Abstract

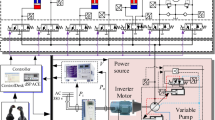

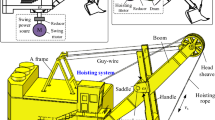

To reduce the energy consumption and emission, an innovative powertrain and the energy management strategy are proposed for hydraulic excavator in this paper. The novel powertrain consists of the engine, motor/generator, planetary gear, gearbox, and variable hydraulic pump. The energy regeneration system is also applied on the system to regenerate the potential energy and charge the battery. An improved equivalent consumption minimization strategy is proposed to control the engine, motor/generator, hydraulic pump and gearbox. The engine working points can be located in high efficiency range, with the proposed powertrain and the energy management strategy. To verify the energy saving efficiency of the proposed system, the test bench is built in laboratory. Compared with the current hybrid system, the energy saving efficiency reaches 11% in condition of a large velocity. Compared with the current hybrid system and conventional system, the energy saving efficiencies are 4% and 48% respectively with different cylinder velocities. The fuel consumption and emission of hydraulic excavator can be reduced effectively with the proposed powertrain and energy management strategy.

Similar content being viewed by others

References

Zhang, S. (2019). The effects of control methods on energy efficiency and position tracking of an electro-hydraulic excavator equipped with zonal hydraulics. Automation in Construction, 100, 129–144.

Chen, M., & Zhao, D. (2017). The gravitational potential energy regeneration system with closed-circuit of boom of hydraulic excavator. Mechanical Systems and Signal Processing, 82, 178–192. https://doi.org/10.1016/j.ymssp.2016.05.017.

Ding, R., Zhang, J., Xu, B., Cheng, M., & Pan, M. (2019). Energy efficiency improvement of heavy-load mobile hydraulic manipulator with electronically tunable operating modes. Energy Conversion and Management, 188, 447–461. https://doi.org/10.1016/j.enconman.2019.03.023.

Wang, Z., Jiao, X., Pu, Z., & Han, L. (2018). Energy recovery and reuse management for fuel-electric-hydraulic hybrid powertrain of a construction vehicle. IFAC-Papers Online, 51, 390–393. https://doi.org/10.1016/j.ifacol.2018.10.080.

Yang, J., Bian, Y., Yang, M., Shao, J., & Liang, A. (2021). Parameter Matching of Energy Regeneration System for Parallel Hydraulic Hybrid Loader. Energies, 14, 5014. https://doi.org/10.3390/en14165014.

Ge, L. (2019). Potential energy regeneration method and its engineering applications in large-scale excavators. Energy Conversion and Management, 195, 1309–1318.

Zhang, C., Wang, L., Li, H., & Wang, L. (2020). Experimental research on parameters of a late-model hydraulic-electromotor hybrid pumping unit. Mathematical Problems in Engineering, 2020, 2923154. https://doi.org/10.1155/2020/2923154.

Lin, T., Wang, Q., Hu, B., & Gong, W. (2010). Development of hybrid powered hydraulic construction machinery. Automation in Construction, 19, 11–19. https://doi.org/10.1016/j.autcon.2009.09.005.

Wang, D., Guan, C., Pan, S., Zhang, M., & Lin, X. (2009). Performance analysis of hydraulic excavator powertrain hybridization. Automation in Construction, 18, 249–257. https://doi.org/10.1016/j.autcon.2008.10.001.

Yu, Y.-X., & Ahn, K. K. (2020). Energy regeneration and reuse of excavator swing system with hydraulic accumulator. Int J of Precis Eng and Manuf-Green Tech, 7, 859–873. https://doi.org/10.1007/s40684-019-00157-7.

Ahn, K. K., Ho, T. H., & Dinh, Q. T. (2008). A study on energy saving potential of hydraulic control system using switching type closed loop constant pressure system. Proceedings of the JFPS International Symposium on Fluid Power, 2008, 317–322. https://doi.org/10.5739/isfp.2008.317.

Xia, L. (2018). Energy efficiency analysis of integrated drive and energy recuperation system for hydraulic excavator boom. Energy Conversion and Management, 156, 680–687.

Zhang, W., Wang, J., Du, S., Ma, H., Zhao, W., & Li, H. (2019). Energy management strategies for hybrid construction machinery: evolution, classification. Comparison and Future Trends. Energies, 12, 2024. https://doi.org/10.3390/en12102024.

Wang, T., & Wang, Q. (2014). Efficiency analysis and evaluation of energy-saving pressure-compensated circuit for hybrid hydraulic excavator. Automation in Construction, 47, 62–68. https://doi.org/10.1016/j.autcon.2014.07.012.

Wang, T., Wang, Q., & Lin, T. (2013). Improvement of boom control performance for hybrid hydraulic excavator with potential energy recovery. Automation in Construction, 30, 161–169. https://doi.org/10.1016/j.autcon.2012.11.034.

Minav, T. A., Virtanen, A., Laurila, L., & Pyrhönen, J. (2012). Storage of energy recovered from an industrial forklift. Automation in Construction, 22, 506–515. https://doi.org/10.1016/j.autcon.2011.11.010.

Yu, Y.-X., & Ahn, K. K. (2019). Optimization of energy regeneration of hybrid hydraulic excavator boom system. Energy Conversion and Management, 183, 26–34. https://doi.org/10.1016/j.enconman.2018.12.084.

