh each element of the chain by the corresponding effective final demand (left aside from the construction of the employment multiplier matrix). We then select European countries and end up with another square matrix called \(\varvec{E^{M}}\) of 27 x 27, where each row/column represents the entire manufacturing sector of a country.Footnote 4 Secondly, we construct a second aggregation matrix by Pavitt Class, disaggregating the entire country-manufacturing system into four macro-subsystems. We define this matrix of dimension 108 x 108 as \(\varvec{E^{P}}\) (4 classes for each of the 27 countries).

Each element of \(\varvec{E^{M}}\) represents linkages between two manufacturing country-subsystems. Columns (or value chains) represent backward bilateral linkages between a given final production stage of country j and each manufacturing supplier located in the remaining \(N-1\) countries. Rows, forward bilateral linkages, represent employees provided by a given manufacturing supplier country to each of the European final-stage manufacturing countries.

By merging the two dimensions, columns and rows, we construct a measure of GVC positioning, in the spirit of Koopman et al. (2010) and Baldwin and Freeman (2022).Footnote 5 This indicator informs about the number of employees that each country-manufacturing c sources from country-manufacturing k (backward) net of the number of employees that c provides to k (forward). It is therefore a bilateral measure between two countries:

In the case of matrix \(\varvec{E^{P}}\), we remove the Pavitt disaggregation from the partner country. That is, we consider the net labour dependence of each domestic Pavitt class from the entire foreign manufacturing sector, and similarly, the provision of the domestic Pavitt class to the entire foreign manufacturing.Footnote 6 Hence, the indicator of GVC positioning, which defines the dependence of Pavitt class i in country c from manufacturing labour inputs in country k (backward), net of the number of labour inputs that class i in country c provides to manufacturing in country k (forward), reads as:

Taking into account all bilateral relations (\(n-1\), as n is the number of countries), the Bilateral Net Labour Dependence (BNLD) of the manufacturing sector of country c reads as:

while, for class i in country c as:

We compute them for each European country-manufacturing and country-macrosubsystem (Pavitt) pair. Finally, to account for the geographical areas, we group the GVC positioning indicator \(\text {BNLD}_{c}^{M}\) by northern, central, southern and eastern European clusters.

The four indicators incorporate all bilateral GVC positioning in the European division of labour, defined by the matrices of employment multipliers aggregated at broad manufacturing or Pavitt class level, by a single country or by geographical areas. BNLD accounts for the net dependence from foreign labour, defining whether a unit of analysis (country, country-macrosubsystem, geographical area) requires more labour than the amount it provides. Hence, it captures asymmetric (dominant vs. dependent) positioning in GVCs, i.e. strong or weak ties in the European division of labour. If BNLD increases it might be due to an overall rise in backward bilateral flows or to an overall decline in forward bilateral flows (or both). The former means that more labour is required, and the latter that more labour is provided. As a result, an increase in BNLD accounts for increasing net dependence on foreign labour, and, correspondingly, to domestic employment units not activated by domestic productions.

The notion of dependence that we develop draws upon Dependency and World System theories (Prebisch 1950; Santos 1970; Wallerstein 1974; Gereffi and Korzeniewicz 1990; Gereffi 1994). Dependence and dominance are two alternative modalities in which countries might participate into value chains. Therefore positioning and dominance are not synonymous. We develop our indicator in order to quantitatively assess along GVCs, proxied by I-O tables, the positioning of Italy in the European division of labour.

4 Italy Within the European Production Network

In this section, we present our results analysing the Italian positioning in the European division of labour, in Sect. 4.1 and then, in a comparative perspective with the core (Germany) and an ascending periphery (Poland) in Sect. 4.2.

4.1 The Division of Labour and Downgrading Trap

In this subsection, we study the cross-sectional and temporal patterns of the proposed indicators. We start first with backward and forward bilateral linkages and we then move to positioning indicators. Our reference points are European in-(out-) flows to (from) Italy. We will present results at the Pavitt class level, to inform about quality of dependence, and at the geographical cluster level to inform about the geography of the division of labour.

