Abstract

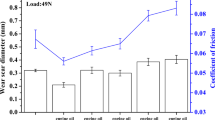

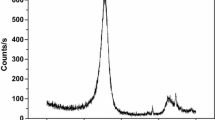

With the development of nanotechnology, the use of nanoparticles added lubrication systems has increased, and the application areas of modern tribology have expanded. In this study, the effects of nanoparticles on gearbox performance were investigated. For this purpose, sunflower oil was chosen as the base oil, and molybdenum disulfide (\({\text{MoS}}_{{2}}\)), titanium dioxide (\({\text{TiO}}_{{2}}\)) and calcium fluoride (\({\text{CaF}}_{{2}}\)) nanoparticles were added to the base oil in certain proportions. The effects of nano additives on the efficiency and power loss of the gearbox under different operating speeds and loads have been comparatively investigated. The experiments were carried out using a gearbox test system and the measurements were obtained.

Similar content being viewed by others

Data Availability

All data generated or analysed during this study are included in this published article.

References

Gulzar M, Masjuki HH, Kalam MA, Varman M, Zulkifli NWM, Mufti RA, Zahid R (2016) Tribological performance of nanoparticles as lubricating oil additives. J Nano Res 18:1–25. https://doi.org/10.1007/s11051-016-3537-4

Deepika (2020) Nanotechnology implications for high performance lubricants. SN Appl Sci 2:1128. https://doi.org/10.1007/s42452-020-2916-8

Xiao H, Liu S (2017) 2D nanomaterials as lubricant additive: a review. Mater Des 135:319–332. https://doi.org/10.1016/j.matdes.2017.09.029

Uzoma PC, Hu H, Khadem M, Penkov OV (2020) Tribology of 2D nanomaterials: a review. Coatings 10:897. https://doi.org/10.3390/coatings10090897

Martini A, Ramasamy US, Len M (2018) Review of viscosity modifier lubricant additives. Tribol Lett 66:1–14. https://doi.org/10.1007/s11249-018-1007-0

Nath AR, Yehye WA, Zulkifli NWM, Johan MR (2018) Ester of thiolated butylated hydroxytoluene: potential antioxidant for synthetic lubricant oil. Therm Acta 670:7–12. https://doi.org/10.1016/j.tca.2018.09.021

Gong H, Yu C, Zhang L, Xie G, Guo D, Luo J (2020) Intelligent lubricating materials: a review. Compos B: Eng 202:108450. https://doi.org/10.1016/j.compositesb.2020.108450

Tang Z (2019) A review of corrosion inhibitors for rust preventative fluids. Curr Opin Solid State Mater Sci 23:100759. https://doi.org/10.1016/j.cossms.2019.06.003

Srivyas PD, Charoo MS (2019) Effect of lubricants additive: use and benefit. Mater Today: Proc 18:4773–4781. https://doi.org/10.1016/j.matpr.2019.07.465

Ilie F, Covaliu C (2016) Tribological properties of the lubricant containing titanium dioxide nanoparticles as an additive. Lubricants 4:12. https://doi.org/10.3390/lubricants4020012

Suthar K, Singh Y, Surana AR, Rajubhai VH, Sharma A (2020) Experimental evaluation of the friction and wear of jojoba oil with aluminium oxide (Al2O3) nanoparticles as an additive. Mater Today: Proc 25:699–703. https://doi.org/10.1016/j.matpr.2019.08.150

Rastogi RB, Kumar D (2016) Synthesis, characterization, and tribological evaluation of SDS-stabilized magnesium-doped zinc oxide nanoparticles as efficient antiwear lubricant additives. ACS Sustain Chem Eng 4:3420–3428. https://doi.org/10.1021/acssuschemeng.6b00472

Borda FLG, de Oliveira SJR, Lazaro LMSM, Leiróz AJK (2018) Experimental investigation of the tribological behavior of lubricants with additive containing copper nanoparticles. Tribol Int 117:52–58. https://doi.org/10.1016/j.triboint.2017.08.012

