Abstract

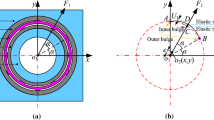

Nowadays, capability of safe operation sufficiently away from the critical speeds is one of the most important design requirements of rotating machineries. The focus of this paper is the application of smart electro-rheological (ER) elastomers to rotor dynamics field to reduce the vibration level of a rotor system. A Jeffcott rotor, supported via two bearings at both ends augmented with ER elastomers, is considered. A finite element approach, based on the Rayleigh beam theory, is used to model the dynamics of the system, and the proposed model accounts for the rotary inertia, gyroscopic effects and shaft’s internal damping. The ER elastomer supports are simulated with four-parameter viscoelastic model. The simulation results reveal that the use of ER elastomer in the conventional bearing supports leads to downshifting of the critical speeds and a considerable reduction in its corresponding vibration amplitude. Also, the stability limit speed of the system is improved by employing the ER elastomer technology. To extend the stability region of the rotor system to higher operating rotational speeds, a simple on–off control strategy is employed. The proposed control scheme determines the required real-time voltage to be applied at ER elastomers and guarantees low vibration amplitude over a wide frequency range. The novel idea of using ER elastomers for vibration suppression of rotor systems can be fairly extended to other applications which suffer from unwanted high amplitude vibrations.

Similar content being viewed by others

Abbreviations

- \( \left[ {\varvec{K}_{{\mathbf{B}}} } \right]_{\text{s}}^{\text{e}} \) :

-

Bending stiffness matrix for shaft element

- \( \left[ {\varvec{K}_{{\mathbf{C}}} } \right]_{\text{s}}^{\text{e}} \) :

-

Circulatory matrix for shaft element

- \( \left[ {\varvec{M}_{{\mathbf{T}}} } \right]_{\text{s}}^{\text{e}} \), \( \left[ {\varvec{M}_{{\mathbf{T}}} } \right]_{\text{d}}^{i} \) :

-

Translational mass matrix for shaft element and disk

- \( \left[ \varvec{C} \right]_{\text{b}}^{i} \) :

-

Bearing damping matrix

- \( \left\{ F \right\}_{ \sup }^{i} \) :

-

Load vector for support

- \( \left[ \varvec{G} \right]_{\text{s}}^{\text{e}} \), \( \left[ \varvec{G} \right]_{\text{d}}^{i} \) :

-

Gyroscopic matrices for shaft element and disk

- \( \left[ \varvec{K} \right]_{\text{b}}^{i} \) :

-

Bearing stiffness matrix

- \( \left[ \varvec{K} \right]_{ \sup }^{i} \) :

-

Support stiffness matrix

- \( \left\{ q \right\}_{\text{b}}^{i} \), \( \left\{ q \right\}_{\text{d}}^{i} \) :

-

Generalized displacement vector for the bearing node and ith disk node, respectively

- \( \left\{ q \right\}_{ \sup }^{i} \) :

-

Generalized displacement vector for the support

- \( \left\{ F \right\}_{\text{s}}^{\text{e}} \), \( \left\{ F \right\}_{\text{d}}^{i} \), \( \left\{ F \right\}_{\text{b}}^{i} \) :

-

Element load vector for shaft elements, ith disk and bearing

- \( \left\{ {F_{\text{c}} } \right\}, \left\{ {F_{\text{s}} } \right\} \) :

-

Unbalance forces associated with \(\cos {{\Omega }} t\) and \( \sin {{\Omega }} t \), respectively

- \( \left\{ {q_{\text{c}} } \right\},\left\{ {q_{\text{s}} } \right\} \) :

-

Unbalance response associated with \( \cos {{\Omega }} t \) and \( \sin {{\Omega }} t \), respectively

- \( \left\{ q \right\}_{\text{s}}^{\text{e}} \) :

-

Nodal displacement vector for a shaft finite element

- \( y_{\text{d}} \), \( z_{\text{d}} \) :

-

Mass center eccentricities of the disk in Y and Z directions measured at t = 0

- \( D_{\text{m}} \) :

-

Mean diameter of ER elastomer ring

- \( G^{\prime} \) :

-

Storage modulus

- \( G^{\prime\prime} \) :

-

Loss modulus

- \( G^{*} \) :

-

Complex shear modulus

- \( \left\{ F \right\} \) :

-

System load vector

- \( I_{\text{P}} \), \( I_{\text{D}} \) :

-

Polar and diametral mass moments of inertia of the disk

- \( b \), \( h \) :

-

Width and height of the ER elastomer ring, respectively

- \( c^{*} \) :