Ranjan, P., Wrat, G., Bhola, M., Mishra, S. K., & Das, J. (2020). A novel approach for the energy recovery and position control of a hybrid hydraulic excavator. ISA Transactions, 99, 387–402. https://doi.org/10.1016/j.isatra.2019.08.066.

Yu, Y.-X., & Ahn, K. K. (2020). Improvement of energy regeneration for hydraulic excavator swing system. International Journal of Precision Engineering and Manufacturing-Green Technology, 7, 53–67. https://doi.org/10.1007/s40684-019-00165-7.

Hao, Y. (2018). Potential energy directly conversion and utilization methods used for heavy duty lifting machinery. Energy, 155, 241–255.

Huang, W., Zhang, X., Ge, L., & Quan, L. (2021). Dual source integrated driving for hydraulic excavator swing system. IEEE Access, 9, 120755–120764. https://doi.org/10.1109/ACCESS.2021.3108796.

Lin, T., Wang, Q., Hu, B., & Gong, W. (2010). Research on the energy regeneration systems for hybrid hydraulic excavators. Automation in Construction. https://doi.org/10.1016/j.autcon.2010.08.002.

Lin, T., Huang, W., Ren, H., Fu, S., & Liu, Q. (2016). New compound energy regeneration system and control strategy for hybrid hydraulic excavators. Automation in Construction, 68, 11–20. https://doi.org/10.1016/j.autcon.2016.03.016.

Chen, Q., Lin, T., Ren, H., & Fu, S. (2019). Novel potential energy regeneration systems for hybrid hydraulic excavators. Mathematics and Computers in Simulation, 163, 130–145. https://doi.org/10.1016/j.matcom.2019.02.017.

Ge, L. (2018). A novel hydraulic excavator boom driving system with high efficiency and potential energy regeneration capability. Energy Conversion and Management, 166, 308–317.

Ge, L. (2017). Efficiency improvement and evaluation of electric hydraulic excavator with speed and displacement variable pump. Energy Conversion and Management, 150, 62–71.

Paganelli, G., Delprat, S., Guerra, T. M., Rimaux, J., & Santin, J. J. (2002). Equivalent consumption minimization strategy for parallel hybrid powertrains. Vehicular technology conference. IEEE 55th Vehicular Technology Conference, 4, 2076–2081. https://doi.org/10.1109/VTC.2002.1002989.

Onori, S., Serrao, L., & Rizzoni, G. (2010). Adaptive equivalent consumption minimization strategy for hybrid electric vehicles. ASME 2010 dynamic systems and control conference (1st ed., pp. 499–505). Cambridge: ASMEDC. https://doi.org/10.1115/DSCC2010-4211.

Sun, C., Sun, F., & He, H. (2017). Investigating adaptive-ECMS with velocity forecast ability for hybrid electric vehicles. Applied Energy, 185, 1644–1653. https://doi.org/10.1016/j.apenergy.2016.02.026.

Tian, X., Cai, Y., Sun, X., Zhu, Z., & Xu, Y. (2019). An adaptive ECMS with driving style recognition for energy optimization of parallel hybrid electric buses. Energy, 189, 116151. https://doi.org/10.1016/j.energy.2019.116151.

Yu, Y., Do, T. C., Park, Y., & Ahn, K. K. (2021). Energy saving of hybrid hydraulic excavator with innovative powertrain. Energy Conversion and Management, 244, 114447. https://doi.org/10.1016/j.enconman.2021.114447.

Chen, Z., Mi, C. C., Xia, B., & You, C. (2014). Energy management of power-split plug-in hybrid electric vehicles based on simulated annealing and Pontryagin’s minimum principle. Journal of Power Sources, 272, 160–168. https://doi.org/10.1016/j.jpowsour.2014.08.057.

Syed, S. A., Lhomme, W., & Bouscayrol, A. (2011). Modeling of power split device with clutch for heavy-duty millitary vehicles. IEEE Vehicle Power and Propulsion Conference. https://doi.org/10.1109/VPPC.2011.6043134.

Zeng, X., Yang, N., Song, D., Zhang, C., Wang, J., Wang, J., et al. (2016). Multi-factor integrated parametric design of power-split hybrid electric bus. Journal of Cleaner Production, 115, 88–100. https://doi.org/10.1016/j.jclepro.2015.07.034.

Liu, J., & Peng, H. (2008). Modeling and control of a power-split hybrid vehicle. IEEE Transactions on Control Systems Technology, 16, 1242–1251. https://doi.org/10.1109/TCST.2008.919447.

Cai, Y., Ouyang, M. G., & Yang, F. (2017). Impact of power split configurations on fuel consumption and battery degradation in plug-in hybrid electric city buses. Applied Energy, 188, 257–269. https://doi.org/10.1016/j.apenergy.2016.11.126.

Chen, S.-Y., Wu, C.-H., Hung, Y.-H., & Chung, C.-T. (2018). Optimal strategies of energy management integrated with transmission control for a hybrid electric vehicle using dynamic particle swarm optimization. Energy, 160, 154–170. https://doi.org/10.1016/j.energy.2018.06.023.

Acknowledgements

This work was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT, South Korean (NRF-2020R1A2B5B03001480 and by China Postdoctoral Science Foundation [2021M701477].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yu, Y., Do, T.C., Yin, B. et al. Improvement of Energy Saving for Hybrid Hydraulic Excavator with Novel Powertrain. Int. J. of Precis. Eng. and Manuf.-Green Tech. 10, 521–534 (2023). https://doi.org/10.1007/s40684-022-00437-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-022-00437-9