Abstract

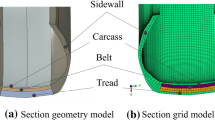

This study is based on the Tire and Rim Association (TRA) load formula, which introduced the relationship between static load and sinking force of the tire. It also established the mathematical model of the cord tension of any layer of the tire ring beam. A finite element model for a 195/65 R15 radial tire is established with the nonlinear analysis software ABAQUS, based on the tire structure and cord parameters. The calculated value from the TRA formula, simulated value and the experimental result demonstrates high consistency for the value of load sinking. Finite element simulation and experimental results of the load-versus-inflatable-section-width relation were compared, yielding little difference between the results. A similar analysis studies the change in the wavelength of sidewall standing waves at different vehicle velocities during high-speed tire-rolling. The value from simulation and the experimental results demonstrate high consistency, concluding that the wavelength of sidewall standing waves increases with vehicle velocity during high-speed tire-rolling. Thus, the accuracy of the finite element model is verified under both static and dynamic conditions. Based on the finite element model of the impact of change on velocity, load and tire pressure on tire cord stress, it can be concluded that with the increase in the speed and the tire pressure, the stress developed on cord increases and the impact of the load on it is lighter. Establishing the relationship between standing wave phenomenon and tire structural stress, it provides a certain mechanical basis for tire designers.

Similar content being viewed by others

References

Clark SK (1981) Mechanics of pneumatic tires. US Government Printing Office, Washington, DC

Togo K (1964) Standing wave on pneumatic tire at high speed. Mem Def Acad 4(1):43–56

Ames F (1970) Waves in tires. Text Res J 20:498–503

Krylov VV, Oliver G (2010) On the theory of standing waves in tyres at high vehicle speeds. J Sound Vib 329(21):4398–4408

Turner DM (1954) Wave phenomenon in tyres at high speed. In: Proceedings of third rubber technology conference, London

Brockman RA, Champion JH, Medzorian JP (1992) Finite element analysis of tire critical speeds. Comput Struct 43(3):581–593

Padovan J (1976) On viscoelasticity and standing waves in tires. Tire Sci Technol 4(4):233–246

Chang YP, El-Gindy M, Streit DA (2003) Influence of tyre loading and inflation pressure on standing waves phenomenon using PAM-SHOCK. Int J Heavy Veh Syst 10(1-2):86–111

Ji XW, Gao YM, Zhuang JD (1994) The dynamic stiffness and damping characteristics of the tire. Automot Eng 16(5):315–320

Chatterjee A, Cusumano JP, Zolock JD (1998) Standing waves in a simple model of a rotating balloon tire. Sci Mech 227(5):209–217

Chatterjee A, Cusumano JP, Zolock JD (1999) On contact-induced standing waves in rotating tires: experiment and theory. J Sound Vib 227(5):1049–1081

Gardner ER, Worswick T (1951) Behavior of tires at high speed. Trans Proc Inst Rubber Ind 27(2):127–146

Wang XY (1999) Mechanical analysis and design of composite materials. National Defense Science and Technology University Press, Changsha

Jie LF (2007) Research on force model and testing technology of tire cord based on composite theory. Jiangsu University, Jiangsu

Jenog KM (2016) Prediction of burst pressure of a radial truck tire using finite element analysis. World J Eng Technol 4(2):228–237

Palanivelu S, Narasimha KV, Ramarathnam KK (2015) Determination of rolling tyre modal parameters using finite element techniques and operational model analysis. Mech Syst Signal Process 64:385–402

Ozaki S, Kondo W (2016) Finite element analysis of tire traveling performance using anisotropic frictional interaction model. J Terrramech 64:1–9

Wei CF, Olatunbosun OA (2014) Transient dynamic behavior of finite element tire traversing obstacles with different heights. J Terrramech 56:1–16

Yu Q, Ding JP, Zhang AQ (2006) Radial tire structure design and manufacturing technology. Chemical Industry Press, Beijing

Yan S (2013) Finite element analysis and experimental study on radial truck tire. Qingdao University of Science and Technology, Shandong

Spenger W, Wagner W (1999) On the formulation of geometrically 3D-rebar-elements using the enhanced assumed strain methods. Eng Struct 21(3):209–218

Mashadi B, Salman EN, Mohammad A (2019) A rolling resistance estimate using nonlinear finite element numerical analysis of a full three-dimensional tyre model. Proc Inst Mech Eng Part D J Automob Eng 233(1):147–160

Lin S (2007) Finite element analysis for the all-steel radial tire. Harbin Institute of Technology, Harbin

Cheng DD (2014) Three-dimensional fine mesh finite element analysis of radial tire. Donghua University, Shanghai

De Eskinazi J, Ridha RA, Feng YM (1980) Finite element analysis of large earthen tires. Rubber Ref Mater 53(4):849–902

Zhang X (2002) Stress analysis of the multi-layered system of a truck tire. Tire Soc 30(4):240–264

Pinnington RJ (2006) A wave model of a circular tyre. Part 1: belt modelling. J Sound Vib 290(1–2):101–132

Acknowledgements

This entire study works are sustained by Natural National Science Foundation of China No. 51475399, the Education and Scientific Research Projects for Middle and Young-aged Teachers of Fujian No. JA15376 and Science & Technology Innovation Project of Fujian Province, China No. 2016H2003.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Wallace Moreira Bessa, D.Sc.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhou, ST., Du, M., Sun, PF. et al. Experimental and theoretical analysis of high-speed radial tire standing waves. J Braz. Soc. Mech. Sci. Eng. 42, 200 (2020). https://doi.org/10.1007/s40430-020-2253-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-2253-2