Abstract

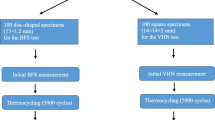

The purpose of this study is to evaluate the effects of aging by thermocycling on the mechanical and tribological properties of two indirect filling commercial resin-based restorative composite materials. The studied composites are referenced by the capital letters: A and B. The commercial trade names are omitted, to avoid commercial references. Forty specimens of each material were produced and divided into three groups: a control group not subjected to aging, and two groups, T1 and T2 submitted to different thermocycling conditions. The studied properties were surface roughness, elastic modulus (determined dynamically by impulse excitation of vibration, and statically by four-point bending test), flexural strength and work of fracture (four-point bending test), micro-hardness (Vickers micro-indentation) and coefficient of friction (scratch test). From this study, it was possible to conclude that Composite A, in addition to having better mechanical properties, is less affected by thermocycling than Composite B, which suggests that it will better withstand the stresses, both mechanical and thermal, which it is subjected to. It is also possible to infer that the thermocycling regimen proposed by Standard ISO 11405 (Dental materials—testing of adhesion to tooth structure, 2003) is not sufficient to adequately simulate the degradation caused by the oral environment on current commercial resin-based restorative composites.

Graphical abstract

Similar content being viewed by others

References

ISO/TS 11405:2015 Dental materials—testing of adhesion to tooth structure. International Organization for Standardization, Geneva, Switzerland. https://www.iso.org/obp/ui/#iso:std:iso:ts:11405:ed-3:v1:en

Antunes PV, Ramalho A, Carrilho EVP (2014) Mechanical and wear behaviors of nano and microfilled polymeric composite: effect of filler fraction and size. Mater Des 61:50–60

Asmussen E, Peutzfeldt A (1998) Influence of UEDMA, BisGMA and TEGDMA on selected mechanical properties of experimental resin composites. Dent Mater 14:51–56

Ru S, Raab WH, Janda R (2007) Polymerization shrinkage and hygroscopic expansion of contemporary posterior resin-based filling materials—A comparative study. J Dent 35:806–813

Amirouche-Korichi A, Mouzali M, Watts DC (2009) Effects of monomer ratios and highly radiopaque fillers on degree of conversion and shrinkage-strain of dental resin composites. Dent Mater 25:1411–1418

Amirouche-Korichi A, Mouzali M, Watts DC (2012) Shrinkage strain—rates study of dental composites based on (BisGMA/TEGDMA) monomers. Arab J Chem. doi:10.1016/j.arabjc.2012.07.021

Indrani DJ, Cooks WD, Televantosd F, Martin J, Harcourtl JK (1995) Fracture toughness of water-aged resin composite restorative materials. Dent Mater 11:201–207

Sideridou ID, Karabela MM, Bikiaris DN (2007) Aging studies of light cured dimethacrylate-based dental resins and a resin composite in water or ethanol/water. Dent Mater 23:1142–1149

Mesquita RV, Geis-Gerstorfer J (2008) Influence of temperature on the visco-elastic properties of direct and indirect dental composite resins. Dent Mater 24:623–632

Ramalho A, Braga de Carvalho MD, Antunes PV (2013) Effects of temperature on mechanical and tribological properties of dental restorative composite materials. Tribol Int 63:186–195

Musanje L, Darvell BW (2004) Effects of strain rate and temperature on the mechanical properties of resin composites. Dent Mater 20:750–765

Gale MS, Darvell BW (1999) Thermal cycling procedures for laboratory testing of dental restorations. J Dent 27:89–99

Göhring TN, Gallo L, Lüthy H (2005) Effect of water storage, thermocycling, the incorporation and site of placement of glass-fibers on the flexural strength of veneering composite. Dent Mater 21:761–772

Meriç G, Ruyter IE (2007) Effect of thermal cycling on composites reinforced with two differently sized silica-glass fibers. Dent Mater 23:1157–1163

Morresi AL, D’Amario M, Capogreco M, Gatto R, Marzo G, D’Arcangelo C, Monaco A (2014) Thermal cycling for restorative materials: does a standardized protocol exist in laboratory testing? A literature review. J Mech Behav Biomed Mater 29:295–308

Zheng SY, Zheng J, Gao SS, Yu BJ, Yu HY, Qian LM, Zhou ZR (2011) Investigation on the microtribological behaviour of human tooth enamel by nanoscratch. Wear 271:2290–2296

Palaniappan S, Celis J-P, Meerbeek BV, Peumans M, Lambrechts P (2013) Correlating in vitro scratch test with in vivo contact free occlusal area wear of contemporary dental composites. Dent Mater 29(3):259–268

Fereira VR, Sukumaran J, Delgado YP, Staia M, Iost A, Baets PD (2013) Scratch evaluation on a high performance polymer. Mech Eng Lett 9:76–84

