Abstract

Coal is the major source of power in India and world over. Coal mining is an essential industry which has a major role in the economic development of the country. Most major mining activities contribute directly or indirectly to air pollution. Coal dust is a major air pollutant which affects the personal working in the mines and also people residing in villages near the mines. Air pollution due to coal particulates can affect human health and cause damages to the environment. Hence effective pollution control mechanisms are needed to keep the pollution levels within permissible levels. The easiest and most common method employed for dust suppression worldwide is sprinkling of water. In majority of mines, water sprinklers are operated manually and can lead to wastage of water due to over sprinkling. It can also prove to be ineffective in dust suppression if sprinkling is not done properly. The paper proposes a system which can be deployed to automate the dust suppressions sprinklers. The system will monitor the concentration of PM10 and PM2.5 in the air and initiate sprinkling operation when the particulate matter content exceeds preconfigured limits.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Air pollution refers to the contamination of air with toxins which are harmful to the health of human beings and the planet as a whole. According to the World Health Organization (WHO), roughly seven million deaths per year are attributed to the adverse effects of air pollution (Mackenzie and Turrentine 2021). More than ninety percent of people are currently breathing air that exceeds WHO’s safe permissible limits for pollutants. Air pollutants have a degrading effect on human health and well-being. Increase in urbanization, traffic on road, ever-increasing demand for power is contributing greatly to air pollution.

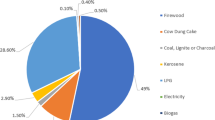

Electricity in India is generated from Thermal, Nuclear, Hydro, Wind and Solar Power Plants. However, more than 75% of electricity is realized from coal powered thermal power plants (Aggarwal et al. 2018). The overall power generation in India towards the end of 2020 was approximately 100 billion units (Central Electricity Authority 2023 and Ministry of Coal 2021).

Coal is the major source of power in India and world over. The overall production of coal in India during 2021–22 was 778.19 MT (Ministry of Coal 2022). Coal production in India is dominated by opencast mining due to ease of extraction, less production cost and less wastage. During the financial year 2016–2017, the production from opencast mines was 93.26% of the total production (Mukherjee and Pahari 2019).

Opencast coal mines contribute more to air pollution than underground mines. While underground mining activities directly affect the health of the people working underground, opencast mining activities results in widespread air-quality degradation due to dust and gaseous pollutants generated in and around the mining facilities. In addition, at the opencast mines, a massive amount of power and resources has to be utilized to remove rock or minerals from the surface in order to reach the mineral deposits. This also leads to extensive use of excavation equipment, transportation vehicles, loaders, conveyor belts etc., resulting in air pollution due to discharge of fine particulate matter (Ghose and Majee 2001; Meng et al. 2010).

As explained above, mining operation leads to air pollution either directly or indirectly. Majority of the mining such as blasting, drilling, crushing, screening, coal washing, dust from mine-waste piles and stock piles, exhaust fumes from equipment and dust from truck movement are sources of air pollution.

Over-exploitation of coal has resulted in the deterioration of the environment and appropriate measures has to be taken to minimize the effect. Therefore, it is essential to evaluate the effect of mining on air quality and implement appropriate measures to control or lessen air pollution.

2 Dust suppression system

As discussed in the previous section, it is necessary to control dust that is getting generated from mining operations since it is vital to maintaining a pollution free environment in the areas near to the mines. This necessitates the deployment of effective dust control and suppression mechanisms. Dust suppression systems play an important role in ensuring health and safety of human beings and the environment. In addition to environmental implications, coal dust has the negative effect of increasing the maintenance of trucks, loaders and material handling machinery that is in operation at the mines area (Blyth 2016).

Dust suppression is referred to as the prevention of particles on the ground or material bed from being air borne or the settling down of fugitive airborne particles back to the ground or material bed. This is accomplished by making use of water sprinklers, foggers or foam generation systems. The most common, convenient and cost-effective way of controlling fugitive dust is sprinkling of water on the coal stock, haul roads and railway sidings. This prevents dust particles getting airborne and also helps in settling of airborne dust back on the ground (Ray 2019).

The sprinklers are usually installed at loading areas, along haul roads and at unloading points in the mines area. In addition, water-spraying systems are deployed at washeries, coal handling plants, feeders, crushers and belt conveyers and coal stock areas.

