Abstract

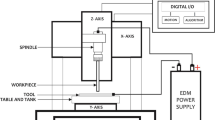

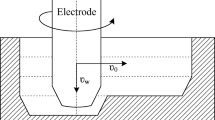

In today’s world, microstructures have a wide range of applications in the field of biomedical devices, aerospace engineering, MEMS device elements, etc. In the recent years, reverse micro-electro-discharge machining (R-µEDM) has evolved from µEDM that has become one of the promising technologies to fabricate precise components and microstructures of various shapes with high aspect ratio. In this work, micro-tools (rods) of average size (diameter) 182 µm have been machined using copper sheet from bulk tungsten rod of 800 µm diameter by R-µEDM process. Moreover, Taguchi’s L16 orthogonal array has also been applied for designing the experiments. Feed rate, capacitance and voltage are considered as the parameters of the process. The response parameters such as machining time, erosion rate and dimensional variation have been analyzed in detail for different combinations of the process parameters. It is a well-known fact that the tool wear is the main culprit and responsible for the error in the micro-rods. Dimensional error has been quantified over the entire length of the micro-rods through the measurement process, and the minimum standard deviation is found to be 1.13 µm at a feed rate of 5 µm/s, capacitance of 1000 pF and voltage of 120 V. Further, machining data have been collected in real time and the behavior of machining time with work feed has been studied. In addition to it, a simple analytical model has been developed for calculating the erosion rate and it is seen that voltage produces more effect on erosion rate and machining time than the other parameters. Additionally, using the feed rate, capacitance and voltage at which minimum deviation took place, an array of 4 × 4, i.e., 16 micro-rods with 58 µm diameter and 830 µm length, has been fabricated on the bulk tungsten rod of 800 µm diameter.

Similar content being viewed by others

References

Masuzawa T, Tönshoff HK (1997) Three-dimensional micromachining by machine tools. CIRP Ann Manuf Technol 46:621–628

Tamang SK, Natarajan N, Chandrasekaran M (2017) Optimization of EDM process in machining micro holes for improvement of hole quality. J Braz Soc Mech Sci Eng 39:1277–1287

Das AK, Kumar P, Sethi A et al (2016) Influence of process parameters on the surface integrity of micro-holes of SS304 obtained by micro-EDM. J Braz Soc Mech Sci Eng 38:2029–2037

Singh AK, Patowari PK, Deshpande NV (2013) Micro-hole drilling on thin sheet metals by micro-electro discharge machining. J Manuf Technol Res 5:137

Kar S, Patowari PK (2018) Electrode wear phenomenon and its compensation in micro electrical discharge milling: a review. Mater Manuf Process 33:1491–1517

Hourmand M, Sarhan AAD, Sayuti M (2017) Characterizing the effects of micro electrical discharge machining parameters on material removal rate during micro EDM drilling of tungsten carbide (WC-Co). In: IOP conference series: materials science and engineering. IOP Publishing, p 12005

Chavoshi SZ, Goel S, Morantz P (2017) Current trends and future of sequential micro-machining processes on a single machine tool. Mater Des 127:37–53

Mishra K, Mukhopadhyay P, Sarkar BR et al (2018) Improvement of micro-EDM performances with aid of vibration. Int J Precis Technol 8:38–65

Chakraborty S, Dey V, Ghosh SK (2015) A review on the use of dielectric fluids and their effects in electrical discharge machining characteristics. Precis Eng 40:1–6

Singh AK, Patowari PK, Deshpande NV (2017) Effect of tool wear on microrods fabrication using reverse μEDM. Mater Manuf Process 32:286–293

Kim BH, Park BJ, Chu CN (2006) Fabrication of multiple electrodes by reverse EDM and their application in micro ECM. J Micromech Microeng 16:843

Talla G, Gangopadhyay S, Kona NB (2017) Experimental investigation and optimization during the fabrication of arrayed structures using reverse EDM. Mater Manuf Process 32:958–969

