Abstract

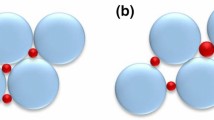

Preparing the particle packing model is a crucial step in modelling continuous materials using discrete element modelling (DEM) due to the close correlation between particle packing and material property. In this paper, two modified cubic packing models are generated by inserting smaller particles into the void space of simple cubic packing (SCP). Packing fractions and coordination numbers of two modified packing models increase gradually with the increase of insertion times. Size effect of each packing model is investigated and different packing models share the same characteristics, i.e. stress–strain curves of continuous materials created using different packing models under tensile loads tend to concentrate gradually with the increase of size ratio and their peak strengths raises gradually and then converge into constants. Uniaxial tensile DEM simulations are performed to investigate the impact of packing type and packing with or without rectangular defects on the mechanical behavior of continuous materials generated using different packing models. It is proven that SCP has the minimum uniaxial tensile strength compared to binary cubic packing (BCP) and triple cubic packing (TCP). Any packing with one of three kinds of rectangular defects tends to weaken its uniaxial tensile strength. From BCP to TCP, peak strength or stress has only slight improvements while total numbers of sub-particles soar greatly. The newly developed packing models in this paper enhance the understanding of the relationship between particle packing and material property although these models are formulated and computed in 2D.

Similar content being viewed by others

References

Galakhov AV, Shevchenko VY (1992) Analysis of two-dimensional packings. Ceram Int 18(4):213–221

Weitz DA (2004) Packing in the spheres. Science 303(5660):968–969

Hudson DR (1949) Density and packing in an aggregate of mixed spheres. J Appl Phys 20(2):154–162

Patankar AN, Mandal G (1980) The packing of solid particles: a review. Trans Indian Ceram Soc 39(4):109–119

Yu A (1989) The packing of solid particles. University of Wollongong [thesis]

He H (2010) Computational modelling of particle packing in concrete. Delft University of Technology [thesis]

Wang P, Arson C (2016) Discrete element modeling of shielding and size effects during single particle crushing. Comput Geotech 78(2016):227–236

Li CX, An XZ, Yang RY, Zou RP, Yu AB (2011) Experimental study on the packing of uniform spheres under three-dimensional vibration. Powder Technol 208(3):617–622

Mobius ME, Lauderdale BE, Nagel SR, Jaeger HM (2001) Size separation of granular particles. Nature 414(6861):270

Hong DC, Quinn PV, Luding S (2001) Reverse Brazil nut problem: competition between percolation and condensation. Phys Rev Lett 86(15):3423–3426

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Géotech 29(1):47–65

Xia H, Tong X, Li Z, Wu X (2017) DEM-FEM coupling simulations of the interactions between particles and screen surface of vibrating screen. Int J Min Miner Eng 8(3):250–263

Cleary PW, Owen PJ (2016) Using DEM to understand scale-up for a HICOM® mill. Miner Eng 92(2016):86–109

Jiang M, Zhao Y, Liu G, Zheng J (2011) Enhancing mixing of particles by baffles in a rotating drum mixer. Particuology 9(3):270–278

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41(8):1329–1364

Cho N, Martin CD, Sego DC (2007) A clumped particle model for rock. Int J Rock Mech Min Sci 44(7):997–1010

Jiang S, Li T, Tan Y (2015) A DEM methodology for simulating the grinding process of SiC ceramics. Procedia Eng 102(2015):1803–1810

Ji S, Di S, Long X (2017) DEM simulation of uniaxial compressive and flexural strength of sea ice: parametric study. J Eng Mech 143(1):1–11

Sheng Y, Yang D, Tan Y, Ye J (2010) Microstructure effects on transverse cracking in composite laminae by DEM. Compos Sci Technol 70(14):2093–2101

Yang D, Ye J, Tan Y, Sheng Y (2011) Modeling progressive delamination of laminated composites by discrete element method. Comput Mater Sci 50(3):858–864

André D, Iordanoff I, Charles J-l, Néauport J (2012) Discrete element method to simulate continuous material by using the cohesive beam model. CMAME 213–216(2012):113–125

Weerasekara NS, Powell MS, Cleary PW et al (2013) The contribution of DEM to the science of comminution. Powder Technol 248(2013):3–24

Mishra BK, Thornton C (2001) Impact breakage of particle agglomerates. Int J Miner Process 61(4):225–239

Thornton C, Liu L (2004) How do agglomerates break? Powder Technol 143–144(2004):110–116

Torquato S, Truskett TM, Debenedetti PG (2000) Is random close packing of spheres well defined? Phys Rev Lett 84(10):2064–2067

Christian E, Robert S, Peter E (2012) A discrete element model predicting the strength of ballast stones. Comput Struct 108–109(2012):3–13

Liu L, Kafui KD, Thornton C (2010) Impact breakage of spherical, cuboidal and cylindrical agglomerates. Powder Technol 199(2):189–196

Pal G, Janosi Z, Kun F, Main IG (2016) Fragmentation and shear band formation by slow compression of brittle porous media. PhRvE 94(5):1–8

Quist J, Evertsson CM (2016) Cone crusher modelling and simulation using DEM. Miner Eng 85(2016):92–105

Borkovec M, Paris WD, Peikert R (1994) The fractal dimension of the Apollonian sphere packing. Fractals 2(4):521–526

Bourke P (2006) An introduction to the Apollonian fractal. Comput Graph 30(1):134–136

Li H, McDowell GR, Lowndes I (2013) Discrete-element modelling of rock breakage using dense random packing agglomerates. Géotech Lett 3(3):98–102

Scholtès L, Donzé F-V (2013) A DEM model for soft and hard rocks: role of grain interlocking on strength. J Mech Phys Solids 61(2):352–369

Antonyuk S, Khanal M, Tomas J, Heinrich S, Mörl L (2006) Impact breakage of spherical granules: experimental study and DEM simulation. Chem Eng Process 45(10):838–856

Timar G, Blomer J, Kun F, Herrmann HJ (2010) New universality class for the fragmentation of plastic materials. Phys Rev Lett 104(9):1–4

Chung YC, Yang ZH, Lin CK (2017) Modelling micro-crack initiation and propagation of crystal structures with microscopic defects under uni-axial tension by discrete element method. Powder Technol 315(2017):445–476

Jia L, Chen M, Zhang W et al (2013) Experimental study and numerical modeling of brittle fracture of carbonate rock under uniaxial compression. MeReC 50:58–62

Yang S-Q, Tian W-L, Huang Y-H, Ranjith PG, Ju Y (2015) An experimental and numerical study on cracking behavior of brittle sandstone containing two non-coplanar fissures under uniaxial compression. Rock Mech Rock Eng 49(4):1497–1515

Yang D, Sheng Y, Ye J, Tan Y (2010) Discrete element modeling of the microbond test of fiber reinforced composite. Comput Mater Sci 49(2):253–259

Acknowledgements

Huihuang Xia and Xin Tong would like to acknowledge the Innovation Foundation for Graduate Students of Huaqiao University (No. 1511303046) for the financial support of this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xia, H., Li, Z. & Tong, X. Modelling continuous materials using discrete element modelling: investigations on the effect of particle packing. Comp. Part. Mech. 6, 823–836 (2019). https://doi.org/10.1007/s40571-019-00270-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-019-00270-z