Abstract

Residual oil zones (ROZs) have high residual oil saturation, which can be produced using CO2 miscible flooding. At the same time, these zones are good candidates for CO2 sequestration. To evaluate the coupled CO2-EOR and storage performance in ROZs for Water-Alternating-CO2 (WAG) flooding, a multi-compositional CO2 miscible model with molecular diffusion was developed. The effects of formation parameters (porosity, permeability, temperature), operation parameters (bottom hole pressure, WAG ratio, pore volume of injected water), and diffusion coefficient on the coupled CO2-EOR and storage were investigated. Five points from the CO2 sequestration curve and the oil recovery factor curve were selected to help better analyze coupled CO2-EOR and storage. The results demonstrate that enhanced performance is observed when formation permeability is higher and a larger volume of water is injected. On the other hand, the performance diminishes with increasing porosity, molecular diffusion of gas, and the WAG ratio. When the temperature is around 100 °C, coupled CO2-EOR and storage performance is the worst. To achieve optimal miscible flooding, it is recommended to maintain the bottom hole pressure (BHP) of the injection well above 1.2 minimum miscibility pressure (MMP), while ensuring that the BHP of the production well remains sufficiently high. Furthermore, the tapered WAG flooding strategy proves to be profitable for enhanced oil recovery, as compared to a WAG ratio of 0.5:1, although it may not be as effective for CO2 sequestration.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

CO2 is one of the main gases causing the greenhouse effect. With the increased amount of resources such as oil and coal consumed, the global warming problem gets worse (Liu et al. 2018).To solve the sharp increase in carbon dioxide emissions, the technology of carbon capture, utilization, and storage (CCUS) has attracted much attention in the energy industry (Jiang et al. 2020).

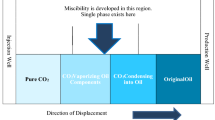

Under reservoir conditions, CO2 normally exists as a supercritical fluid, which has been widely known as a favorable and promising EOR agent for decades. Miscible flooding is more effective than immiscible flooding due to the disappearance of surface tension and capillary pressure. Miscible flooding between the injected supercritical CO2 and oil can be achieved at pressures above the MMP (Gong and Gu 2015). Hence, the displacement pressure is supposed to be higher than MMP to ensure the miscible flooding is maintained during the whole flooding process. Many studies have shown a significant improvement in oil recovery by CO2 miscible flooding (Brock and Bryan 1989; Farajzadeh et al. 2010; Rui et al. 2017). Recently, research on CO2 flooding has grown because CO2 flooding can enhance oil recovery and store a considerable amount of CO2 underground. Thus, appropriate implementation of CO2-EOR offers two advantages: (1) environmental benefits from storing injected CO2 and (2) economic benefits from enhanced oil recovery.

Residual oil zones (ROZs) are portions of an oil reservoir, or even whole reservoirs, in which the oil saturations are near residual levels. These zones exhibit characteristics similar to those of a reservoir after waterflooding. ROZs are widely distributed within the Permian Basin of West Texas. Koperna et al. (2006) estimated the recoverable oil volume from ROZs in the San Andres and Canyon Reef formations of the Permian Basin to be approximately 12 billion barrels. Conventional methods, such as water flooding, are insufficient for the production of oil from ROZs; instead, enhanced oil recovery (EOR) techniques such as CO2-EOR becomes imperative, which incidentally sequesters CO2. As noted by Al Eidan et al. (2015), ROZs are regarded as the most favorable reservoir sections for CO2 storage. Consequently, the significance of CO2 sequestration in CO2-EOR projects is of paramount importance. Notably, ongoing commercial-scale WAG injections of CO2 into ROZs are being carried out in eight San Andres oil fields within the Permian Basin, as reported by Ren and Duncan (2019a). However, research on the coupled CO2-EOR and storage in ROZs remains insufficient.