Jatti VS, Singh TP (2015) Copper oxide nano-particles as friction-reduction and anti-wear additives in lubricating oil. J Mech Sci Tech 29:793–798. https://doi.org/10.1007/s12206-015-0141-y

Salah N, Abdel-wahab MS, Habib SS, Khan ZH (2017) Lubricant additives based on carbon nanotubes produced from carbon-rich fly ash. Tribol Trans 60:166–175. https://doi.org/10.1080/10402004.2016.1155784

Mushtaq Z, Hanief M (2021) Evaluation of tribological performance of jatropha oil modified with molybdenum disulphide micro-particles for steel-steel contacts. J Tribol 143:021401. https://doi.org/10.1115/1.4047752

Chen W, Thummavichai K, Chen X, Liu G, Lv X, Zhang L, Zhu Y (2021) Design and evaluation the anti-wear property of inorganic fullerene tungsten disulfide as additive in PAO6 oil. Curr Comput-Aided Drug Des 11:570. https://doi.org/10.3390/cryst11050570

Raina A, Anand A (2017) Tribological investigation of diamond nanoparticles for steel/steel contacts in boundary lubrication regime. Appl Nano 7:371–388. https://doi.org/10.1007/s13204-017-0590-y

Baş H, Karabacak YE (2014) Investigation of the effects of boron additives on the performance of engine oil. Tribol Trans 57:740–748. https://doi.org/10.1080/10402004.2014.909549

Çelik ON, Ay N, Göncü Y (2013) Effect of nano hexagonal boron nitride lubricant additives on the friction and wear properties of AISI 4140 steel. Part Sci Technol 31:501–506. https://doi.org/10.1080/02726351.2013.779336

Thampi AD, Prasanth MA, Anandu AP, Sneha E, Sasidharan B, Rani S (2021) The effect of nanoparticle additives on the tribological properties of various lubricating oils—review. Mater Today: Proc 47:4919–4924. https://doi.org/10.1016/j.matpr.2021.03.664

Singh A, Verma N, Mamatha TG, Kumar A, Singh S, Kumar K (2021) Properties, functions and applications of commonly used lubricant additives: a review. Mat Today: Proc 44:5018–5022. https://doi.org/10.1016/j.matpr.2021.01.029

Zhao J, Huang Y, He Y, Shi Y (2021) Nanolubricant additives: a review. Friction 9:891–917. https://doi.org/10.1007/s40544-020-0450-8

Jason YJJ, How HG, Teoh YH, Chuah HG (2020) A study on the tribological performance of nanolubricants. Process 8:1372. https://doi.org/10.3390/pr8111372

Shafi WK, Charoo MS (2021) An overall review on the tribological, thermal and rheological properties of nanolubricants. Tribol Mater Surf Interfaces 15:20–54. https://doi.org/10.1080/17515831.2020.1785233

Suryawanshi SR, Pattiwar JT (2019) Tribological performance of commercial Mobil grade lubricants operating with titanium dioxide nanoparticle additives. Ind Lubr Tribol 71:188–198. https://doi.org/10.1108/ILT-04-2018-0147

Patel J, Kiani A (2019) Tribological capabilities of graphene and titanium dioxide nano additives in solid and liquid base lubricants. Appl Sci 9:1629. https://doi.org/10.3390/app9081629

Ingole S, Charanpahari A, Kakade A, Umare SS, Bhatt DV, Menghani J (2013) Tribological behavior of nano TiO2 as an additive in base oil. Wear 301:776–785. https://doi.org/10.1016/j.wear.2013.01.037

Shafi WK, Charoo MS (2019) Experimental study on rheological properties of vegetable oils mixed with titanium dioxide nanoparticles. J Braz Soc Mech Sci Eng 41:1–13. https://doi.org/10.1007/s40430-019-1905-6