3 Manual sprinkling for dust suppression

In order to minimize dust generation, sprinklers are used at various points in the coal handling and transportation areas. Water sprinklers have proven to be effective in minimizing air pollution due to dust particles. However, majority of the sprinklers are operated manually at periodic intervals, without assessing the pollution content in the air. In some cases, water is sprinkled even when there is relatively less dust in the air, thus wasting water. In some cases, the sprinklers are not operated even when the dust generation is very high, resulting in severe air pollution. In most cases, due the inherent difficulties of manual operation, such as manual operation of the sprinkler valves and manual operation of the pumps, the sprinklers are operated for a longer duration than required. This results in coal sludge being formed which eventually seeps into the groundwater. Coal contains pollutants like arsenic, mercury, cadmium and selenium (Zhang 2014). When coal sludge or slurry is formed due to excessive sprinkling, these contaminants pollute the ground water and the soil (Nriagu & Pacyna 1988).

India is the second largest producer of coal in the world. Coal India Limited, the state-owned coal mining corporate is the single largest coal producer in the world. It has 352 coal mines of which 158 are underground, 174 are opencast and 20 are mixed mines (Coal India Limited 2023). Most of the dust suppression sprinklers in these coal mine areas are manually operated and hence face the same problems as mentioned above.

This paper showcases the design and deployment of an automatic dust suppression system which activates dust suppression sprinklers based on the dust concentration level.

4 Coal dust suppression system

The shortcomings of the manual operation of sprinklers can be overcome by implementing an automatic sprinkling system. With this aim a Coal Dust Suppression System (CDSS) has been developed which monitors the air pollutants at areas near coal mines and activates sprinklers when the dust concentration exceeds preconfigured safe limits.

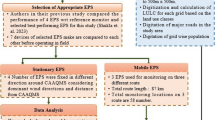

The Coal Dust Suppression System, shown in Fig. 1, consists of Coal Dust Suppression Units (CDSU), deployed at various locations at opencast coal mines, which senses the amount of coal-dust present in the air and activates the sprinklers when the dust content exceeds permissible limits. The CDSU has provision for both wired and wireless activation of sprinklers.

The CDSUs may be installed along the road between the mines and the stockyard, coal handling plant or at railway sidings where it is loaded on to coal carrying goods train. The sprinklers sprays water on the road or coal heaps, thus preventing coal-dust from becoming air-borne and also bring down coal dust particles in the air.

Based on the sensors present, two variants of CDSU’s are available—CDSU Base and CDSU Pro. CDSU Base senses the amount of PM10 and PM2.5 in the ambient air, whereas the CDSU Pro senses the concentration of PM10, PM2.5, SO2, NO2, NO and CO in ambient air. The CDSU Base is primarily used for coal dust suppression and the CDSU Pro acts as an ambient air quality monitoring instrument.

In addition to controlling the sprinklers, the CDSU sends the sensed parameters to an Online Monitoring Software (OMS) running in a central server, where the data is displayed in an HMI and logged to database. This data is then used to generate daily reports about the ambient air quality with regards to the concentration of air pollutants—PM10, PM2.5, SO2, NO2, NO and CO.

The system was implemented and tested at RCM railway siding of Ashoka Opencast Mine in the state of Jharkhand in India.

5 Coal Dust Suppression Unit Base

The Coal Dust Suppression Unit Base (CDSU Base) is an industrial grade dust monitoring and suppression unit which senses the concentration of PM10 and PM2.5 in the atmosphere and activates dust suppression sprinklers when the particulate matter content exceeds safe permissible limit.

The CDSU Base consists of Dust Sensor, Air Intake System, Monitoring and Control Unit (MCU), GPRS Module, Radio Module, Display, Power Module and Temperature Sensor and Humidity Sensor as shown in Fig. 2.

The Air Intake System consisting of air inlet hood and air pumps deliver air sample to the Dust Sensors. The Dust Sensors senses the concentration of PM10 and PM2.5 particles in the air and sends the information to the MCU. The MCU reads the sensor values, process it based on temperature and humidity and issues a command to activate dust suppression sprinklers if the dust content exceeded safe limits.

Dust Sensor in the CDSU Base measures the concentration of PM10 & PM2.5 in the air. It works on the principle of laser light scattering photometry. According to Mie scattering theory (Müller et al. 2019; Yu et al. 2017), when light falls on a dust particle whose size is comparable with its wavelength, the light gets scattered. The intensity of the scattered light is proportional to the size of the particle and the angle of scattering. The concentration of PM10 & PM2.5 is obtained by counting the number of dust particles confirming to the corresponding size and then converting it to dust concentration in µg/m3 (Geng et al. 2017; Yu et al. 2017).

