Abstract

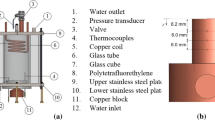

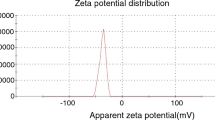

Nanocoating techniques have been used to increase the heat transfer coefficient by changing the surface morphology, which could potentially increase the heat transfer in pool boiling systems. The present study aims to determine the influence of nanocoated surfaces and the gap size on the heat transfer coefficient and the critical heat flux during the pool boiling of deionized water, at saturation temperature in atmospheric pressure. Tests were performed on a copper heating bare surface with an average roughness of 0.330 μm. The nanocoated surfaces were produced by alumina (Al2O3) nanoparticle deposition with 0.007% of volumetric concentration by using nanofluid boiling process. A gap size of 1.0 mm, corresponding to a Bond number equal to 0.4, was analyzed, and the results were compared with the cases without confinement. Concerning the heat transfer coefficient, the coated surface showed deterioration in the heat transfer performance (approximately 29%) as compared with the uncoated surface mainly due to the fouling resistance formed on the heating surface, confirmed by the surface characterization (SEM images). However, for coated surfaces and for confined cases, enhancement of 28% in the dryout heat flux was observed; the coating process significantly increases the surface wettability, which, in turn, increases the re-wetting capacity during the confined boiling process. Moreover, the heat transfer coefficient is more influenced by the gap size effect than the coating process. The chemical analysis showed that changes in the surface morphology occurred due to the effects of the confinement as compared to the original coated layer (the morphological aspect and melting mechanism were similar to the named liquid phase sintering).

Similar content being viewed by others

References

Liang G, Mudawar I (2019) Review of pool boiling enhancement by surface modification. Int J Heat Mass Transf 128:892–933

Bang IC, Chang SH (2005) Boiling heat transfer performance and phenomena of Al2O3-water nano-fluids from a plain surface in a pool. Int J Heat Mass Transf 48:2407–2419. https://doi.org/10.1016/j.ijheatmasstransfer.2004.12.047

Kiyomura IS, Manetti LL, da Cunha AP, Ribatski G, Cardoso EM (2017) An analysis of the effects of nanoparticles deposition on characteristics of the heating surface and ON pool boiling of water. Int J Heat Mass Transf 106:666–674. https://doi.org/10.1016/j.ijheatmasstransfer.2016.09.051

Kim J, Seongchul J, Laksnarain R, You SM (2016) Effect of surface roughness on pool boiling heat transfer at a heated surface having moderate wettability. Int J Heat Mass Transf 101:992–1002. https://doi.org/10.1016/j.ijheatmasstransfer.2016.05.067

Kim JS, Girard A, Jun S, Lee J, You SM (2018) Effect of surface roughness on pool boiling heat transfer of water on hydrophobic surfaces. Int J Heat Mass Transf 118:802–811. https://doi.org/10.1016/j.ijheatmasstransfer.2017.10.124

Khan SA, Atieh MA, Koç M (2018) Micro-nano scale surface coating for nucleate boiling heat transfer: a critical review. Energies 11:3189

Gupta SK, Misra RD (2019) An experimental investigation on pool boiling heat transfer enhancement using Cu–Al2O3 nano-composite coating. Exp Therm Fluid Sci 32(2):133–158. https://doi.org/10.1080/08916152.2018.1485785

Cao Z, Wu Z, Pham A, Yang Y, Abbood S, Falkman P, Ruzgas T, Albèr C, Sundén B (2019) Pool boiling of HFE-7200 on nanoparticle-coating surfaces: experiments and heat transfer analysis. Int J Heat Mass Transf 133:548–560. https://doi.org/10.1016/j.ijheatmasstransfer.2018.12.140

Wu Z, Cao Z, Sundén B (2019) Saturated pool boiling heat transfer of acetone and HFE-7200 on modified surfaces by electrophoretic and electro-chemical deposition. Appl Energy 249:286–299. https://doi.org/10.1016/j.apenergy.2019.04.160

Ishibashi E, Nishikawa K (1969) Saturated boiling heat transfer in narrow spaces. Int J Heat Mass Transf 12:863–894

