Abstract

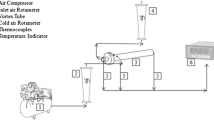

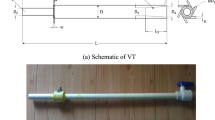

In this study, by considering the changes in inlet pressures, connection nozzle materials and the number of orifices, the performances of Ranque–Hilsch vortex tubes (RHVTs) were modelled by multiple linear regression method at which carbon dioxide (CO2) was used as compressed fluid, and optimum operating conditions were tried to be determined by Taguchi method. In the experiment, counterflow RHVTs having Ø10 mm inner diameter and 100 mm body length were used, hot fluid outlet of which was left completely open. In the tests designed using Taguchi L16 mix type (8 × 1 2 × 3) orthogonal array, 8 different inlet pressures (200, 250, 300, 350, 400, 450, 500 and 550 kPa), 2 different types of connections (parallel and series), 2 different types of nozzle materials (brass and polyamide) and 2 different numbers of orifices (4 and 6) were chosen as control factors and levels. Maximum temperature gradient (∆T) was determined as quality characteristics, and RHVT’s performance tests were done. In order to determine the effect rates of selected control factors on quality characteristics (∆T), analysis of variance (ANOVA) was applied within 95% confidence level. According to the statistical results, it was determined that ΔT values were mostly influenced by the inlet pressure and this was followed by connection type, number of orifices and nozzle material. With the confirmation test performed, reliability of the optimization was tested and confirmed.

Similar content being viewed by others

References

Kaya H, Günver F, Uluer O, Kırmacı V (2018) Experimental study about performance analysis of parallel connected Ranque-Hilsch counter flow vortex tubes with different nozzle numbers and materials. J Heat Transfer 140:112801

Kandil HA, Abdelghany ST (2015) Computational investigation of different effects on the performance of the Ranquee-Hilsch vortex tube. Energy 84:207–218

Bornare T, Badgujar A, Natu P (2015) Vortex tube refrigeration system based on compressed air. Int J Mech Eng Technol (IJMET) 6(7):99–104

Khodorkov IL, Poshernev NV, Zhidkov MA (2003) The vortex tube-a universal device for heating, cooling, cleaning, and drying gases and separating gas mixtures. Chem Pet Eng 39:7–8

Pinar AM, Uluer O, Kırmacı V (2019) Optimization of counter flow Ranque-Hilsch vortex tube performance using Taguchi method. Int J Refrig 32:1487–1494

Aghagoli A, Sorin M (2019) Thermodynamic performance of a CO2 vortex tube based on 3D CFD flow analysis. Int J Refrig 108:124–137

Xue Y, Arjomandi M, Kelso R (2010) A critical review of temperature separation in a vortex tube. Exp Thermal Fluid Sci 34:1367–1374

Eiamsa-ard S, Promvonge P (2008) Review of Ranque-Hilsch effects in vortex tubes. Renew Sustain Energy Rev 12:1822–1842

Gutak AD (2015) Experimental investigation and industrial application of Ranque-Hilsch vortex tube. Int J Refrig 49:93–98

Fröhlıngsdorf W, Unger H (1999) Numerical investigations of compressible flow and the energy separation in the Ranque-Hilsch vortex tube. Int J Heat Mass Transf 42:415–422

Saidi MH, Valipour MS (2003) Experimental modeling of vortex tube refrigerator. Appl Therm Eng 23:1971–1980

Dincer K, Başkaya Ş (2009) Assessment of plug angle effect on exergy efficiency of counterflow Ranque-Hilsch vortex tubes with the exergy analysis method. J Fac Eng Arch Gazi Univ 24(3):533–538

Kırmacı V (2009) Exergy analysis and performance of a Ranque-Hilsch counter flow vortex tube having various nozzle numbers at different inlet pressures of oxygen and air. Int J Refrig 32(7):1626–1633

Kaya H, Günver F, Kirmaci V (2018) Experimental investigation of thermal performance of parallel connected vortex tubes with various nozzle materials. Appl Therm Eng 136:287–292

Shamsoddini R, Abolpour B (2018) A geometric model for a vortex tube based on numerical analysis to reduce the effect of nozzle number. Int J Refrig 94:49–58

Hamdan MO, Al-Omari SAB, Oweimer AS (2018) Experimental study of vortex tube energy separation under different tube design. Exp Thermal Fluid Sci 91:306–311

Kirmaci V, Kaya H, Cebeci I (2018) An experimental and exergy analysis of a thermal performance of a counter flow Ranque-Hilsch vortex tube with different nozzle materials. Int J Refrig 85:240–254

Majidi D, Alighardashi H, Farhadi F (2018) Best vortex tube cascade for highest thermal separation. Int J Refrig 85:282–291

Stephan K, Lin S, Durst M, Huang F, Seher D (1983) An investigation of energy separation in a vortex tube. Int J Heat Mass Transf 26(3):341–348

Gao CM, Bosschaart KJ, Zeegers JCH, de Waele ATAM (2005) Experimental study on a simple Ranque-Hilsch vortex tube. Cryogenics 45:173–183

Saidi MH, Yazdi MRA (1999) Exergy model of a vortex tube system with experimental results. Energy 24:625–632