CDSU Base supports both wired and wireless activation of sprinklers. Wired activation is done by providing 24V digital output supply to motorized valves connected on pipes leading to the sprinklers. Wireless activation is achieved by making use of the 2.4 GHz Radio Module, which communicates with the CDSU Wireless Slave (CWS) device. The CWS operates the motorized valves based on the commands received from the CDSU.

The MCU also maintains remote connection with the Online Monitoring Software running on a central server via GPRS communication. The MCU also displays the sensed parameters on a Display Unit with touchscreen functionality. The MCU computes the temperature and relative humidity information from an analog Temperature & Humidity Sensor installed inside the air inlet hood. The CDSU Base, shown in Fig. 3., has been designed to be dust and water proof and is suitable for outdoor use.

6 Coal Dust Suppression Unit Pro

The Coal Dust Suppression Unit Pro (CDSU Pro) is an advanced ambient air quality monitoring instrument which senses the concentration of PM10 and PM2.5 and toxic gases like SO2, NO2, NO and CO present in the ambient air. The CDSU features a dust sensor which works on laser light scattering principle and gas sensors which are based on electrochemical sensors (Krishnan et al. 2022). In addition, the device has sensors for ambient temperature and relative humidity.

The CDSU Pro uploads the sensed parameters to a central server using GPRS communication. The device features a 3.5″ display which displays the sensed parameters along with the status information of the unit. The CDSU Pro, Fig. 4, is dust and water proof and is suitable for outdoor use.

7 CDSU Wireless Slave (CWS)

The CWS, shown in Fig. 5, is a wireless node used to facilitate the wireless activation of sprinklers. The CWS forms part of the wireless mesh network (Howitt et al. 2003; Dulman et al. 2005) consisting of CDSU Master and CDSU Base units. The CDSU Master is a CDSU Base unit which also acts as a coordinator for the wireless mesh network consisting of CDSU Base and CWS units. The CWS accepts wireless commands from CDSU and sends out digital output signals to activate motorized valves connected on sprinkler pipes. The digital output signals provide for opening and closing of the valves which results in starting and stopping of sprinkling action. Each CWS is configured for operating up to two Motorized Vales.

The CWS has been built based on the industrial grade Wireless Sensor Node—iWiSe (Daniel et al. 2010) which features an IEEE802.15.4 2.4 GHz radio which works on SmartConnect mesh networking protocol (Bhattacharya et al. 2013). The CWS consists of a radio module, a sensor module and a power module. The radio module manages the wireless communication, the sensor module manages the hardware interface for operating the sprinkler valves and the power module manages the power for the CWS and the motorized valves connected to the sprinklers.

8 Online Monitoring Software (OMS)

The Online Monitoring Software (OMS) is a standalone application designed to acquire, process and display ambient air quality data received from CDSU Base and CDSU Pro. The software manages connectivity with CDSU’s deployed in the field, process and store the received data, display on an HMI and generate reports (Shankar et al. 2022).

The OMS consists of the following seven submodules, the GUI for which is arranged in a tab navigator mode in the software—CDSU Configurator, OMS Configurator, HMI Module, Report Module, User Management System, GPRS backend service, Data logger backend service and MySQL Database. The basic architecture of OMS is shown in Fig. 6.

9 Field experiment at RCM railway siding

The CDSS system was implemented for automatic dust suppression at RCM Railway Siding of Ashoka Opencast Mine, Piparwar Area, Chatra District, Jharkhand. The system consists of 9 CDSU Base units and 4 CWS units deployed at various locations along the railway siding, as shown in Fig. 7.

The existing manual sprinkling system consisted of seven sets of sprinklers with each set having 5 sprinklers each. The manual valves which were used to operate the sprinklers were replaced with motorized valves powered from a solar panel. The motorized valves are controlled by CDSU Wireless Slave (CWS) which receives wireless commands from CDSU Base.

The CDSU Bases, shown inn Fig. 8, senses the concentration of PM10 and PM2.5 and when the dust content exceeds safe permissible limits, it will intimate a master CDSU Base which will initiate activation of sprinkler valve and sprinkler pump. This has been accomplished by setting up a wireless sensor network (Gungor and Hancke 2009; Krishnan et al. 2020) of CDSU units and CWS devices, as shown in Fig. 7. The radio unit in the CDSU Master is based on the industrial grade wireless base station (Daniel et al. 2011) designed as part of an earlier experiment. The CWS units receive sprinkler activation commands from the master CDSU and operates motorized valves, V1 to V7 shown in in Fig. 7, connected to sprinklers.

