Abstract

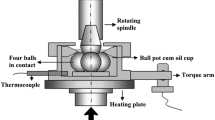

The development of basestock oil derived from renewable sources has become crucial as the world oil reserves are depleting. In this study, samples based on pequi oil (Caryocarbrasiliensis) were obtained by hydrolysis and esterification reactions, using a long-chain alcohol (2-ethylhexanol). Tribological tests in a four-ball configuration were performed to evaluate the lubricating behavior. A comparison of the Stribeck curve of the bio-based sample with that of a mineral hydrotreated basestock oil showed that the samples from pequi oil had a lower friction coefficient at all studied sliding speeds, ranging from 0 to 9.33 × 105 μm/s. The friction coefficient of the bio-based sample was 30.7% lower than that of a mineral hydrotreated basestock oil sample. The wear scar diameters were 0.371 mm for the bio-based samples and 0.195 mm for the mineral oil. This tribological performance indicates that a bio-based sample obtained from pequi oil may be potentially used as a lubricant basestock oil.

Similar content being viewed by others

References

BP (2021) Statistical Review of World Energy - 70th edition. https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2021-full-report.pdf

Energy Information Agency (2019) Annual energy outlook 2019 with projections to 2050 https://www.eia.gov/outlooks/aeo/pdf/aeo2019.pdf

Pillot B, Muselli M, Poggi P, Dias JB (2019) Historical trends in global energy policy and renewable power system issues in Sub-Saharan Africa: the case of solar PV. Energy Policy 127:113–124. https://doi.org/10.1016/j.enpol.2018.11.049

Attia NK, El-Mekkawi SA, Elardy OA, Abdelkader EA (2020) Chemical and rheological assessment of produced biolubricants from different vegetable oils. Fuel 271:117578. https://doi.org/10.1016/j.fuel.2020.117578

Tulashie SK, Kotoka F (2020) The potential of castor, palm kernel, and coconut oils as biolubricant base oil via chemical modification and formulation. Therm Sci Eng Prog 16:100480. https://doi.org/10.1016/j.tsep.2020.100480

Fernandes KV, Cavalcanti ED, Cipolatti EP, Aguieiras EC, Pinto MC, Tavares FA, Assunção CL (2020) Enzymatic synthesis of biolubricants from by-product of soybean oil processing catalyzed by different biocatalysts of Candida rugosa lipase. CatalToday. https://doi.org/10.1016/j.cattod.2020.03.060

Aguieiras ÉC, Cavalcanti ED, da Silva PR, Soares VF, Fernandez-Lafuente R, Assunção CLB, Freire DM (2020) Enzymatic synthesis of neopentyl glycol-bases biolubricants using biodiesel from soybean and castor bean as raw materials. Renew Energy 148:689–696. https://doi.org/10.1016/j.renene.2019.10.156

Caryocaraceae (2017) In: Flora do Brasil 2020 em construção Jardim Botânico do Rio de Janeiro Available fromhttp://floradobrasil.jbrj.gov.br/reflora/floradobrasil/FB47900

Guedes AMM, Antoniassi R, de Faria-Machado AF (2017) Pequi: a Brazilian fruit with potential uses for the fat industry. OCL 24(5):D507

Johner JCF, Hatami T, Meireles MAA (2018) Developing a supercritical fluid extraction method assisted by cold pressing for extraction of pequi (Caryocar brasiliense). J Supercrit Fluids 137:34–39

Oliveira MEBD, Guerra NB, Maia ADHN, Alves RE, Xavier DDS, Matos NMDS (2009) Caracterização física de frutos do pequizeiro nativos da chapada do Araripe-CE. Rev Bras Frutic 31(4):1196–1201. https://doi.org/10.1590/S0100-29452009000400038

dos Santos Alves CE, Belarmino LC, Padula AD (2017) Feedstock diversification for biodiesel production in Brazil: using the policy analysis matrix (PAM) to evaluate the impact of the PNPB and the economic competitiveness of alternative oilseeds. Energy Policy 109:297–309. https://doi.org/10.1016/j.enpol.2017.07.009

Silva TA, de Assunção RMN, Vieira AT, de Oliveira MF, Batista ACF (2014) Methylic and ethylic biodiesels from pequi oil (CaryocarbrasilienseCamb.): production and thermogravimetric studies. Fuel 136:10–18. https://doi.org/10.1016/j.fuel.2014.07.035

dos Santos RCM, Gurgel PC, Pereira NS, Breves RA, de Matos PRR, Silva LP, Lopes RDVV (2020) Ethyl esters obtained from pequi and macaúba oils by transesterification with homogeneous acid catalysis. Fuel 259:116206. https://doi.org/10.1016/j.fuel.2019.116206