Yang C-Y, Liu C-F (2013) Effect of coating layer thickness for boiling heat transfer on microporous coated surface in confined and unconfined spaces. Exp Therm Fluid Sci 47:40–47. https://doi.org/10.1016/j.expthermflusci.2013.01.001

Souza RR, Passos JC, Cardoso EM (2014) Influence of nanoparticle size and gap size on nucleate boiling using HFE7100. Exp Therm Fluid Sci 59:195–201. https://doi.org/10.1016/j.expthermflusci.2013.11.001

Souza RR, Cardoso EM, Passos JC (2018) Confined and unconfined nucleate boiling of HFE7100 in the presence of nanostructured surfaces. Exp Therm Fluid Sci 91:312–319. https://doi.org/10.1016/j.expthermflusci.2017.10.029

Yao S-C, Chang Y (2010) Pool boiling heat transfer in a confined space. Int J Heat Mass Transf 26:841–848. https://doi.org/10.1016/s0017-9310(83)80108-2

Katto Y, Yokoya S, Teraoka K (1977) Nucleate and transition boiling in a narrow space between two horizontal parallel disk-surface. Bull JSME 20(143):638–643

Passos JC, Hirata FR, Possamai LFB, Balsamo M, Misale M (2004) Confined boiling of FC72 and FC87 on a downward facing heating copper disk. Int J Heat Fluid Flow 25:313–319. https://doi.org/10.1016/j.ijheatfluidflow.2003.11.016

Cardoso EM, Kannengieser O, Stutz B, Passos JC (2011) FC72 and FC87 nucleate boiling inside a narrow horizontal space. Exp Therm Fluid Sci 35:1038–1045. https://doi.org/10.1016/j.expthermflusci.2011.02.006

Cardoso EM, Passos JC (2013) Nucleate boiling of n-pentane in horizontal confined space. Heat Transf Eng 34:470–478. https://doi.org/10.1080/01457632.2012.722438

Nolan E, Rioux R, Jiang P, Peterson GP, Li CH (2013) Experimental study of contact angle and active nucleation site distribution on nanostructure modified copper surface in pool boiling heat transfer enhancement. Heat Transf Res 44:115–131. https://doi.org/10.1615/heattransres.2012005687

Matre GA, Karwande RL (2015) Critical heat flux enhancement in pool boiling with Al2O3–water nanofluid. Int J Res Eng Technol 04:177–185. https://doi.org/10.15623/ijret.2015.0405035

Sarafraz MM, Kiani T, Hormozi F (2016) Critical heat flux and pool boiling heat transfer analysis of synthesized zirconia aqueous nanofluids. Int Commun Heat Mass Transf 70:75–83. https://doi.org/10.1016/j.icheatmasstransfer.2015.12.008

Mori S, Utaka Y (2017) Critical heat flux enhancement by surface modification in a saturated pool boiling: a review. Int J Heat Mass Transf 108:2534–2557

Manetti LL, Mogaji TS, Beck PA, Cardoso EM (2017) Evaluation of the heat transfer enhancement during pool boiling using low concentrations of Al2O3-water based nanofluid. Exp Therm Fluid Sci 87:191–200. https://doi.org/10.1016/j.expthermflusci.2017.04.018

Souza RR, Manetti LL, Kiyomura IS, Cardoso EM (2018) Liquid/surface interaction during pool boiling of DI-water on nanocoated heating surfaces. J Braz Soc Mech Sci Eng 40(11):514

Tyler DE, Black WT (1995) Properties and selection: nonferrous alloys. ASM Handbook 2:759–839

Nunes JM, Manetti LL, Cardoso EM (2017) Experimental analysis of nucleate boiling on nanostructured surfaces under confined conditions. In: Proceedings of the 24th ABCM international congress of mechanical engineering COBEM2017. Curitiba, Brazil

Rohsenow WM (1952) A method of correlating heat transfer data for surface boiling of liquids. Trans ASME J Heat Transf 74:969–976

Li Y, Chen Y, Liu Z (2014) A uniform correlation for predicting pool boiling heat transfer on plane surface with surface characteristics effect. Int J Heat Mass Transf 77:809–817

Stephan K (1992) Heat transfer in condensation and boiling. Springer, Berlin

Vachon RI, Nix GH, Tanger GE (1968) Evaluation of constants for the Rohsenow pool-boiling correlation. ASME J Heat Transf 90:239–246. https://doi.org/10.1115/1.3597489

