Abstract

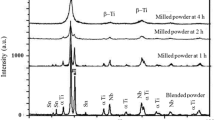

β-Titanium alloy forms one of the most versatile materials in processing, microstructure, and mechanical properties. These alloys are widely used in biomedical applications, mainly replacing stiff fabrics due to their properties, such as lower modulus of elasticity, high biocompatibility, and better corrosion resistance than other alloys. This paper focuses on recent developments of low modulus β-type Ti-based alloys, where indium additions were made by four different (0.5, 1, 1.5, 2) wt% for biomedical applications. Alloys were produced using a powder metallurgy method in a steel mold, then sintered at 950 °C for 6 h. The effect of indium alloys additives was investigated using X-ray diffraction, scanning electron microscope, and mechanical properties of Brinell hardness, compression, elastic modulus, and wear, and corrosion behavior in hanks and saliva solutions. It is found that increasing indium content results increase the porosity. However, the increasing volume fraction of indium particles improves the micro-hardness, compressive strength, and wear resistance. In contrast, the wear resistance decreased by increasing the applied loads for all reinforcement content. The results, in conclusion, the alloy that content at 2 wt% indium particles relatively have high mechanical and wear properties, and it could be considered suitable because of high corrosion resistance in our daily life applications. Microhardness, elasticity modulus, and corrosion testing results showed that the prepared Ti–15Mo alloy has excellent potential for use as biomaterial, mainly in orthopaedic applications.

Graphic Abstract

Similar content being viewed by others

References

de Viteri VS, Fuentes E (2013) Titanium and titanium alloys as biomaterials, Chap. 5. In: Gegner J (ed) Tribology—fundamentals and advancements. In Tech, Rijeka, pp 155–181

El-Hajje A, Kolos EC, Wang JK, Maleksaeedi S, He Z, Wiria FE et al (2014) Physical and mechanical characterization of 3D-printed porous titanium for biomedical applications. J Mater Sci Mater Med 25(11):2471–2480

Al-Humairi ANS, Majdi HS, Al-Humairi SNS, Al-Maamori M (2020) Biomaterials: multidisciplinary approaches related applications. White Falcon Publishing, Chandigarh

Xu DS, Wang H, Zhang JH, Bai CG, Yang R (2020) Titanium alloys: from properties prediction to performance optimization. In: Andreoni W, Yip S (eds) Handbook of materials modeling. Springer, Cham. https://doi.org/10.1007/978-3-319-44680-6_116

Kolli RP, Devaraj A (2018) A review of metastable beta titanium alloys. Metals 8(7):506

Sudhagara Rajan S, Jithin V, Geetha M, Nageswara Rao M (2020) Heat treatment of metastable beta titanium alloys, welding - modern topics, Sadek Crisóstomo Absi Alfaro, Wojciech Borek and Błażej Tomiczek, IntechOpen. Available from: https://www.intechopen.com/chapters/72078

Hassan AG, Yajid MM, Saud SN, Bakar TA, Arshad A, Mazlan N (2020) Effects of varying electrodeposition voltages on surface morphology and corrosion behavior of multi-walled carbon nanotube coated on porous Ti-30 at. %-Ta shape memory alloys. Surf Coat Technol 401:126257

Gunawarman, Mulyadi I, Arif Z, Nuswantoro N, Affi J, Niinomi M (2021) Effect of particle size on adhesion strength of bovine hydroxyapatite layer on Ti-12Cr coated by using electrophoretic deposition (EPD) method. In: IOP conference series: materials science and engineering, vol 104. p 012054

Fajri H, Ramadhan F, Nuswantoro NF, Juliadmi D, Tjong DH, Manjas M, Affi J, Yetri Y, Gunawarman (2020) Electrophoretic deposition (EPD) of natural hydroxyapatite coatings on titanium Ti-29Nb-13Ta-4.6Zr substrates for implant material. Mater Sci Forum 1000:123–131. https://doi.org/10.4028/www.scientific.net/msf.1000.123

Xu Z, Wang Y, Xu R, Hu Q, Shi D, Lu X (2020) Research on microstructure and properties of Ti-15Mo-3Al alloy with high oxygen content. Mater Res Express 7(11):116528

Bahador A, Hamzah E, Kondoh K, Abubakar TA, Yusof F, Umeda J, Ibrahim MK (2018) Microstructure and superelastic properties of free forged Ti-Ni shape-memory alloy. Trans Nonferr Met Soc China 28(3):502–514

Han MK, Im JB, Hwang MJ, Kim BJ, Kim HY, Park YJ (2015) effect of indium content on the microstructure, mechanical properties, and corrosion behavior of titanium alloys. Metals 5(2):850–862

Ho W-F, Wu S-C, Hsu S-K, Li Y-C, Hsu H-C (2012) Effects of molybdenum content on the structure and mechanical properties of as-cast Ti–10Zr-based alloys for biomedical applications. Mater Sci Eng C 32:517–522

Hansen DC (2008) Metal corrosion in the human body: the ultimate bio-corrosion scenario. Electrochem Soc Interface 17(2):31

Ibrahim MK, Saud SN, Hamzah E, Nazim EM (2020) Shape memory characteristics of microwave sintered porous Ti–30 at. % Ta alloy for biomedical applications. Proc Inst Mech Eng Part C J Mech Eng Sci 234(10):1979–1989