Several studies have investigated the optimization of CO2-EOR storage in different types of oil reservoirs with different operation parameters. Ghaderi et al. (2012) analyzed the effect of development patterns and WAG parameters on oil recovery, CO2 sequestration, and NPV in tight oil formations. Karimaie et al. (2017) investigated CO2-EOR performance in high permeability layers under various flooding scenarios, such as continuous gas injection, constant water-alternating-gas injection, and tapered WAG injection. Song et al. (2014) used the orthogonal experimental design method to optimize the reservoir and operation parameters for enhanced oil recovery and CO2 sequestration in high-water-cut oil reservoirs. Ren and Duncan (2019b) evaluated the effects of injection strategies and reservoir heterogeneities on the performance of CO2 sequestration based on the San Andre residual oil zones. Ettehadtavakkol et al. (2014) analyzed the coupled CO2-EOR and storage, considering reservoir properties, design parameters, and economic parameters. However, coupled CO2-EOR and storage performance in residual oil zones still needs to be investigated. This study considers molecular diffusion and analyzes the effects of formation parameters, operation parameters, and diffusion coefficients on coupled CO2-EOR and storage.

In this study, a multi-compositional CO2 miscible model with molecular diffusion was developed. The effects of formation parameters (porosity, permeability, temperature), operation parameters (bottom hole pressure, WAG ratio), and diffusion coefficient on coupled CO2-EOR and storage were analyzed. The optimum parameters under which the highest oil recovery and highest CO2 sequestration can be achieved were investigated.

2 Methodology and model setup

2.1 Governing equations

The mass conservation equation considering molecular diffusion for each chemical component \({\text{i}}\) in the oil, gas, and water phases can be presented as:

where, \(t\) is the time; \(\phi\) is the porosity; \(\rho\) is the density; \(S\) is phase saturation; \(w_{i\ell }\) is mass fraction of component i in phase \(\ell\); \(v\) is Darcy’s velocity; \(D_{i\ell }\) is the molecular diffusion coefficient of component i in phase \(\ell\); \(r\) is the injection or production mass rate; the subscripts \(\ell\) denote oil, gas or water phase; the subscript \(i\) refers to chemical component.

The Darcy’s velocity \(v_{\ell }\) is formulated by Darcy’s law.

where \(K\) is absolute permeability, \(k_{\text{r}\ell }\) is relative permeability of phase \(\ell\). \(P_{\ell }\) is phase pressure. \(\mu_{\ell }\) is phase viscosity. \(\rho_{\ell }\) is phase density.

The mass rate \(r_{i}\) can be expressed as:

where \(p_{\text{well}}\) is wellbore pressure, \(p_{\text{block}}\) is pressure existing within block and \(\text{WI}\) is well index.

The two-phase relative permeability curves of water–oil and liquid–gas are fitted given the relative permeability tables. The three-phase relative permeability curve is generated using Stone’s Model II (Stone 1970).

The mass exchange between the oil and gas phases is modeled by the thermodynamic equilibrium conditions, which is defined by the equality of fugacity of all components.

where, \(f_{\text{o}}^{i}\) is the fugacity of component \(i\) in oil phase; \(f_{\text{g}}^{i}\) is the fugacity of component \(i\) in gas phase; the Peng-Robinson EOS equations (Peng and Robinson 1976) are used to do two-phase flash calculation, and the calculation is solved using QNMs (Quasi-Newton Methods).

The equation system is closed by the sum of saturations and concentrations.

2.2 Model setup

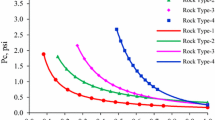

A three-dimensional reservoir model is built in CMG-GEM to investigate: (1) the WAG flooding performance to enhance the oil recovery; and (2) the amount of CO2 sequestrated in the reservoir. The reservoir model is 225 m, 225 m, and 18 m in the x, y, and z dimensions, respectively. A five-spot pattern is used, with a well spacing (the distance between producers) of 220 m, as shown in Fig. 1. All six layers of the formation are perforated. The initial oil saturation, connate water saturation, and residual oil saturation for oil–water system are 0.793, 0.207, and 0.25, respectively. The connate gas saturation and maximum gas saturation for gas–liquid system are 0 and 0.422, respectively. The relative permeability curves are shown in Fig. 2. Other basic simulation parameters are summarized in Table 1.

