Abstract

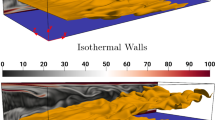

The present study focuses on the effect of the wall heat loss on a confined swirling diffusion flame. The objective is to assess the effect of changing the wall thermal boundary condition (i.e., from isothermal to adiabatic) on the flow structure, the flame shape, and the mixing behavior. Reynolds-averaged Navier–Stokes equations are solved. The diffusion flamelet model is employed in the simulation. The comparison of the numerical and experimental axial wall heat flux distributions shows a good agreement. The inner recirculation zone (IRZ) is shorter in the case of the adiabatic wall. It features higher negative axial velocities. The radial gradient of the axial velocity is higher which could enhance mixing and flame stability. The outer recirculation zone (ORZ) size does not change with the wall thermal boundary condition. Generally, the exit flow from the furnace decelerates due to the formation of the IRZ. This effect is more pronounced when the IRZ is longer, as the case when there is a wall heat loss. The flame is longer in the adiabatic wall case. However, its position relative to the burner exit does not change compared to the isothermal wall. In both cases, the flame is stabilized on the boundary of the IRZ. The mixing behavior is similar for the two wall thermal boundary conditions. However, the adiabatic wall case features a more fuel-rich mixture in the flame stabilization region, mainly due to the different velocity fields. Pockets of very fuel-rich mixtures are formed in the ORZ.

Similar content being viewed by others

Abbreviations

- \( a \) :

-

Absorption coefficient

- \( C_{p} \) :

-

Mixture specific heat

- \( C_{1\varepsilon } ,\;C_{2\varepsilon } ,\;C_{g} ,\;C_{d1} \) :

-

Constants

- \( D_{\text{f}} \) :

-

Furnace diameter

- \( D_{\text{i}} \) :

-

Hub diameter of the swirler

- \( D_{\text{k,eff}} \) :

-

Effective diffusion coefficient of turbulence kinetic energy

- \( D_{\text{o}} \) :

-

Outer diameter of the swirler (burner mouth)

- \( D_{{\varepsilon ,{\text{eff}}}} \) :

-

Effective diffusion coefficient of turbulent dissipation rate

- \( \overline{f} \) :

-

Mean mixture fraction

- \( \overline{{f^{{{\prime }2}} }} \) :

-

Mixture fraction variance

- \( G_{\text{k}} \) :

-

Generation of turbulence kinetic energy

- \( I \) :

-

Radiation intensity

- \( K \) :

-

Turbulence kinetic energy

- \( k \) :

-

Mixture thermal conductivity

- \( n \) :

-

Refractive index

- \( pr \) :

-

Prandtl number

- \( R \) :

-

Radius

- \( R_{\varepsilon } \) :

-

A term to account for rapid strain and streamline curvature

- \( \vec{r} \) :

-

Position vector

- \( S \) :

-

Swirl number

- \( \vec{S} \) :

-

Direction vector

- \( \overrightarrow {{s^{\prime}}} \) :

-

Scattering direction vector

- \( T_{\text{ad}} \) :

-

Temperature in the case of adiabatic wall

- \( T_{\text{is}} \) :

-

Temperature in the case of isothermal wall

- \( T_{\text{o}} \) :

-

Reference temperature (300 K)

- \( u_{i} \) :

-

Velocity vector

- \( u^{\prime}_{i} \) :

-

Velocity fluctuation vector

- \( V_{\text{ax}} \) :

-

Axial velocity

- \( V_{\text{j}} \) :

-

Fuel jet velocity

- \( X \) :

-

Axial distance

- \( \varepsilon \) :

-

Turbulent dissipation rate

- \( \mu_{\text{t}} \) :

-

Turbulent viscosity

- \( \rho \) :

-

Mass density

- \( \rho_{\text{ad}} \) :

-

Mass density in the case of adiabatic wall

- \( \rho_{\text{is}} \) :

-

Mass density in the case of isothermal wall

- \( \sigma \) :

-

Stefan–Boltzmann constant (5.67 × 10−8 W/m2 K4)

- \( \sigma_{\text{s}} \) :

-

Scattering coefficient

- \( \varPhi \) :

-

Phase function

- \( \varphi \) :

-

Swirler vane angle

- \( \varOmega^{\prime} \) :

-

Solid angle

- \( \delta_{ij} \) :

-

Kronecker delta

References

Huang Y, Yang V (2009) Dynamics and stability of lean-premixed swirl-stabilized combustion. Prog Energy Combust Sci 35(4):293–364. https://doi.org/10.1016/j.pecs.2009.01.002

Candel S, Durox D, Schuller T, Bourgouin J-F, Moeck JP (2014) Dynamics of swirling flames. Annu Rev Fluid Mech 46(1):147–173. https://doi.org/10.1146/annurev-fluid-010313-141300

Boxx I, Stöhr M, Carter C, Meier W (2010) Temporally resolved planar measurements of transient phenomena in a partially pre-mixed swirl flame in a gas turbine model combustor. Combust Flame 157(8):1510–1525. https://doi.org/10.1016/j.combustflame.2009.12.015

Santhosh R, Basu S (2016) Transitions and blowoff of unconfined non-premixed swirling flame. Combust Flame 164(Supplement C):35–52. https://doi.org/10.1016/j.combustflame.2015.10.034

