Abstract

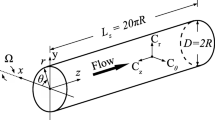

Large eddy simulation with an extended Smagorinsky model has been carried out to study a fully developed turbulent forced convection of thermally independent shear-thinning (n = 0.75) fluid through a heated axially rotating pipe. Uniform constant heat flux has been imposed at the wall as a thermal boundary condition. The Reynolds and Prandtl numbers of the simulation have been assumed to be Res = 4000 and Prs = 1, respectively, over a rotation rate range of 0 ≤ N ≤ 3. The computations procedure is based on a finite difference scheme, second-order accurate in space and time; the numeric resolution is 653 grid points in axial, radial and circumferential directions, respectively, with a computational domain length of 20R. The aim of the present study is to investigate the effects of the rotating pipe wall on the turbulent and thermal statistics. The emerged findings suggest that the centrifugal force induced by the rotating pipe wall results in a marked enhancement of the mean axial velocity and an attenuation of the temperature profiles along the radial coordinates; this trend is more pronounced as the rotation rate increases. The increased rotation rate also induces a significant reduction in the temperature fluctuations intensity and consequently, in the axial turbulent heat flux. The predictions also show that the friction factor and Nusselt number are reduced when the rotation rate varies from 0 to 0.5, while they are enhanced with increasing N for N ≥ 1.

Similar content being viewed by others

Abbreviations

- \( U_{b} \) :

-

Average velocity (m s−1)

- \( U_{\tau } \) :

-

Friction velocity \( U_{\tau } = \left( {{{\tau_{\text{w}} } \mathord{\left/ {\vphantom {{\tau_{\text{w}} } \rho }} \right. \kern-0pt} \rho }} \right)^{{{1 \mathord{\left/ {\vphantom {1 2}} \right. \kern-0pt} 2}}} \) (m s−1)

- \( U_{\text{CL}} \) :

-

Centreline axial velocity for analytical fully developed laminar profile \( U_{\text{CL}} = {{\left( {3n + 1} \right)U_{b} } \mathord{\left/ {\vphantom {{\left( {3n + 1} \right)U_{b} } {\left( {n + 1} \right)}}} \right. \kern-0pt} {\left( {n + 1} \right)}} \) (m s−1)

- \( R \) :

-

Pipe radius (m)

- \( n \) :

-

Flow index

- \( K \) :

-

Consistency index (pa sn)

- \( q \) :

-

Heat flux

- \( k \) :

-

Turbulent kinetic energy

- \( T_{\text{ref}} \) :

-

Reference temperature \( T_{\text{ref}} = {{q_{\text{w}} } \mathord{\left/ {\vphantom {{q_{\text{w}} } {\rho C_{p} U_{\text{CL}} }}} \right. \kern-0pt} {\rho C_{p} U_{\text{CL}} }} \) (K)

- \( Y^{ + } \) :

-

Wall distance \( Y^{ + } = {{\rho U_{\tau } Y} \mathord{\left/ {\vphantom {{\rho U_{\tau } Y} {\eta_{\text{w}} }}} \right. \kern-0pt} {\eta_{\text{w}} }} \)

- \( T_{\text{w}} \) :

-

Wall temperature (K)

- \( \varOmega_{k} \) :

-

Rotational velocity of the pipe wall

- \( N_{k} \) :

-

Rotation rate \( N_{k} = {{2\varOmega_{k} R} \mathord{\left/ {\vphantom {{2\varOmega_{k} R} {U_{\text{CL}} }}} \right. \kern-0pt} {U_{\text{CL}} }} \)

- \( f \) :

-

Friction factor \( f = {{2\tau_{W} } \mathord{\left/ {\vphantom {{2\tau_{W} } {\left( {\rho U_{b}^{2} } \right)}}} \right. \kern-0pt} {\left( {\rho U_{b}^{2} } \right)}} \)

- \( {\text{Nu}} \) :