In Fig. 1, we show the joint distribution of backward and forward linkages between Italian manufacturing by Pavitt classes (macro-subsystem) and European (manufacturing) countries. For each linkage (forward or backward) between Italy and a European trading country, we plot four dots, each representing an Italian Pavitt class. For instance, we can measure the bilateral backward linkage (x-axis) between the Italian Specialised Suppliers class and German manufacturing, i.e. the number of employees activated in German manufacturing to produce one unit of final good of Italian Specialised Suppliers industries (macrosubsystem), as required labour inputs. Symmetrically, we can measure the bilateral forward linkage (y-axis) between the two same units, i.e. the number of employees in Italian Specialised Suppliers industries which are activated by one unit of final production by German manufacturing, as provided labour inputs. Points on the bisector represent a GVC positioning indicator equal to 1. Dots above the bisector show forward linkages higher than backward ones (GVC positioning \(< 1\)), for each bilateral flow; the opposite holds for points below the bisector (GVC positioning \(> 1\)). Among all European countries, Germany is the only one recording higher backward rather than forward linkages (below the bisector) for all Italian Pavitt Classes and such provision in terms of labour input requirements shows a higher imbalance for Science Based and Specialised Suppliers classes, the two most strategic classes. All remaining country-macrosubsystems are above the bisector, indicating forward higher than backward linkages. The majority of points are distributed in an area of relatively low imbalance between forward vis-à-vis backward linkages, while Slovenia displays the highest forward connections with Italian Scale Intensive and Specialised Suppliers productions. Germany is the only country with which Italy has a GVC positioning greater than 1, meaning that all four classes require more labour than the amount they provide to German manufacturing as a whole. The evidence so far is already a first mark of the downgrading hypothesis, particularly in the most complex production processes.Footnote 7 The Figure in addition presents the histogram and kernel density distributions of forward (y-axis, right-hand side of the plot) and backward (x-axis, top side of the plot) linkages for each Pavitt class. Notably, the distributions of backward linkages are more similar across classes, and dominated by the modal attribute of Germany, while forward linkages distributions are more distinct across Pavitt classes, which, in turn, drive the different patterns of GVC positioning per Pavitt class. Specifically, Scale Intensive and Specialised Suppliers industries, the two intermediate classes, are those recording the highest forward linkages toward other European economies, while Science Based industries are the least (forward) labour provider classes?.

Overall, the best GVC positioning of Italian productions – i.e. where forward linkages mostly overcome backward ones (although with a relatively small advantage) – is in Scale Intensive, followed by Specialised Suppliers industries. Taking the magnitudes of both linkages as a proxy of the intensity of traded inputs, beyond Germany, countries with intensive trade flows are France, Poland, the Czech Republic, and Romania, the latter three representing the post-Visegrad European GVCs phase.

Bipartite network of Backward and Forward Bilateral linkages. On the left: flows of employees activated in all manufacturing industries of European supplier countries in 2014 in order to produce 1 mln USD of Italian (ITA) Final stage manufacturing goods distinguished by Pavitt classes; On the right: flows of employees provided by Italian (ITA) Pavitt classes in manufacturing as supplier country to all final stage European countries in 2014 in order to produce 1 mln USD of the final commodity in their manufacturing subsystems

The bipartite employment network representation of Italy’s backward and forward linkages with European countries (distinguished by Pavitt classes) is presented in Fig. 2. The bipartite structure of the network allows for assessing the asymmetric relationships between different nodes, according to the nature of the flow (inward or outward). It provides a synthetic picture of the relative importance of each bilateral exchange, coupling the information with a quality characterisation of the flows by Pavitt classes, and a composition figure in terms of shares of total inputs demanded/provided by each class. The left-hand side of the network shows backward bilateral linkages flowing into each Italian Pavitt class as macrosubsystems. The share of each four macrosubsystems for Italy (each of a different colour), and the country-level employment manufacturing shares for the remaining countries are indicated in each bar. In line with previous evidence, Germany (DEU) is responsible for the highest share of employment provision (30%) to Italian manufacturing. Such share is almost equally provided across the four classes except for Suppliers Dominated (SD). Notably, the highest dependent class in terms of labour inputs is Specialised Suppliers (SS), where the country used to have a historical specialisation and now losing independence in production, therefore downgrading its internal capacity. The right-hand side of the network presents the symmetric outflow dynamics, with forward linkages from each Italian Pavitt class to European manufacturing across countries. As already detected, forward linkages are more scattered across countries, without a clear preferential partnership in traded employment flows. In terms of providing industries, again Specialised Suppliers (SS) peaks, while Science Based (SB) industries represent the lowest share of input provided. Comparing backward and forward linkages a clear pattern emerges: while there is a dependence on German production in all classes, there is no clear trading partner to which Italian productions are specifically sold. This evidence represents a second element corroborating the downgrading hypothesis.

