Abstract

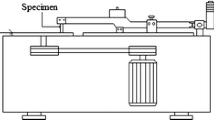

Present work deals with the parametric study of dry sliding wear behaviour of TiB2-reinforced aluminium matrix composites (AMCs). Aluminium 6082-T6 alloy specimens reinforced with 0, 3, 6, 9 and 12 wt% of TiB2 particles were fabricated by the in situ reaction of K2TiF6 and KBF4 in heated liquid aluminium. Experiments were conducted to study the wear behaviour of AA6082–T6/TiB2 composites using pin-on-disc apparatus at room temperature. Weight percentage of reinforcement, sliding speed, load and sliding distance were the process parameters studied in the present investigation, with five different levels of each parameter. The parametric optimization was done employing response surface methodology. The results confirmed that an increase in the amount of reinforcement and sliding speed decreased the wear loss, and an increase in load and sliding distance increased the wear in TiB2-reinforced AMCs. However, the relative significance of these parameters on the sliding wear resistance of the AMCs was very much different. Analysis of variance showed that the sliding distance was the most dominating factor with 65.28% to influence the wear loss in the fabricated composites; it was preceded by the sliding speed with 14.78%, load (9.39%) and reinforcement percentage (3.86%), respectively. The present model was validated by conducting confirmation tests. Thus in this work an accurate wear model has been developed, and it can be used as a predictive tool for wear applications.

Similar content being viewed by others

References

Dwivedi SP, Sharma S, Mishra RM (2015) Microstructure and mechanical behavior of A356/SiC/Fly-ash hybrid composites produced by electromagnetic stir casting. J Braz Soc Mech Sci Eng 37:57–67

Sahin Y, Ozdin K (2008) A model for the abrasive wear behaviour of aluminium based composites. Mater Des 29:728–733

Tee KL, Lu L, Lai MO (1999) Synthesis of in situ Al–TiB2 composites using stir cast route. Compos Struct 47:589–593

Natrajan S, Narayanasamy R, Kumaresh SP, Dinesh G, Anil B, Sivaprasad K (2009) Sliding wear behaviour of Al 6063/TiB2 in situ composites at elevated temperatures. Mater Des 30:2521–2531

Suresh S, Shenbag N, Moorthi V (2012) Aluminum–titanium diboride (Al–TiB2) metal matrix composites: challenges and opportunities. Proc Eng 38:89–97

Mandal A, Chakraborty M, Murty BS (2007) Effect of TiB2 particles on sliding wear behaviour of Al–4Cu alloy. Wear 262:160–166

Kumar S, Chakraborty M, Subramanya SV, Murthy BS (2008) Tensile and wear behaviour of in situ Al–7Si/TiB2 particulate composites. Wear 265:134–142

Mandal A, Murty BS, Chakraborty M (2009) Sliding wear behaviour of T6 treated A356–TiB2 in situ composites. Wear 266:865–872

Mallikarjuna C, Shashidhara SM, Mallik US, Parashivamurthy KI (2011) Grain refinement and wear properties evaluation of aluminum alloy 2014 matrix-TiB2 in situ composites. Mater Des 32:3554–3559

Ramesh CS, Ahamed A (2011) Friction and wear behaviour of cast Al 6063 based in situ metal matrix composites. Wear 271:1928–1939

Niranjan K, Lakshminarayanan PR (2013) Dry sliding wear behaviour of in situ Al–TiB2 composites. Mater Des 47:167–173

Radhika N, Raghu R (2015) Dry sliding wear behaviour of aluminium Al–Si12Cu/TiB2 metal matrix composite using response surface methodology. Tribol Lett 59:1–9

Lee HL, Lu WH, Chan SLI (1992) Abrasive wear of powder metallurgy Al alloy 6061–SiC particle composites. Wear 159:223–231

Lee HL, Lu WH, Chan SLI (1995) Effect of aging on the sliding abrasive wear of P/M 2014 and 6061 Al alloy–SiC particle composites. Mater Lett 15:49–52

Kang YC, Chan SLI (2004) Tensile properties of nanometric Al2O3 particulate-reinforced aluminum matrix composites. Mater Chem Phys 85:438–443