-

Nusselt number \( {\text{Nu}} = {{hD} \mathord{\left/ {\vphantom {{hD} k}} \right. \kern-0pt} k} \)

- \( \bar{S}_{ij} \) :

-

Strain rate tensor \( \bar{S}_{ij} = {1 \mathord{\left/ {\vphantom {1 2}} \right. \kern-0pt} 2}\left( {{{\partial \bar{u}_{i} } \mathord{\left/ {\vphantom {{\partial \bar{u}_{i} } {\partial x_{j} }}} \right. \kern-0pt} {\partial x_{j} }} + {{\partial \bar{u}_{j} } \mathord{\left/ {\vphantom {{\partial \bar{u}_{j} } {\partial x_{i} }}} \right. \kern-0pt} {\partial x_{i} }}} \right) \)

- \( T_{\varTheta j} \) :

-

Subgrid heat flux tensor \( T_{\varTheta j} = {{ - \alpha_{t} \partial \bar{T}} \mathord{\left/ {\vphantom {{ - \alpha_{t} \partial \bar{T}} {\partial x_{j} }}} \right. \kern-0pt} {\partial x_{j} }} \)

- \( \text{Re}_{\text{s}} \) :

-

Reynolds number of the simulations \( \text{Re}_{\text{s}} {{ = \rho U_{\text{CL}}^{2 - n} R^{n} } \mathord{\left/ {\vphantom {{ = \rho U_{\text{CL}}^{2 - n} R^{n} } K}} \right. \kern-0pt} K} \)

- \( \text{Re}_{\text{MR}} \) :

-

Reynolds number of Metzner and Reed \( \text{Re}_{\text{MR}} = {{8\rho D^{n} U_{b}^{2 - n} } \mathord{\left/ {\vphantom {{8\rho D^{n} U_{b}^{2 - n} } {K\left( {6 + {2 \mathord{\left/ {\vphantom {2 n}} \right. \kern-0pt} n}} \right)}}} \right. \kern-0pt} {K\left( {6 + {2 \mathord{\left/ {\vphantom {2 n}} \right. \kern-0pt} n}} \right)}}^{n} \)

- \( \text{Re}_{\text{g}} \) :

-

Generalised Reynolds number \( \text{Re}_{\text{g}} = {{\rho U_{b} D} \mathord{\left/ {\vphantom {{\rho U_{b} D} {\eta_{\text{w}} }}} \right. \kern-0pt} {\eta_{\text{w}} }} \)

- \( \text{Re}_{\text{cr}} \) :

-

Critical Reynolds number \( \text{Re}_{\text{cr}} = 2100\left( {{{\left( {4n + 2} \right)\left( {5n + 3} \right)} \mathord{\left/ {\vphantom {{\left( {4n + 2} \right)\left( {5n + 3} \right)} {3\left( {3n + 1} \right)^{2} }}} \right. \kern-0pt} {3\left( {3n + 1} \right)^{2} }}} \right) \)

- \( \Pr_{\text{s}} \) :

-

Prandtl number of the simulations \( \Pr_{\text{s}} = {K \mathord{\left/ {\vphantom {K {\rho \alpha R^{n - 1} U_{\text{CL}}^{1 - n} }}} \right. \kern-0pt} {\rho \alpha R^{n - 1} U_{\text{CL}}^{1 - n} }} \)

- \( F\left( {U_{i}^{'} } \right) \) :

-

Flatness factor \( F\left( {U_{i}^{'} } \right) = {{\left\langle {U_{i}^{'4} } \right\rangle } \mathord{\left/ {\vphantom {{\left\langle {U_{i}^{'4} } \right\rangle } {\left\langle {U_{i}^{'2} } \right\rangle }}} \right. \kern-0pt} {\left\langle {U_{i}^{'2} } \right\rangle }}^{2} \)

- \( S\left( {U_{i}^{'} } \right) \) :

