Abstract

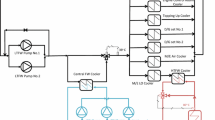

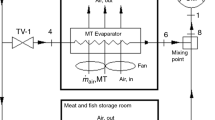

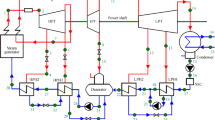

Ship refrigeration compressors are sized to provide required capacity under extreme atmospheric and sea water temperatures, as well as full load and pulldown rates. Refrigeration compressors usually operate at 50–60 Hz in on/off mode at partial load in cold and temperate sea waters. The most efficient way to meet variable cooling demands is to change refrigerant mass flow by adjusting compressor speed. This paper is based on experimental investigation of ship cold storage refrigeration system on laboratory scale. Compressor is driven by inverter, and condenser is water-cooled type just like on ships. The refrigeration compressor has a power range of 600–1000 W and a maximum power of 1500 W. The system’s refrigeration capacity ranges from 500 to 1350 W, with a maximum capacity of 2000 W. Experimental results were subjected to energy and exergy analyses. At 60 Hz, exergy efficiencies of compressor, condenser, expansion valve, and cold storage are 37.9%, 91.1%, 86.2%, and 69.8%, at − 5 °C cold storage and 18 °C water temperatures. In the same order, they contributed 73.2%, 7.6%, 10.4%, and 7% to wasted power. When water temperature increased from 18 to 35 °C at − 5 °C storage temperature and 50 Hz, coefficient of performance (COP) decreased by 55.2%. Despite compressor's thermodynamic irreversibility decreasing, combined electrical–mechanical efficiency deteriorated as frequency decreased. When compressor frequency was reduced from 60 to 40 Hz at − 5 °C cold storage and 18 °C water temperatures, COP increased by 13.9%.

Similar content being viewed by others

Abbreviations

- f :

-

Frequency (Hz)

- h :

-

Specific enthalpy (J/kg)

- \(\dot{m}\) :

-

Mass flow rate (kg/s)

- p :

-

Pressure (Pa, bar)

- \(\dot{Q}\) :

-

Heat transfer rate (W)

- s:

-

Specific entropy (J/kg °C)

- T :

-

Temperature (°C)

- V :

-

Cylinder volume (m3)

- \(\dot{W}\) :

-

Power (W)

- \({\eta }_{\mathrm{I}}\) :

-

First law efficiency

- \({\eta }_{\mathrm{II}}\) :

-

Exergy efficiency

- υ :

-

Specific volume (m3/kg)

- \(\dot{X}\) :

-

Exergy transfer rate (J/s)

- ψ :

-

Flow exergy (J/kg)

- in:

-

Inlet of components

- o:

-

Dead state

- out:

-

Outlet of components

- ref:

-

Refrigerant

- w:

-

Water

References

Başhan V, Kökkülünk G (2020) Exergoeconomic and air emission analyses for marine refrigeration with waste heat recovery system: a case study. J Mar Eng Technol 19:147–160. https://doi.org/10.1080/20464177.2019.1656324

Dere C, Deniz C (2019) Load optimization of central cooling system pumps of a container ship for the slow steaming conditions to enhance the energy efficiency. J Clean Prod 222:206–217. https://doi.org/10.1016/j.jclepro.2019.03.030

IMO (2021) Highlights and executive summary of the fourth IMO GHG study 2020. International Maritime Organization, London

Cao T, Lee H, Hwang Y et al (2015) Performance investigation of engine waste heat powered absorption cycle cooling system for shipboard applications. Appl Therm Eng 90:820–830. https://doi.org/10.1016/j.applthermaleng.2015.07.070

IMO-MARPOL (2021) International convention for the prevention of pollution from ships. https://www.imo.org/en/About/Conventions/Pages/International-Convention-for-the-Prevention-of-Pollution-from-Ships-(MARPOL).aspx. Accessed 20 Aug 2021

ASHRAE (2010) ASHRAE handbook—refrigeration. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc., Atlanta

Fitzgerald WB, Howitt OJA, Smith IJ, Hume A (2011) Energy use of integral refrigerated containers in maritime transportation. Energy Policy 39:1885–1896. https://doi.org/10.1016/j.enpol.2010.12.015

Pigani L, Boscolo M, Pagan N (2016) Marine refrigeration plants for passenger ships: low-GWP refrigerants and strategies to reduce environmental impact. Int J Refrig 64:80–92. https://doi.org/10.1016/j.ijrefrig.2016.01.016