Beel A, Gottschalk M, Huetten A, Toensing K, Anselmetti D (2017) Tribological performance of TiO2-nanostructured particles as oil-lubricant additives for different iron-carbon alloys. Mater Today: Proc 4:75–80. https://doi.org/10.1016/j.matpr.2017.09.170

Singh A, Verma N, Chaurasia A, Kumar A (2020) Effect of TiO2 additive volume fraction in lubricant oil on the performance of hydrodynamic journal bearing. Mater Sci Eng 802:012005. https://doi.org/10.1088/1757-899X/802/1/012005

Suryawanshi SR, Pattiwar JT (2018) Effect of TiO2 nanoparticles blended with lubricating oil on the tribological performance of the journal bearing. Tribol Ind 40:370–391. https://doi.org/10.24874/ti.2018.40.03.04

Deepak SN, Ram CN (2021) Physio-chemical study of traditional lubricant SAE 20 W40 and virgin coconut oil using TiO2 nano-additives. Mater Today: Proc 42:1024–1029. https://doi.org/10.1016/j.matpr.2020.12.046

Kumari S, Mungse HP, Gusain R, Kumar N, Sugimura H, Khatri OP (2017) Octadecanethiol-grafted molybdenum disulfide nanosheets as oil-dispersible additive for reduction of friction and wear. Flat Chem 3:16–25. https://doi.org/10.1016/j.flatc.2017.06.004

Farsadi M, Bagheri S, Ismail NA (2017) Nanocomposite of functionalized graphene and molybdenum disulfide as friction modifier additive for lubricant. J Mol Liq 244:304–308. https://doi.org/10.1016/j.molliq.2017.09.008

Xu ZY, Hu KH, Han CL, Hu XG, Xu YF (2013) Morphological influence of molybdenum disulfide on the tribological properties of rapeseed oil. Tribol Lett 49:513–524. https://doi.org/10.1007/s11249-012-0092-8

Srinivas V, Thakur RN, Jain AK (2017) Antiwear, antifriction, and extreme pressure properties of motor bike engine oil dispersed with molybdenum disulfide nanoparticles. Tribol Trans 60:12–19. https://doi.org/10.1080/10402004.2016.1142034

Bojarska Z, Kopytowski J, Mazurkiewicz-Pawlicka M, Bazarnik P, Gierlotka S, Rożeń A, Makowski Ł (2021) Molybdenum disulfide-based hybrid materials as new types of oil additives with enhanced tribological and rheological properties. Tribol Int 160:106999. https://doi.org/10.1016/j.triboint.2021.106999

Guimarey MJ, Abdelkader AM, Comuñas MJ, Alvarez-Lorenzo C, Thomas B, Fernández J, Hadfield M (2020) Comparison between thermophysical and tribological properties of two engine lubricant additives: electrochemically exfoliated graphene and molybdenum disulfide nanoplatelets. Nanotech 32:025701. https://doi.org/10.1088/1361-6528/abb7b1

Srinivas V, Thakur RN, Jain AK, Saratchandra Babu M (2017) Tribological studies of transmission oil dispersed with molybdenum disulfide and tungsten disulfide nanoparticles. J Tribol 139:041301. https://doi.org/10.1115/1.4034766

Ramesh P, Krishnan GS, Kumar JP, Bakkiyaraj M, Pradhan R (2021) A critical investigation on viscosity and tribological properties of molybdenum disulfide nano particles on diesel oil. Mater Today: Proc 43:1830–1833. https://doi.org/10.1016/j.matpr.2020.10.718

Alper Yılmaz M, Özkan D (2021) The anti-wear enhancement of boric acid+ molybdenum disulfide derived tribofilm. Proc Inst Mech Eng J: J Eng Tribol 235:1060–1072. https://doi.org/10.1177/1350650120960273

Mohan S, Anand A, Haq MIU, Raina A, Kumar R (2020) Calcium fluoride a potential solid lubricant for green tribology and sustainability. In: Kumar H, Jain PK (eds) Recent advances in mechanical engineering. Springer, Singapore, pp 587–595. https://doi.org/10.1007/978-981-15-1071-7_48