Yamamoto T, Hanabusa M, Momoi Y, Sakaguchi RL (2015) Polymerization stress of dental resin composite continues to develop 12 hours after irradiation. J Esthet Restor Dent 27(1):44–54

Fugolin APP, Correr-Sobrinho L, Correr AB, Sinhoreti MAC, Guiraldo RD, Consani S (2016) Influence of irradiance on Knoop hardness, degree of conversion, and polymerization shrinkage of nanofilled and microhybrid composite resins. General Dent 64:26–31

Narene AVK, Veniashok B, Subbiya A, Vivekanandhan P, Sukumaran VG (2014) Polymerisation shrinkage in resin composites—a review. Middle East J Sci Res 21:107–112

Yang S, Choi J, Cho M (2012) Elastic stiffness and filler size effect of covalently grafted nanosilica polyimide composites: molecular dynamics study. ACS Appl Mater Interfaces 4:4792–4799

Mandikos MN, McGivney GP, Davis E, Bush PJ, Carter JM (2001) A comparison of the wear resistance and hardness of indirect composite Resins. J Prosthet Dent 85(4):386–395

ISO 4288:1996/Cor.1:1998 (en), Geometrical Product Specifications (GPS)—Surface texture: profile method—rules and procedures for the assessment of surface texture, International Organization for Standardization, Geneva, Switzerland

Braem M, Lambrechts P, Doren VVAN, Vanherle G (1986) The impact of composite structure on its elastic response. J Dent Res 65:648–653

C1259 (2015) Standard test method for dynamic young’s modulus, Shear modulus, and poisson’s ratio for advanced ceramics by impulse excitation of vibration, Developed by subcommittee: C28.01, Book of standards vol 15.01, American Society for Testing and Materials ASTM C1259

C1161 (2013) Standard test method for flexural strength of advanced ceramics at ambient temperature, Developed by subcommittee: C28.01, Book of standards vol 15.01, American Society for Testing and Materials ASTM C1161

E384 (2016) Standard test method for microindentation hardness of materials, Developed by subcommittee: E04.05, Book of standards vol 03.01, American Society for Testing and Materials ASTM E384-16

G171 (2009) Standard test method for scratch hardness of materials using a diamond stylus, Developed by subcommittee: G02.30, Book of standards vol 03.02, American Society for Testing and Materials ASTM G171-03(2009)e2

Stalio E (2002) Direct numerical simulation of heat transfer enhancing surfaces. Doctoral Thesis, pp 75–90

Tuncer S, Demirci M, Tiryaki M, Ünlü N, Uysal Ö (2013) The effect of a modeling resin and thermocycling on the surface hardness, roughness, and color of different resin composites. J Esthet Restor Dent 25:404–419

Beun S, Glorieux T, Devaux J, Vreven J, Leloup G (2013) Characterization of nanofilled compared to universal and microfilled composites. Dent Mater 23:51–59

Heintze SD, Zellweger G, Zappini G (2007) The relationship between physical parameters and wear of dental composites. Wear 263:1138–1146

Mesquita RV, Axmann D, Geis-Gerstorfer J (2006) Dynamic visco-elastic properties of dental composite resins. Dent Mater 22:258–267

Xu HH, Smith DT, Jahanmir S, Romberg E, Kelly JR, Thompson VP, Rekow ED (1998) Indentation damage and mechanical properties of human enamel and dentin”. J Dent Res 77:472–480

El-Safty S, Akhtar R, Silikas N, Watts DC (2012) Nanomechanical properties of dental resin-composites. Dent Mater 28:1292–1300

Belli R, Petschelt A, Lohbauer U (2014) Are linear elastic material properties relevant predictors of the cyclic fatigue resistance of dental resin composites? Dent Mater 30:381–391

ISO 4049:2009 (2009) Dentistry—polymer-based restorative materials, ISO/TC 106/SC 1, standard was last reviewed in 2014, International Organization for Standardization, Geneva, Switzerland

Asmussen E, Peutzfeldt A (1998) Influence of UDMA, bis-GMA and TEGDMA on selected mechanical properties of experimental resin composites. Dent Mater 56:14–51

Sideridou ID, Karabela MM, Bikiaris DN (2009) Aging studies of light cured dimethacrylate-based dental resins and a resin composite in water or ethanol/water. Dent Mater 23(9):1142–1149

Ruyter IE, Øysæd H (1987) Composites for use in posterior teeth: composition and conversion. J Biomed Mater Res 21:11–23

Peutzfeldt A, Asmussen E (1992) Modulus of resilience as predictor for clinical wear of restorative resins. Dent Mater 8:146–148

Asmussen E, Peutzfeldt A (1998) Influence of UEDMA BisGMA and TEGDMA on selected mechanical properties of experimental resin composites. Dent Mater 14(1):51–56

