Abstract

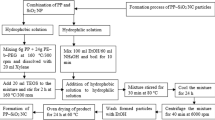

This study is justified by the issues on site in directional well as blowouts, abnormal formation pressure, obstructions in the wellbore, inaccessible target locations caused by an obstacle (for example dome of salt) and the pollution of formations. The objective of this study is to optimize the hole cleaning in directional well with environmentally drilling muds. For this goal, different formulations of “green” drilling muds were tested for 4 inclinations of 10°, 20°, 30° and 40° compared with a horizontal plane for modeling the vertical drill. The drilling muds used are water based with environmentally friendly products; this study tested two biopolymer-based formulations, which are the constants of the experiment. For the specific needs of drilling muds, different products as clay, weighting and potassium chloride were added to the based solution. The microstructure and quantification of the chemical content of biopolymers were examined with SEM–EDS (scanning electronic microscope and energy dispersive X-ray spectrometer). Rheological properties were evaluated with modular rheometer; biopolymer solutions exhibit a non-Newtonian behavior. The samples tested in this study are compliant with API standards. For a suspension of macroscopic particles in the non-Newtonian environment, the sedimentation velocity shows a rapid increase according to the angle value which is well known in macroscopic suspensions under the name of “Boycott effect”. The results showed the close link between the composition of the drilling mud and its ability to transport cuttings predictive for directional drilling.

Similar content being viewed by others

References

Mohiuddin MA, Khan K, Abdulraheem A, Al-Majed MRA (2007) Analysis of wellbore instability in vertical, directional, and horizontal wells using field data. J Pet Sci Eng 55:83–92

Ma TS, Chen P, Zhao J (2016) Overview on vertical and directional drilling technologies for the exploration and exploitation of deep petroleum resources. Geomech Geophys Geo-Energy Geo-Resour 2:365–395

Fernandez LC, Zegarra H, Baca G, Torres LG (2008) Characterization and surfactant enhanced washing treatability of drilling fluids stored for more than 20 years. Surfactants Deterg 11:307–314

Davis LR, Albright S, Mohebbi B, Herron J (1989) Experimental verification of a drilling mud plume model. Exp Thermal Fluid Sci 2:91–99

Rafati R, Smith SR, Haddad AS, Novara R, Hamidi H (2018) Effect of nanoparticles on the modifications of drilling fluids properties: a review of recent advances. J Pet Sci Eng 161:61–76

Dave VJ, Patel HS (2017) Synthesis and characterization of interpenetrating polymer networks from transesterified castor oil based polyurethane and polystyrene. J Saudi Chem Soc 21:18–24

Ma TS, Chen P, Yang CH, Zhao J (2015) Wellbore stability analysis and well path optimization based on the breakout width model and Mogi–Coulomb criterion. J Pet Sci Eng 135:678–701

Singh HKG, Jaafar A, Suzana Y (2014) The effect of sodium hydroxide on drag reduction using a biopolymer. In: Matec web of conferences. EDP Sciences. https://doi.org/10.1051/matecconf/20141302030

Houwen O, Ladva H, Meeten G, Reid P, Williamson D (1997) A new slogan for drilling fluids engineers. Oilfield Rev 9(1):16

Allen E, Uhlherr PHT (1989) Nonhomogeneous sedimentation in viscoelastic fluids. J Rheol 33:627

Bobroff S, Phillips RJ (1998) Nuclear magnetic resonance imaging investigation of sedimentation of concentrated suspensions in non-Newtonian fluids. J Rheol 42:1419

Boyoua NV, Ismail I, Sulaiman WRW, Haddad AS, Husein N, Hui HT, Nadaraja K (2019) Experimental investigation of hole cleaning in directional drilling by using nano-enhanced water-based drilling fluids. J Pet Sci Eng 176:220–231

Brigand G (1993) Industrial gums. In: Whistler RL, BeMiller JN (eds) Polysaccharides and their derivatives. Academic Press, Inc, San Diego, pp 461–474

Garcia-Ochoa F, Santos VE, Casas JA, Gomez E (2000) Xanthan gum: production, recovery, and properties. Biotechnol Adv 18:549–579

James B (2009) Advances in “wet” electron microscopy techniques and their application to the study of food structure. Trend Food Sci Technol 20:114–124

Plucknett KP, Baker FS, Normand V, Donald AM (2001) Fractographic examination of biopolymer gel composites using environmental scanning electron microscopy. J Mater Sci Lett 20:1553–1557