-

Skewness factor \( S\left( {U_{i}^{'} } \right) = {{\left\langle {U_{i}^{'3} } \right\rangle } \mathord{\left/ {\vphantom {{\left\langle {U_{i}^{'3} } \right\rangle } {\left\langle {U_{i}^{'2} } \right\rangle }}} \right. \kern-0pt} {\left\langle {U_{i}^{'2} } \right\rangle }}^{{{3 \mathord{\left/ {\vphantom {3 2}} \right. \kern-0pt} 2}}} \)

- \( \alpha_{\text{t}} \) :

-

Thermal diffusivity \( \alpha_{\text{t}} = {{\nu_{\text{t}} } \mathord{\left/ {\vphantom {{\nu_{\text{t}} } {\Pr_{\text{t}} }}} \right. \kern-0pt} {\Pr_{\text{t}} }} \) (m2 s−1)

- \( \dot{\gamma } \) :

-

Shear rate \( \dot{\gamma } = \sqrt {S_{ij} S_{ij} } \)

- \( \Delta \) :

-

Computational grid

- \( \eta \) :

-

Apparent viscosity \( \eta = K\dot{\gamma }^{n - 1} \)

- \( \varTheta \) :

-

Dimensionless temperature

- ρ :

-

Density

- \( \bar{\tau }_{ij} \) :

-

Subgrid stress tensor \( \bar{\tau }_{ij} = - 2\nu_{\text{t}} \bar{S}_{ij} \)

- d:

-

Dimensionless

- \( z,r,\theta \) :

-

Axial, radial, tangential velocity

- b :

-

Average

- C:

-

Centreline

- L:

-

Laminar

- t:

-

Turbulent

- s:

-

Simulation

- w:

-

Wall

- g:

-

Generalised

- 〈〉:

-

Statistically averaged

- \( \left( {} \right)^{ + } \) :

-

Normalised by \( U_{\tau } \), or \( T_{\tau } \)

- \( \left( {} \right)^{\prime } \) :

-

Fluctuation component

- \( \left( {\overline{{}} } \right) \) :

-

Filtered variable

References

Murakami M, Kikuyama K (1980) Turbulent flow in axially rotating pipes. J Fluids Eng 102(1):97

Kikuyama K, Murakami M, Nishibori K, Maeda K (1983) Flow in an axially rotating pipe: a calculation of flow in the saturated region. Bull JSME 26(214):506–513

Nishibori K, Kikuyama K, Murakami M (1987) Laminarization of turbulent flow in the inlet region of an axially rotating pipe. JSME Int J 30(260):255–262

Reich G, Beer H (1989) Fluid flow and heat transfer in an axially rotating pipe-I. Effect of rotation on turbulent pipe flow. Int J Heat Mass Transf 32(3):551–562

Imao S, Itoh M, Harada T (1996) Turbulent characteristics of the flow in an axially rotating pipe. Int J Heat Fluid Flow 17(5):444–451

Hirai S, Takagi T, Matsumoto M (1988) Predictions of the laminarization phenomena in an axially rotating pipe flow. J Fluids Eng 110(4):424

Eggels JGM, Unger F, Weiss MH, Westerweel J, Adrian RJ, Friedrich R, Nieuwstadt FTM (1994) Fully developed turbulent pipe flow: a comparison between direct numerical simulation and experiment. J Fluid Mech 268(1):175

Orlandi P, Fatica M (1997) Direct simulations of turbulent flow in a pipe rotating about its axis. J Fluid Mech 343:S0022112097005715

Yang Z (2000) Large Eddy simulation of fully developed turbulent flow in a rotating pipe. Int J Numer Methods Fluids 33(5):681–694

Feiz AA, Ould-Rouis M, Lauriat G (2003) Large Eddy simulation of turbulent flow in a rotating pipe. Int J Heat Fluid Flow 24(3):412–420

Cannon JN, Kays WM (1969) Heat transfer to a fluid flowing inside a pipe rotating about its longitudinal axis. J Heat Transfer 91(1):135

Satake S, Kunugi T (2002) Direct numerical simulation of turbulent heat transfer in an axially rotating pipe flow. Int J Numer Methods Heat Fluid Flow 12(8):958–1008

