Abstract

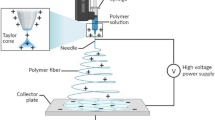

In this study, the effects of various fabrication parameters on the electrical performance of an electrospun nanofiber-based triboelectric nanogenerator (EN-TENG) are systematically investigated through the design of experiments. We selected four fabrication parameters to examine, namely: (i) working distance (needle to collector distance), (ii) needle gauge, (iii) electrospinning time, and (iv) counter materials. A mixed orthogonal array of L18 experiments was designed with respect to the one factor having two level values and three factors having three level values. The open circuit voltage of the EN-TENG was varied from 86.1 to 576.7 V with the aforementioned fabrication parameters. A longer working distance, a larger needle gauge, and a longer electrospinning time increased the open circuit voltage. The power density of the optimized EN-TENG was approximately 2.39 W/m2 at a 100 MΩ load resistance and was sufficient to illuminate a total of 200 LEDs.

Similar content being viewed by others

Abbreviations

- ρ A :

-

Charge density on the surface of the contact materials

- Q :

-

Transferred charges

- ε 0 :

-

Relative permittivity of the air

- ε r :

-

Relative permittivity of contact material

- d :

-

Thickness of the contact material

- x(t):

-

Distance variation between the contact materials

References

Izhar, Khan F. U. (2018). Three degree of freedom acoustic energy harvester using improved helmholtz resonator. Int J Precis Eng Manuf, 19(1), 143–154.

Park, H. (2017). Vibratory electromagnetic induction energy harvester on wheel surface of mobile sources. Int J Precis Eng Manuf Green Tech, 4(1), 59–66.

Jang, S., & Oh, J. H. (2018). Rapid fabrication of microporous BaTiO3/PDMS nanocomposites for triboelectric nanogenerators through one-step microwave irradiation. Sci Rep, 8, 14287.

Cao, L., Li, Z., Guo, C., Li, P., Meng, X., & Wang, T. (2019). Design and test of the MEMS coupled piezoelectric-electromagnetic energy harvester. Int J Precis Eng Manuf, 20(4), 673–686.

Wang, Z. L. (2013). Triboelectric nanogenerators as new energy technology for self-powered systems and as active mechanical and chemical sensors. ACS Nano, 7(11), 9533–9557.

Yang, Y., Zhu, G., Zhang, H., Chen, J., Zhong, X., Lin, Z.-H., et al. (2013). Triboelectric nanogenerator for harvesting wind energy and as self-powered wind vector sensor system. ACS Nano, 7(10), 9461–9468.

Lee, J.-H., Ryu, H., Kim, T.-Y., Kwak, S.-S., Yoon, H.-J., Kim, T.-H., et al. (2015). Thermally induced strain-coupled highly stretchable and sensitive pyroelectric nanogenerators. Adv Energy Mater, 5, 1500704.

Jang, S., Kim, H., & Oh, J. H. (2017). Simple and rapid fabrication of pencil-on-paper triboelectric nanogenerators with enhanced electrical performance. Nanoscale, 9, 13034–13041.

Zhu, G., Lin, Z.-H., Jing, Q., Bai, P., Pan, C., Yang, Y., et al. (2013). Toward large-scale energy harvesting by a nanoparticle-enhanced triboelectric nanogenerator. Nano Lett, 13, 847–853.

Fan, F.-R., Lin, L., Zhu, G., Wu, W. Z., Zhang, R., & Wang, Z. L. (2012). Transparent triboelectric nanogenerators and self-powered pressure sensors based on micropatterned plastic films. Nano Lett, 12, 3109–3114.

Niu, S., Wang, S., Lin, L., Liu, Y., Zhou, Y. S., Hu, Y., et al. (2013). Theoretical study of contact-mode triboelectric nanogenerators as an effective power source. Energy Environ Sci, 6, 3576–3583.

Wang, X., Yang, B., Liu, J., Zhu, Y., Yang, C., & He, Q. (2016). A flexible triboelectric-piezoelectric hybrid nanogenerator based on P(VDF-TrFE) nanofibers and PDMS/MWCNT for wearable devices. Sci Rep, 6, 36409.

Jang, S., Kim, Y., & Oh, J. H. (2016). Influence of processing conditions and material properties on electrohydrodynamic direct patterning of a polymer solution. J Electron Mater, 45(4), 2291–2298.

Cho, Y. S., Lee, J. S., Hong, M. W., Lee, S.-H., Kim, Y. Y., & Cho, Y.-S. (2018). Comparative assessment of the ability of dual-pore structure and hydroxyapatite to enhance the proliferation of osteoblast-like cells in well-interconnected scaffolds. Int J Precis Eng Manuf, 19(4), 605–612.

Chen, F., Wu, Y., Ding, Z., Xia, X., Li, S., Zheng, H., et al. (2019). A novel triboelectric nanogenerator based on electrospun polyvinylidene fluoride nanofibers for effective acoustic energy harvesting and self-powered multifunctional sensing. Nano Energy, 56, 241–251.

Garain, S., Jana, S., Sinha, T. K., & Mandal, D. (2016). Design of in situ Poled Ce3+-doped electrospun PVDF/graphene composite nanofibers for fabrication of nanopressure sensor and ultrasensitive acoustic nanogenerator. ACS Appl Mater Interfaces, 8, 4532–4540.

