Abstract

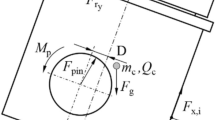

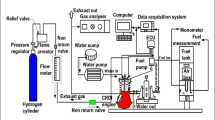

Under the global efforts to implement strict emission regulations, higher requirements are placed on diesel engines, and a reasonable piston ring set structure can effectively reduce diesel engine lubricating oil consumption. Taking an off-road high-pressure common rail diesel engine as the research object, the numerical simulation model of piston ring assembly dynamics was built by measuring the cylinder pressure and the temperature field of the piston and cylinder liner and combined with the test results of the gas blow-by and lubricating oil consumption. The influence of piston ring assembly structure parameters on lubricating oil consumption was systematically studied, and the mathematical regression model of lubricating oil consumption was established by using the response surface method. Based on it, the optimal solution of the piston ring assembly parameters was obtained by desirability optimization. The results show that the thickness of oil ring scraping edge will have the greatest influence on lubricating oil consumption and the lowest significance of the thickness of second ring scraping edge. With the increase of the upper end reduction of the top ring and the thickness of the oil ring scraping edge, the lubricating oil consumption gradually decreases. The optimal solution with the desirability of 1 is 0.02 mm reduction of the upper end of the top ring, 0.40 mm thickness of the oil ring scraping edge and 0 mm thickness of the second ring scraping edge. And the lubricating oil consumption is 3.07 g/h, which is 15.89% less than that of the original machine.

Similar content being viewed by others

Abbreviations

- a :

-

Ring opening end area, mm2

- b :

-

Height of the top ring moving surface, mm

- b fl :

-

Ring width of the overlapping part of the top ring and the ring groove, mm

- c :

-

Lubricating oil concentration

- D :

-

Cylinder bore, mm

- D C :

-

Diffusion coefficient

- f amot, f blw :

-

Correction factor

- h fl :

-

Upper end gap of the top, mm

- h film :

-

Thickness of the oil film at the fire shore, mm

- h s :

-

Thickness of the residual oil film, mm

- \(\dot{m}_{{{\text{acc}}}}\) :

-

The amount of lubricating oil accumulated by the top ring, g/h

- \(\dot{m}_{{\text{blw-up}}}\) :

-

The amount of oil channeled by the top ring, g/h

- \(\dot{m}_{{\text{evap,Oil}}}\) :

-

The amount of evaporation on the wall surface of the cylinder liner, g/h

- \(\dot{m}_{{\text{pmp,top}}}\) :

-

The amount of oil pumped by the top ring, g/h

- \(\dot{m}_{{{\text{scr}}}}\) :

-

The amount of oil scraped by the top ring, g/h

- \(\dot{m}_{{\text{thrw-off}}}\) :

-

The amount of oil thrown by the top ring, g/h

- P :

-

Local pressure, MPa

- P c :

-

Gas pressure, MPa

- P g :

-

Back pressure of the top ring, MPa

- P film :

-

Oil film pressure, MPa

- \(P_{1/2}\) :

-

Pressure at the ring bank, MPa

- R :

-

Gas constant

- t :

-

Time, s

- T :

-

Gas temperature, °C

- R 2 :

-

Coefficient of determination

- R adj 2 :

-

Adjusted coefficient of determination

- R pred 2 :

-

Predicted coefficient of determination

- \(\rho\) :

-

Lubricating oil density

- \(\eta\) :

-

Dynamic viscosity of the lubricating oil

- \(\Delta t\) :

-

Time step, s

- \(\Delta r\) :

-

Relative displacement of top ring, mm

- \(\Delta \overline{u}\) :

-

Average speed difference of the oil film

- \(\beta\) :

-

Material transfer coefficient

References

Zhang S, Chen WY (2021) China’s energy transition pathway in a carbon neutral vision. Engineering. https://doi.org/10.1016/j.eng

Roper E, Wang YD, Zhang ZC (2022) Numerical investigation of the application of miller cycle and low-carbon fuels to in-crease diesel engine efficiency and reduce emissions. Energies 15(5):1783. https://doi.org/10.3390/en15051783

Zottin W, Clemente M, Leite JMM (1995) Predictive analysis of lube oil consumption for a diesel engine. SAE Trans 104:949–954. https://doi.org/10.2307/44633267