Cao T, Lee H, Hwang Y et al (2016) Modeling of waste heat powered energy system for container ships. Energy 106:408–421. https://doi.org/10.1016/j.energy.2016.03.072

Salmi W, Vanttola J, Elg M et al (2017) Using waste heat of ship as energy source for an absorption refrigeration system. Appl Therm Eng 115:501–516. https://doi.org/10.1016/j.applthermaleng.2016.12.131

Castelein B, Geerlings H, Van Duin R (2020) The reefer container market and academic research: a review study. J Clean Prod 256:120654. https://doi.org/10.1016/j.jclepro.2020.120654

Harbach J (2005) Marine refrigeration and air-conditioning. Cornell Maritime Press, Atglen

Cengel YA, Ghajar AJ (2015) Heat and mass transfer: fundamentals and applications. McGraw-Hill, New York

ASHRAE (2013) ASHRAE handbook—fundamentals. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc., Atlanta

Diniz MC, Melo C, Deschamps CJ (2018) Experimental performance assessment of a hermetic reciprocating compressor operating in a household refrigerator under on–off cycling conditions. Int J Refrig 88:587–598. https://doi.org/10.1016/j.ijrefrig.2018.03.024

Li W (2013) Simplified steady-state modeling for variable speed compressor. Appl Therm Eng 50:318–326. https://doi.org/10.1016/j.applthermaleng.2012.08.041

Jolly PG, Tso CP, Wong YW, Ng SM (2000) Simulation and measurement on the full-load performance of a refrigeration system in a shipping container. Int J Refrig 23:112–126. https://doi.org/10.1016/S0140-7007(99)00044-4

Brown E, Colling A, Park D et al (2004) Seawater: its composition, properties and behaviour. Butterworth-Heinemann in Association with the Open University, Oxford

IMO-MEPC (2016) 2016 guidelines for the development of a ship energy efficiency management plan (SEEMP). https://gmn.imo.org/wp-content/uploads/2017/05/MEPC-28270-2017-SEEMP-Guidelines.pdf. Accessed 10 Aug 2021

Perreira EP, Parise JAR (1993) Performance analysis of capacity control devices for heat pump reciprocating compressors. Heat Recover Syst CHP 13:451–461. https://doi.org/10.1016/0890-4332(93)90046-X

Tassou S, Qureshi T (1998) Comparative performance evaluation of positive displacement compressors in variable-speed refrigeration applications. Int J Refrig 21:29–41. https://doi.org/10.1016/S0140-7007(97)00082-0

Aprea C, Renno C (2004) An experimental analysis of a thermodynamic model of a vapour compression refrigeration plant on varying the compressor speed. Int J Energy Res 28:537–549. https://doi.org/10.1002/er.983

Nasution H, Wan Hassan MN (2006) Potential electricity savings by variable speed control of compressor for air conditioning systems. Clean Technol Environ Policy 8:105–111. https://doi.org/10.1007/s10098-006-0040-0

Aprea C, Mastrullo R, Renno C (2009) Determination of the compressor optimal working conditions. Appl Therm Eng 29:1991–1997. https://doi.org/10.1016/j.applthermaleng.2008.10.002

Ekren O, Celik S, Noble B, Krauss R (2013) Performance evaluation of a variable speed DC compressor. Int J Refrig 36:745–757. https://doi.org/10.1016/j.ijrefrig.2012.09.018

Piedrahita-Velásquez CA, Ciro-Velásquez HJ, Gómez-Botero MA (2014) Identification and digital control of a household refrigeration system with a variable speed compressor. Int J Refrig 48:178–187. https://doi.org/10.1016/j.ijrefrig.2014.09.009

Dechesne BJ, Tello-Oquendo FM, Gendebien S, Lemort V (2019) Residential air-source heat pump with refrigerant injection and variable speed compressor: experimental investigation and compressor modeling. Int J Refrig 108:79–90. https://doi.org/10.1016/j.ijrefrig.2019.08.034

Elsayed AO, Kayed TS (2020) Dynamic performance analysis of inverter-driven split air conditioner. Int J Refrig 118:443–452. https://doi.org/10.1016/j.ijrefrig.2020.05.014

Ozsipahi M, Kose HA, Cadirci S et al (2019) Experimental and numerical investigation of lubrication system for reciprocating compressor. Int J Refrig 108:224–233. https://doi.org/10.1016/j.ijrefrig.2019.08.026

