Abstract

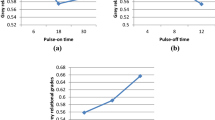

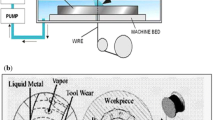

The study presents machining aspects of particulate silicon carbide reinforced aluminium metal matrix composite (Al/SiCp-MMC) using wire-cut electric discharge machining process. The influences of process parameters such as pulse on time, pulse off time, spark gap voltage, peak current, wire tension and wire feed rate on response variables such as workpiece cutting speed, surface roughness (Ra) and spark gap have been investigated. The Box–Behnken’s design has been utilized to plan the experiments, and response surface methodology is employed for developing quadratic regression models for selected response variables. Desirability function approach has been used to solve the multi-response optimization problem by assigning the weightages to the selected responses as per the user’s requirement of quality or productivity. The study recommends optimal process conditions such as pulse on time 0.75 µs, pulse off time 16 µs, spark gap voltage 35 V, peak current 120 A, wire tension 1200 g, and wire feed rate 10 m/min for effective machining of Al/SiCp-MMC, which has been validated by conducting confirmation experiments. The developed regression models for selected responses revealed compatible results, thereby justifying their acceptability.

Similar content being viewed by others

Abbreviations

- Al-MMCs:

-

Aluminum metal matrix composites

- Al/SiCp-MMC:

-

Particulate silicon-reinforced aluminum matrix composite

- BBD:

-

Box–Behnken’s design

- RSM:

-

Response surface methodology

- SEM:

-

Scanning electron micrograph

- CS:

-

Cutting speed

- SR:

-

Surface roughness, Ra (µm)

- SG:

-

Spark gap

- Ip:

-

Peak current

- SV:

-

Spark gap voltage

- T on :

-

Pulse on time

- T off :

-

Pulse off time

- WF:

-

Wire feed rate

- WT:

-

Wire tension

References

Chawla N, Chawla KK (2006) Metal matrix composites, 1st ed edn. Springer, New York. https://doi.org/10.1007/b101197

Davim JP (2012) Machining of metal matrix composites. Springer. https://doi.org/10.1007/978-0-85729-938-3

Vedrtnam A, Kumar A (2017) Fabrication and wear characterization of silicon carbide and copper reinforced aluminium matrix composite. Mater Discov 9:16–22

Manna A, Bhattacharayya B (2003) A study on machinability of Al/SiC-MMC. J Mater Process Technol 140:711–716

Muller F, Monaghan J (2001) Non-conventional machining of particle reinforced metal matrix composite. J Mater Process Technol 118:278–285

Rao RV (2011) Advance modeling and optimization of manufacturing processes. Springer, Berlin. https://doi.org/10.1007/978-0-85729-015-1

Yan BH, Tsai HC, Huang FY, Lee LC (2004) Examination of wire electrical discharge machining of Al2O3p/6061Al composites. Int J Mach Tools Manuf 45(3):251–259

Tosun N, Cogun C (2003) An investigation on wire wear in WEDM. J Mater Process Technol 134(3):273–278

Patil NG, Brahmankar PK (2010) Determination of material removal rate in wire electro-discharge machining of metal matrix composites using dimensional analysis. Int J Adv Manuf Technol 51(5):599–610

Patil NG, Brahmankar PK (2010) Some studies into wire electro-discharge machining of alumina particulate-reinforced aluminum matrix composites. Int J Adv Manuf Technol 48:537–555

Shandilya P, Jain PK, Jain NK (2013) RSM and ANN modeling approaches for predicting average cutting speed during WEDM of SiCp/6061-Al MMC. Procedia Eng IConDM 64:767–774

Manna A, Bhattacharayya B (2005) Influence of machining parameters on the machinability of particulate reinforced Al/SiC--MMC. Int J Adv Manuf Technol 25:850–856

Patel K, Pandey PM, Rao PV (2008) Understanding the role of weight percentage and size of silicon carbide particulate reinforcement on electro-discharge machining of aluminum-based composites. Mater Manuf Processes 23(7):665–673

Shandilya P, Jain PK, Jain NK (2012) Parametric optimization during wire electric discharge machining using response surface methodology. Procedia Eng 38:2371–2377