In order to better assess the downgrading hypothesis, we turn into a dynamic analysis in Fig. 3 where we present the growth of in(out) labour flows from 2000 to 2014, and of the ensuing growth in GVC positioning. An increase in GVC Positioning indicator stands for the deterioration of Italy’s industrial capacity in terms of bilateral net labour provision, i.e. more labour is required than the amount provided. The European map groups countries according to an ex-ante segmentation in three equally-spaced intervals of variation. The grouping results in nine classes based on the annual compound growth rate of backward and forward linkage levels, distinct by different colours. Pink-purple countries record forward linkages out-weighting backward ones. On the opposite, blue-grey countries record backward linkages out-weighting forward ones. The analysis is repeated for each Pavitt class. The four maps present different colour gradations, informing about the distinct ongoing dynamics. Finally, we also plot, by means of size-weighting coloured dots, changes in GVC positioning, with blue dots for negative changes and red dots for positive ones. Starting with the dynamics by Pavitt classes, Specialised Suppliers and Science Based, the productions that entail more complex activities, are those recording first, higher variations in growth dynamics and, second, overall deterioration of the positioning indicator, as shown by the many big red dots. This means that, overall, backward linkages have been growing more than forward ones, or alternatively, forward linkages have been decreasing. Indeed while Germany, Poland, Czech Republic, Bulgaria, and Hungary record medium/high backward increases vis-à-vis medium/high forward increases, countries like Spain, Greece, and Romania record an increase in the indicator mostly because of absent forward linkages. In contrast, the decrease in the positioning indicator is relevant in the least complex productions, Scale Intensive and Suppliers Dominated industries, with the former recording the lowest level of variation meaning that, given the intensity in the colour map, backward and forward flows have been moving hand in hand. However, also in this case a form of country clustering, with an ascending periphery-core-descending periphery structure, applies. Forward linkages increase more than backward particularly toward northern countries, France and Spain, while backward linkages increase more than forward in the ascending Visegrad and in the central core. Overall, the analysis has revealed first, the new geography of the Italian division of labour and the ascending role assumed by the eastern cluster. In addition, this cluster looks to be well integrated in terms of a variety of production flows, with intense reciprocal employment flows in all classes. Finally, the least integrated countries with Italy, or alternatively, the least involved in the fragmentation of Italian production are Great Britain, Norway, Sweden and Spain.

Table 2 presents the variation of the BNLD indicators, one aggregated for each subsystem at the Pavitt class level across all European countries, \(\varvec{E^{P}}\), and the other aggregated at the manufacturing subsystem level, \(\varvec{E^{M}}\), distinct across geographical areas, split into pre-and post-crisis periods, including the initial level in 2000. Starting with Pavitt classes’ dynamics, in 2000 Scale Intensive industries registered the lowest value of BNLD, while Science Based accounted for the highest magnitude. Until 2007, all Pavitt classes showed a declining trend, but after the crisis and till 2014, Specialised Suppliers and Science Based industries recorded a reverse of the trend, demanding more labour inputs than providing them. This evidence is in line with the increasing offshoring tendencies taking place in such industries as a restructuring process, after the 2008 crisis (Cresti and Virgillito 2022), and contextually of the downgrading GVC trap already discussed. The changing geography of production sees central Europe, toward which Italy records the highest level of labour input dependence at the beginning, an opposing pre- and post-crisis dynamics, confirming however its core position along the period. The clear ascending role of the eastern periphery is more marked in the pre-crisis period but keeps ongoing in the post-crisis one, with increasing dependence in both periods. Northern and southern countries recorded a negative variation in the post-crisis period, signalling the relatively less dependent position of Italy toward them, while the pre-crisis phase was characterised by a higher dependence from the South. However, rather than the opposite dominant position of Italy as a net provider of inputs, considering the low-intensity flows, this group of countries is characterised by weak trading relationships in manufacturing goods.

Italian forwards and backward linkages compound annual growth rate in the European production network divided by Pavitt classes. Each distribution is divided into 3 equally-spaced groups forming 9 clusters. The blue and red dots refer to respectively negative and positive GVC positioning changes. The size of the dots is proportional to changes in absolute values