2.3 Minimum miscible pressure (MMP) determination

The minimum miscible pressure (MMP) was calculated in CMG-WinProp. The components of reservoir oil were lumped into seven pseudo-components, and the parameters of the Peng-Robinson equation of state were fitted based on the experiment data from the constant composition expansion (CCE) test, the differential liberation (DL) test, and the swelling test (ST). The regression procedure by Agarwal et al. (1987) was used to improve the regression efficiency. The fitted pseudo-component description of crude oil is shown in Table 2. In this case, the traditional Cell-to-Cell simulation method, which uses a vaporizing drive mechanism, was utilized to calculate MMP. The MMP calculated is 18 MPa in this case. The miscible flooding is achieved at pressures above MMP, as described by the interfacial tension decreasing to zero in the CMG-GEM model.

3 Results and discussion

This section initiates with the simulation of a comprehensive production process, consisting of depletion-drive, water flooding, and WAG flooding, aimed at emulating the conditions prevalent in the residual oil zone. Following this, an extensive comparison is carried out to assess the performance of water flooding, continuous CO2 flooding, and CO2 WAG flooding. Finally, a sensitivity analysis is performed to examine the impact of formation parameters, operation parameters, and diffusion coefficients.

3.1 Base case

In this section, a complete production process is described, and three flooding methods are compared. The reservoir is under depletion-driven development for the first half of the year. Then, 1.5 PV (pore volume) of water is injected. After the water flooding process, 4.5 PV of CO2 is injected for WAG flooding. The maximum cycle duration of WAG flooding is 90 days. The maximum BHP and maximum injection rate of the injector constrain the injection rate, while the minimum BHP and maximum production rate constrain the production rate. In the base case, the maximum injection and production rates are never achieved during the simulation, and all wells are constrained by the maximum or minimum BHP. The well configuration information is presented in Table 3.

The oil recovery factor and CO2 sequestrated with water or gas injected are shown in Fig. 3. The ultimate oil recovery factor in the base case is 72.7% after WAG flooding. However, the oil recovery factor nearly stabilizes after injecting 1 PV CO2, and this value is 68.3%. Concerning the amount of CO2 sequestrated, it increases first and then decreases after injecting 0.4 PV CO2. The maximum amount of CO2 sequestrated is 31.9%. After injecting 1 PV CO2, the amount of CO2 sequestrated stabilizes.

In order to compare the performance, cases of water flooding and continuous CO2 flooding utilizing the same data set were conducted. The findings, presented in Fig. 4, illustrate the ultimate oil recovery factors of water flooding, continuous CO2 flooding, and CO2 WAG flooding as 41.17%, 71.53%, and 67.51%, respectively. The substantial increase in ultimate oil recovery by 26% in CO2 WAG flooding and 30% in continuous CO2 flooding can be attributed to the improved displacement efficiency resulting from the miscible flooding between CO2 and crude oil. Furthermore, consistent with prior investigations (Ren and Duncan 2019b), continuous CO2 flooding exhibits superior production performance compared to CO2 WAG flooding, owing to the injection of a greater volume of CO2 within the same time frame, resulting in higher sweep efficiency and displacement efficiency. However, continuous CO2 flooding entails a cumulative injected gas volume of 6.9 × 107 m3 and a sequestrated CO2 to injected CO2 ratio of 0.19. Conversely, CO2 WAG flooding involves a cumulative injected gas volume of 2.8 × 107 m3 and a sequestrated CO2 to injected CO2 ratio of 0.25. As a result, CO2 WAG flooding offers lower injection costs and higher CO2 sequestration efficiency, making it an attractive option in residual oil zones. The aforementioned results are derived from simulations conducted on homogeneous formations utilizing a five-spot pattern. However, the performances of continuous CO2 flooding and CO2 WAG flooding may vary under different conditions. For instance, in reservoirs exhibiting a rhythmic formation, WAG flooding does not present any notable advantage over water flooding in reverse rhythmic reservoirs. Conversely, compound reverse rhythmic reservoirs could experience the greatest economic benefits from WAG flooding, as highlighted by Song et al. (2014). Furthermore, when production and injection wells are arranged in a linear drive pattern, CO2 WAG flooding demonstrates higher oil recovery compared to continuous CO2 flooding. The enhanced recovery achieved through WAG injection can be attributed to a more stable advancing front, resulting in improved volumetric sweep, as discussed by Namani and Kleppe (2011).