Pramanik A (2015) Electrical discharge machining of MMCs reinforced with very small particles. Mater Manuf Process. https://doi.org/10.1080/10426914.2015.1048360

Das MK, Kumar K, Barman TK, Sahoo P (2014) Application of artificial bee colony algorithm for optimization of MRR and surface roughness in EDM of EN31 tool steel. Procedia Mater Sci ICMPC 6:741–751. https://doi.org/10.1016/j.mspro.2014.07.090

Mahapatra SS, Patnaik A (2007) Optimization of wire electric discharge parameters using Taguchi method. Int J Adv Manuf Technol 34:911–925

Fard RK, Afza RA, Teimouri R (2013) Experimental investigation, intelligent modeling and multi-characteristics optimization of dry WEDM process of Al--SiC metal matrix composite. J Manuf Process. https://doi.org/10.1016/j.jmapro.2013.09.002

Mahapatra SS, Patnaik A (2006) Parametric optimization of Wire EDM process using Taguchi method. J Braz Soc Mech Sci Eng 28(4):422–429

Garg SK, Manna A, Jain A (2016) Experimental investigation of spark gap and material removal rate of Al/ZrO2p-MMC machined with wire EDM. J Braz Soc Mech Sci Eng 38:481–491

Prasad DVSSSV, Krishna AG (2015) Empirical modeling and optimization of kerf width and wire wear ratio in wire electrical discharge machining. Int J Adv Manuf Technol 77:427–441

Assarzadeh S, Ghoreishi M (2013) A dual response surface-desirability approach to process modeling and optimization of Al2O3 power-mixed electrical discharge machining (PMEDM) parameters. Int J Adv Manuf Technol 64:1459–1477. https://doi.org/10.1007/s00170-012-4115-2

Cheema MS, Dvivedi A, Sharma AK (2013) A hybrid approach to multi criteria optimization based on user’s preference rating. Proc Inst Mech Eng, Part B: J Eng Manuf. https://doi.org/10.1177/0954405413491958

Montgomery DC (2001) Design and analysis of experiments, 5th edn. Wiley, New York

Kumar H, Manna A, Kumar R (2014) Analysis of parametric effects on response characteristics and faults diagnosis during WEDM of Al/SiCp-MMC. In: Design and research conference (AIMTDR 2014) December 12th–14th, 2014, IIT Guwahati, Assam, India, pp 702(1)–702(6)

Rao TB, Krishna AG (2014) Selection of optimal process parameters in WEDM while machining Al7075/SiCp metal matrix composites. Int J Adv Manuf Technol 73:299–314

Satishkumar D, Kanthababu M, Vajjiravelu V (2011) Investigation of wire electrical discharge machining characteristics of Al6063/SiCp composites. Int J Adv Manuf Technol 56:975–986. https://doi.org/10.1007/s00170-011-3242-5

Kumar A, Kumar V, Kumar J (2013) Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-013-4861-9

Mouralova K, Kovar J, Klakurkova I, Bednar J, Benes L, Zahradnicek R (2018) Analysis of surface morphology and topography of pure aluminium machined using WEDM. Measurement 114:169–176

Arikatla SV, Manna KT, Krishnaiah A (2017) Parametric optimization in wire electrical discharge machining of titanium alloy using response surface methodology. Mater Today Proc 4:1434–1441

Habib S, Okada A (2016) Study on the movement of wire electrode during fine wire electrical discharge machining process. J Mater Process Technol 227:147–152

Goswami A, Kumar J (2014) Investigation of surface integrity, material removal rate and wire wear ratio for WEDM of Nimonic 80A alloy using GRA and Taguchi method. Eng Sci Technol Int J 17:173–184. https://doi.org/10.1016/j.jestch.2014.05.002

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva.

Rights and permissions

About this article

Cite this article

Kumar, H., Manna, A. & Kumar, R. Modeling and desirability approach-based multi-response optimization of WEDM parameters in machining of aluminum metal matrix composite. J Braz. Soc. Mech. Sci. Eng. 40, 458 (2018). https://doi.org/10.1007/s40430-018-1368-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1368-1