4.2 Italy, Poland and Germany: A Comparison Between Two Peripheries and a Core

In order to provide a comparative perspective of the different strategic positioning of countries in GVCs, we present in this Subsection a comparison among the positioning of Italy, which we define as a descending periphery, whose downgrading patterns have been documented so far, the German core, and an ascending periphery, that is Poland. The choice of these two countries is motivated by the intensity of bilateral relationships with Italy emerging from Fig. 2. Figure 4 proposes a three-country bipartite network representation in 2014 of manufacturing bilateral linkages, with backward linkages (in)flowing from European countries to Germany, Italy and Poland, on the left panel, and with forward linkages (out)flowing from them towards the rest of European countries, on the right panel. Colours reflect distinct pairs of bilateral trades, given the three countries of reference. The Figure allows for studying the different positioning of countries. Germany positions itself as a net labour input provider, a dominant country, with 54% of forward linkages versus 34% of backward ones. Poland, on the opposite, presents the highest level of inflows (40%) but also a notable share of outflows (25%), positioning however as a net labour-dependent country. Italy is the country presenting the most balanced inflows (25%) vs outflows (21%), but still with a net dominant labour input dependence. Labour inputs required by Germany come from Czech Republic (11%), Italy (9%) and Poland (8%), while the latter demands 22% of its labour inputs from Germany itself. For Italy, beyond Germany, France and Poland are the top suppliers. Finally, beyond Germany, Czech Republic and Italy are the largest providers of labour inputs to Poland. Moving to forward linkages, there is no leading country as a labour input receiver, with scattered shares. Germany provides a significant amount of labour to Austria, Czech Republic, Hungary and Slovakia. Meanwhile, Italy’s largest share of forward linkages goes to Slovenia and then equally provides inputs to a series of other countries. Poland supplies mainly Czech Republic, Estonia, Hungary, Lithuania, Latvia and Slovakia hinting at a regional value chain emerging in the Visegrad area. Therefore, while Germany and Poland do present more specific and structured European chains, particularly in forward dimensions, Italy looks to be in a weak position, with clear labour input providers, but with scattered buyers. The lack of a dominant forward positioning versus specific countries, also considering the relatively tiny share of forward linkages when compared to Germany and Poland, is the nth evidence in favour of the downgrading trap.

Bipartite network of Backward and Forward Bilateral linkages. On the left: flows of employees activated in all manufacturing industries of European supplier countries in 2014 in order to produce 1 mln USD of German (DEU), Italian (ITA) and Polish (POL) final manufacturing goods; On the right: flows of employees provided by German (DEU), Italian (ITA) and Polish (POL) manufacturing branch as supplier countries to all European countries in 2014 in order to produce 1 mln USD of the final commodity in their manufacturing subsystems

Taking advantage of the temporal dimension, Fig. 5 compares GVC positioning among Germany, Italy and Poland, with respect to each European partner. Each bar registers the variation from 2000 to 2014, and partner countries are ranked according to such variations. Values below zero indicate a decreasing GVC positioning. The opposite holds for values above zero. A common geographical pattern emerges across the three countries of reference, with relatively less relevance of the northern area, and higher relevance of the eastern one. Central Europe, the core, maintains an overall steady positioning as a cluster. More nuanced are southern countries, such as Portugal and Greece, which however display growing dynamics mostly because of the low initial integration level and a relatively faster increase in backward vis-à-vis forward linkages, as per Figs. 2 and 3 in the Italian case.

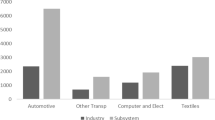

Figures 6 and 7 offer a complementary time series perspective on BNLD by Pavitt classes and for the whole manufacturing by geographical areas. In line with the evidence presented so far, Germany shows on average lower labour dependence followed by Italy and Poland. This ordering reflects the size of their manufacturing sector. Notably, Italy and Poland lowest dependence rates are in Scale Intensive productions, while for Germany, it is in Science Based industries. On the contrary, Science Based industries are the most outward dependent for Italy and Poland. In terms of dynamics, we observe an overall improvement in BNLD in Poland and Germany. Interestingly, most of Poland’s decline in its dependence on the European trade network happened in the pre-crisis period, whereas in Germany after the 2008 crisis. In contrast, Italy witnesses a general static behaviour in its BNLDs, considering the range of variation, with the only exception being the Scale Intensive class which steadily improves its positioning. Overall, Poland has the best BNLD performance dynamics among the three countries, as it converges to Italian levels in all four Pavitt classes at a very high pace, in line with the ascending periphery attribute. On the opposite, Italy lost production autonomy, particularly in Science Based productions, in line with the descending periphery attribute. In Fig. 13 in the appendix, we present an industry-level representation of the Italian BNLD divided by Pavitt class in order to provide a more granular account at a finer disaggregation level.

Looking at the geographical dimension in Fig. 7, all three countries increase their bilateral net dependence with respect to Eastern Europe, while the northern cluster becomes less and less relevant throughout the whole period. Central Europe, the core, remains mostly flat, with only a slight downward trend in Poland and Germany, meaning an increased reliance of these countries on core countries’ inputs, reinforcing regional value chains. Notably, the dependence on the central core is the highest for Poland and Italy, the two opposing peripheries. For Italy, the southern cluster is the geographical area with the lowest labour dependence, showing an anti-regional value chain, compared to Germany and Poland. While, for both Germany and Poland, the South (Italy included which drives the result) represents the area with the second-highest labour dependence. Finally, we highlight the divergence of Germany’s BNLD with respect to eastern and southern Europe. The two figures almost overlap in 2000 but diverge throughout the period, with the former overcoming the latter as the geographical area upon which Germany becomes mostly dependent. The latter dynamics prove therefore the reconfiguration of the geography of production, and labour requirements therein, occurred in the last fourteen years.