3.2 Effects of reservoir porosity

For the sensitivity analysis below, the model is carried out with the same data set and production schedule as the base case except that 1 PV CO2 is injected rather than 4.5 PV because both oil recovery and CO2 sequestration stabilize after injecting 1PV CO2. Five points shown in Fig. 3 are used to help analyze the coupled CO2-EOR and storage, where 1 refers to the amount of gas injected at the highest point of CO2 sequestration, 2 refers to the highest amount of CO2 sequestration, 3 refers to the oil recovery at the highest point of CO2 sequestration, 4 refers to the amount of CO2 sequestration after injecting 1PV CO2, 5 refers to the ultimate oil recovery after injecting 1PV CO2. The related parameter ranges are determined by screening criteria suitable for CO2 flooding and storage (He et al. 2020; Khan et al. 2016; Qin et al. 2015; Shaw and Bachu 2002; Zhang et al. 2019).

Six cases with the porosity changing from 0.08 to 0.24 are designed to study the impact of reservoir porosity on coupled CO2-EOR and storage. It is worth mentioning that the porosity does not have much influence on all five parameters when it is higher than 0.12, as shown in Fig. 5. In comparison, the coupled CO2-EOR and storage performance gets better with the decrease in porosity when the porosity is lower than 0.12. The reason is that the lower porosity limits the gas overriding problem, which improves the displacement efficiency of the bottom layers of the reservoir. However, this study only focuses on the relative values of oil produced and CO2 sequestrated. If the absolute values are considered, the formation with higher porosity contributes to a higher amount of CO2 sequestrated and oil produced, which is preferable for CO2-EOR and storage projects.

3.3 Effects of reservoir permeability

Figure 6 presents the coupled CO2-EOR and storage performance at different levels of permeability. All five parameters increase with reservoir permeability because better transmissibility improves sweep efficiency. Conversely, according to Song et al. (2014), when the permeability exceeds 400 mD, the performance of WAG flooding deteriorates due to the exacerbation of CO2 overriding caused by higher permeability. This reduces the sweep efficiency at the reservoir’s bottom. Moreover, the rapid decline in reservoir pressure below the MMP caused by increased gas production diminishes the extent of the ultimate miscible CO2 flooding area, jeopardizing displacement efficiency. These conclusions are predicated on analyses conducted in homogeneous reservoirs. However, for heterogeneous reservoirs, Ren and Duncan (2019b) observed that increased homogeneity in the permeability field leads to higher oil recovery and CO2 sequestration. The presence of reservoir heterogeneity tends to induce premature CO2 breakthrough and reduce sweep efficiency. Furthermore, Song et al. (2014) demonstrated that as the ratio of vertical to horizontal permeability increases, the efficiency of WAG flooding diminishes. This is attributable to an elevation in gas saturation within the top layer due to decreased permeability variation coefficient, subsequently accentuating the CO2 overriding.

3.4 Effects of reservoir temperature

To investigate the effect of reservoir temperature, the reservoir temperature is changed from 80 to 120 °C. The results are shown in Fig. 7. When the temperature remains below 100 °C, there is a decrease observed in all five parameters with an increase in temperature, mainly because the oil has a relatively higher viscosity at lower temperatures, which makes the mobility ratio lower. The lower mobility ratio delays gas breakthrough time and improves the effect of miscible flooding. As a result, oil recovery and CO2 sequestration increase. In contrast, When the temperature exceeds 100 ℃, an increase in temperature leads to a corresponding increase in all five parameters. This is because the increase in reservoir temperature reduces oil viscosity, making the crude oil move easier toward the production well. The increased oil transmissibility improves sweep efficiency during both water flooding and WAG flooding. The findings of Perera et al. (2016) support the observed trends, explaining that the decline in oil production as temperature rises can be attributed to CO2 vaporization from the oil phase, which limits contact with the oil. Conversely, the substantial increase in oil production at higher temperatures is ascribed to the prevailing impact of kinetic energy increment, accompanied by a corresponding rise in CO2 mobility. This effect outweighs the influence of CO2 vaporization in high-temperature conditions.