Gohl M, Matz G, Preuss A-C, Pischinger S, Günther M, Ebert T (2018) Investigation of oil sources in the combustion chamber of direct injection gasoline engines. SAE Tech Pap. https://doi.org/10.4271/2018-01-1811

Rabuté R, Tian T (2001) Challenges involved in piston top ring designs for modern SI engines. J Eng Gas Turbines Power 123(2):448–459. https://doi.org/10.1115/1.1364520

Tian T (2002) Dynamic behaviours of piston rings and their practical impact. Part 2: oil transport, friction and wear of ring/liner interface and the effects of piston and ring dynamics. Proc Inst Mech Eng Part J J Eng Tribol 216(4):229–247. https://doi.org/10.1243/135065002760199970

Mitsuhiro S, Yasuo H, Toshiro H, Yutaro W (2017) Study on lubricating oil consumption from evaporation of oil-film on cylinder wall for diesel engine. SAE Int J Fuels Lubr 10(2):487–501. https://doi.org/10.4271/2017-01-0883

Yang HX, Lei JL, Wen J, Wen ZG, Shen LZ (2021) Study on lube oil consumption characteristics of high-pressure common-rail diesel engine. Chin Intern Combust Engine Eng 42(2):104–108. https://doi.org/10.13949/j.cnki.nrjgc.2021.02.014

Tornehed P, Olofsson U (2011) Lubricant ash particles in diesel engine exhaust. Literature review and modelling study. Proc Inst Mech Eng Part D J Automob Eng 225(8):1055–1066. https://doi.org/10.13949/j.cnki.nrjgc.2021.02.014

Duvvuri PP, Shrivastava RK, Sukumaran S, Sreedhara S (2020) Numerical modeling of thermophoretic deposition on cylinder liner of a diesel engine using a sectional soot model. J Aerosol Sci 139:105464. https://doi.org/10.1016/j.jaerosci.2019.105464

Whitacre S (2021) Low-metal engine oil reduces ash loading. ATZheavy Duty Worldwide 14(4):38–41. https://doi.org/10.1007/s41321-021-0446-y

Kim JH, Kim KH, Lee JM (2018) Effect of the properties of diesel engine oil and aging on exhaust gases and DPF. Tribol Lubr 34(6):292–299. https://doi.org/10.9725/kts.2018.34.6.292

Feng DQ, Khalifa B, Zhao H, Wei HQ, Chen CY (2019) Investigation of lubricant induced pre-ignition and knocking combustion in an optical spark ignition engine. Proc Combust Inst 37(4):4901–4910. https://doi.org/10.1016/j.proci.2018.07.061

Distaso E, Amirante R, Calò G, Palma PD, Reitz RD (2020) Predicting lubricant oil induced pre-ignition phenomena in modern gasoline engines: the reduced gas lube reaction mechanism. Fuel 281:118709. https://doi.org/10.1016/j.fuel.2020.118709

Li J, Zuo ZX, Jia BR, Feng HH, Wei YD, Zhang ZY, Small-bone A, Paul RA (2021) Comparative analysis on friction characteristics between free-piston engine generator and traditional crankshaft engine. Energy Convers Manag 245:104–108. https://doi.org/10.1016/j.enconman.2021.114630

Lei JL, Wen J, Song GF, Shen LZ, Bi YH (2015) The effect of piston structural parameters on the lubricating oil consumption of diesel engines. Chin Intern Combust Engine Eng 36(4):126–132. https://doi.org/10.13949/j.cnki.nrjgc.2015.04.024

Nakamura M, Hayashi H, Ito A (2005) A study on the mechanism of lubricating oil consumption of diesel engines-2nd report: mechanism of oil film generation on piston skirt. Trans Soc Autom Eng Jpn 36(3):141–143

Lei QM, Lei JL, Deng XW, Xin QF, Wen J, Wen ZG (2021) Influence of piston component structural parameters on sealing performance of a diesel engine. Chin Intern Combust Engine Eng 42(4):47–53. https://doi.org/10.13949/j.cnki.nrjgc.2021.04.007

Zhang JH, Zhang GC, Zhenpeng HE, Lin JW, Liu H (2013) Analysis of oil consumption in cylinder of diesel engine for optimization of piston rings. Chin J Mech Eng 26(1):207–216. https://doi.org/10.3901/CJME.2013.01.207