Valera-Medina A, Vigueras-Zuniga MO, Baej H, Syred N, Chong CT, Bowen PJ (2017) Outlet geometrical impacts on blowoff effects when using various syngas mixtures in swirling flows. Appl Energy 207(Supplement C):195–207. https://doi.org/10.1016/j.apenergy.2017.05.119

Lee C-E, Park S-H, Hwang C-H (2016) Numerical study of the effect of inlet geometry on combustion instabilities in a lean premixed swirl combustor. J Mech Sci Technol 30(11):5293–5303. https://doi.org/10.1007/s12206-016-1048-y

Liu X, Elbaz AM, Gong C, Bai XS, Zheng HT, Roberts WL (2017) Effect of burner geometry on swirl stabilized methane/air flames: a joint LES/OH-PLIF/PIV study. Fuel 207(Supplement C):533–546. https://doi.org/10.1016/j.fuel.2017.06.092

Boushaki T, Merlo N, Chauveau C, Gökalp I (2017) Study of pollutant emissions and dynamics of non-premixed turbulent oxygen enriched flames from a swirl burner. Proc Combust Inst 36(3):3959–3968. https://doi.org/10.1016/j.proci.2016.06.046

Ranga Dinesh KKJ, Luo KH, Kirkpatrick MP, Malalasekera W (2013) Burning syngas in a high swirl burner: effects of fuel composition. Int J Hydrog Energy 38(21):9028–9042. https://doi.org/10.1016/j.ijhydene.2013.05.021

Li S, Li S, Mira D, Zhu M, Jiang X (2017) Investigation of dilution effects on partially premixed swirling syngas flames using a LES-LEM approach. J Energy Inst 91:902–915. https://doi.org/10.1016/j.joei.2017.09.005

Guiberti TF, Durox D, Scouflaire P, Schuller T (2015) Impact of heat loss and hydrogen enrichment on the shape of confined swirling flames. Proc Combust Inst 35(2):1385–1392. https://doi.org/10.1016/j.proci.2014.06.016

Guiberti TF, Durox D, Zimmer L, Schuller T (2015) Analysis of topology transitions of swirl flames interacting with the combustor side wall. Combust Flame 162(11):4342–4357. https://doi.org/10.1016/j.combustflame.2015.07.001

Nogenmyr KJ, Cao HJ, Chan CK, Cheng RK (2013) Effects of confinement on premixed turbulent swirling flame using large Eddy simulation. Combust Theory Model 17(6):1003–1019. https://doi.org/10.1080/13647830.2013.820842

Tay-Wo-Chong L, Zellhuber M, Komarek T, Im HG, Polifke W (2016) Combined influence of strain and heat loss on turbulent premixed flame stabilization. Flow Turbul Combust 97(1):263–294. https://doi.org/10.1007/s10494-015-9679-0

Poinsot T, Echekki T, Mungal MG (1992) A study of the laminar flame tip and implications for premixed turbulent combustion. Combust Sci Technol 81(1–3):45–73. https://doi.org/10.1080/00102209208951793

Mercier R, Guiberti TF, Chatelier A, Durox D, Gicquel O, Darabiha N, Schuller T, Fiorina B (2016) Experimental and numerical investigation of the influence of thermal boundary conditions on premixed swirling flame stabilization. Combust Flame 171(Supplement C):42–58. https://doi.org/10.1016/j.combustflame.2016.05.006

Zhang H, Mastorakos E (2016) Prediction of global extinction conditions and dynamics in swirling non-premixed flames using LES/CMC Modelling. Flow Turbul Combust 96(4):863–889. https://doi.org/10.1007/s10494-015-9689-y

Colorado A, McDonell V (2018) Emissions and stability performance of a low-swirl burner operated on simulated biogas fuels in a boiler environment. Appl Therm Eng 130:1507–1519. https://doi.org/10.1016/j.applthermaleng.2017.11.047

ANSYS fluent theory guide (2018) ANSYS, Inc., USA

Peters N (1984) Laminar diffusion flamelet models in non-premixed turbulent combustion. Prog Energy Combust Sci 10(3):319–339. https://doi.org/10.1016/0360-1285(84)90114-X

Chemical-kinetic mechanisms for combustion applications. San Diego Mechanism web page, Mechanical and Aerospace Engineering (Combustion Research), University of California at San Diego. http://web.eng.ucsd.edu/mae/groups/combustion/mechanism.html. Accessed 15 March 2017

Gómez Montoya JP, Amell AA, Olsen DB (2016) Prediction and measurement of the critical compression ratio and methane number for blends of biogas with methane, propane and hydrogen. Fuel 186(Supplement C):168–175. https://doi.org/10.1016/j.fuel.2016.08.064

Markovich DM, Abdurakipov SS, Chikishev LM, Dulin VM, Hanjalić K (2014) Comparative analysis of low- and high-swirl confined flames and jets by proper orthogonal and dynamic mode decompositions. Phys Fluids 26(6):065109. https://doi.org/10.1063/1.4884915

Yin Z, Nau P, Meier W (2017) Responses of combustor surface temperature to flame shape transitions in a turbulent bi-stable swirl flame. Exp Therm Fluid Sci 82(Supplement C):50–57. https://doi.org/10.1016/j.expthermflusci.2016.11.004

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Technical Editor: Mário Eduardo Santos Martins.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ahdy, S., Boraey, M.A., Abdel Hameed, H. et al. Effect of the wall thermal boundary condition on the structure of a confined swirling diffusion flame. J Braz. Soc. Mech. Sci. Eng. 41, 517 (2019). https://doi.org/10.1007/s40430-019-2007-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-019-2007-1