3.5 Effects of diffusion coefficient of oil and gas

The diffusion coefficients of seven pseudo-components in oil and gas phases are set from 0.01 to 0.03 cm2/s and from \({10}^{{ - {6}}}\) to 2.4 × 10-6 cm2/s, respectively. Figure 8 compares the results of different gas diffusion coefficients and shows that all other four parameters decrease with the increase in gas diffusion coefficient except for the amount of gas injected at the highest point of CO2 sequestration. The results indicate that gas diffusion harms the coupled CO2-EOR and storage. This is because gas diffusion improves gas transmissibility, worsening the gas overriding problem and leading to a lower displacement efficiency. The ultimate oil recovery and CO2 sequestrated decrease by 3.6% and 1.2%, respectively, with the change in gas diffusion coefficient from 0.01 to 0.03 cm2/s. On the contrary, the diffusion in the oil phase has a limited impact on the coupled CO2-EOR and storage, as described in Fig. 9. This is because the oil diffusion coefficient is four orders of magnitude lower than the gas diffusion coefficient.

3.6 Effects of BHP of injection well and production well

The BHPs of the injection and production wells play an important role in WAG flooding as they determine the feasibility of maintaining the MMP. In this study, the BHP of the injection well is varied within the range of 0.9 MMP to 1.4 MMP, as depicted in Fig. 10. Notably, a clear increment is observed for all five data points as the BHP of the injection well increases, particularly when it exceeds 1.1 MMP, aligning with the findings of a previous study (Yan and Stenby 2009). This phenomenon can be attributed to the attainment and sustainable maintenance of the desired miscible flooding state over a more extensive area, resulting in enhanced final displacement efficiency. Moreover, this improvement is attributed to the augmented injection rate facilitated by the enhanced BHP (Ren and Duncan 2019b). The higher injection rate intensifies the viscous force and reduces the time required for gravity force to segregate the fluids, as highlighted by Namani and Kleppe (2011).

The BHP of the production well is selected from 3000 to 11,000 kPa to investigate its influence on the coupled CO2-EOR and storage, as shown in Fig. 11. The coupled CO2-EOR and storage performance does not change a lot, except that the BHP of the production well increases from 5000 to 7000 kPa. This is because if the production pressure differential is too high, the displacement pressure cannot be maintained above the MMP, jeopardizing the displacement efficiency and the performance of the coupled CO2-EOR and storage.

3.7 Effects of WAG ratio

The cases of different WAG ratios and tapered WAG are carried out to investigate their effects on coupled CO2-EOR and storage. Five WAG ratio patterns are under investigation. Pattern 1 refers to the WAG ratio of 0.5:1, which means 45 days of water injection followed by 90 days of CO2 injection. Patterns 2, 3, and 4 refer to the WAG ratios of 1:1, 2:1, and 4:1, respectively. The meanings are the same as in pattern 1. Pattern 5 refers to the tapered WAG ratio shown in Table 4. As shown in Fig. 12, the coupled CO2-EOR and storage performance worsens as the WAG ratio increases, which is supported by Kohata et al. (2017). The reason is that the hindrance of oil and CO2 contact resulting from a large volume of injected water negatively impacts the efficiency of miscible flooding. Moreover, tapered WAG flooding demonstrates favorable performance in terms of oil enhancement. However, when the objective is CO2 sequestration, with a focus on injecting the maximum amount of CO2 and achieving the desired oil recovery, the overall performance of Pattern 1 surpasses that of tapered WAG flooding. Additionally, the optimal WAG ratio for projects in ROZs is influenced by whether the zone is a virgin ROZ or a man-made waterflooding (MMWF) zone, as highlighted by Ren and Duncan (2021). It is speculated that the prevalent high water saturation in virgin ROZs contributes to consistently smaller favorable WAG ratios in virgin ROZs compared to those in zones following MMWF. Notably, the performance of coupled CO2-EOR and storage is contingent not only upon the WAG ratio but also on the half-cycle time. Namani and Kleppe (2011) underscored that cases with shorter gas injection times exhibit reduced oil recovery, while a decrease in water injection time has minimal impact on the oil recovery factor. Therefore, when designing WAG flooding, careful consideration must be given to the WAG ratio, cycle time, and half-cycle duration.

3.8 Effects of PV of water injected

The efficacy of coupled CO2-EOR and storage is affected by the volume of water injected during the water flooding. To investigate the impact of water injection on the coupled process, simulations are conducted with varying volumes of injected water: 1 PV, 2 PV, 4 PV, and 6 PV. Figure 13 illustrates that all five parameters exhibit an increasing trend with the progressive injection of water. This phenomenon can be attributed to the enhancement of sweep efficiency and displacement efficiency associated with higher volumes of water injection. However, the absence of miscible flooding during water flooding limits the significant improvement in displacement efficiency, resulting in a modest increase of only 2% and 3.5% in ultimate oil recovery and CO2 sequestration, respectively.