Lei JL, Zhang DS, Deng XW, Bi YH, Zhou F, Yang YZ (2018) Influence of piston ring component structural parameters on diesel engine blow-by and oil consumption. Trans Chin Soc Agric Eng 34(5):54–62. https://doi.org/10.11975/j.issn.1002-6819.2018.05.008

Kagnici F, Akalin O (2014) The effect of cylinder bore distortion on lube oil consumption and blow-by. J Tribol 136(1):011103. https://doi.org/10.1115/1.4025208

Sun J, Zhang X, Zhu JX, Gao YM, Zhu G, Wang H, Zhao XY, Teng Q, Ren YP, Zhu GX (2020) On the lubrication characteristics of piston ring under different engine operation conditions. Ind Lubr Tribol 72(1):101–108. https://doi.org/10.1108/ILT-06-2019-0220

Bi YH, Wang P, Luo L, Wang H, Xin QF, Lei JL, Shen LZ (2021) Analysis of out-of-round deformation of a dry cylinder liner of a non-road high-pressure common-rail diesel engine based on multi-field coupling. J Braz Soc Mech Sci Eng. https://doi.org/10.1007/s40430-020-02737-0

Tian T, Wong VW (2000) Modeling the lubrication, dynamics, and effects of piston dynamic tilt of twin-land oil control rings in internal combustion engines. J Eng Gas Turbines Power 122(1):119–129. https://doi.org/10.1115/1.483183

Wang Z, Ahling S, Tian T (2021) Modeling the three piece oil control ring dynamics and oil transport in internal combustion engines. In: SAE WCX Digital Summit

Zhou L, Bai ML, Sun GH (2019) 3D heat transfer, lubrication and friction coupled study for piston ring-liner on diesel engines. J Mech Sci Technol 33(2):939–953. https://doi.org/10.1007/s12206-019-0151-2

Herbst HM, Priebsch HH (2000) Simulation of piston ring dynamics and their effect on oil consumption. SAE Trans 109(3):862–873. https://doi.org/10.2307/44634272

Miao R, Jing G, Zeng X, Ge H (2020) Optimization of piston-ring system for reducing lube oil consumption by CAE approach. SAE Tech Pap. https://doi.org/10.4271/2020-01-1339

Ji-Young K, Jee-Woon K, Myung-Rae C, Dong-Chul H (2002) Fric-tion characteristics of piston ring pack with consideration of mixed lubrication: parametric investigation. KSME Int J 16(4):468–475. https://doi.org/10.1007/BF03185076

Yang HX, Lei JL, Deng XW, Wen J, Wen ZG, Song GF, Mo R (2021) Research on the influence of key structural parameters on piston secondary motion. Sci Rep 11(1):19080. https://doi.org/10.1038/s41598-021-98686-2

Carley KM, Kamneva NY, Reminga J (2004) Response surface methodology. Wiley

Sitkei G (1964) Kraftstoffaufbereitung und Verbrennung bei Dieselmotoren. Springer, Berlin

Wang J, Shen LZ, Yang YZ, Bi YH, Wan MD (2017) Optimizing calibration of design points for non-road high pressure com-mon rail diesel engine base on response surface methodology. Trans Chin Soc Agric Eng 33(3):31–39. https://doi.org/10.11975/j.issn.1002-6819.2017.03.005

Funding

This work was supported by the Chinese National Natural Science Foundation [Grant Nos. 51965027, 51805233]. Numerial computations were performed on Hefei advanced computing center.

Author information

Authors and Affiliations

Contributions

JL was involved in conceptualization, funding acquisition, supervision and project administration. JT was involved in conceptualization, data curation, results analysis, investigation, writing—original draft and model validation. QL was involved in experiment, data curation, model validation and results analysis. YL was involved in visualization, validation, writing—review and editing and investigation. XD was involved in funding acquisition, supervision and conceptualization. GS was involved in resources and investigation. KL was involved in resources and validation.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Technical Editor: Zilda de Castro Silveira.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lei, J., Tang, J., Lei, Q. et al. Study on the influence of piston ring assembly structure on lubricating oil consumption and optimization design. J Braz. Soc. Mech. Sci. Eng. 45, 388 (2023). https://doi.org/10.1007/s40430-023-04304-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04304-9