Cardoso CMM, Zavarize DG, Vieira GEG (2019) Transesterification of Pequi (CaryocarbrasiliensisCamb) bio-oil via heterogeneous acid catalysis: catalyst preparation, process optimization and kinetics. Indus Crops Prod 139:111485. https://doi.org/10.1016/j.indcrop.2019.111485

Ferreira EN, Arruda TBMG, Rodrigues FEA, Arruda DTD, da Silva Junior JH, Porto DL, Ricardo NMPS (2019) Investigation of the thermal degradation of the biolubricant through TG-FTIR and characterization of the biodiesel–Pequi (Caryocarbrasiliensis) as energetic raw material. Fuel 245:398–405. https://doi.org/10.1016/j.fuel.2019.02.006

Biresaw G, Bantchev G (2008) Effect of chemical structure on film-forming properties of seed oils. J Synth Lubr 25(4):159–183. https://doi.org/10.1002/jsl.58

Suresha B, Hemanth G, Rakesh A, Adarsh KM (2019) Tribologicalbehaviour of pongamia oil as lubricant with and without halloysite nanotubes using four-ball tester. In AIP Conference Proceedings (Vol. 2128, No. 1, p. 030011) AIP Publishing LLC https://doi.org/10.1063/1.5117954

Zulkifli NWM, Masjuki HH, Kalam MA, Yunus R, Azman SSN (2014) Lubricity of bio-based lubricant derived from chemically modified jatropha methyl ester. JurnalTribologi 1:18–39

Sharma UC, Sachan S (2019) Friction and wear behavior of karanja oil derived biolubricant base oil. SN Appl Sci 1(7):668. https://doi.org/10.1007/s42452-019-0706-y

Dodos GS, Karonis D, Zannikos F, Lois E (2015) Renewable fuels and lubricants from Lunaria annua L. Ind Crops Prod 75:43–50. https://doi.org/10.1016/j.indcrop.2015.05.046

Zulkifli NWM, Kalam MA, Masjuki HH, Shahabuddin M, Yunus R (2013) Wear prevention characteristics of a palm oil-based TMP (trimethylolpropane) ester as an engine lubricant. Energy 54:167–173. https://doi.org/10.1016/j.energy.2013.01.038

Wu X, Zhang X, Yang S, Chen H, Wang D (2000) The study of epoxidized rapeseed oil used as a potential biodegradable lubricant. J Am Oil Chem Soc 77(5):561–563. https://doi.org/10.1007/s11746-000-0089-2

Zulkifli NWM, Azman SSN, Kalam MA, Masjuki HH, Yunus R, Gulzar M (2016) Lubricity of bio-based lubricant derived from different chemically modified fatty acid methyl ester. Tribol Int 93:555–562. https://doi.org/10.1016/j.triboint.2015.03.024

Stribeck R (1901) Ball bearings for any stress. Z des VDI 45:664

Stribeck R (1902) Die wesentlichenEigenschaften der Gleit-und Rollenlager (The basic properties of plain and roller bearing). Z VerDtschIng 46(36):1342–1348

Hamdan SH, Chong WWF, Ng JH, Ghazali MJ, Wood RJK (2017) Influence of fatty acid methyl ester composition on tribological properties of vegetable oils and duck fat derived biodiesel. Tribol Int 113:76–82. https://doi.org/10.1016/j.triboint.2016.12.008

Nguyen PT, Kravchuk O, Bhandari B, Prakash S (2017) Effect of different hydrocolloids on texture, rheology, tribology and sensory perception of texture and mouthfeel of low-fat pot-set yoghurt. Food Hydrocolloids 72:90–104. https://doi.org/10.1016/j.foodhyd.2017.05.035

Luo Y, Liu X, Pang Z (2019) Tribo-rheological properties of acid milk gels with different types of gelatin: effect of concentration. J Dairy Sci 102(9):7849–7862. https://doi.org/10.3168/jds.2019-16305

Mukherjee S, Ghosh M (2017) Studies on performance evaluation of a green plasticizer made by enzymatic esterification of furfuryl alcohol and castor oil fatty acid. Carbohyd Polym 157:1076–1084