-

Damping of ER elastomer ring

- \( c_{yy} \), \( c_{yz} \), \( c_{zy} \), \( c_{zz} \) :

-

Elements bearing damping matrix

- \( k^{*} \) :

-

Stiffness of ER elastomer ring

- \( k_{yy} \), \( k_{yz} \), \( k_{zy} \), \( k_{zz} \) :

-

Elements of bearing stiffness matrix

- \( m_{\text{A}} \) :

-

Assembly mass of ball bearing and inner steel ring

- \( m_{\text{d}} \) :

-

Mass of the disk

- \( m_{\text{e}} \) :

-

Mass of the shaft element per unit length

- \( \left\{ q \right\} \) :

-

Generalized displacement vector for the entire system

- \( v, w \) :

-

Translational displacement of a point on rotor along Y and Z axes, respectively

- \( \left[ \varvec{D} \right] \) :

-

System damping matrix

- \( \left[ \varvec{K} \right] \) :

-

System stiffness matrix

- \( \left[ \varvec{M} \right] \) :

-

System mass matrix

- \( {{\Omega }} \) :

-

Spin speed of rotor about its axis

- \( \eta_{\upupsilon} \) :

-

Viscous internal damping coefficient

- \( \theta ,\psi \) :

-

Slope of elastic line of rotor about Y and Z axes, respectively

- \( {\text{EI}} \) :

-

Bending stiffness per unit curvature

- \( F\left( {{\Omega }} \right) \) :

-

Excitation force in frequency domain

- \( {\text{E}} \) :

-

Electric field strength

- \( \omega \) :

-

Natural frequency

- \( f\left( {\text{t}} \right) \) :

-

Excitation force in time domain

- \( j \) :

-

\( \sqrt { - 1} \)

- \( k \) :

-

Ball bearing stiffness

- \( l \) :

-

Length of rotor element

- \( n \) :

-

Number of elastomer rings in parallel

- \( t \) :

-

Time

- \( \eta \) :

-

Loss factor

- \( \beta \) :

-

Ratio of width-to-height of the ER elastomer

- \( r \) :

-

Radius of the shaft element

- \( k_{\text{L}} \) :

-

Form factor influencing the stiffness of the ring

- \( k_{\text{eq}} \) :

-

Equivalent dynamic stiffness

References

Muszynska A (1988) Stability of whirl and whip in rotor-bearing systems. J Sound Vib 127:49–64

Li G, Lin Z, Allaire PE, Luo J (2006) Modeling of a high speed rotor test rig with active magnetic bearings. J Vib Acoust 128(3):269–281

Dutt JK, Nakra BC (1992) Stability of rotor systems with viscoelastic supports. J Sound Vib 153:89–96

Dutt JK, Nakra BC (1993) Vibration response reduction of a rotor shaft system using viscoelastic polymeric supports. J Vib Acoust 115:221–223

Liebich R, Scholz A, Wieschalla A (2012) Rotors supported by elastomer-ring-dampers: experimental and numerical investigations. In: 10th international conference on vibrations in rotating machinery, London

Varney P, Green I (2014) Rotor dynamic analysis using complex transfer matrix: an application to elastomer support suing viscoelastic correspondence principle. J Sound Vib 333:6258–6272

Ribeiro EA, Pereira JT, Bavastri CA (2015) Passive vibration control in rotor dynamics: optimization of composed support using viscoelastic materials. J Sound Vib 351:43–56

Das AS, Nighil MC, Dutt JK, Irretier H (2008) Vibration control and stability analysis of rotor-shaft system with electromagnetic exciters. Mech Mach Theory 43:1295–1316

Dutta JK, Toi T (2003) Rotor vibration reduction with polymeric sectors. J Sound Vib 262:769–793

Bavastri CA, Ferreira EMS, Espíndola JJ, Lopes EMO (1999) Modeling of dynamic rotors with flexible bearings due to the use of viscoelastic materials. J Braz Soc Mech Sci Eng 30(2008):22–29

Yalcintas M, Dai H (1999) Magneto rheological and electro rheological materials in adaptive structures and their performance comparison. Smart Mater Struct 8:560–573

Gawade SS, Jadhav AA (2012) A review on electro rheological (ER) fluids and its applications. Int J Eng Res Technol 1:1–7

Stanway R, Sproston JL, El-Wahed AK (1996) Applications of electro-rheological fluids in vibration control: a survey. Smart Mater Struct 5:464–482

Bauer J, Daniel GB (2011) Modeling and testing of an ERF vibration damper for light rotors with large amplitudes. In: 21st international congress of mechanical engineering, October 24–28 (2011) Natal, RN, Brazil