Ho CT, Vijayaraghavan TV, Lee SY, Tsai A, Huang HM, Pan LC (2001) Flexural behaviour of post-cured composites at oral-simulating temperatures. J Oral Rehabil 28:658–667

Kao EC (1989) Influence of food-simulating solvents on resin composites and glass-ionomer restorative cement. Dent Mater 5:201–208

Ferracane JL, Berge HX, Condon JR (1998) In vitro aging of dental composites in water—effect of degree of conversion, filler volume, and fillermatrix coupling. J Biomed Mater Res 42:465–472

Ferracane JL, Berge HX (1988) Fracture toughness of experimental dental composites aged in ethanol. J Dent Res 74:1418–1423

Pilliar RM, Vowles R, Williams DF (1987) The effect of environmental aging on the fracture toughness of dental composites. J Dent Res 66:722–726

Prakki A, Cilli R, Mondelli RFL, Kalachandra S, Pereira JC (2005) Influence of pH environment on polymer based dental material properties. J Dent 33:91–98

Ortengren U, Andersson F, Elgh U, Terselius B, Karlsson S (2001) Influence of pH and storage time on the sorption and solubility behaviour of three composite resin materials. J Dent 29:35–41

Sarkar NK, Karmaker A, Prasad A, Shih F (1999) Simulation of in vivo degradation of dental composites. J Mater Sci Lett 18:1749–1752

Zaytsev D, Panfilov P (1999) Deformation behavior of human enamel and dentin-enamel junction under compression. Mater Sci Eng C 34:15–21

Alshali RZ, Salim NA, Satterthwaite JD, Silikas N (2015) Post-irradiation hardness development, chemical softening, and thermal stability of bulk-fill and conventional resin-composites. J Dent 43:209–218

Rahim TNAT, Mohamad D, Akil HM, Rahman IA (2012) Water sorption characteristics of restorative dental composites immersed in acidic drinks. Dent Mater 28(6):e63–e70

Ferracane JL (2006) Hygroscopic and hydrolytic effects in dental polymer networks. Dent Mater 22(3):211–222

Curtis AR, Shortall AC, Marquis PM, Palin WM (2008) Water uptake and strength characteristics of a nanofilled resin-based composite. J Dent 36(3):186–193

Moraes RR, Sinhoreti MAC, Correr-Sobrinho L, Ogliari FA, Piva E, Petzhold CL (2010) Preparation and evaluation of dental resin luting agents with increasing content of bisphenol-A ethoxylated dimethacrylate. J Biomater Appl 24(5):453–473

Kalachandra S, Turner DT (1987) Water sorption of polymethacrylate networks: Bis-GMA/TEGDM copolymers. J Biomed Mater Res 21(3):329–338

Kobrick RL, Klaus DM, Street KW (2011) Standardization of a volumetric displacement measurement for two-body abrasion scratch test data analysis. Wear 270(9–10):650–657

Jardret V, Morel P (2003) Viscoelastic effects on the scratch resistance of polymers: relationship between mechanical properties and scratch properties at various temperatures. Prog Org Coat 48:322–331

Barletta M, Gisario A, Trovalusci F, Vesco S (2013) Visual appearance and scratch resistance of high performance thermoset and thermoplastic powder coatings. Prog Org Coat 76:244–256

Barletta M, Tagliaferri V, Gisario A, Venettacci S (2013) Progressive and constant load scratch testing of single- and multi-layered composite coatings. Tribol Int 64:39–52

Bastos FS, Oliveira EA, Fonseca LG, Vargas SM, Las Casas EB (2016) A FEM-based study on the influence of skewness and kurtosis surface texture parameters in human dental occlusal contact. J Comput Appl Math 295:139–148

Sedlaček M, Podgornik B, Vižintin J (2012) Correlation between standard roughness parameters skewness and kurtosis and tribological behaviour of contact surfaces. Tribol Int 48:102–112

Ţălu Ş, Stach S, Lainović T, Vilotić M, Blažić L, Alb SF, Kakaš D (2015) Surface roughness and morphology of dental nanocomposites polished by four different procedures evaluated by a multifractal approach. Appl Surf Sci 330:20–29

Palaniappan S, Celis J-P, Van Meerbeek B, Peumans M, Lambrechts P (2013) Correlating in vitro scratch test with in vivo contact free occlusal area wear of contemporary dental composites. Dent Mater 29:259–268

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Estevam Las Casas.

Rights and permissions

About this article

Cite this article

Carreira, M., Antunes, P.V., Ramalho, A. et al. Thermocycling effect on mechanical and tribological characterization of two indirect dental restorative materials. J Braz. Soc. Mech. Sci. Eng. 39, 1–17 (2017). https://doi.org/10.1007/s40430-016-0579-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40430-016-0579-6