Yunus R, Lye OT, Fakhru’l-Razi A, Basri S (2002) A simple capillary column GC method for analysis of palm oil-based polyol esters. J Am Oil Chem Soc 79(11):1075–1080. https://doi.org/10.1007/s11746-002-0606-3

ASTM International (2014) Standard test method for dynamic viscosity and density of liquids by Stabinger viscometer (and the calculation of kinematic viscosity) ASTM International

ASTM International (2006) Standard test method for kinematic viscosity of transparent and opaque liquids:(and Calculation of Dynamic Viscosity) ASTM International

Rade LL, Lemos COT, Barrozo MAS, Ribas RM, Monteiro RS, Hori CE (2018) Optimization of continuous esterification of oleic acid with ethanol over niobic acid. Renew Energy 115:208–216. https://doi.org/10.1016/j.renene.2017.08.035

Pessoa AS, Podesta R, Block JM, Franceschi E, Dariva C, Lanza M (2015) Extraction of pequi (Caryocarcoriaceum) pulp oil using subcritical propane: determination of process yield and fatty acid profile. J Supercrit Fluids 101:95–103. https://doi.org/10.1016/j.supflu.2015.03.006

Rios ÍC, Cordeiro JP, Arruda TB, Rodrigues FEA, Uchoa AF, Luna FMT, Ricardo NM (2020) Chemical modification of castor oil fatty acids (Ricinuscommunis) for biolubricant applications: an alternative for Brazil’s green market. Ind Crops Prod 145:112000. https://doi.org/10.1016/j.indcrop.2019.112000

Owuna FJ, Dabai MU, Sokoto MA, Dangoggo SM, Bagudo BU, Birnin-Yauri UA, Jibrin MS (2019) Chemical modification of vegetable oils for the production of biolubricants using trimethylolpropane: a review. Egypt J Pet. https://doi.org/10.1016/j.ejpe.2019.11.004

Duggal B (2013) Rheology – viscosity index In: Wang QJ, Chung YW (eds) Encyclopedia of tribology Springer, Boston, MA https://doi.org/10.1007/978-0-387-92897-5_961

Pirro DM, Daschner E (2001) Lubrication fundamentals. CRC Press, USA

Marques JPC, Rios IC, Arruda TBMG, Rodrigues FEA, Uchoa AFJ, de Luna FMT, Ricardo NMPS (2019) Potential bio-based lubricants synthesized from highly unsaturated soybean fatty acids: physicochemical properties and thermal degradation. Ind Eng Chem Res 58(38):17709–17717. https://doi.org/10.1021/acs.iecr.9b03038

Marques JPC, Rios ÍC, ParenteJr EJ, Quintella SA, Luna FMT, Cavalcante CL Jr (2019) Synthesis and characterization of potential bio-based lubricant basestocks via epoxidation process. J Am Oil Chem Soc. https://doi.org/10.1002/aocs.12317

Sripada PK, Sharma RV, Dalai AK (2013) Comparative study of tribological properties of trimethylolpropane-based biolubricants derived from methyl oleate and canola biodiesel. Indus Crops Prod 50:95–103. https://doi.org/10.1016/j.indcrop.2013.07.018

Melo MAR, Melo MAM, da Silva EV, Carvalho Filho JR, de Souza AG (2014) Study of the oxidative stability of oils vegetables for production of Biodiesel. Revista Verde de Agroecologia e Desenvolvimento Sustentável 9(1):13

Zhou J, Xiong Y, Gong Y, Liu X (2017) Analysis of the oxidative degradation of biodiesel blends using FTIR, UV–Vis, TGA and TD-DES methods. Fuel 202:23–28. https://doi.org/10.1016/j.fuel.2017.04.032

Arbain NH, Salimon J (2010) Synthesis and characterization of ester trimethylolpropane based Jatropha curcas oil as biolubricant base stocks. J Sci Technol 2(2). Retrieved from https://publisher.uthm.edu.my/ojs/index.php/JST/article/view/245

Pavia DL, Lampman GM, Kriz GS (2009) Introduction to spectroscopy. Thomson Learning, USA

Bhardwaj RM (2016) Aims and objectives In Control and prediction of solid-state of pharmaceuticals (pp 29–30) Springer, Cham https://doi.org/10.1007/978-3-319-27555-0