4 Conclusions

This paper conducted a numerical study on the coupled CO2-EOR and storage performance in ROZs. The sensitivity analysis was designed to investigate the optimal parameters with molecular diffusion. The conclusions are as follows.

-

(1)

The reservoir porosity does not greatly influence the relative values of oil produced and CO2 sequestrated if it is larger than 0.12. In comparison, the coupled CO2-EOR and storage performance gets better with the decrease in porosity when the porosity is lower than 0.12.

-

(2)

The coupled CO2-EOR and storage performance improves with the increased reservoir permeability because of the better sweep efficiency achieved. However, the MMP might not be maintained long if the permeability is too high.

-

(3)

When the temperature is around 100 ℃, the coupled CO2-EOR and storage exhibit their most unfavorable performance, which results from the combination of gas breakthrough and a change in gas transmissibility.

-

(4)

The increased gas diffusion coefficient lowers the amount of oil produced and CO2 sequestrated due to the enhanced gas breakthrough. In contrast, the effect of oil diffusion is small because the oil diffusion coefficient is four orders of magnitude lower than the gas diffusion coefficient.

-

(5)

The BHP of the injection well is supposed to be higher than 1.2 MMP during the WAG flooding to achieve ideal miscible flooding. The BHP of the production well should not be too low. If the production pressure differential exceeds a certain limit, the displacement pressure cannot be maintained above the MMP.

-

(6)

By increasing the WAG ratio from 0.5 to 4, the amounts of CO2 sequestration and oil recovery decrease. Besides, tapered WAG flooding is promising when the goal is ultimate oil recovery. However, for CO2 sequestration, whose goal is to inject as much CO2 as possible and achieve the desired oil recovery, the overall performance of 0.5 WAG ratio is the best.

Availability of data and materials

Data available on request from the authors.

References

Agarwal R, Li YK, Nghiem L (1987) A regression technique with dynamic-parameter selection or phase behavior matching. In: SPE california regional meeting

Al Eidan AA, Bachu S, Melzer LS, Lars EI, Ackiewicz M (2015) Technical challenges in the conversion of CO2-EOR projects to CO2 storage projects. In: SPE asia pacific enhanced oil recovery conference

Brock WR, Bryan LA (1989) Summary results of CO2 EOR field tests. In: Low permeability reservoirs symposium

Ettehadtavakkol A, Lake LW, Bryant SL (2014) CO2-EOR and storage design optimization. Int J Greenhouse Gas Control 25:79–92. https://doi.org/10.1016/j.ijggc.2014.04.006

Farajzadeh R, Andrianov A, Zitha PLJ (2010) Investigation of immiscible and miscible foam for enhancing oil recovery. Ind Eng Chem Res 49:1910–1919

Ghaderi SM, Clarkson CR, Chen S (2012) Optimization of WAG process for coupled CO2 EOR-storage in tight oil formations: an experimental design approach. In: SPE Canadian unconventional resources conference

Gong Y, Gu Y (2015) Miscible CO2 simultaneous water-and-gas (CO2-SWAG) injection in the bakken formation. Energy Fuels 29(9):5655–5665. https://doi.org/10.1021/acs.energyfuels.5b01182

He Y, Zhao S, Bingyu JI, Liao H, Zhou Y, Amp PE, SINOPEC (2020) Screening method and potential evaluation for EOR by CO_2 flooding in sandstone reservoirs. In: Petroleum geology and recovery efficiency.