The CDSU Master analyses the dust content in the railway siding and identifies areas where the dust content has exceeded safe limits. The master CDSU then sends wireless commands to the corresponding CWS in that area for opening of the sprinkler valve. After ensuring that the corresponding motorized valve has been fully opened and adequate water is present in the water tanks, the CDSU Master will start the sprinkler pump. The CDSU Master continuously monitors the level in the water tank using a level sensor which is used to compute the amount water consumed. Three number of CDSU Wireless Repeaters (CWR) has been deployed on light towers in order to provide better wireless connectivity to the CWS.

A CDSU Pro, shown in Fig. 9, has been installed at the farthest end of the railway siding in order to sense the air quality parameters in the area. The CDSU Base and Pro also sends the ambient air quality parameters, via GPRS, to the Online Monitoring Software running in the central server. The dust levels at various places in the railway siding is displayed on the HMI tab in the OMS, as shown in Fig. 10 and automatic pdf reports are generated on daily basis (Shankar et al. 2022). GPRS mode of communication was used since the server is located at the General Managers office which is located several kilometers away from the railway siding area. The data is also displayed in a local operator console for viewing by the officials at the RCM Railway Siding.

10 Experimental results

Before the implementation of the CDSS system, the sprinkling was done manually, once every hour, without considering the quantity of coal particulate matter present in the air. This led to either excessive sprinkling, which resulted in wastage of water, or inadequate sprinkling, which resulted in ineffective dust suppression. Furthermore, during manual operation, the sprinklers were operated for longer duration at a time which resulted in a slurry being formed at these areas. The average duration of sprinkler operation for seven sets of sprinklers were 35 min with approximately 5 min each for one sprinkler set.

With the implementation of CDSS, sprinkling operation is performed more efficiently, with smaller duration. The average interval between two sprinkling operations reduced from 60 to 30 min thus increasing the number of sprinkling cycles from 24 to 48 numbers per day. The average sprinkling duration for one set of sprinklers reduced from 5 min to approximately 2 min. By computing the water consumption per day, it was seen that the consumption reduced from an average of 252000 L to 201600 L per day. The water consumption per sprinkle cycle was computed based on the specification of the sprinkler valves and the number of sprinklers in operation at a time. The summary of the experimental field data is given in Table 1

The field data shows that with the implementation of the automatic Coal Dust Suppression System the frequency of sprinkling has increased which resulted in better dust suppression. Additionally, the sprinkling duration was reduced which resulted in considerable savings in water and power consumption.

It is to be noted that the savings in water consumption and subsequent power consumption will depend on the concentration of air borne dust and also on the weather conditions on each day. The dust generation is more on a sunny day compared to a cloudy or overcast day. During rainy days, dust generation is very minimal since the coal sample and the roads are wet.

11 Conclusion

The paper showcases the design and implementation of Coal Dust Suppression System which automates the sprinkling operation based on concentration of dust in the air. The system was successfully installed and commissioned at RCM Railway Siding of Ashoka OCP, Central Coal Fields Ltd. in the Piparwar Area of Jharkhand, India. The field trial study showed that the CDSS system is much more effective in dust suppression than traditional manual sprinkling operation. The experimental results from the field trial shows that with the implementation of the CDSS system the frequency of sprinkling had increased which resulted in improved dust suppression. It can also be seen that even though the number of sprinkling operations in a day had increased, the overall consumption of water and power had improved since the duration of operation of the sprinklers was reduced.

References

Bhattacharya A et al. (2013) SmartConnect: a system for the design and deployment of wireless sensor networks. In: 2013 fifth international conference on communication systems and networks (COMSNETS), Bangalore, pp 1–10. https://doi.org/10.1109/COMSNETS.2013.6465582

Blyth D (2016) A Practical Guide to Dust Suppression. Sealpump Engineering Limited, 2016. [Online]: http://www.sealpump.com/wp- content/uploads/2016/03 /Kolour-GoWeb-Dust-Suppression-Booklet-whole-1.pdf. Accessed 28 Sep 2020

Central Electricity Authority, Ministry of Power, Govt. of India (2023) Annual Generation Report. https://cea.nic.in/annual-generation-report/?lang=en

Coal India Limited (2023) About the Company. https://archive.coalindia.in/en-us/company/aboutus.aspx

Daniel JJ, Panicker ST, Thomas L, Mathew JT (2010) Design of industrial grade wireless sensor node. In: International conference on “System Modeling, Optimization and Process Automation-SYMOPA 2010”

Daniel JJ, Panicker ST, Thomas L, Mathew JT, Mathew A (2011) Industrial grade wireless base station for Wireless sensor networks. In: 2011 3rd international conference on electronics computer technology, Kanyakumari, India, pp 245–249, doi: https://doi.org/10.1109/ICECTECH.2011.5941694

Dennis M, Glöckler F, Kienle A (2019) Application of Mie theory for enhanced size determination of microparticles using optical particle counters. Appl Opt 58:4575–4584

Dulman S, Chatterjea S, Havinga P (2005) Introduction to wireless sensor networks. Embedded Systems: Handbook.

