Abstract

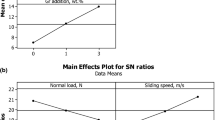

This paper investigates the mechanical and tribological characteristics of aluminum alloy 7075 (AA7075) composites reinforced with (2, 4 & 6) wt% of silicon carbide fabricated using powder metallurgy technique. The microstructural examination confirms the even distribution of SiC particles in the AA7075 matrix. An increase in hardness and density is observed with an increase in reinforcement Wt%. This is mainly due to the formation of interfacial bonds. Tribological examinations are carried on pin-on-disk equipment under dry conditions at three different loads (10, 20, and 30 N), three sliding distances (500, 1000, and 1500 m) at a constant sliding speed of 1 m/s. Volume loss is considered as output response in this research. Experiments have been conducted using L27 complete factorial design. The effect of sliding factors on volume loss is studied using analysis of variance and artificial neural networks. Analysis of variance (ANOVA) identifies load as a primary contributing parameter for volume loss followed by sliding distance and wt% of SiC. Load at level-1(10 N), the sliding distance at level-1(500 m), and wt% of SiC at level-3(6wt%) are identified as optimal sliding parameters for minimum volume loss. The application of artificial neural networks resulted in MSE, RMSE, and MAE values of 0.11380, 0.3373, and 0.1768, respectively are extremely low, which implies that the predicted results from the model are in good agreement.

Similar content being viewed by others

References

Ravindran P, Manisekar K, Narayanasamy R, Narayanasamy P (2013) Tribological behaviour of powder metallurgy-processed aluminium hybrid composites with the addition of graphite solid lubricant. Ceram Int 39(2):1169–1182

Dey D, Biswas A (2020) Comparative study of physical, mechanical and tribological properties of Al2024 alloy and SiC-TiB2 composites. SILICON 13:1895–1906

Surya MS, Prasanthi G (2021) Effect of SiC weight percentage on tribological characteristics of Al7075/SiC composites. SILICON. https://doi.org/10.1007/s12633-020-00885-5

Dey D, Bhowmik A, Biswas A (2020) Effect of SiC content on mechanical and tribological properties of Al2024-SiC composites. SILICON. https://doi.org/10.1007/s12633-020-00560-9

Surya MS, Prasanthi G (2021) Effect of silicon carbide weight percentage and number of layers on microstructural and mechanical properties of Al7075/SiC functionally graded material. SILICON. https://doi.org/10.1007/s12633-020-00865-9

Srinivas PNS, Balakrishna B (2020) Microstructural, mechanical and tribological characterization on the Al based functionally graded material fabricated powder metallurgy. Mater Res Express 7(2):26513

Stojanović B, Vencl A, Bobić I, Miladinović S, Skerlić J (2018) Experimental optimization of the tribological behaviour of Al/SiC/Gr hybrid composites based on Taguchi’s method and artificial neural network. J Braz Soc Mech Sci Eng 40(6):1–14

Reddy PV, Prasad PR, Krishnudu DM, Goud EV (2019) An investigation on mechanical and wear characteristics of Al 6063/TiC metal matrix composites using RSM. J Bio Tribo Corros 5(4):1–10

Kumar PS, Panwar RS, Pandey OP (2012) Tribological characteristics of Aluminium tri-reinforced particles (Al-TRP) composites developed by liquid metallurgy route. Adv Mater Res 585:574–578

Naik MN, Reddy KD, Ramaiah PV, Narayana BV, Reddy GB (2017) Exploration of mechanical behaviour and wear behaviour of Al4C3 reinforced aluminium metal matrix composites. Mater Today 4(2):2989–2998

Fadhil MC, Ravikiran BS (2016) The dry-sliding wear behavior of aluminium alloy/SiC metal matrix composites. Int J Adv Sci Res Eng 2(08):1–6

Surya MS, Gugulothu SK (2021) Fabrication, mechanical and wear characterization of silicon carbide reinforced aluminium 7075 metal matrix composite. SILICON. https://doi.org/10.1007/s12633-021-00992-x

Mishra AK, Sheokand R, Srivastava RK (2012) Tribological behaviour of Al-6061/SiC metal matrix composite by Taguchi’s techniques. Int J Sci Res Publ 2(10):1–8

Dharanikota V (2014) Optimization of tribological properties of Al-6082/SiC metal matrix composite by Grey-Taguchi’s method. Int J Sci Eng Res 5(12):629–636

Surya MS (2021) Effect of SiC weight percentage and sintering duration on microstructural and mechanical behaviour of Al6061/SiC composites produced by powder metallurgy technique. SILICON. https://doi.org/10.1007/s12633-021-01053-z

Kumar N, Gautam G, Gautam RK, Mohan A, Mohan S (2016) Synthesis and characterization of TiB 2 reinforced aluminium matrix composites: a review. J Inst Eng Ser D 97(2):233–253

Surya MS, Prasanthi G, Gugulothu SK (2021) Investigation of mechanical and wear behaviour of Al7075/SiC composites using response surface methodology. SILICON 13(7):2369–2379

Surya MS, Prasanthi G (2018) Tribological behaviour of aluminum silicon carbide functionally graded material. Tribol Ind 40:2

Meti VKV, Shirur S, Nampoothiri J, Ravi KR, Siddhalingeshwar IG (2018) Synthesis, characterization and mechanical properties of AA7075 based MMCs reinforced with TiB 2 particles processed through ultrasound assisted in-situ casting technique. Trans Indian Inst Met 71(4):841–848

Zhang X, Zhang Z, Liu Y, Wang A, Tian S, Wang W, Wang J (2019) High-performance B4C–TiB2–SiC composites with tuneable properties fabricated by reactive hot pressing. J Eur Ceram Soc 39(10):2995–3002

Kurapati VB, Kommineni R, Sundarrajan S (2018) Statistical analysis and mathematical modeling of dry sliding wear parameters of 2024 aluminium hybrid composites reinforced with fly ash and SiC particles. Trans Indian Inst Met 71(7):1809–1825

Cerit AA, Karamis MB, Nair FEHMİ, Yildizli K (2008) Effect of reinforcement particle size and volume fraction on wear behaviour of metal matrix composites. J Balkan Tribol Assoc 12(4):482–489

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Surya, M.S., Prasanthi, G., Kumar, A.K. et al. Optimization of Tribological Properties of Powder Metallurgy-Processed Aluminum7075/SiC Composites Using ANOVA and Artificial Neural Networks. J Bio Tribo Corros 7, 161 (2021). https://doi.org/10.1007/s40735-021-00600-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-021-00600-w