Jiang K, Ashworth P, Zhang S, Liang X, Sun Y, Angus D (2020) China’s carbon capture, utilization and storage (CCUS) policy: a critical review. Renewable Sustainable Energy Rev 119:109601. https://doi.org/10.1016/j.rser.2019.109601

Karimaie H, Nazarian B, Aurdal T, Nøkleby PH, Hansen O (2017) Simulation study of CO2 EOR and storage potential in a north sea reservoir. Energy Procedia 114:7018–7032. https://doi.org/10.1016/j.egypro.2017.03.1843

Khan MY, Kohata A, Patel H, Syed FI, Al Sowaidi AK (2016) Water alternating gas WAG optimization using tapered WAG technique for a giant offshore middle east oil field. In: Abu Dhabi international petroleum exhibition & conference

Kohata A, Willingham T, Yunus Khan M, Al Sowaidi A (2017) Extensive miscible water alternating gas WAG simulation study for a giant offshore oil field. In: Abu Dhabi international petroleum exhibition & conference

Koperna GJ, Melzer LS, Kuuskraa VA (2006) Recovery of oil resources from the residual and transitional oil zones of the permian basin. In: SPE annual technical conference and exhibition

Liu S, Ji C, Wang C, Chen J, Jin Y, Zou Z, Zou J (2018) Climatic role of terrestrial ecosystem under elevated CO(2): a bottom-up greenhouse gases budget. Ecol Lett 21(7):1108–1118. https://doi.org/10.1111/ele.13078

Namani M, Kleppe J (2011) Investigation of the effect of some parameters in miscible WAG process using black-oil and compositional simulators. In: SPE enhanced oil recovery conference

Peng D-Y, Robinson DB (1976) A new two-constant equation of state. Ind Eng Chem Fundam 15(1):59–64. https://doi.org/10.1021/i160057a011

Perera MSA, Gamage RP, Rathnaweera TD, Ranathunga AS, Koay A, Choi X (2016) A review of CO2-enhanced oil recovery with a simulated sensitivity analysis. Energies 9(7):481

Qin J, Han H, Liu X (2015) Application and enlightenment of carbon dioxide flooding in the United States of America. Petrol Explorat Dev 42(2):232–240. https://doi.org/10.1016/S1876-3804(15)30010-0

Ren B, Duncan I (2019) Modeling oil saturation evolution in residual oil zones: implications for CO2 EOR and sequestration. J Petrol Sci Eng 177:528–539. https://doi.org/10.1016/j.petrol.2019.02.072

Ren B, Duncan I (2019) Reservoir simulation of carbon storage associated with CO2 EOR in residual oil zones San Andres formation of West Texas, Permian Basin, USA. Energy 167:391–401. https://doi.org/10.1016/j.energy.2018.11.007

Ren B, Duncan IJ (2021) Maximizing oil production from water alternating gas (CO2) injection into residual oil zones: the impact of oil saturation and heterogeneity. Energy 222:119915. https://doi.org/10.1016/j.energy.2021.119915

Rui Z, Peng F, Ling K, Chang H, Chen G, Zhou X (2017) Investigation into the performance of oil and gas projects. J Natl Gas Sci Eng 38:12–20. https://doi.org/10.1016/j.jngse.2016.11.049

Shaw J, Bachu S (2002) Screening, evaluation, and ranking of oil reservoirs suitable for CO2-flood EOR and carbon dioxide sequestration. J Can Petrol Technol. https://doi.org/10.2118/02-09-05

Song Z, Li Z, Wei M, Lai F, Bai B (2014) Sensitivity analysis of water-alternating-CO2 flooding for enhanced oil recovery in high water cut oil reservoirs. Comput Fluids 99:93–103. https://doi.org/10.1016/j.compfluid.2014.03.022

Stone (1970) Probability model for estimating three-phase relative permeability. J Petrol Technol 22(02):214–218

Yan W, Stenby EH (2009). The influence of CO2 solubility in brine on CO2 flooding simulation. In: SPE annual technical conference and exhibition

Zhang N, Yin M, Wei M, Bai B (2019) Identification of CO2 sequestration opportunities: CO2 miscible flooding guidelines. Fuel 241:459–467. https://doi.org/10.1016/j.fuel.2018.12.072

Acknowledgements

This work was supported by the National Natural Science Foundation of China (52034010)

Funding

This work was supported by the National Natural Science Foundation of China (52034010).

Author information

Authors and Affiliations

Contributions

BL: Conceptualization, methodology, software, investigation, writing-original draft. JY: validation, writing-review & editing, supervision, project administration, funding acquisition. TS: software, resources.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, B., Yao, J. & Sun, T. Numerical analysis of water-alternating-CO2 flooding for CO2-EOR and storage projects in residual oil zones. Int J Coal Sci Technol 10, 73 (2023). https://doi.org/10.1007/s40789-023-00647-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-023-00647-9