Donot F, Fontana A, Baccou JC, Schorr-Galindo S (2012) Microbial exopolysaccharides: main examples of synthesis, excretion, genetics and extraction. Carbohydr Polym 87:951–962

Viloria Ochoa M (2006) Analysis of drilling fluid rheology and tool joint effects to reduce errors in hydraulics calculations, Ph.D. theses, August 2006, http://hdl.handle.net/1969.1/4334

Bourgoyne AT, Millheim KK, Chenevert ME, Young SF (1984) Applied drilling engineering. SPE Textbook Series, Richardson

Bourgoyne AT, Millheim KK, Chenevert ME, Young SF (1991) Applied drilling engineering, second (revised) printing, vol 2. Textbook Series, SPE, Richardson

Samuel GR (2010) Appendix: useful conversion factors, formulas and calculations for drilling operations. Scrivener Publishing LLC, Beverly

Pang B, Wang S, Liu G, Jiang X, Lu H, Li Z (2018) Numerical prediction of flow behavior of cuttings carried by Herschel-Bulkley fluids in horizontal well using kinetic theory of granular flow. Powder Technol 329:386–398

Lenschow J (1992) Pressure drop calculations for drilling fluid. In: Paper SPE 25520 submitted to SPE for consideration for publication in one of its technical journals, 1992, 10 August

Daugan S, Talini L, Herzhaft B, Allain C (2002) Aggregation of particles settling in shear-thinning fluids. Eur Phys J E 9:55–62

Derakhshani SM, Schott DL, Lodewijks G (2017) Modeling particle sedimentation in viscous fluids with a coupled immersed boundary method and discrete element method. Particuology 31:191–199

Babu RP, O’Connor K, Seeram R (2013) Current progress on bio-based polymers and their future trends. Prog Biomater 2:1–16

Salerno A, Pascual CD (2015) Bio-based polymers, supercritical fluids and tissue engineering. Process Biochem 50:826–838

Wang B, Wang LJ, Li D, Özkan N, Li SJ, Mao ZH (2009) Rheological properties of waxy maize starch and xanthan gum mixtures in the presence of sucrose. Carbohydr Polym 77(3):472–481

Moscovici M (2015) Present and future medical applications of microbial exopolysaccharides. Front Microbiol 6:1012

Rehm BHA (2010) Bacterial polymers: biosynthesis, modifications and applications. Nat Rev Microbiol 8:578–592

Yu L, Dean K, Li L (2006) Polymer blends and composites from renewable resources. Prog Polym Sci 31:576–602

Schiffman JD, Schauer CL (2008) A review: electrospinning of biopolymer nanofibers and their applications. Polym Rev 48:317–352

Power D, Hight C, Weisinger DC, Rimer C (2000) Drilling practices and sweep selection for efficient hole cleaning in deviated wellbores. In: Paper IADC/SPE 62794 presented at the 2000 IADC/SPE Asia Pacific drilling technology held in Kuala Lumpur, Malaysia, 11–13 September 2000

Nasser MS, James AE (2007) Effect of polyacrylamide polymers on floc size and rheological behaviour of kaolinite suspensions. Colloids Surf A 301:311–322

Kenny P, Sunde E, Hemphill T (1996) Hole-cleaning model: what does the fluid-flow index have to do with it? J Pet Technol. pp 1055–1057

Akhshik S, Behzad M, Rajabi M (2016) CFD-DEM simulation of the hole cleaning process in a deviated well drilling: the effects of particle shape. Particuology 25:72–82

Safdel M, Anbaz MA, Daryasafar A, Jamial-Ahmadi M (2017) Microbial enhanced oil recovery, a critical review on worldwide implemented field trials in different countries. Renew Sustain Energy Rev 74:159–172

Shams R, Tavakoli A, Shad S (2017) Experimental investigation of two phase flow in horizontal wells: flow regime assessment and pressure drop analysis. Exp Therm Fluid Sci 88:55–64

Daugan S, Talini L, Herzhaft B, Peysson Y, Allain C (2004) Sedimentation of suspensions in shear-thinning fluids oil & gas science and technology. Rev IFP 59(1):71–80

Valluri SG, Miska SZ, Ahmed RM, Takach NE (2006) Experimental study of effective hole cleaning using “sweeps” in horizontal wellbores. In: SPE 101220, SPE annual technical conference, San Antonio, 24–27 September

Tory EM, Pickard DK (1984) Sedimentation of slurries: the long and winding road to chaos. In: Small RD (ed) Proceedings of Atlantic math days 1983. University of New Brunswick, Fredericton, pp 84–96