Nikolajsen JL, Hoque MS (1990) An electro viscous damper for rotor applications. ASME J Vib Acoust 112:440–443

Yao GZ, Meng G (1999) Vibration control of a rotor system by disk type electro rheological damper. J Sound Vib 219(1):175–188

Lim S, Park S, Kim K (2005) AI vibration control of high-speed rotor systems using electro rheological fluid. J Sound Vib 284:685–703

Dimarogonas AD, Kollias A (1992) Electro-rheological fluid controlled smart journal bearings. STLE Tribol Trans 35(4):611–618

Guozhi Y, Fah YF, Guang M (2000) Electro-rheological multi-layer squeeze film damper and its application to vibration control of rotor system. J Vib Acoust Trans ASME 122:7–11

Morishita S, Mitsui Y (1992) Controllable squeeze film damper an application of electro-rheological fluid. J Vib Acoust 114(2):354–357

Tichy JA (1993) Behavior of a squeeze film damper with an electro-rheological fluid. STLE Tribol Trans 36(1):127–133

Loumpasefski O, Tzifas I, Nikolakopoulos PG, Papadopoulos CA (2017) Dynamic analysis of rotor-bearing systems lubricated with electro rheological fluids. Proc Inst Mech Eng, K: J Multi-body Dyn 232:153–168

Wei K, Bai Q, Meng G, Ye L (2011) Vibration characteristics of electro rheological elastomer sandwich beams. Smart Mater Struct 20, 055012, 8 pp

Zhu C (2001) Dynamics of a rotor supported on magneto-rheological fluid squeeze film damper. Chin J Aeronaut 14:7–12

Dong X, Niu C, Qi M (2017) Electrorheological elastomers. Elastomers. https://doi.org/10.5772/intechopen.68396

Gao L, Zhao X (2007) Mechanical and electrical properties of hydrous electro rheological elastomers based on gelatin/glycerin/water hybrid. J Appl Polym Sci 104:1738–1743

Hao L, Shi Z, Zhao X (2009) Mechanical behavior of starch/silicone oil/silicone rubber hybrid electric elastomer. React Funct Polym 69:165–169

Li WH, Zhou Y, Tian TF (2010) Viscoelastic properties of MR elastomers under harmonic loading. Rheol Acta 49:733–740

Nashif AD, Jones DIG, Henderson JP (1985) Vibration damping. Wiley, New York

Zhu G, Liu X (1996) Theory of viscoelasticity, 1st edn. The Press of the University of Science and Technology of China, Hefei

Zorzi ES, Nelson HD (1977) Finite element simulation of rotor-bearing systems with internal damping. ASME J Eng Power 99:71–76

Han Q, Chu F (2015) Parametric instability of flexible rotor-bearing system under time-periodic base angular motions. Appl Math Model 39:4511–4522

Das AS, Dutt JK, Ray K (2010) Active vibration control of unbalanced flexible rotor–shaft systems parametrically excited due to base motion. Appl Math Model 34:2353–2369

Peng B, Zhu R, Li M, Tang Z (2017) Bending vibration suppression of a flexible multispan shaft using smart spring support. Shock Vib., 7859164, 12 pages

Nelson HD, McVaugh JM (1976) The dynamics of rotor-bearing systems using finite elements. J Eng Ind 98:593–600

Ma H, Zhao Q, Zhao X, Han Q, Wen B (2015) Dynamic characteristics analysis of a rotor–stator system under different rubbing forms. Appl Math Model 39:2392–2408

Han Q, Yao H, Wen B (2010) Parameter identifications for a rotor system based on its finite element model and with varying speeds. Acta Mech Sin 26:299–303

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Pedro Manuel Calas Lopes Pacheco, D.Sc..

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: shaft element matrices

In these equations,\( {\text{EI}} \) is the bending stiffness per unit curvature, \( l \) is the length of the rotor element, \( m_{\text{e}} \) is mass of the shaft element per unit length, and \( r \) is the radius of the shaft element.

Appendix B: rigid disk element matrices

It has to be noted that since a disk is placed on a single node (having four DoFs), the size of the disk element matrices will be \( 4 \times 4 \).

In these equations, \( m_{\text{d}} \) is the mass of the disk, \( I_{\text{D}} \) is its diametral mass moment of inertia, and \( I_{\text{P}} \) is its polar mass moment of inertia.

Rights and permissions

About this article

Cite this article

AL Rkabi, M., Moeenfard, H. & Rezaeepazhand, J. Vibration attenuation of rotor-bearing systems using smart electro-rheological elastomer supports. J Braz. Soc. Mech. Sci. Eng. 41, 258 (2019). https://doi.org/10.1007/s40430-019-1748-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-019-1748-1