Sharma SM, Anand A (2017) Friction and wear behaviour of Fe-Cu-C based self lubricating material with CaF2 as solid lubricant. Ind Lubr Tribol 69:715–722. https://doi.org/10.1108/ILT-04-2016-0085

Zhang J, Wang F, Li D, Yan J, Wei J, Wang X, Wang Z (2021) Defect induced luminescence from surface modified calcium fluoride nanoparticles for in-situ temperature monitoring of lubricating oil. Appl Nanosci. https://doi.org/10.1007/s13204-020-01654-x

Liu L, Zhou M, Jin L, Li L, Mo Y, Su G, Li X, Zhu H, Tian Y (2019) Recent advances in friction and lubrication of graphene and other 2D materials: mechanisms and applications. Friction 7:199–216. https://doi.org/10.1007/s40544-019-0268-4

Srivyas PD, Charoo MS (2020) Tribological behavior of aluminum silicon eutectic alloy based composites under dry and wet sliding for variable load and sliding distance. SN Appl Sci 2:1654. https://doi.org/10.1007/s42452-020-03433-3

Cortes V, Sanchez K, Gonzalez R, Alcoutlabi M, Ortega JA (2020) The performance of SiO2 and TiO2 nanoparticles as lubricant additives in sunflower oil. Lubricants 8:10. https://doi.org/10.3390/lubricants8010010

Zhao C, Jiao Y, Chen YK, Ren G (2014) The tribological properties of zinc borate ultrafine powder as a lubricant additive in sunflower oil. Tribol Trans 57:425–434. https://doi.org/10.1080/10402004.2013.878776

Alves SM, Barros BS, Trajano MF, Ribeiro KSB, Moura EJTI (2013) Tribological behavior of vegetable oil-based lubricants with nanoparticles of oxides in boundary lubrication conditions. Tribol Int 65:28–36. https://doi.org/10.1016/j.triboint.2013.03.027

Pirro DM, Daschner E, Wessol AA (2010) Lubrication fundamentals. CRC Press, Boca Raton. https://doi.org/10.1201/9781420029239

Dresel W, Mang T (2017) Lubricants and lubrication. Wiley, NJ. https://doi.org/10.1002/9783527645565

Karabacak YE, Gürsel Özmen N, Gümüşel L (2020) Worm gear condition monitoring and fault detection from thermal images via deep learning method. Maint Reliab 22:544–556. https://doi.org/10.17531/ein.2020.3.18

Karabacak YE, Özmen NG, Gümüşel L (2022) Intelligent worm gearbox fault diagnosis under various working conditions using vibration, sound and thermal features. Appl Acoust 186:108463. https://doi.org/10.1016/j.apacoust.2021.108463

Karabacak YE, Özmen NG (2021) Common spatial pattern-based feature extraction and worm gear fault detection through vibration and acoustic measurements. Measurement 187:110366. https://doi.org/10.1016/j.measurement.2021.110366

Rudnick LR (2020) Synthetics, mineral oils, and bio-based lubricants: chemistry and technology. CRC Press, New York. https://doi.org/10.1201/9781315158150

Liu H, Liu H, Zhu C, Parker RG (2020) Effects of lubrication on gear performance: a review. Mech Mach Theory 145:103701. https://doi.org/10.1016/j.mechmachtheory.2019.103701

Fox NJ, Stachowiak GW (2007) Vegetable oil-based lubricants—a review of oxidation. Tribol Int 40:1035–1046. https://doi.org/10.1016/j.triboint.2006.10.001

Danish M, Gupta MK, Rubaiee S, Ahmed A, Sarikaya M (2021) Influence of graphene reinforced sunflower oil on thermo-physical, tribological and machining characteristics of inconel 718. J Mater Res Technol 15:135–150. https://doi.org/10.1016/j.jmrt.2021.07.161