Mi, H.-Y., Jing, X., Zheng, Q., Fang, L., Huang, H.-X., Turng, L.-S., et al. (2018). High-performance flexible triboelectric nanogenerator based on porous aerogels and electrospun nanofibers for energy harvesting and sensitive self-powered sensing. Nano Energy, 48, 327–336.

Li, Z., Shen, J., Abdalla, I., Yu, J., & Ding, B. (2017). Nanofibrous membrane constructed wearable triboelectric nanogenerator for high performance biomechanical energy harvesting. Nano Energy, 36, 341–348.

Zheng, Y., Cheng, L., Yuan, M., Wang, Z., Zhang, L., Qin, Y., et al. (2014). An electrospun nanowire-based triboelectric nanogenerator and its application in a fully self-powered UV detector. Nanoscale, 6, 7842–7846.

Huang, T., Wang, C., Yu, H., Wang, H., Zhang, Q., & Zhu, M. (2015). Human walking-driven wearable all-fiber triboelectric nanogenerator containing electrospun polyvinylidene fluoride piezoelectric nanofibers. Nano Energy, 14, 226–235.

Ye, B. U., Kim, B.-J., Ryu, J., Lee, J. Y., Baik, J. M., & Hong, K. (2015). Electrospun Ion gel nanofibers for flexible triboelectric nanogenerator: electrochemical effect on output power. Nanoscale, 7, 16189–16194.

Jang, S., Kim, H., Kim, Y., Kang, B. J., & Oh, J. H. (2016). Honeycomb-like nanofiber based triboelectric nanogenerator using self-assembled electrospun poly(vinylidene fluoride-co-trifluoroethylene) nanofibers. Appl Phys Lett, 108, 143901.

Lee, D., Chung, J., Yong, H., Lee, S., & Shin, D. (2019). A deformable foam-layered triboelectric tactile sensor with adjustable dynamic range. Int J Precis Eng Manuf Green Tech, 6(1), 43–51.

Wang, H., Shi, M., Zhu, K., Su, Z., Cheng, X., Song, Y., et al. (2016). High performance triboelectric nanogenerators with aligned carbon nanotubes. Nanoscale, 8, 18489–18494.

Chen, J., Guo, H., He, X., Liu, G., Xi, Y., Shi, H., et al. (2016). Enhancing performance of triboelectric nanogenerator by filling high dielectric nanoparticles into sponge PDMS film. ACS Appl Mater Interfaces, 8, 736–744.

He, X., Guo, H., Yue, X., Gao, J., Xi, Y., & Hu, C. (2015). Improving energy conversion efficiency for triboelectric nanogenerator with capacitor structure by maximizing surface charge density. Nanoscale, 7, 1896–1903.

Seung, W., Yoon, H.-J., Kim, T. Y., Ryu, H., Kim, J., Lee, J.-H., et al. (2017). Boosting power-generating performance of triboelectric nanogenerators via artificial control of ferroelectric polarization and dielectric properties. Adv Energy Mater, 7, 1600988.

Kwon, Y. H., Shin, S.-H., Kim, Y.-H., Jung, J.-Y., Lee, M. H., & Nah, J. (2016). Triboelectric contact surface charge modulation and piezoelectric charge inducement using polarized composite thin film for performance enhancement of triboelectric generators. Nano Energy, 25, 225–231.

Song, J., Xie, H., Wu, W., Joseph, V. R., Wu, C. F. J., & Wang, Z. L. (2010). Robust optimization of the output voltage of nanogenerators by statistical design of experiments. Nano Res, 3(9), 613–619.

Karthikeyan, P., & Mahadevan, K. (2015). Investigation on the effects of sic particle addition in the weld zone during friction stir welding of Al 6351 alloy. Int J Adv Manuf Technol, 80, 1919–1926.

Tosun, N., Cogun, C., & Tosun, G. (2004). A study on kerf and material removal rate in wire electrical discharge machining based on taguchi method. J Mater Process Technol, 152, 316–322.

Wang, J., Wu, C., Dai, Y., Zhao, Z., Wang, A., Zhang, T., et al. (2017). Achieving ultrahigh triboelectric charge density for efficient energy harvesting. Nat Commun, 8(1), 88.

Zheng, Q., Fang, L., Guo, H., Yang, K., Cai, Z., Meador, M. A. B., et al. (2018). Highly porous polymer aerogel film-based triboelectric nanogenerators. Adv Funct Mater, 28, 1706365.

Baker, S. C., Atkin, N., Gunning, P. A., Granville, N., Wilson, K., Wilson, D., et al. (2006). Characterisation of electrospun polystyrene scaffolds for three-dimensional in vitro biological studies. Biomaterials, 27(16), 3136–3146.

Yuan, X., Zhang, Y., Dong, C., & Sheng, J. (2004). Morphology of ultrafine polysulfone fibers prepared by electrospinning. Polym Int, 53(11), 1704–1710.

Zhou, F.-L., Gong, R.-H., & Porat, I. (2010). Needle and needleless electrospinning for nanofibers. J Appl Polym Sci, 115, 2591–2598.

Acknowledgements

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIP) (No. 2019R1A2C1005023).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jang, S., Kim, Y., Lee, S. et al. Optimization of Electrospinning Parameters for Electrospun Nanofiber-Based Triboelectric Nanogenerators. Int. J. of Precis. Eng. and Manuf.-Green Tech. 6, 731–739 (2019). https://doi.org/10.1007/s40684-019-00134-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-019-00134-0