Ould-Rouiss M, Dries A, Mazouz A (2010) Numerical predictions of turbulent heat transfer for air flow in rotating pipe. Int J Heat Fluid Flow 31(4):507–517

Bousbai M, Ould-Rouiss M, Mazouz A, Mataoui A (2013) Turbulent heat transfer characteristics of water flow in a rotating pipe. Heat Mass Transf und Stoffuebertragung 49(4):469–484

Metzner AB, Reed JC (1955) Flow of non-newtonian fluids—correlation of the laminar, transition, and turbulent-flow regions. AIChE J 1(4):434–440

Metzner AB (1957) Non-Newtonian fluid flow. Relationships between recent pressure-drop correlations. Ind Eng Chem 49(9):1429–1432

Dodge DW, Metzner AB (1959) Turbulent flow of non-Newtonian systems. AIChE J 5(2):189–204

Pinho FT, Whitelaw JH (1990) Flow of non-Newtonian fluids in a pipe. J Nonnewton Fluid Mech 34(2):129–144

Malin MR (1997) Turbulent pipe flow of power-law fluids. Int Commun Heat Mass Transf 24(7):977–988

Rudman M, Blackburn HM, Graham LJW, Pullum L (2004) Turbulent pipe flow of shear-thinning fluids. J Nonnewton Fluid Mech 118(1):33–48

Gnambode PS, Orlandi P, Ould-Rouiss M, Nicolas X (2015) Large-Eddy simulation of turbulent pipe flow of power-law fluids. Int J Heat Fluid Flow 54:196–210

Vidyanidhi V, Sithapathi A (1970) Non-Newtonian flow in a rotating straight pipe. J Phys Soc Jpn 29(1):215–219

Gunn RW, Mena B, Walters K (1974) On Newtonian and non-Newtonian flow in a rotating pipe”, Zeitschrift für Angew. Math und Phys ZAMP 25(5):591–606

Ohta T, Miyashita M (2014) DNS and LES with an extended Smagorinsky model for wall turbulence in non-Newtonian viscous fluids. J Nonnewton Fluid Mech 206:29–39

Montreuil E (2000) Simulation Numérique Pour l’aérothermique Avec Des Modèles Sous-Maille

Zang TA (1991) Numerical Simulation of the dynamics of turbulent boundary layers: perspectives of a transition simulator. Philos Trans R Soc A Math Phys Eng Sci 336(1641):95–102

Redjem-Saad L, Ould-Rouiss M, Lauriat G (2007) Direct numerical simulation of turbulent heat transfer in pipe flows: effect of Prandtl number. Int J Heat Fluid Flow 28(5):847–861

Piller M (2005) Direct numerical simulation of turbulent forced convection in a pipe. Int J Numer Methods Fluids 49(6):583–602

Pinho FT, Coelho PM (2010) Non-Newtonian heat transfer. Rheology II:52

Gnambode S (2015) Simulation Des Grandes Échelles Des Transferts Thermo-Convectifs Dans Les Écoulements Turbulents d’un Fluide Non-Newtonien En Conduite Cylindrique. http://www.theses.fr

Xu C, Zhang Z, den Toonder JMJ, Nieuwstadt FTM (1996) Origin of high Kurtosis levels in the viscous sublayer. Direct numerical simulation and experiment. Phys Fluids 8:1938

Acknowledgements

The authors would like to acknowledge the Laboratory of Industrial Technologies (Ibn-Khaldoun University Tiaret, Algeria). The authors would like to thank Pr. Paolo Orlandi for his useful discussion and comments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Technical Editor: Cezar Negrao, PhD.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abdi, M., Noureddine, A. & Ould-Rouiss, M. Numerical simulation of turbulent forced convection of a power law fluid flow in an axially rotating pipe. J Braz. Soc. Mech. Sci. Eng. 42, 17 (2020). https://doi.org/10.1007/s40430-019-2099-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-019-2099-7