Lee IS, Hsu CJ, Chen CF, Ho NJ, Kao PW (2011) Particle-reinforced aluminum matrix composites produced from powder mixtures via friction stir processing. Compos Sci Technol 71:693–698

Ceschini L, Minak G, Morri A (2006) Tensile and fatigue properties of the AA6061/20 vol% Al2O3p and AA7005/10 vol% Al2O3p composites. Compos Sci Technol 66:333–342

Arasu PT, Dhanasekaran R, Kumar PS, Srinivasan N (2013) Effect of hardness and microstructure on En 353 steel by heat treatment. Int J Eng Sci 2:1–5

Rabinowicz ED (1965) Friction and wear of work hardening in the design of wear resistant materials. Wiley, New York, pp 168–174

Kumar R, Dhiman S (2013) A study of sliding wear behaviors of Al-7075 alloy and Al-7075 hybrid composite by response surface methodology analysis. Mater Des 50:351–359

Baradeswaran A, Vettivel SC, Perumal AE, Selvakumar N, Franklin Issac R (2014) Experimental investigation on mechanical behaviour, modelling and optimization of wear parameters of B4C and graphite reinforced aluminium hybrid composites. Mater Des 63:620–632

Montgomery DC (2007) Design and analysis of experiments. Wiley India (P) Ltd, New Delhi

Yue NL, Lu L, Lai MO (1999) Application of thermodynamic calculation in the in situ process of Al/TiB2. Compos Struct 47:691–694

Ma ZY, Tjong SC, Li YL, Liang Y (1997) High temperature creep behavior of nanometric Si3N4 particulate reinforced aluminium composite. Mater Sci Eng, A 225:125–134

Singh G, Goyal S (2016) Dry sliding wear behaviour of AA6082–T6/SiC/B4C hybrid metal matrix composites using response surface methodology. Proc Inst Mech Eng L J Mater Des Appl. https://doi.org/10.1177/1464420716657114

Ramesh CS, Pramod S, Keshavamurthy R (2011) A study on microstructure and mechanical properties of Al 6061–TiB2 in situ composites. Mater Sci Eng, A 528:4125–4132

Mandal A, Murty BS, Chakraborty M (2009) Wear behaviour of near eutectic Al–Si alloy reinforced with in situ TiB2 particles. Mater Sci Eng, A 506:27–33

Michael Rajan HB, Ramabalan S, Dinaharan I, Vijay SJ (2013) Synthesis and characterization of in situ formed titanium diboride particulate reinforced AA7075 aluminum alloy cast composites. Mater Des 44:438–445

Sharma P, Sharma S, Khanduja D (2015) Parametric study of dry sliding wear behaviour of hybrid metal matrix composite produced by a novel process. Metall Mater Trans A 46A:3260–3270

Sharma N, Khanna R, Singh G, Kumar V (2016) Fabrication of 6061 aluminium alloy reinforced with Si3N4/n-Gr and its wear performance optimization using integrated RSM-GA. Part Sci Technol. https://doi.org/10.1080/02726351.2016.1196276

Chowdhury MA, Khalil MK, Nuruzzaman DM (2011) Effect of sliding speed and normal load on friction and wear property of aluminum. Int J Mech Mechatron Eng 11:45–49

Bhushan B, Jahsman WE (1978) Propagation of weak waves in elastic–plastic and elastic–viscoplastic solids with interfaces. Int J Solids Struct 14:39–51

Bhushan B, Jahsman WE (1978) Measurement of dynamic material behaviour under nearly uniaxial strain condition. Int J Solids Struct 14:739–753

Szklarska-Smialowska Z (1998) Pitting corrosion of aluminum. Corros Sci 41:1743–1767

Acknowledgements

The authors wish to express their gratitude to the authorities of Mechanical Engineering Department, Thapar University, Patiala, for providing the experimental facilities to conduct the work for this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Paulo de Tarso Rocha de Mendonça.

Rights and permissions

About this article

Cite this article

Singh, G., Chan, S.LI. & Sharma, N. Parametric study on the dry sliding wear behaviour of AA6082–T6/TiB2 in situ composites using response surface methodology. J Braz. Soc. Mech. Sci. Eng. 40, 310 (2018). https://doi.org/10.1007/s40430-018-1235-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1235-0