Burt CM, Piao X, Gaudi F et al (2008) Electric motor efficiency under variable frequencies and loads. J Irrig Drain Eng 134:129–136. https://doi.org/10.1061/(asce)0733-9437(2008)134:2(129)

Wang G, Han Z (2019) Investigation of the accuracy of VFD analog output data and the energy performance of different voltage controls in a VFD-motor-belt-fan system. Energy Build 194:260–272. https://doi.org/10.1016/j.enbuild.2019.04.008

Koury RNN, Machado L, Ismail KAR (2001) Numerical simulation of a variable speed refrigeration system. Int J Refrig 24:192–200. https://doi.org/10.1016/S0140-7007(00)00014-1

Ust Y, Sinan Karakurt A, Gunes U (2016) Performance analysis of Multipurpose Refrigeration System (MRS) on fishing vessel. Pol Marit Res 23:48–56. https://doi.org/10.1515/pomr-2016-0020

Su P, Ji J, Cai J et al (2020) Dynamic simulation and experimental study of a variable speed photovoltaic DC refrigerator. Renew Energy 152:155–164. https://doi.org/10.1016/j.renene.2020.01.047

Lee C-H, Liu Z-W, Chen C-N et al (2015) Assessment of energy savings with variable speed drives in ship’s cooling pumps. IEEE Trans Energy Convers 30:1288–1298. https://doi.org/10.1109/TEC.2015.2431733

Pariotis, Zannis, Katsanis (2019) An integrated approach for the assessment of central cooling retrofit using variable speed drive pump in marine applications. J Mar Sci Eng 7:253. https://doi.org/10.3390/jmse7080253

Liang Y, Shu G, Tian H et al (2013) Analysis of an electricity-cooling cogeneration system based on RC-ARS combined cycle aboard ship. Energy Convers Manag 76:1053–1060. https://doi.org/10.1016/j.enconman.2013.08.056

Ammar NR, Sediek IS (2018) Thermo-economic analysis and environmental aspects of absorption refrigeration unit operation onboard marine vehicles: Ro-Pax vessel case study. Pol Marit Res 25:94–103. https://doi.org/10.2478/pomr-2018-0100

Kasera S, Nayak R, Chandra Bhaduri S (2021) Performance analysis of solar milk refrigerator using energy efficient R290. Case Stud Therm Eng 24:100855. https://doi.org/10.1016/j.csite.2021.100855

Cebi S, Celik M, Kahraman C, Er ID (2009) An expert system towards solving ship auxiliary machinery troubleshooting: SHIPAMTSOLVER. Expert Syst Appl 36:7219–7227. https://doi.org/10.1016/j.eswa.2008.09.060

Morris AS, Langari R (2012) Measurement and instrumentation: theory and application. Academic Press, San Diego

Cengel YA, Boles MA (2015) Thermodynamics: an engineering approach. McGraw-Hill, New York

Kızılkan Ö, Kabul A, Yakut AK (2010) Exergetic performance assessment of a variable-speed R404a refrigeration system. Int J Energy Res 34:463–475. https://doi.org/10.1002/er.1553

Hundy GH, Trott AR, Welch TC (2008) Refrigeration and air-conditioning. Butterworth-Heinemann, Oxford

Aprea C, Renno C (2009) Experimental model of a variable capacity compressor. Int J Energy Res 33:29–37. https://doi.org/10.1002/er.1468

Shao S, Shi W, Li X, Chen H (2004) Performance representation of variable-speed compressor for inverter air conditioners based on experimental data. Int J Refrig 27:805–815. https://doi.org/10.1016/j.ijrefrig.2004.02.008

Cho H, Chung JT, Kim Y (2003) Influence of liquid refrigerant injection on the performance of an inverter-driven scroll compressor. Int J Refrig 26:87–94. https://doi.org/10.1016/S0140-7007(02)00017-8

Acknowledgements

This work has been supported by Yildiz Technical University Scientific Research Projects Coordination Unit under Project Number 2015-10-02-KAP02. We also would like to thank Mr. Doğan Tuptaş, Hakan Bakır, Kenan Arı, Hüseyin, and İsmet for their assistance in building the experimental setup.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Jader Barbosa Jr.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yilmaz, O., Bayar, H., Başhan, V. et al. Experimental energy and exergy analyses of ship refrigeration system operated by frequency inverter at varying sea water temperatures. J Braz. Soc. Mech. Sci. Eng. 44, 133 (2022). https://doi.org/10.1007/s40430-022-03439-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03439-5