Esteban B, Riba JR, Baquero G, Rius A, Puig R (2012) Temperature dependence of density and viscosity of vegetable oils. Biomass Bioenergy 42:164–171. https://doi.org/10.1016/j.biombioe.2012.03.007

Chattopadhyay R (2001) Surface wear: analysis, treatment, and prevention. ASM international, OH. https://www.asminternational.org/documents/10192/1849770/ACFAA55.pdf. Accessed 19 Mar 2022

Chen Y, Renner P, Liang H (2019) Dispersion of nanoparticles in lubricating oil: a critical review. Lubricants 7:7. https://doi.org/10.3390/lubricants7010007

Hou X, Jiang H, Ali MKA, Liu H, Su D, Tian Z (2020) Dispersion behavior assessment of the molybdenum disulfide nanomaterials dispersed into poly alpha olefin. J Mol Liq 311:113303. https://doi.org/10.1016/j.molliq.2020.113303

Laad M, Jatti VKS (2018) Titanium oxide nanoparticles as additives in engine oil. J King Saud Uni Eng Sci 30:116–122. https://doi.org/10.1016/j.jksues.2016.01.008

Omer AM (2008) Energy, environment and sustainable development. Renew Sustain Energy Rev 12:2265–2300. https://doi.org/10.1016/j.rser.2007.05.001

Anand A, Haq MIU, Vohra K, Raina A, Wani MF (2017) Role of green tribology in sustainability of mechanical systems: a state of the art survey. Mater Today: Proc 4:3659–3665. https://doi.org/10.1016/j.matpr.2017.02.259

Kanoğlu M, Çengel YA, Dinçer İ (2012) Efficiency evaluation of energy systems. Springer Science & Business Media, London. https://doi.org/10.1007/978-1-4614-2242-6

Fernandes CM, Marques PM, Martins RC, Seabra JH (2015) Gearbox power loss. Part I: losses in rolling bearings. Tribol Int 88:298–308. https://doi.org/10.1016/j.triboint.2014.11.017

Fernandes CM, Marques PM, Martins RC, Seabra JH (2015) Gearbox power loss. Part II: friction losses in gears. Tribol Int 88:309–316. https://doi.org/10.1016/j.triboint.2014.12.004

Fernandes CM, Marques PM, Martins RC, Seabra JH (2015) Gearbox power loss. Part III: application to a parallel axis and a planetary gearbox. Tribol Int 88:317–326. https://doi.org/10.1016/j.triboint.2015.03.029

Li Y, Liu M, Lau J, Zhang B (2015) A novel method to determine the motor efficiency under variable speed operations and partial load conditions. Appl Energy 144:234–240. https://doi.org/10.1016/j.apenergy.2015.01.064

Michaelis K, Höhn BR, Hinterstoißer M (2011) Influence factors on gearbox power loss. Ind Lubr Tribol 63:46–55. https://doi.org/10.1108/00368791111101830

Marques PM, Fernandes CM, Martins RC, Seabra JH (2014) Efficiency of a gearbox lubricated with wind turbine gear oils. Tribol Int 71:7–16. https://doi.org/10.1016/j.triboint.2013.10.017

Zhang Y, Li P, Ji L, Liu X, Wan H, Chen L, Li H, Jin Z (2021) Tribological properties of MoS2 coating for ultra-long wear-life and low coefficient of friction combined with additive g-C3N4 in air. Friction 9:789–801. https://doi.org/10.1007/s40544-020-0374-3

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

HB and YEK conceived and designed the study. YEK conducted the literature search. HB and YEK were involved in the analysis and interpretation of data. HB and YEK drafted the manuscript. The study was supervised by HB and YEK. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Baş, H., Karabacak, Y.E. Investigation of Tribological Properties of TiO2, MoS2 and CaF2 Particles as Vegetable Oil Additives and Their Effects on Gearbox Performance. J Bio Tribo Corros 8, 66 (2022). https://doi.org/10.1007/s40735-022-00664-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-022-00664-2