Takata Y, Hidaka S, Cao JM, Nakamura T, Yamamoto H, Masuda M, Ito T (2005) Effect of surface wettability on boiling and evaporation. Energy 30:209–220. https://doi.org/10.1016/j.energy.2004.05.004

Zuber N (1959) (Thesis), Hydrodynamic aspects of boiling heat transfer. No. AECU-4439

Kiyomura IS, Mogaji TS, Manetti LL, Cardoso EM (2017) A predictive model for confined and unconfined nucleate boiling heat transfer coefficient. Appl Therm Eng 127:1274–1284. https://doi.org/10.1016/j.applthermaleng.2017.08.135

Chen G, Tang Y, Wan Z, Zhong G, Tang H, Zeng J (2019) Heat transfer characteristic of an ultra-thin flat plate heat pipe with surface-functional wicks for cooling electronics. Int Commun Heat Mass 100:12–19. https://doi.org/10.1016/j.icheatmasstransfer.2018.10.011

Carey VP (1992) Liquid-vapor phase-change phenomena. Hemi-sphere/Taylor & Francis, Washington, DC

Friel JJ, Lyman CE (2006) Microscopy microanalysis X-ray mapping in electron-beam instruments. Microsc Microanal 12:2–25

Callister WD Jr (2007) Materials science and engineering: an introduction, 7th edn. Wiley, Hoboken

El-Shamy TM, Pantano CG (1977) Decomposition of silicate glasses in alkaline solution. Nature 266:704–706

Gin S, Jollivet P, Fournier M, Berthon C, Wang Z, Mitroshkov A, Zhu Z, Ryan JV (2015) The fate of silicon during glass corrosion under alkaline conditions: a mechanistic and kinetic study with the International Simple Glass. Geochim Cosmochim Acta 151:68–85. https://doi.org/10.1016/j.gca.2014.12.009

Vashko SD, Aggen G (1995) Properties and selection: irons, steels, and high-performance alloys. ASM Handbook 1:1303–1305

Shi J, Sun B, Zhang G, Song F, Yang L (2016) Prediction of dryout and post-dryout wall temperature at different operating parameters for once-through steam generators. Int J Heat Mass Transf 103:66–76. https://doi.org/10.1016/j.ijheatmasstransfer.2016.07.027

Nguyen NH, Moon SK (2015) An improved heat transfer correlation for developing post-dryout region in vertical tubes. Nucl Eng Technol 47:407–415. https://doi.org/10.1016/j.net.2015.04.004

Hudelson S, Newman BK, Bernardis S, Fenning DP, Bertoni MI, Marcus MA, Fakra SC, Lai B, Buonassisi T (2010) Retrograde melting and internal liquid gettering in silicon. Adv Mater 22:3948–3953. https://doi.org/10.1002/adma.200904344

Liu Z, DeVoe DL (2001) Micromechanism fabrication using silicon fusion bonding. Robot Comput Integr Manuf 17:131–137. https://doi.org/10.1016/S0736-5845(00)00046-6

Hynes NRJ, Velu PS, Kumar R, Raja MK (2017) Investigate the influence of bonding temperature in transient liquid phase bonding of SiC and copper. Ceram Int 43:7762–7767. https://doi.org/10.1016/j.ceramint.2017.03.084

German RM, Suri P, Park SJ (2009) Review: liquid phase sintering. J Mater Sci 44:1–39. https://doi.org/10.1007/s10853-008-3008-0

Acknowledgements

The authors are grateful for the financial support from the PPGEM – UNESP/FEIS, CAPES, CNPq (grant number 458702/2014-5), and FAPESP (grant numbers 2013/15431-7, 2014/19497-5, 2016/02034-8, and 2019/02566-8). Further thanks to Dr. Márcio de Paula for SEM analyses.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Francis HR Franca, Ph.D.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nunes, J.M., Souza, R.R., Rodrigues, A.R. et al. Influence of coated surfaces and gap size on boiling heat transfer of deionized water. J Braz. Soc. Mech. Sci. Eng. 42, 127 (2020). https://doi.org/10.1007/s40430-020-2223-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-2223-8