Abstract

The aim of this paper is to calibrate a Eulerian–Eulerian multiphase CFD model for the discharge process of an off-road self-loading concrete mixer drum, by using the viscosity model applied to fresh concrete. Two different viscosity models for the simulated concrete were studied: the Newtonian fluid model and the Bingham fluid model. The final parameters applied for calibration were defined by means of comparisons between numerical simulations, literature search on concrete rheology, experimental tests of drum discharge process and experimental Abrams’ cone tests applied to concrete. The results show that concrete, simulated as a Bingham fluid, matches with the experimental results for the discharge process. On the other hand, a good fit between numerical and experimental results is not reached with concrete simulated as a Newtonian fluid. The calibration of the material model is essential in further numerical analyses for new mixer drums and concrete machinery production design.

Similar content being viewed by others

Abbreviations

- d :

-

Characteristic length (m)

- Fr :

-

Froude number

- g :

-

Standard gravity (m/s2)

- h :

-

Height (m)

- K :

-

Plastic viscosity (Pa s)

- n :

-

Power index

- n c :

-

Critical speed (rpm)

- p 0 :

-

Relative pressure (Pa)

- R :

-

Radius (m)

- Re B :

-

Bingham Reynolds number

- r :

-

Volume fraction

- S :

-

Slump (mm)

- T :

-

Slump time (s)

- U :

-

Scalar velocity (m/s)

- v b :

-

Bulk velocity (m/s)

- η :

-

Apparent viscosity (Pa s)

- \(\dot{\gamma }\) :

-

Shear rate (1/s)

- µ :

-

Newtonian viscosity (Pa s)

- ρ :

-

Density (kg/m3)

- σ :

-

Surface tension coefficient (mN/m)

- τ 0 :

-

Yield stress (Pa)

- ω :

-

Angular speed (rad/s)

References

Koehler EP, Fowler DW (2003) Summary of concrete workability test methods. Research Report ICAR-105-1. International Center for Aggregates Research, The University of Texas at Austin

BRITISH STANDARD (2009) Testing fresh concrete part 2: Slump-test, BS EN 12350-2:2009

Patzak B, Bittnar Z (2009) Modeling of fresh concrete flow. Comput Struct 87:962–969

Roussel N, Gram A (2014) Simulation of fresh concrete flow, RILEM state-of-the-art reports 15, state-of-the-art report of the RILEM Technical Committee 222-SCF. Springer, Heidelberg

Saak AW, Jennings HM, Shah SP (2004) A generalized approach for the determination of yield stress by slump and slump flow. Cem Concr Res 34:363–371

Dufour F, Pijaudier-Cabot G (2005) Numerical modelling of concrete flow: homogeneous approach. Int J Numer Anal Methods Geomech 29:395–416

Roussel N (2006) Correlation between yield stress and slump: comparison between numerical simulations and concrete rheometers results. Mater Struct 39:501–509

Cremonesi M, Ferrara L, Frangi A, Perego U (2010) Simulation of the flow of fresh cement suspensions by a Lagrangian finite element approach. J Non-Newton Fluid Mech 165:1555–1563

Thrane LN (2007) Form filling with self-compacting concrete. Technical University of Denmark, Lyngby

Roussel N, Gram A, Cremonesi M, Ferrara L, Krenzer K, Mechtcherine V, Shyshko S, Skocec J, Spangeberg J, Svec O, Thrane LN, Vasilic K (2015) Numerical simulations of concrete flow: a benchmark comparison. Cem Concr Res 79:265–271

Vasilic K, Schmidt W, Kühne HC, Haamkens F, Mechtcherine V, Roussel N (2016) Flow of fresh concrete through reinforced elements: experimental validation of the porous analogy numerical method. Cem Concr Res 88:1–6

Gram A, Silfwerbrand J, Lagerblad B (2014) Obtaining rheological parameters from flow test—analytical, computational and lab test approach. Cem Concr Res 63:29–34

Secrieru E (2018) Pumping behaviour of modern concretes—characterisation and prediction. TU Dresden, Dresden

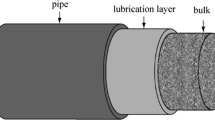

Jo SD, Park CK, Jeong JH, Lee SH, Kwon SH (2012) A computational approach to estimating a lubricating layer in concrete pumping. Comput Mater Contin 27:189–210

Wallewik JE, Wallewik OH (2017) Analysis of shear rate inside a concrete truck mixer. Cem Concr Res 95:9–17

Ferraris CF (1999) Measurement of the rheological properties of high performance concrete: state of the art report. J Res Natl Inst Stand Technol 104:461–478

Hu C, de Larrard F (1996) The rheology of fresh high-performance concrete. Cem Concr Res 26:283–294

Banfill PFG (2006) Rheology of fresh cement and concrete. Rheol Rev 2006:61–130

Bilgil A (2012) Estimation of slump value and Bingham parameters of fresh concrete mixture composition with artificial neural network modelling. Sci Res Essays 5:1753–1765

Hočevar A, Kavčič F, Bokan-Bosiljkov V (2013) Rheological parameters of fresh concrete—comparison of rheometers. Građevinar 65:99–109

Wallevik JE (2006) Relationship between the Bingham parameters and slump. Cem Concr Res 36:1214–1221

Banfill PFG, Beaupre D, Chapdelaine F, de Larrard F, Domone P, Nachbaur L, Sedran T, Wallevik OH, Wallevik JE (2001) Comparison of concrete rheometers: international tests at LCPC. National Institute of Standard and Technology (NIST), Gaithersburg

Roussel N (2012) Understanding the rheology of concrete. Woodhead Publishing Limited, Cambridge

Hema V, Savithri S (2003) Mathematical modelling of the dynamics of granular materials in a rotating cylinder. Cochin University of Science and Technology, Kochi

Balaz P (2008) Mechanochemistry in nanoscience and minerals engineering. Springer, New York

Hurtado FSV, Maliska CR, da Silva AFC, Cordazzo J (2005) An element-based finite volume formulation for reservoir simulation. In: Proceedings of the XXVI Iberian Latin-American congress on computational methods in engineering

Sahin Y, Akkaya Y, Boylu F, Tasdemir MA (2017) Characterization of air entraining admixtures in concrete using surface tension measurements. Cem Concr Compos 82:95–104

Brackbill JU, Kothe DB, Zemach C (1992) A continuum method for modeling surface tension. J Comput Phys 100:335–354

Malin MR (1997) The turbulent flow of Bingham plastic fluids in smooth circular tubes. Int Commun Heat Mass Transf 24:793–804

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Technical Editor: Cezar Negrao, PhD.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Beccati, N., Ferrari, C., Bonanno, A. et al. Calibration of a CFD discharge process model of an off-road self-loading concrete mixer. J Braz. Soc. Mech. Sci. Eng. 41, 76 (2019). https://doi.org/10.1007/s40430-019-1578-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-019-1578-1