Tory EM (1990) A stochastic model for the slow sedimentation of small particles in a viscous fluid. In: Rahman M (ed) Ocean waves mechanics, computational fluid dynamics and mathematical modelling. Computational Mechanics Publications, Boston, pp 671–685

Feng S, Yan T, Sun X, Sun S (2011) Study on the impacts of cuttings on well deviation in gas drilling. Int Conf Pipelines Trenchless Technol Beijing 4(26):259–266

Sun P, Mo D, Ariaratnam ST, Cao H, Zhang P (2020) Laboratory study of fluid properties owing to cutting intrusions during horizontal directional drilling. Undergr Sp 5(20):29

Piroozian A, Ismail I, Yaacob Z, Babakhani P, Ismail ASI (2012) Impact of drilling fluid viscosity, velocity and hole inclination on cuttings transport in horizontal and highly deviated wells. J Pet Explor Prod Technol 2:149–156

Comminala R, Pimentab F, Hattela JH, Alvesb MA, Spangenberga J (2018) Numerical simulation of the planar extrudate swell of pseudoplastic and viscoelastic fluids with the stream function and the VOF methods. J Fluid Mech 252:1–18

Souza GS, Luporini S, Rigoli IC (2017) Rheological characterization of bentonite dispersions with xanthan for oil well drilling fluids. Mater Res 20:159–166

Winger M, Christen M, Van Gunsteren WF (2009) On the conformational properties of amylose and cellulose oligomers in solution. Int J Carbohydr Chem 2009, Hindawi Publishing Corporation Article ID 307695

Mazzuca C, Bocchinfuso G, Palleschi A, Conflitti P, Grassi M, Di Meo C, Alhaique F, Coviello T (2017) The influence of pH on the scleroglucan and scleroglucan/borax systems. Molecules 22:435

Alsewailem FD (2015) Polysaccharides in petroleum industry: a brief overview. Appl Res Polysacch 125–137. ISBN: 978-81-308-0559-7

Jian F, Zhang Y, Wang J, Ba K, Mao RY, Lai WL (2012) Toxicity of biodegradable nanoscale preparations. Curr Drug Metab 13:440–446

Survase SA, Saudagar PS, Bajaj IB, Singhal RS (2007) Scleroglucan: fermentative production, downstream processing and applications. Food Technol Biotechnol 45:107–118

Bachmann RT, Johnson AC, Edyvean RGC (2014) Biotechnology in the petroleum industry: an overview. Int Biodeterior Biodegrad 86:225–237

Johnson M (1996) Fluid systems for controlling fluid losses during hydrocarbon recovery operations. EP Patent 691 454

Sanchez E, Audibert-Hayet A, Rousseau L (2003) Influence of drill-in fluids composition on formation damage. In: Paper SPE 82 274 presented at 2003 at the SPE European formation damage, The Netherlands 13–14 May 2003

Baba Hamed S, Belhadri M (2009) Rheological properties of biopolymers drilling fluids. J Pet Sci Eng 67:84–90

Baba Hamed S, Belhadri M (2010) A comparison between two biopolymers used in drillings muds. Pet Sci Technol 28:723–730

Freitas FVA, Torres CAM, Reis M (2017) Engineering aspects of microbial exopolysaccharide production. Biores Technol 245:1674–1683

Kambourova M, Toksoy Oner E, Poli A (2015) Exopolysaccharides from prokaryotic microorganisms—promising sources for white biotechnology processes. Ind Biorefin White Biotechnol. https://doi.org/10.1016/B978-0-444-63453-5

Kelessidis VC, Bandelis GE (2007) Flow of dilute solid–liquid mixtures in horizontal concentric and eccentric annuli. J Can Pet Technol 46(5):56–61

Kenny P, Sunde E, Hemphill T (1996) Hole cleaning modelling: what’s “n” got to do with it? In: IADC/SPE drilling conference, New Orleans, Louisiana, IADC/SPE 35099, March 12–15, 1996

Green M, Power D (1999) Cuttings transport performance evaluation in high angle wellbores. In: CADE/CAODC spring drilling conference, Calgary, Canada, April 7–8

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Celso Kazuyuki Morooka.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Baba Hamed, S. Optimizing the transport of cuttings with ecological drilling muds: application to directional well. J Braz. Soc. Mech. Sci. Eng. 42, 619 (2020). https://doi.org/10.1007/s40430-020-02698-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02698-4