Abstract

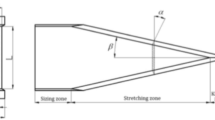

We propose a novel conical roll-twist-bending (RTB) process to fabricate a metallic Archimedes spiral blade which has variable curvatures on its surface, and it is a key element of a novel wind power generator having a remarkably higher efficiency of about 34% compared with conventional wind power systems. The RTB system consists of a pair of conical rollers (upper and lower sides) and cylindrical twist-bending rollers in the both lateral sides. With the help of forming analysis results, multi-step regional forming method was utilized to fabricate the blade. Also, the process parameters were optimized by a response surface methodology. In this work, we installed the experimental equipment of RTB process, and it was experimentally proven that the developed RTB process was capable of producing a spiral blade with a shape error less than approximately 5%. Furthermore, we believe that the RTB process can be utilized to fabricate diverse sheet metal structures having continuously changing curvatures for various applications.

Similar content being viewed by others

References

Burton, T., Jenkins, N., Sharpe, D., and Bossanyi, E., “Wind Energy Handbook,” John Wiley & Sons, 2001.

Kim, J. H., Yang, H. D., Lee, K. J., Song, S. D., Park, S. H., et al., “An Experiment on Power Properties in a Small-Scaled Wind Turbine Generator,” Journal of Power and Energy Engineering, Vol. 1, No. 7, pp. 6–13, 2013.

Simic, Z., Havelka, J. G., and Vrhovcak, M. B., “Small Wind Turbines-A Unique Segment of the Wind Power Market,” Renewable Energy, Vol. 50, pp. 1027–1036, 2013.

Chong, W. T., Muzammil, W. K., Fazlizan, A., Hassan, M. R., Taheri, H., et al., “Urban Eco-Greenergy™ Hybrid Wind-Solar Photovoltaic Energy System and Its Applications,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 7, pp. 1263–1268, 2015.

Matsushima, T., Takagi, S., and Muroyama, S., “Characteristics of a Highly Efficient Propeller Type Small Wind Turbine with a Diffuser,” Renewable Energy, Vol. 31, No. 9, pp. 1343–1354, 2006.

Howell, R., Qin, N., Edwards, J., and Durrani, N., “Wind Tunnel and Numerical Study of a Small Vertical Axis Wind Turbine,” Renewable Energy, Vol. 35, No. 2, pp. 412–422, 2010.

Lubitz, W. D., “Impact of Ambient Turbulence on Performance of a Small Wind Turbine,” Renewable Energy, Vol. 61, No. 1, pp. 69–73, 2014.

Kot, R., Rolax, M., and Malinowski, M., “Comparison of Maximum Peak Power Tracking Algorithms for a Small Wind Turbine,” Mathematics and Computers in Simulation, Vol. 91, pp. 29–40, 2013.

Dabiri, J. O., “Potential Order-of-Magnitude Enhancement of Wind Farm Power Density via Counter-Rotating Vertical-Axis Wind Turbine Array,” Journal of Renewable and Sustainable Energy, Vol. 3, No. 4, Paper No. 043104, 2011.

Sung, C. M. and Han, M. C., “Design and Performance Evaluation of Hinge Type Pitch Control System in Small-Size Wind Turbine,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 3, No. 4, pp. 335–341, 2016.

Ji, H. S., Qiang, L., Beak, J. H., Mieremet, R., and Kim, K. C., “Effect of the Wind Direction on the Near Wake Structures of an Archimedes Spiral Wind Turbine Blade,” Journal of Visualization, Vol. 19, No. 4, pp. 653–665, 2016.

Kim, K. C., Ji, H. S., Kim, Y. K., Lu, Q., Baek, J. H., et al., “Experimental and Numerical Study of the Aerodynamic Characteristics of an Archimedes Spiral Wind Turbine Blade,” Energies, Vol. 7, No. 12, pp. 7893–7914, 2014.

Chaudhary, S., Jaiswal, S., Nanda, R., Patel, S., Kumar, P., et al., “Comparison of Torque Characteristics of Archimedes Wind Turbine Evaluated by Analytical and Experimental Study,” International Journal of Mechanical and Production Engineering, Vol. 4, No. 8, pp. 75–78, 2016.

Safdari, A. and Kim, K. C., “Aerodynamic and Structural Evaluation of Horizontal Archimedes Spiral Wind Turbine,” Journal of Clean Energy Technologies, Vol. 3, No. 1, 2015.

Saroinsong, T., Soenoko, R., Wahyudi, S., and Sasongko, M., “Fluid Flow Phenomenon in a Three-Bladed Power-Generating Archimedes Screw Turbine,” Journal of Engineering Science and Technology Review, Vol. 9, No. 2, pp. 72–79, 2016.