5 The Division of Labour in Sourcing and Provision of Service Inputs

Considering the progressive process of servitization of the manufacturing sector and the role of services as production inputs for exported goods (Lodefalk 2014), it could be restrictive to look only at the manufacturing labour inputs. Indeed, the downgrading trap could have been occurring in insourced manufacturing inputs, but for example, the opposite dynamics could have been occurring in service based production ones.

We start by distinguishing service vs. manufacturing in backward (forward) linkages originating from (directed to) each of the four regions. Notably, the share of service inputs, both as inflows and outflows, accounts for a notable part of the traded employment flows. Figure 8 (top-panel) shows the composition of labour inputs from the four European regions activated by the Italian manufacturing subsystems. Over time, a generalised increase in the service share of inputs is quite visible. However, group heterogeneity is strong, with the Northern and Western countries as the top-providers, while Visegrad countries largely provide manufacturing inputs. Coming to forward linkages (bottom-panel), similarly to manufacturing flows we do not detect primarily trading partners, with outsourced inputs out-flowing to all European countries.

Bipartite network of backward and forward bilateral linkages. On the left: flows of employees activated in all services industries of European supplier countries in 2014 in order to produce 1 mln USD of Italian (ITA) final stage manufacturing goods divided by Pavitt classes; On the right: flows of employees provided by Italian (ITA) Pavitt classes in services as supplier country to all final stage European countries in 2014 in order to produce 1 mln USD of the final goods in their manufacturing subsystems

To parallel the analysis of manufacturing, Fig. 9 provides a visual representation of the bipartite network of flows of labour embodied in service-based inputs. The backward linkages originating from the European service sectors and contributing to Italian manufacturing subsystems (inflows) are shown in the left panel, while the forward linkages of Italian service sectors directed to the European manufacturing subsystems are displayed in the right panel. We disaggregate Italian manufacturing subsystem into Pavitt classes and concerning the forward linkages we take advantage of the revised version of the taxonomy including services following Bogliacino and Pianta (2016) in order to account for the inherent technological complexity of the traded service activity.

Comparing the manufacturing (Fig. 2) versus service (Fig. 9) bipartite networks, we do not detect strong differences in the positioning of Italy inside the European production network when it comes to service inputs. Italian manufacturing Science-Based (SB) subsystems are the major dependent on foreign inputs (30%). These inputs primarily originate from Science-Based services located in the northern European regions, as shown by the prominent flows from Germany, France, the UK, and the Netherlands. In contrast, Science-Based services have a more limited representation among Italian forward linkages, representing the smallest share at 13% in terms of providers of labour-embodied services. The opposite holds for the Suppliers Dominated (SD) class, characterised by the lowest technological content and learning attributes, which provides the largest share (50%) of forward service inputs.

Overall, the weak specialization strategy of the Italian production system is manifested both in manufacturing and in service based inputs. Italy’s reliance on foreign knowledge-intensive service sectors is notable, while its contribution to European production primarily involves delivering basic service activities. These observations match with the widespread trend of increased service inputs within European Global Value Chains (GVCs). Taken together, these two tendencies indicate that the ongoing shift toward a more service-oriented production process within Europe does not contribute to the enhancement of Italy’s positioning within the European production network. At the opposite, the servitization of manufacturing productions reinforces the GVC downgrading trap that we have identified by looking at manufacturing inputs alone.

To conclude, Fig. 10 provides a comparison among Italy, Germany and Poland regarding the sourcing and provision of labour embodied in services from and to the production of manufacturing final commodities. Notably, the graph exhibits significant similarity to the manufacturing labour flows depicted in Fig. 4, particularly concerning the proportions of in- and out-flows of labour for the three reference countries. Specifically, forward linkages in services (right panel) closely mirror those in manufacturing, with Germany holding a dominant position in most bilateral interdependencies. Poland primarily provides labour to Germany and a few Eastern European countries, while Italy lacks clear specialization and relevance in any exchange. In terms of backward linkages (left panel), we observe a more pronounced role for Central and Northern European economies and a corresponding decrease in sourcing from Eastern Europe. This aligns with the evidence presented in Fig. 8. Notable differences from Fig. 4 include a heightened role for the United Kingdom (GBR) and the Netherlands (NLD), increasing from 3% as providers of labour embodied in manufacturing inputs to 8% as providers of labour embodied in services. France (FRA) and Italy (ITA) also show slightly higher shares as services providers, while countries like Czechia (CZE), Poland (POL), and Romania (ROU) see reductions in their shares.

