Abstract

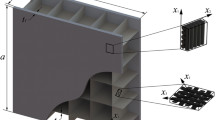

In this paper, the dynamic response of fiber-metal laminate (FML) double-layer sandwich plates under blast loading is studied through theoretical analysis and finite element (FE) calculation. The membrane mode solution is obtained for the dynamic response of the clamped FML double-layer sandwich plate under blast loading, and the so-called ‘bounds’ are obtained through circumscribing and inscribing lines of the exact yield locus. The FE model is established, and the analytical model is proved by the FE method. The influences of geometrical parameters and material properties on the dynamic response of FML double-layer sandwich plates are researched based on the analytical model. Finally, it is found that FML double-layer sandwich plates have better anti-explosion performance with equal mass by comparing with the metal sandwich plates.

Similar content being viewed by others

References

Liu JL, Liu JY, Mei J et al (2018) Investigation on manufacturing and mechanical behavior of all composite sandwich structure with Y-shaped cores. Compos Sci Technol 159:87–102

Mahdi KM, Vahid B (2016) Bending and buckling analysis of corrugated composite sandwich plates. J Braz Soc Mech Sci 38(8):2571–2588

Tao Y, Li WG, Cheng TB et al (2021) Out-of-plane dynamic crushing behavior of joint-based hierarchical honeycombs. J Sandwich Struct Mater 23(7):2832–2855

Zhang JX, Qin QH, Ai WL et al (2016) Indentation of metal foam core sandwich beams: experimental and theoretical investigations. Exp Mech 56:771–784

Wang ZG, Deng JJ, Liu K et al (2022) Hybrid hierarchical square honeycomb with widely tailorable effective in-plane elastic modulus. Thin Wall Struct 171:108816

Zhang Y, Li YG, Guo KL et al (2021) Dynamic mechanical behaviour and energy absorption of aluminium honeycomb sandwich panels under repeated impact loads. Ocean Eng 219:108344

Yang JS, Xiong J, Ma L et al (2013) Vibration and damping characteristics of hybrid carbon fiber composite pyramidal truss sandwich panels with viscoelastic layers. Compos Struct 106:570–580

Peng Y, Wei K, Mei M et al (2021) Simultaneously program thermal expansion and Poisson’s ratio in three dimensional mechanical metamaterial. Compos Struct 262:113365

Cai SP, Zhang P, Dai WX et al (2019) Multi-objective optimization for designing metallic corrugated core sandwich panels under air blast loading. J Sandw Struct Mater 23:1192–1220

Sun Z, Chen HJ, Song ZW et al (2021) Three-point bending properties of carbon fiber/honeycomb sandwich panels with short-fiber tissue and carbon-fiber belt interfacial toughening at different loading rate. Compos A 143:106289

Zhang JX, Wu XW, Sun H et al (2022) Plastic behaviour of foam-filled X-shaped core sandwich beam. J Braz Soc Mech Sci 44:355

Chen XJ, Yu GC, Wang ZX et al (2021) Enhancing out-of-plane compressive performance of carbon fiber composite honeycombs. Compos Struct 255:112984

Zhang JX, Ye Y, Qin QH et al (2018) Low-velocity impact of sandwich beams with fibre-metal laminate face-sheets. Compos Sci Technol 168:152–159

Xiong J, Vaziri A, Ma L et al (2012) Compression and impact testing of two-layer composite pyramidal-core sandwich panels. Compos Struct 94:793–801

Sinmazçelik T, Avcu E, Bora MÖ et al (2011) A review: fibre metal laminates, background, bonding types and applied test methods. Mater Des 32:3671–3685

Dharmasena K, Queheillalt D, Wadley H et al (2009) Dynamic response of a multilayer prismatic structure to impulsive loads incident from water. Int J Impact Eng 36:632–643

Fan HL, Zhou Q, Yang W et al (2011) Experimental research of compressive responses of multilayered woven textile sandwich panels under quasi-static loading. Compos B 41(8):686–692

Fleck NA, Deshpande VS (2004) The resistance of clamped sandwich beams to shock loading. ASME J Appl Mech 71:386–401