Lide D (2004) CRC handbook of chemistry and physics: a ready-reference book of chemical and physical data, 85th edn. CRC Press, Boca Raton

Mutlu I, Oktay E (2013) Characterization of 17-4 P.H. stainless steel foam for biomedical applications in simulated body fluid and artificial saliva environments. Mater Sci Eng C 33(3):1125–1131

Kumanan S, Manikandan N, Narayanan CS (2014) Investigations of process parameters on electrochemical machining of titanium Ti6Al4V alloy using grey relational analysis. International colloquium on materials, manufacturing and metrology, ICMMM 2014 August 8–9, 2014, IIT Madras, Chennai, India

Gulay L, Schuster J (2003) Investigation of the titanium–indium system. J Alloys Compd 360:137–142

Hauptmann A (2020) Archaeometallurgy – materials science aspects. Springer Nature, Heidelberg, Cham, pp 433–443

Ho WF, Ju CP, Chern Lin JH (1999) Structure and properties of cast binary Ti-Mo alloys. Biomaterials 20(22):2115–2122

Jayaraman M, Meyer U, Bühner M, Joos U, Wiesmann HP (2004) Influence of titanium surfaces on attachment of osteoblast-like cells in vitro. Biomaterials 25(4):625–631

Kunzler TP, Drobek T, Schuler M, Spencer ND (2007) Systematic study of osteoblast and fibroblast response to roughness by means of surface-morphology gradients. Biomaterials 28(13):2175–2182

Safdar A, He HZ, Wei LY, Snis A, de Paz LEC (2012) Effect of process parameters settings and thickness on surface roughness of EBM produced Ti-6Al-4V. Rapid Prototyp J Prototyp J 18(5):6

Han M-K, Im J-B, Hwang M-J, Kim B-J, Kim H-Y, Park Y-J (2015) Effect of indium content on the microstructure, mechanical properties and corrosion behavior of titanium alloys. Metals 5(2):850–862. https://doi.org/10.3390/met5020850

Wang QY, Wang YB, Lin JP, Zheng YF (2013) Development and properties of Ti–In binary alloys as dental biomaterials. Mater Sci Eng C 33(3):1601–1606

Xu JL, Tao SC, Bao LZ, Luo JM, Zheng YF (2019) Effects of Mo contents on the microstructure, properties and cytocompatibility of the microwave sintered porous Ti-Mo alloys. Mater Sci Eng C 97:156–165

Nie L, Zhan Y, Hu T, Chen X, Wang C (2014) β-Type Zr–Nb–Ti biomedical materials with high plasticity and low modulus for hard tissue replacements. J Mech Behav Biomed Mater 29:1–6

Asmita F, Wibisono G, Judawisastra H, Priambodo TA (2018) Determination of elastic modulus of ceramics using ultrasonic testing. In: AIP conference proceedings, vol 1945, issue 1. AIP Publishing LLC, p 020017

Senkov ON, Miracle DB (2001) Effect of the atomic size distribution on glass forming ability of amorphous metallic alloys. Mater Res Bull 36(12):2183–2198

Song Y, Xu DS, Yang R, Li D, Wu WT, Guo ZX (1999) Theoretical study of the effects of alloying elements on the strength and modulus of β-type bio-titanium alloys. Mater Sci Eng A 260(1–2):269–274

Calin M, Helth A, Gutierrez Moreno JJ, Bönisch M, Brackmann V, Giebeler L et al (2014) Elastic softening of β-type Ti–Nb alloys by indium (In) additions. J Mech Behav Biomed Mater 39:162–174

Jasim AH, Joudi WM, Radhi NS, Saud AN (2020) Mechanical properties and wear characteristic of (Aluminum-Zinc Oxide) metal matrix composite prepared using stir casting process. In: Materials science forum, vol 1002. Trans Tech Publications Ltd, pp 175–184

Choubey A, Basu B, Balasubramaniam R (2004) Tribological behaviour of Ti-based alloys in simulated body fluid solution at fretting contacts. Mater Sci Eng A 379(1–2):234–239

Koç E (2019) Corrosion behaviour of as cast β-Mg17Al12 phase in 3.5 wt% NaCl solution. Acta Phys Pol A 135(5):881–883

Scully JR, Budiansky ND, Tiwary Y, Mikhailov AS, Hudson JL (2008) An alternate explanation for the abrupt current increase at the pitting potential. Corros Sci 50(2):316–324

Putz B (2014) The influence of high current densities on intact and cracked thin gold films on flexible polyimide substrate. Diploma Thesis, University of Leoben

Gebert A, Oswald S, Helth A, Voss A, Gostin PF, Rohnke M et al (2015) Effect of indium (In) on corrosion and passivity of a beta-type Ti–Nb alloy in Ringer’s solution. Appl Surf Sci 335:213–222

Mohammed MT, Khan ZA, Siddiquee AN (2014) Surface modifications of titanium materials for developing corrosion behavior in human body environment: a review. Procedia Mater Sci 6:1610–1618

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Al-Murshdy, J.M.S., Al-Deen, H.H.J. & Hussein, S.R. Investigation of the Effect of Indium Addition on the Mechanical and Electrochemical Properties of the Ti–15Mo Biomedical Alloy. J Bio Tribo Corros 7, 148 (2021). https://doi.org/10.1007/s40735-021-00581-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-021-00581-w