Bipartite network of backward and forward bilateral linkages. On the left: flows of employees activated in all services industries of European supplier countries in 2014 in order to produce 1 mln USD of German (DEU), Italian (ITA) and Poland (POL) final stage manufacturing goods; On the right: flows of employees provided by German (DEU), Italian (ITA) and Poland (POL) services industries as supplier countries to all final stage European countries in 2014 in order to produce 1 mln USD of the final goods in their manufacturing subsystems

6 Concluding Remarks

This paper contributes to the literature investigating European production networks and Italian participation in GVCs. We put forward the hypothesis of Italy downgrading along GVCs, and we characterise the attributes and patterns of a core, and two peripheries, an ascending and a descending one, as traits of the European production network. Differently from the extant GVCs literature, we focus on labour requirements, both in manufacturing and in services. With this scope, we reconstruct the European division of labour, capturing employment fragmentation by means of a series of indicators. We focus on employment rather than value added, as we consider the former informative about the patterns of knowledge flows, and ensuing productive capabilities, acquired or lost by European countries along GVCs trades. We distinguish labour dependence in terms of Pavitt classes and geographical clusters, in order to highlight the quality of the underlying positioning in terms of the production processes involved and the geography of the division of labour.

According to our framing of labour as collective knowledge, the indicator is able to capture the positioning of Italy in the European division of productive capabilities, embedded in labour flows. With this aim, the indicator proves to be effective in capturing the declining position of Italy in the European production network, having the latter offshored many strategic activities, and becoming increasingly dependent on (net) foreign labour, both in manufacturing and service-based labour inputs. We account for this pattern by measuring Italian labour out-flows, represented by increasing backward linkages in terms of employment multipliers. Considering Italian labour in-flows, we performed country-by-country bilateral comparisons by investigating the ratio and dynamics of the two flows. Notably, our notion of dominance/dependence is not related to headquarter functions (see Timmer et al. 2019) which go beyond the scope of this contribution, requiring alternatively the use of firm-level data, or functional data.

Our results read as follows: first, we corroborate our hypothesis about Italy as trapped into a downgrading path along GVCs. The country over fourteen years records an increasing labour dependence in the most strategic productive sectors as Science Based and Specialised Suppliers industries, and a lack of a clear forward penetration with stable and strategic partners. This occurs in both manufacturing and service inputs. In addition, over time, the country has increased its dependence mostly on the core and the eastern periphery in manufacturing and on the northern area in services, with weaker relationships with the southern cluster, to which it belongs to. Second, the participation of countries in GVCs is distinctively asymmetric, with some of them assuming a dominant position, like Germany, some presenting an upgrading path, Poland, and some others presenting a downgrading path, like Italy. Third, in terms of geographical clustering, we do confirm the strong ascending role of the Visegrad area, particularly in the pre-crisis period, and the descending role of the southern one, particularly in the post-crisis period. The northern cluster appears to be mostly outside the European manufacturing network, while other big countries such as France and Spain are dramatically absent from exercising clear positioning in the network. The core has maintained its position. A process of increasing fragmentation of manufacturing productions in service inputs along European GVCs is documented as well. Service based labour inputs not only represent a notable and increasing fraction of insourced/outsourced inputs but according to our evidence, are structured along production chains that reinforce rather than curb the Italian downgrading trap.

Such evidence, besides depicting the different configurations (core-periphery) and paths (upgrading-downgrading) that countries may assume inside GVCs, sheds new light on the relevance of employment inputs loss/acquisition for strategic positioning, and on the eventual impacts they might exert upon overall country performance. Future lines of research entail the estimation of such impacts via an econometric setting as in Cresti and Virgillito (2023), leveraging on most updated I-O releases from OECD, increasing country and time coverage, a limitation per sè in the current setting, due to the restrictive number of observations. In addition, the analytical and measurement framework put forward might be useful in assessing the eventual emergence of so-called regional value chains fuelled by the post-COVID restructuring and geopolitical tensions toward shorter chains. Moreover, such type of analysis might be combined with more fine-grained import–export UN COMTRADE trade data, in order to better qualify the nature of the productions involved, and finally be complemented by upstreamness versus downstreamness indicators. In terms of income distribution in the European division of labour, the analysis of impacts upon the labour share is also a relevant line of investigation, distinguishing workers by occupational categories (Riccio et al. 2022; Riccio and Virgillito 2023).