Wick, C., Benedic, J. T., and Veilleux, R. F., “Tool and Manufacturing Engineers Handbook,” Society of Manufacturing Engineers, 4.h Ed., 1984.

Hua, M. and Lin, Y. H., “Effect of Strain Hardening on the Continuous Four-Roll Plate Edge Bending Process,” Journal of Materials Processing Technology, Vol. 89, pp. 12–18, 1999.

Lee, M. S., Seo, H. Y., and Kang, C. G., “Comparative Study on Mechanical Properties of CR340/CFRP Composites through Three Point Bending Test by Using Theoretical and Experimental Methods,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 3 No. 4, pp. 359–365, 2016.

Cai, Z. Y., Li, M. Z., and Lan, Y. W., “Three-Dimensional Sheet Metal Continuous Forming Process Based on Flexible Roll Bending: Principle and Experiments,” Journal of Materials Processing Technology, Vol. 212, No. 1, pp. 120–127, 2012.

Shim, D. S., Yang, D. Y., Kim, K. H., Chung, S. W., and Han, M. S., “Investigation into Forming Sequences for the Incremental Forming of Doubly Curved Plates Using the Line Array Roll Set (LARS) Process,” International Journal of Machine Tools and Manufacture, Vol. 50, No. 2, pp. 214–218, 2010.

Kuczmarski, F., “Bend, Twist, and Roll: Using Ribbons and Wheels to Visualize Curvature and Torsion,” Mathematics Magazine, Vol. 88, No. 1, pp. 11–26, 2015.

Feng, Z. and Champliaud, H., “Modeling and Simulation of Asymmetrical Three-Roll Bending Process,” Simulation Modelling Practice and Theory, Vol. 19, No. 9, pp. 1913–1917, 2011.

Fang, G., Gao, W. R., and Zhang, X. G., “Finite Element Simulation and Experiment Verification of Rolling Forming for the Truck Wheel Rim,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 7, pp. 1509–1515, 2015.

Baek, G. Y. and Shim, D. S., “FE Simulation-Based Process Design for Manufacturing Structural Members of Commercial Vehicle Using Pipes with Rectangular Cross-Sections,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 4, pp. 723–733, 2015.

Lee, C. W., Yang, D. Y., Ham, H. C., and Yoon, S. P., “A New Leveling Process Using Skew-Arranged Roll Sets for the Doubly- Curved Plate,” Int. J. Precis. Eng. Manuf., Vol. 17, No. 10, pp. 1275–1284, 2016.

Feng, Z., Champliaud, H., and Dao, T. M., “Numerical Studying of Non-Kinematical Conical Bending with Cylindrical Rolls,” Simulation Modelling Practice and Theory, Vol. 17, No. 10, pp. 1710–1722, 2009.

Feng, Z. and Champliaud, H., “Investigation of Non-Kinematic Conical Roll Bending Process with Conical Rolls,” Simulation Modelling Practice and Theory, Vol. 27, pp. 65–75, 2012.

Shen, Z., Yao, B., Teng, W., Feng, W., and Sun, W., “Generating Grinding Profile between Screw Rotor and Forming Tool by Digital Graphic Scanning (DGS) Method,” Int. J. Precis. Eng. Manuf., Vol. 17, No. 1, pp. 35–41, 2016.

Yang, S. M., Shim, D. S., Ji, H. S., Baek, J. H., Kim, B. S., et al., “Process Design of a Conical Roll-Shaping for Fabrication of a Spiral Blade Having Variable Curvature,” J. Korean Soc. Precis. Eng., Vol. 33, No. 11, pp. 911–918, 2016.

Bourke, P., “Calculating the Area and Centroid of a Polygon,” Swinburne University of Technology, 1988.

Thipprakmas, S. and Phanitwong, W., “Process Parameter Design of Spring-Back and Spring-Go in V-Bending Process Using Taguchi Technique,” Materials & Design, Vol. 32, No. 8, pp. 4430–4436, 2011.

Myers, R. H., Montgomery, D. C., Vining, G. G., Borror, C. M., and Kowalski, S. M., “Response Surface Methodology: A Retrospective and Literature Survey,” Journal of Quality Technology, Vol. 36, No. 1, pp. 53–78, 2004.

Montgomery, D. C., “Design and Analysis of Experiments,” John Wiley & Sons, 2017.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, SM., Ji, HS., Shim, DS. et al. Conical roll-twist-bending process for fabrication of metallic Archimedes spiral blade used in small wind power generator. Int. J. of Precis. Eng. and Manuf.-Green Tech. 4, 431–439 (2017). https://doi.org/10.1007/s40684-017-0048-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-017-0048-4