Qiu X, Deshpande VS (2004) Fleck NA (2004) Dynamic response of a clamped circular sandwich plate subject to shock loading. ASME J Appl Mech 71(5):637–645

Qin QH, Wang TJ (2009) A theoretical analysis of the dynamic response of metallic sandwich beam under impulsive loading. Eur J Mech A/Solids 28:1014–1025

Zhang JX, Qin QH, Wang TJ (2013) Compressive strengths and dynamic response of corrugated metal sandwich plates with unfilled and foam-filled sinusoidal plate cores. Acta Mech 224:759–775

Cui X, Zhao L, Wang Z et al (2012) A lattice deformation based model of metallic lattice sandwich plates subjected to impulsive loading. Int J Solids Struct 49(19–20):2854–2862

Feng Z, Wang Z, Lu G et al (2010) Some theoretical considerations on the dynamic response of sandwich structures under impulsive loading. Int J Impact Eng 37(6):625–637

Qin QH, Yuan C, Zhang JX et al (2014) Large deflection response of rectangular metal sandwich plates subjected to blast loading. Eur J Mech A/Solids 47:14–22

Zhu F, Wang ZH, Lu GX et al (2009) Analytical investigation and optimal design of sandwich panels subjected to shock loading. Mater Des 30:91–100

Zhu F, Zhao LM, Lu GX et al (2008) Structural response and energy absorption of sandwich panels with an aluminium foam core under blast loading. Adv Struct Eng 11(5):525–536

Rezasefat M, Mostofi TM, Ozbakkaloglu T (2019) Repeated localized impulsive loading on monolithic and multi-layered metallic plates. Thin Wall Struct 144:106332

Mostofi TM, Babaei H, Alitavoli M et al (2019) Large transverse deformation of double-layered rectangular plates subjected to gas mixture detonation load. Int J Impact Eng 125:93–106

Ziya-Shamami M, Babaei H, Mostofi TM et al (2020) Structural response of monolithic and multi-layered circular metallic plates under repeated uniformly distributed impulsive loading: an experimental study. Thin-Wall Struct 157:107024

Zhang JX, Zhou RF, Wang MS et al (2018) Dynamic response of double-layer rectangular sandwich plates with metal foam cores subjected to blast loading. Int J Impact Eng 122:265–275

Cai S, Liu J, Zhang P et al (2019) Dynamic response of sandwich panels with multi-layered aluminum foam/UHMWPE laminate cores under air blast loading. Int J Impact Eng 138:103475

Liang MZ, Li XY, Lin YL et al (2020) Influence of multi-layer core on the blast response of composite sandwich cylinders. Int J Appl Mech 12(2):2050018

Wang ZQ, Zhou YB, Wang XH et al (2017) Multi-objective optimization design of a multi-layer honeycomb sandwich structure under blast loading. Proc Inst Mech Eng D 231(10):1449–1458

Cui J, Ye RC, Zhao N et al (2019) Assessment on energy absorption of double layered and sandwich plates under ballistic impact. Thin Wall Struct 130:520–534

Selvaraj R, Subramani M, More G et al (2021) Dynamic responses of laminated composite sandwich beam with double-viscoelastic core layers. Mater Today Proc 46:7468–7472

Zhu YF, Sun YG (2021) Low-velocity impact response of multilayer foam core sandwich panels with composite face sheets. Int J Mech Sci 209:106704

AL-Shamary AKJ, Karakuzu R, Ozdemir O, et al (2016) Low-velocity impact response of sandwich composites with different foam core configurations. J Sandwich Struct Mater 18(6):754–768

Zhang JX, Ye Y, Qin QH (2019) On dynamic response of rectangular sandwich plates with fibre-metal laminate face-sheets under blast loading. Thin Wall Struct 144:106288

Ma XM, Li X, Li SQ et al (2018) Blast response of gradient honeycomb sandwich panels with basalt fiber metal laminates as skins. Int J Impact Eng 123:126–139