Two main limitations emerge in this work. First of all, the lack of breakdown in different types and functions of labour inputs, distinguishing among heterogeneous occupational categories. Further lines of research will entail a more granular look at the heterogeneous functions performed along GVCs and their contributions therein, in line with Timmer et al. (2019). The measurement framework proposed in this paper is well-suited to account for this additional dimension as soon as data will be available. Furthermore, it’s worth noting that the diverse and varied nature of knowledge flows has not been tackled in our approach. We focused on labour as a proxy for productive capabilities with our primary objective being to capture the tacit knowledge, routines, and accumulated learning within the workforce. Additionally, we adopted an employment multipliers approach to leverage information on inter-sectoral labour flows for measuring positioning within the European division of labour. However, we do acknowledge that knowledge spillovers can originate from other sources, such as, for instance, disembodied capital and intangible assets (Corrado et al. 2017; Jona-Lasinio and Meliciani 2019). These sources can also have a substantial impact on productivity growth and knowledge diffusion and deserve to be investigated in future lines of research.

Concerning policy implications, our results suggest the need for European industrial policies able to promote internal cooperation in strategic productions, from microprocessors to decarbonization processes. Indeed, the recent US CHIPS Act and the Inflation Reduction Act are clear investment strategies put forward by the US to regain an international positioning in strategic productions, inducing many German firms already to offshore on the other side of the Atlantic. Given the detrimental effects of off-shoring and delocalization for losing downgrading countries, it should be a primary concern for policymakers to design industrial policies able to preserve and upgrade European strategic productions, rather than considering such dynamics as natural tendencies. Industrial policies, in green processes and strategic productions, would not only act in favour of employment protection and upgrading but, more broadly, of the macroeconomic performance of countries and Europe as a whole.

Data Availability

The data used in this work are available upon request.

Notes

The hat over variables stands for the transformation from vector to the diagonalized matrix.

Backward and forward multipliers are calculated always using the cells of the Leontief matrix after having pre-multiplied it by the diagonalized vector of employment coefficients: as inputs of a given production chain j, in combination with other productive inputs for the production of final output (vertical dimension) or, complementary, measuring how “widespread” and intense is the demand of each given input/sector i across the other chains (horizontal dimension). This approach is in line with Rasmussen (1956).

The choice of restricting the analysis to manufacturing is due to two reasons: first of all, the concept of capabilities embodied in labour flows mainly refers to the manufacturing sectors, and in fact, the Pavitt Taxonomy is more apt to study the manufacturing rather than services. Indeed, many service inputs activated in manufacturing refer to the Not Assigned Pavitt classification (see Cresti and Virgillito 2022, Fig. 7), showing how the latter is not the most appropriate categorization for services. Second, trade in services was limited in the pre-2014 period (e.g. Baldwin and Freeman 2022).

We exclude Malta, Luxembourg and Cyprus since their manufacturing sector is very small compared to the other countries in the sample. On the other hand, we include Switzerland and Norway since they have strong ties with other European countries and are characterized by a strong manufacturing sector. We end up with 27 countries that are listed in Table 4 in the Appendix. The aggregation procedure builds upon the method laid out in Miller and Blair (2022), p. 161, chapter 4.

The concept of GVC positioning has also been adopted to analyse upstreamness and downstreamness (Fally 2012; Antràs et al. 2012; Antràs and Chor 2013, 2018; Miller and Temurshoev 2017) with the aim of defining the positioning in terms of production stages of country-industry. In this paper, we are more interested in assessing bilateral dependence vs. dominance relationships.

As a result, matrix \(\varvec{E^{P}}\) takes dimensions \(27 \times 108\) when we compute backward bilateral linkages and 108 \(\times \) 27 for determining forward ones.

Such dependence relationships emerge in absolute terms, at constant demand level for all countries (1 mln USD), and exclusively inform about technical coefficients of production.

References

Accetturo, A., A. Bassanetti, M. Bugamelli, I. Faiella, P. Finaldi Russo, D. Franco, S. Giacomelli, and M. Omiccioli (2013). Il sistema industriale italiano tra globalizzazione e crisi. Occasional paper, n.193, Bank of Italy Occasional Paper

Accetturo A, Giunta A (2018) Value chains and the great recession: Evidence from italian and german firms. Int Econ 153:55–68

Accetturo A, Giunta A, Rossi S (2011) Le imprese italiane tra crisi e nuova globalizzazione. L’industria 32(1):145–164

Agostino M, Giunta A, Scalera D, Trivieri F (2016) Italian firms in global value chains: Updating our knowledge. Rivista di Politica Economica 7:155–186

Andreoni A (2014) Structural learning: embedding discoveries and the dynamics of production. Struct Change Econ Dynam 29:58–74

Andreoni A, Chang H-J, Estevez I (2021) The missing dimensions of the human capabilities approach: Collective and productive. Eur J Develop Res 33(2):179–205

Andreoni A, Scazzieri R (2014) Triggers of change: structural trajectories and production dynamics. Cambridge J Econ 38(6):1391–1408