Ghose MK, Majee SR (2001) Air pollution caused by opencast mining and its abatement measures in India. J Environ Manag 63(2):193–202

Gungor VC, Hancke GP (2009) Industrial wireless sensor networks: challenges, design principles, and technical approaches. IEEE Trans Industr Electron 56(10):4258–4265. https://doi.org/10.1109/TIE.2009.2015754

Howitt I, Gutierrez JA (2003) IEEE 802.15.4 low rate - wireless personal area network coexistence issues. In: 2003 IEEE wireless communications and networking, WCNC 2003, New Orleans, LA, USA, pp 1481–1486 vol 3, doi: https://doi.org/10.1109/WCNC.2003.1200605

Krishnan AK, Panicker ST, Sandeep S, Jithin S, Daniel JJ, Sajjad T (2022) Electrochemical based gas sensing for ambient air quality monitoring in opencast coal mines. In: 2022 first international conference on electrical, electronics, information and communication technologies (ICEEICT), pp 1–8, doi: https://doi.org/10.1109/ICEEICT53079.2022.9768541

Krishnan A et al. (2020) A need-to-basis dust suppression system using wireless sensor network. In: 2020 IEEE recent advances in intelligent computational systems (RAICS), Thiruvananthapuram, India, pp 207–212, doi: https://doi.org/10.1109/RAICS51191.2020.9332515

Kuiwei G, Zhenjing P, Guodong Z (2017) Design of particle detection system based on optical transmission and scattering method. In: IEEE international conference on information and automation, China

Mackenzie J, Turrentine J (2021) Air pollution: everything you need to know, NRDC Guide. https://www.nrdc.org/stories/air-pollution-everything-you-need-know. Accessed 22 June 2021

Meng X, Jiang M, Qi Z (2010) The health risk assessment of coal city-a case study of Qitaihe City. In: 2010 4th international conference on bioinformatics and biomedical engineering, Chengdu, China, pp 1–4, doi: https://doi.org/10.1109/ICBBE.2010.5515442

Ministry of Coal, Govt. of India (2021), Generation of Thermal Power from Raw Coal. https://coal.nic.in/en/major-statistics/generation-of-thermal-power-from-raw-coal

Ministry of Coal, Govt. of India (2022), Production and Supplies. https://coal.nic.in/en/major-statistics/production-and-supplies

Mukherjee S, Pahari DP (2019) Underground and opencast coal mining methods in India: a comparative assessment. Space Culture India 7(1):39–55

Nriagu J, Pacyna J (1988) Quantitative assessment of worldwide contamination of air, water and soils by trace metals. Nature 333:134–139. https://doi.org/10.1038/333134a0

Ray R (2019) Coal dust control, Power Engineering. https://www.power-eng.com/2013/07/15/coal-dust-control/. Accessed 25 Sep 2020

Shankar SS, Senju TP, Jerry DJ, Tarique S (2022) Online monitoring software for air pollutants in areas near coal mines. Int J Eng Res Technol 11(12):556

Stegmayer GS, Chiotti OA, Gugliotta LM, Vega JR (2006) Particle size distribution from combined light scattering measurements. In: IEEE international conference on computational intelligence for measurement systems and applications

Yu X, Shi Y, Wang T, Sun X (2017) Dust-concentration measurement based on Mie scattering of a laser beam. PLoS One 12(8):e0181575. https://doi.org/10.1371/journal.pone.0181575

Zhang X (2014) Management of coal combustion wastes, IEA Clean Coal Centre

Acknowledgements

The Coal Dust Suppression System discussed in the paper was designed, developed and deployed by Centre for Development of Advanced Computing (C-DAC), Thiruvananthapuram and Central Mine Planning and Design Institute (CMPDI) as part of a project funded by Ministry of Coal, Government of India. The authors would like to thank the officials at Ashoka OCP and RCM Railway Siding for their support in the field installation and commissioning of the system.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The work was funded by Ministry of Coal, Government of India under S&T Grants of Coal India Limited. The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Panicker, S., Shankar, S.S., Jithin, S. et al. Online coal dust suppression system for opencast coal mines. Int J Coal Sci Technol 10, 60 (2023). https://doi.org/10.1007/s40789-023-00624-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-023-00624-2