Kamalakar K, Rajak AK, Prasad RBN, Karuna MSL (2013) Rubber seed oil-based biolubricant base stocks : a potential source for hydraulic oils. Ind Crop Prod 51:249–257. https://doi.org/10.1016/j.indcrop.2013.08.058

Marques JPC, Rios ÍC, ParenteJr EJ, Quintella SA, Luna FMT, CavalcanteJr CL (2020) Synthesis and characterization of potential bio-based lubricant basestocks via epoxidation process. J Am Oil Chem Soc 97(4):437–446. https://doi.org/10.1002/aocs.12317

Rios ÍC, Cordeiro JP, Parente EJ, Quintella SA, Alemán J, Cavalcante CL, Luna FMT (2020) Biodegradable base stock oils obtained from ricinoleic acid using C 8 alcohols and process integration into a biodiesel industry. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-00942-4

Padmaja KV, Rao BVSK, Reddy RK, Bhaskar PS, Singh AK, Prasad RBN (2012) 10- Undecenoic acid-based polyol esters as potential lubricant base stocks. Ind Crop Prod 35:237–240. https://doi.org/10.1016/j.indcrop.2011.07.005

Tercariol WT (2018) Tribo-rheometry: quantifying friction between surfaces on rotational rheometers In VIII Brazilian conference on rheology

Ruggiero A, D’Amato R, Merola M, Valašek P, Müller M (2017) Tribological characterization of vegetal lubricants: comparative experimental investigation on Jatrophacurcas L. oil, rapeseed methyl ester oil hydrotreated rapeseed oil. Tribol Int 109:529–540. https://doi.org/10.1016/j.triboint.2017.01.030

Quinchia LA, Delgado MA, Reddyhoff T, Gallegos C, Spikes HA (2014) Tribological studies of potential vegetable oil-based lubricants containing environmentally friendly viscosity modifiers. Tribol Int 69:110–117. https://doi.org/10.1016/j.triboint.2013.08.016

Noorawzi N, Samion S (2016) Tribological effects of vegetable oil as alternative lubricant: a pin-on-disk tribometer and wear study. Tribol Trans 59(5):831–837. https://doi.org/10.1080/10402004.2015.1108477

Bahari A (2017) Investigation into tribological performance of vegetable oils as biolubricants at severe contact conditions (Doctoral dissertation, University of Sheffield)

Ing TC, Mohammed Rafiq AK, Azli Y, Syahrullail S (2012) The effect of temperature on the tribological behavior of RBD palm stearin. Tribol Trans 55(5):539–548. https://doi.org/10.1080/10402004.2012.680176

Buyanovskii IA (2010) Boundary lubrication by an adsorption layer. J Frict Wear 31(1):33–47

Afifah AN, Syahrullail S, Azlee NIW, Sidik NAC, Yahya WJ, Rahim EA (2019) Biolubricant production from palm stearin through enzymatic transesterification method. Biochem Eng J 148:178–184. https://doi.org/10.1016/j.bej.2019.05.009

Acknowledgements

Financial support from CNPq (Conselho Nacional de Pesquisa e Desenvolvimento Científico) is gratefully acknowledged. Ribeiro-Filho thanks the FAPEMA (Fundação de Amparo à Pesquisa e ao Desenvolvimento Científico e Tecnológico do Maranhão) and Universidade Estadual do Maranhão (UEMA) for financial support.

Funding

The authors received financial support from CNPq (Conselho Nacional de Pesquisa e Desenvolvimento Científico). Ribeiro-Filho received personal financial support from Scientific and Technological Research and Development Support Foundation of Maranhão (FAPEMA) and Universidade Estadual do Maranhão (UEMA). The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper. The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions. The authors have read and approved the final version of the manuscript. Paulo Roberto Campos Flexa Ribeiro Filho took the experimental measurements, carried out the data analysis and wrote the original draft; Matheus Rocha do Nascimento and Silvia Shelly Otaviano da Silva assisted in the experimental measurements; and Sandra de Aguiar Soares, Francisco Murilo Tavares de Luna and Célio Loureiro Cavalcante Jr. supervised the work and critically reviewed the results reported in this paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

Additional information

Technical Editor: by João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ribeiro Filho, P.R.C.F., da Silva, S.S.O., do Nascimento, M.R. et al. Tribological properties of bio-based lubricant basestock obtained from pequi oil (Caryocar brasiliensis). J Braz. Soc. Mech. Sci. Eng. 44, 51 (2022). https://doi.org/10.1007/s40430-021-03358-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-03358-x