Baştürk SB, Tanoğlu M, Çankaya MA et al (2016) Dynamic behavior predictions of fiber-metal laminate/aluminum foam sandwiches under various explosive weights. J Sandw Struct Mater 18:321–342

Zhang JX, Zhu YQ, Li KK et al (2022) Dynamic response of sandwich plates with GLARE face-sheets and honeycomb core under metal foam projectile impact: Experimental and numerical investigations. Int J Impact Eng 164:10420

Liu C, Zhang YX, Ye L (2017) High velocity impact responses of sandwich panels with metal fibre laminate skins and aluminium foam core. Int J Impact Eng 100:139–153

Reyes G (2010) Mechanical behavior of thermoplastic FML-reinforced sandwich panels using an aluminum foam core: experiments and modeling. J Sandwich Struct Mater 12:81–96

Liu C, Zhang YX, Li J (2017) Impact responses of sandwich panels with fibre metal laminate skins and aluminium foam core. Compos Struct 182:183–190

Jones N (2017) Note on the impact behaviour of fibre-metal laminates. Int J Impact Eng 108:147–152

Jones N (1989) Structural impact. Cambridge University, Cambridge

Jones N (1971) A theoretical study of the dynamic plastic behavior of beams and plates with finite-deflections. Int J Solids Struct 7:1007–1029

Qiu X, Deshpande VS, Fleck NA (2005) Impulsive loading of clamped monolithic and sandwich beams over a central patch. J Mech Phys Solids 53:1015–1046

Qin QH, Wang TJ (2007) Impulsive loading of a fully clamped circular metallic foam core sandwich plate.In: Proceedings of the 7th international conference on shock & impact loads on structures. pp 481–488.

Cloete TJ, Nurick GN (2014) On the influence of radial displacements and bending strains on the large deflections of impulsively loaded circular plates. Int J Mech Sci 82:140–148

Mehreganian N, Louca L, Langdon G et al (2018) The response of mild steel and armour steel plates to localised air-blast loading-comparison of numerical modelling techniques. Int J Impact Eng 115:81–93

Barras G, Souli M, Aquelet N et al (2012) Numerical simulation of underwater explosions using an ALE method. The pulsating bubble phenomena, Ocean Eng 41:53–66

Henchie TF, Yuen SCK, Nurick G et al (2014) The response of circular plates to repeated uniform blast loads: An experimental and numerical study. Int J Impact Eng 74:36–45

Behtaj M, Babaei H, Mostofi TM (2022) Repeated uniform blast loading on welded mild steel rectangular plates. Thin Wall Struct 178:109523

Cerik BC (2017) Damage assessment of marine grade aluminium alloy-plated structures due to air blast and explosive loads. Thin Wall Struct 110:123–132

Park BE, Cho SR (2006) Simple design formulae for predicting the residual damage of unstiffened and stiffened plates under explosion loadings. Int J Impact Eng 32:1721–1736

Deshpande VS, Fleck NA (2000) Isotropic constitutive models for metallic foams. J Mech Physics Solids 48:1253–1283

Tagarielli VL, Fleck NA, Deshpande VS (2004) Collapse of clamped and simply supported composite sandwich beams in three-point bending. Compos B 35(6–8):523–534

Acknowledgements

The authors are grateful for their financial support through the Fund for the Shandong Key Laboratory of Civil Engineering Disaster Prevention and Mitigation (CDPM2021KF07) and NSFC (12272290 and 11872291), opening project of State Key Laboratory of Structural Analysis for Industrial Equipment, China (GZ22110).

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: The inscribing coefficient of inscribing yield criterion

Appendix A: The inscribing coefficient of inscribing yield criterion

The inscribing coefficient of compressed double-layer metal sandwich section is given in Ref. [30], and the inscribing coefficient of compressed sandwich section with FML face-sheets \(\vartheta^{\prime}\) can be expressed as

where

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Du, J., Su, H., Bai, J. et al. On dynamic response of double-layer rectangular sandwich plates with FML face-sheets and metal foam cores under blast loading. J Braz. Soc. Mech. Sci. Eng. 45, 31 (2023). https://doi.org/10.1007/s40430-022-03956-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03956-3