Rafiee SE, Sadeghiazad MM (2016) Heat and mass transfer between cold and hot vortex cores inside Ranque-Hilsch vortex tube-optimization of hot tube length. Int J Heat Technol 34(1):31–38

Attalla M, Ahmed H, Ahmed MS, El-wafa AA (2017) Experimental investigation for thermal performance of series and parallel Ranque-Hilsch vortex tube systems. Appl Therm Eng 123:327–339

Cebeci İ, Kirmaci V, Topcuoglu U (2016) The effects of orifice nozzle number and nozzle made of polyamide plastic and aluminum with different inlet pressures on heating and cooling performance of counter flow Ranque-Hilsch vortex tubes: An experimental investigation. Int J Refrig 72:140–146

Rafiee SE, Ayenehpour S, Sadeghiazad MM (2016) A study on the optimization of the angle of curvature for a Ranque-Hilsch vortex tube, using both experimental and full reynolds stress turbulence numerical modelling. Heat Mass Transfer 52:337–350

Devade K, Pise AT (2016) Optimization of thermal performance of Ranque Hilsch vortex tube: MADM techniques. In: 2016 International Conference on New Energy and Future Energy System (NEFES 2016) IOP Conf. Series: Earth and Environmental Science 40:012073

Guo X, Bo Z, Liu B, Xu X (2019) A critical review on the flow structure studies of Ranque-Hilsch vortex tubes. Int J Refrig 104:51–64

Kirmaci V, Kaya H (2018) Effects of working fluid, nozzle number, nozzle material and connection type on thermal performance of a Ranque-Hilsch vortex tube: a review. Int J Refrig 91:254–266

Subudhi S, Sen M (2015) Review of Ranque-Hilsch vortex tube experiments using air. Renew Sustain Energy Rev 52:172–178

Polat K, Kirmaci V (2011) Application of the output dependent feature scaling in modeling and prediction of performance of counter flow vortex tube having various nozzles numbers at different inlet pressures of air, oxygen, nitrogen and argon. Int J Refrig 34(6):1387–1397

Aydemir ME (2014) Bazı optimizasyon yöntemlerinin yama anten problemlerindeki performansı. J Faculty Eng Archit Gazi Univ 29(3):579–588

Şahin İ (2018) Mühimmat sistemlerinde kullanılan askı kancalarında geometri tabanlı topoloji optimizasyonu. In: Conference: 3’rd International Symposium on Industrial Design Engineering (ISIDE 2018) Antalya, Turkey

Şahin İ, Dörterler M, Gökçe H (2017) Optimum design of compression spring according to minimum volume using grey wolf optimization method. Gazi J Eng Sci (GJES) 3(2):21–27

Çiftçi İ, Gökçe H (2019) Optimisation of cutting tool and cutting parameters in machining of molybdenum alloys through the Taguchi Method. J Faculty Eng Archit Gazi Univ 34(1):201–213

Gökçe H, Çiftçi İ, Demir H (2018) Cutting parameter optimization in shoulder milling of commercially pure molybdenum. J Braz Soc Mech Sci Eng 40:360

Canel T, Zeren M, Sınmazçelik T (2019) Laser parameters optimization of surface treating of Al 6082–T6 with Taguchi method. Optic Laser Technol 120:105714

Terzioğlu H (2020) Analysis of effect factors on thermoelectric generator using Taguchi method. Measurement 149:106992

Pinar AM, Uluer O, Kirmaci V (2009) Optimization of counter flow Ranque-Hilsch vortex tube performance using Taguchi method. Int J Refrig 32(6):1487–1494

Maiyar LM, Ramanujam R, Venkatesan K, Jerald J (2013) Optimization of machining parameters for end milling of inconel 718 super alloy using Taguchi based grey relational analysis. Proc Eng 64:1276–1282

Selek M, Tasdemir S, Dincer K, Baskaya S (2011) Experimental examination of the cooling performance of Ranque-Hilsch vortex tube on the cutting tool nose point of the turret lathe through infrared thermography method. Int J Refrig 34:807–815

Kirmaci V, Uluer O (2009) An experimental investigation of the cold mass fraction, nozzle number, and inlet pressure effects on performance of counter flow vortex tube. J Heat Transfer 131(8):081701

https://www.matweb.com/search/DataSheet.aspx?MatGUID=d3bd4617903543ada92f4c101c2a20e5&ckck=1. Accessed 01 Jan 2020

Moffat RJ (1988) Describing the uncertainties in experimental results. Exp Therm Fluid Sci 1:3–17

Başar G, Kahraman F (2017) Delik işleme prosesinde kesme parametrelerinin Taguchi metodu ve regresyon analizi kullanılarak modellenmesi ve optimizasyonu. In: 2nd International Mediterranean Science and Engineering Congress (IMSEC 2017) pp 688–695

Hitesh RT, Ashok DP (2020) Experimental investigation of Ranque-Hilsch vortex tube and techno—Economical evaluation of its industrial utility. Appl Thermal Eng 169:114934

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Jose A. R. Parise.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gökçe, H. Optimization of Ranque–Hilsch vortex tube performances via Taguchi method. J Braz. Soc. Mech. Sci. Eng. 42, 558 (2020). https://doi.org/10.1007/s40430-020-02649-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02649-z