Abstract

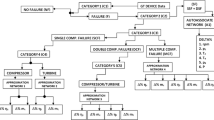

The great challenge in the field of combustion monitoring and fault diagnosis in diesel engines is understanding the dynamic interactions that reveal the trajectory between the causes located in engine items and their effects or measurable symptoms to establish the rules that can generate diagnoses. In this context, the fault tree analysis (FTA) technique was applied to transform the engine and its subsystems into a structured logical diagram, in which were arranged the various combinations of failures in the engine component items that possibly may lead to undesirable events. With the set of diagnostic rules generated by the FTA serving as a knowledge base, inferences were made by an artificial neural network created to provide the operational condition of the engine submitted to tests. Despite the value errors and knowing that a perfect classification model must have values close to the expected values, it was very easy to distinguish the simulated operating conditions, which makes the diagnosis very consistent when compared with the expected results.

Similar content being viewed by others

Abbreviations

- FTA:

-

Fault tree analysis

- SRASE:

-

System reliability assessment and safety engineering

- ANFIS:

-

Adaptive neuro-fuzzy inferencing system

- PRA:

-

Probabilistic risk assessment

- CFR:

-

Cooperative fuel research

- CUSUM:

-

Cumulative sum

- DOD:

-

Domestic object damage

- FOD:

-

Foreign object damage

- AI:

-

Artificial intelligence

- CI:

-

Compression ignition

- CMFD:

-

Condition monitoring and fault diagnosis

- ICE:

-

Internal combustion engines

- MLP:

-

Multilayer perceptron

- RBFN:

-

Radial base functional network

- ANN:

-

Artificial neural network

References

Lipowsky H, Staudacher S, Bauer M, Schmidt KJ (2010) Application of Bayesian forecasting to change detection and prognosis of gas turbine performance. J Eng Gas Turbines Power 132:1–8

Chen YZ (2022) A dynamic performance diagnostic method applied to hydrogen-powered aero engines operating under transient conditions. Appl Energy 317:1–20

Li J, Ying Y (2020) Gas turbine gas path diagnosis under transient operating conditions: a steady state performance model based local optimization approach. Appl Therm Eng 170:1–14

Simon DL (2010) Propulsion diagnostic method evaluation strategy (ProDiMES) user’s guide. National Aeronautics and Space Administration, Cleveland

Sarkar S, Rao C, Ray A (2009) Estimation of multiple faults in aircraft gas-turbine engines. In: Proceedings of the 2009 conference on American control conference, pp 216–221. https://doi.org/10.1109/ACC.2009.5159981

Dantas W (2010) Interpretação das definições de termos de manutenção estabelecidos pela norma ABNT NBR 5462—manutenabilidade e confiabilidade. http://www.webartigos.com/artigos/. Acessed 26 Feb 2019

Kang DW, Kim TS (2018) Model-based performance diagnostics of heavy-duty gas turbines using compressor map adaptation. Appl Energy 212:1345–1359

Tahan M, Tsoutsanis E, Muhammad M, Abdul Karim ZA (2017) Performance-based health monitoring, diagnostics and prognostics for condition-based maintenance of gas turbines: a review. Appl Energy 198:122–144

Bai M, Liu J, Chai J, Zhao X, Yu D (2020) Anomaly detection of gas turbines based on normal pattern extraction. Appl Therm Eng 166:114664. https://doi.org/10.1016/j.applthermaleng.2019.114664

Tang S, Tang H, Chen M (2019) Transfer-learning based gas path analysis method for gas turbines. Appl Therm Eng 155:1–13. https://doi.org/10.1016/j.applthermaleng.2019.03.156

Escher PC (1995) Pythia: an object-orientated gas path analysis computer program for general applications. Ph.D. thesis. Cranfield University

Li YG, Nilkitsaranont P (2009) Gas turbine performance prognostic for condition-based maintenance. Appl Energy 86:2152–2161

Provost, MJ (1994) The use of optimal estimation techniques in the analysis of gas turbines. Ph.D. thesis. Cranfield University

Li YG, Pilidis P (2010) GA-based design-point performance adaptation and its comparison with ICM-based approach. Appl Energy 87:340–348

Doel DL (1993) An assessment of weighted-least-squares based gas path analysis. In: Proceedings of the ASME 1993 international gas turbine and aeroengine congress and exposition, pp 366–373

Kong C (2014) Review on advanced health monitoring methods for aero gas turbines using model based methods and artificial intelligent methods. Int J Aeronaut Sp Sci 15:123–137

Koskoletos AO, Aretakis N, Alexiou A, Romesis C, Mathioudakis K (2018) Evaluation of aircraft engine gas path diagnostic methods through ProDiMES. J Eng Gas Turbines Power 140:1–13