Antràs P, Chor D (2013) Organizing the global value chain. Econometrica 81(6):2127–2204

Antràs P, Chor D (2018) On the measurement of upstreamness and downstreamness in global value chains. World Trade Evol Growth Product Employment 5:126–194

Antràs P, Chor D, Fally T, Hillberry R (2012) Measuring the upstreamness of production and trade flows. Am Econ Rev 102(3):412–416

Antràs P, de Gortari A (2020) On the geography of global value chains. Econometrica 88(4):1553–1598

Arrighetti A, Ninni A (2014) La trasformazione silenziosa. Cambiamento strutturale e strategie d’impresa nella industria italiana. Dipartimento di Economia Università di Parma, Collana di Economia Industriale e Applicata

Baker D, Lee TM (1993) Employment multipliers in the US economy. Economic Policy Institute

Baldwin R (2011) Trade and industrialisation after globalisation’s 2nd unbundling: How building and joining a supply chain are different and why it matters. Working Paper 17716, National Bureau of Economic Research

Baldwin R, Freeman R (2022) Risks and global supply chains: What we know and what we need to know. Ann Rev Econ 14:153–180

Baldwin R, Ito T (2021) The smile curve: Evolving sources of value added in manufacturing. Canadian J Econ 54(4):1842–1880

Baldwin R, Lopez-Gonzalez J (2015) Supply-chain trade: A portrait of global patterns and several testable hypotheses. World Economy 38(11):1682–1721

Barrientos S, Gereffi G, Rossi A (2011) Economic and social upgrading in global production networks: A new paradigm for a changing world. Int Labour Rev 150(3–4):319–340

Battiati C, Jona-Lasinio C, Sopranzetti S (2020) Productivity growth and global value chain participation in the digital age. Economic Statistics Centre of Excellence (ESCoE) Discussion Papers ESCoE DP-2020-04, Economic Statistics Centre of Excellence (ESCoE)

Bivens J (2003) Updated employment multipliers for the us economy. Technical report, Report, Economic Policy Institute, Citeseer

Bivens J (2019) Updated employment multipliers for the us economy. Technical report, Report, Economic Policy Institute, Citeseer

Bogliacino F, Pianta M (2016) The pavitt taxonomy, revisited: patterns of innovation in manufacturing and services. Econ Politica 33(2):153–180

Bontadini F, Evangelista R, Meliciani V, Savona M (2022) Patterns of integration in global value chains and the changing structure of employment in Europe. Indus Corporate Change 31(3):811–837

Borin A, Mancini M (2016) Participation in global value chains: measurement issues and the place of italy. Rivista di Politica Econ 7:15–64

Bugamelli M, Lotti F, Amici M, Ciapanna E, Colonna F, D’Amuri F, Giacomelli S, Linarello A, Manaresi F, Palumbo G, et al. (2018) Productivity growth in italy: a tale of a slow-motion change. Occasional paper, n. 422, Bank of Italy Occasional Paper

Bundesbank D (2011) Developments in the exports of the four largest euro-area member states since the launch of monetary union. Monthly Report 63(7):15–34

Celi G, Ginzburg A, Guarascio D, Simonazzi A (2018) Crisis in the European Monetary Union: A core-periphery perspective. Routledge

Celi G, Guarascio D, Reljic J, Simonazzi A, Zezza F (2022) The asymmetric impact of war: Resilience, vulnerability and implications for eu policy. Intereconomics 57(3):141–147

Celi G, Guarascio D, Simonazzi A (2020) A fragile and divided european union meets covid-19: further disintegration or‘hamiltonian moment’? J Indus Business Econ 47(3):411–424

Ceron M, Palermo CM (2022) Structural core-periphery divergences in the eu: the case of responses to the covid-19 crisis in 2020. European Politics Soc 24(3):372–391

Cimoli M, Dosi G, Stiglitz JE (2009) Industrial policy and development: The political economy of capabilities accumulation. New York: Oxford

Confindustria CS (2012) La politica industriale serve? si, dicono la teoria (vecchia e nuova) e l’esperienza degli altri paesi

Constantinescu C, Mattoo A, Ruta M (2019) Does vertical specialisation increase productivity? World Economy 42(8):2385–2402

Coricelli F, Wörgötter A (2012) Structural Change and the Current Account: The Case of Germany. OECD Economics Department Working Papers 940, OECD Publishing

Corrado C, Haskel J, Jona-Lasinio C (2017) Knowledge spillovers, ict and productivity growth. Oxford Bull Econ Stat 79(4):592–618

Costa S, De Santis S, Dosi G, Monducci R, Sbardella A, Virgillito ME (2021) From organizational capabilities to corporate performances: at the roots of productivity slowdown. Technical report, LEM Working Paper Series