Tong H, Li Y, Zhang L (2018) Servo scanning 3D micro EDM for array micro cavities using on-machine fabricated tool electrodes. J Micromech Microeng 28:25013

Gao S, Huang H (2017) Recent advances in micro-and nano-machining technologies. Front Mech Eng 12:18–32

Hourmand M, Sarhan AAD, Sayuti M (2017) Micro-electrode fabrication processes for micro-EDM drilling and milling: a state-of-the-art review. Int J Adv Manuf Technol 91:1023–1056

Singh AK, Patowari PK, Deshpande NV (2016) Experimental analysis of reverse micro-EDM for machining microtool. Mater Manuf Process 31:530–540

Nicolelis MAL (2010) Methods for neural ensemble recordings. CRC Press, Boca Raton

Tathireddy P, Rakwal D, Bamberg E, Solzbacher F (2009) Fabrication of 3-dimensional silicon microelectrode arrays using micro electro discharge machining for neural applications. In: Solid-state sensors, actuators and microsystems conference, 2009. TRANSDUCERS 2009. International. IEEE, pp 1206–1209

Amorim FL, Weingaertner WL (2007) The behavior of graphite and copper electrodes on the finish die-sinking electrical discharge machining (EDM) of AISI P20 tool steel. J Braz Soc Mech Sci Eng 29:366–371

Jain VK (2009) Advanced machining processes. Allied Publishers, New Delhi

Mastud SA, Singh RK, Joshi SS (2009) Investigation of reverse micro-EDM process for generating high aspect ratio micro-electrode arrays. Professional Engineering Publishing Ltd, London

Mujumdar SS, Mastud SA, Singh RK, Joshi SS (2010) Experimental characterization of the reverse micro-electrodischarge machining process for fabrication of high-aspect-ratio micro-rod arrays. Proc Inst Mech Eng Part B J Eng Manuf 224:777–794

Mastud SA, Kothari NS, Singh RK, Joshi SS (2015) Modeling debris motion in vibration assisted reverse micro electrical discharge machining process (R-MEDM). J Microelectromech Syst 24:661–676

Singh AK, Patowari PK, Deshpande NV (2013) Fabrication of micro tool using reverse-micro EDM. In: International conference on precision, meso, micro and nano engineering (COPEN-8: 2013). NIT Calicut, India, pp 218–221

Roy RK (2001) Design of experiments using the Taguchi approach: 16 steps to product and process improvement. Wiley, New York

Wangikar SS, Patowari PK, Misra RD (2017) Effect of process parameters and optimization for photochemical machining of brass and german silver. Mater Manuf Process 32:1747–1755

Gul M, Shah AN, Jamal Y, Masood I (2016) Multi-variable optimization of diesel engine fuelled with biodiesel using grey-Taguchi method. J Braz Soc Mech Sci Eng 38:621–632

Abhishek K, Datta S, Biswal BB, Mahapatra SS (2017) Machining performance optimization for electro-discharge machining of Inconel 601, 625, 718 and 825: an integrated optimization route combining satisfaction function, fuzzy inference system and Taguchi approach. J Braz Soc Mech Sci Eng 39:3499–3527

Khazaali H, Fereshteh-Saniee F (2018) Application of the Taguchi method for efficient studying of elevated-temperature incremental forming of a titanium alloy. J Braz Soc Mech Sci Eng 40:43

Gadhave ND, Gawande SH (2018) Optimizing performance of the Jatropha biodiesel engine using Taguchi approach. J Braz Soc Mech Sci Eng 40:235

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Technical Editor: Márcio Bacci da Silva, Ph.D.

Rights and permissions

About this article

Cite this article

Singh, A.K., Patowari, P.K. & Deshpande, N.V. Analysis of micro-rods machined using reverse micro-EDM. J Braz. Soc. Mech. Sci. Eng. 41, 15 (2019). https://doi.org/10.1007/s40430-018-1519-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1519-4