Burdzik R (2022) A comprehensive diagnostic system for vehicle suspensions based on a neural classifier and wavelet resonance estimators. Measurement 200:111602. https://doi.org/10.1016/j.measurement.2022.111602

Martins J (2006) Internal combustion engines, 2nd edn. Publindústria, Porto (in Portuguese)

Ericson II CA (1999) Fault tree analysis-a history. In: Proceedings of the 17th international system safety conference, pp 1–9

Sumit N, Singh A (2016) Fault tree analysis of single cylinder vertical diesel engine. Int Res J Eng Technol 3:2278–2283

Ünver B, Gürgen S, Sahin B, Altin I (2019) Crankcase explosion for two-stroke marine diesel engine by using fault tree analysis method in fuzzy environment. Eng Fail Anal 97:288–299

Hong B, Shao B, Guo J, Fu J, Li C, Zhu B (2023) Dynamic Bayesian network risk probability evolution for third-party damage of natural gas pipelines. Appl Energy 333:120620. https://doi.org/10.1016/j.apenergy.2022.120620

Ceylan BO, Akyuz E, Arslanoğlu Y (2022) Modified quantitative systems theoretic accident model and processes (STAMP) analysis: a catastrophic ship engine failure case. Ocean Eng 253:111187. https://doi.org/10.1016/j.oceaneng.2022.111187

Uzlu E, Akpınar A, Özturk HT, Nacar S, Kankal M (2014) Estimates of hydroelectric generation using neural networks with the artificial bee colony algorithm for Turkey. Energy 269:638–647. https://doi.org/10.1016/j.energy.2014.03.059

Moradi GR, Dehghani S, Khosravian F, Arjmandzadeh A (2013) The optimized operational conditions for biodiesel production from soybean oil and application of artificial neural networks for estimation of the biodiesel yield. Renew Energy 50:915–920. https://doi.org/10.1016/j.renene.2012.08.070

Al-Geelani NA, Piah MAM, Bashir M (2015) A review on hybrid wavelet regrouping particle swarm optimization neural networks for characterization of partial discharge acoustic signals. Renew Sustain Energy Rev 45:20–35. https://doi.org/10.1016/j.rser.2015.01.047

Yang F, Cho H, Zhang H, Zhang J, Wu Y (2018) Artificial neural network (ANN) based prediction and optimization of an organic Rankine cycle (ORC) for diesel engine waste heat recovery. Energy Convers Manage 164:15–26

de Nola F, Giardiello G, Gimelli A, Molteni A, Muccillo A, Picariello R (2019) Volumetric efficiency estimation based on neural networks to reduce the experimental effort in engine base calibration. Fuel 244:31–39

Yang L, Zhao CC, Liang HY, Lu HH, Cui NY, Bao KY (2022) A rotor fault diagnosis method based on BP-Adaboost weighted by non-fuzzy solution coefficients. Measurement 196:111280. https://doi.org/10.1016/j.measurement.2022.111280

Can O, Baklacioglu T, Özturk E, Turan O (2022) Artificial neural networks modeling of combustion parameters for a diesel engine fueled with biodiesel fuel. Energy 247:123473. https://doi.org/10.1016/j.energy.2022.123473

Zio E (2007) An Introduction to the basics of reliability and risk analysis. World Scientific Publishing, Singapore

Alho ALP, Belchior CRP (1998) MEP-MAN engine operating status assessment report from the CIAGA machinery laboratory. Department of Naval Engineering, Universidade Federal do Rio de Janeiro, Unpublished work (in Portuguese)

Coelho RNC (1999) Analysis of a monitoring and diagnosis system of the combustion of diesel engines. M.Sc. Dissertation, Universidade Federal do Rio de Janeiro (in Portuguese)

New Sulzer Diesel (1990) General technical data of ZA40S marine propulsion diesel engines. Wintertur, Switzerland

Coelho RNC (2017) Use of the fault tree analysis technique for the determination of the generalized heuristic algorithm for diagnosing faults in diesel engines. D.Sc. Thesis, Universidade Federal do Pará (in Portuguese)

Matlab M (2010) The language of technical computing. The MathWorks, Inc. http://www.mathworks.com

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Additional information

Technical Editor: Mario Eduardo Santos Martins.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Coelho, R.N.C., Macêdo, E.N. & Quaresma, J.N.N. Monitoring the operational condition of a diesel engine by evaluating the parameters of its thermodynamic operation cycle. J Braz. Soc. Mech. Sci. Eng. 45, 447 (2023). https://doi.org/10.1007/s40430-023-04357-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04357-w