Abstract

Common rail diesel engines with electronic fuel injection can accurately meter the fuel injection quantity with more accurate fuel injection control capability. In this work a common rail fuel injection system of a single cylinder diesel engine has been proposed and the important parameters like injection pressure, energizing time and high pressure pipes diameter and length are designed such that to be compatible with the engine basic design in case of pressure waves and injected mass variations. A one-dimensional approach has been used to model the injector using AMESim code in which Adiabatic models have been used to model injector system. Injected mass quantity has been calculated for different working point of fuel injection system that can be utilized as engine electronic control maps as inlet parameters. Results indicated that pressure fluctuation at the injector inlet is increased by decreasing pipe diameter while tube length has no significant effect on pressure waves. It is also shows that using biodiesel as fuel will lead to decrease in injection quantity but there is no significant impact on pressure fluctuations.

Similar content being viewed by others

Notes

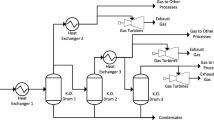

AMsim is a one dimensional software that is capable to model a system with hydraulically, mechanical and electrical components. As the fuel injection system for common rail engines includes electromechanical and hydraulic parts, this software is suitable for modeling of this system.

Abbreviations

- A 0 :

-

Area of nozzle hole (mm3)

- C d :

-

Discharge coefficient

- CN:

-

Cavitation number

- CR:

-

Common-rail

- d :

-

Spring spire diameter (mm)

- D :

-

Spring diameter (mm)

- D 0 :

-

Diameter at the orifice outlet (mm)

- ET:

-

Energizing time (ms)

- EDC:

-

Electronic desel control

- HPCR:

-

High pressure Common-rail

- IQA:

-

Injection Quantity Adjustment

- k :

-

Stiffness of spring (N/m)

- L :

-

Length

- \(\dot{m}_f\) :

-

Mass flow rate (kg/s)

- n a :

-

Spring number of spires

- P b :

-

Discharge pressure (bar)

- P i :

-

Injection pressure (bar)

- P v :

-

Vapor pressure of fuel (bar)

- PWC:

-

Pressure wave correction

- RME:

-

Rape seed methyl ester

- u :

-

Velocity (m/s)

- λ :

-

Flow number

- v f :

-

Fuel kinematic viscosity (cSt)

- ρ f :

-

Fuel density (kg/m3)

- ΔP :

-

Pressure drop (bar)

References

Reif K (2014) Diesel engine management. Springer, Berlin

Hummel K et al (2004) Third-generation common rail system with piezo inline injectors from Bosch for passenger cars. MTZ Worldw 65(3):9–12

Coppo M, Dongiovanni C, Negri C (2002) Numerical analysis and experimental investigation of a common rail type diesel injector. In: ASME 2002 internal combustion engine division fall technical conference: American Society of Mechanical Engineers, pp 271–80

Ahlin K (2000) Modelling of pressure waves in the common rail diesel injection system. Linköpings Universitet, SE-581, 83

Gullaksen J (2003) Simulation of diesel fuel injection dynamics: MSc Thesis, Department of Mechanical Engineering, Technical University of Denmark, Denmark

Boudy F, Seers P (2009) Impact of physical properties of biodiesel on the injection process in a common-rail direct injection system. Energy Convers Manag 50:2905–2912

Salvador FJ, Plazas AH, Gimeno J, Carreres M (2014) Complete modelling of a piezo actuator last-generation injector for diesel injection systems. Int J Engine Res 15:3–19

Ubertini S (2006) Injection pressure fluctuations model applied to a multidimensional code for diesel engines simulation. J Eng Gas Turbines Power 128:694–701

Catania A, Ferrari A, Mittica A, Spessa E (2007) Common rail without accumulator: development, theoretical-experimental analysis and performance enhancement at di-hcci level of a new generation FIS. SAE Technical Paper

Beierer P (2007) Experimental and numerical analysis of the hydraulic circuit of a high pressure common rail diesel fuel injection system. Ph.D. thesis, Tampere University of Technology, Finland

Imagine SA (2004) AMESim v4.2 User Manual. Imagine SA, Roanne

Baratta M, Catania AE, Ferrari A (2008) Hydraulic circuit design rules to remove the dependence of the injected fuel amount on dwell time in multi jet CR systems. J Fluids Eng 130(12):121104

Hajialimohammadi A, Honnery D, Abdullah A, Mirsalim MA (2013) Time resolved characteristics of gaseous jet injected by a group-hole nozzle. Fuel 113:497–505

Han D, Duan Y, Wang C, Lin H, Huang Z (2014) Experimental study on injection characteristics of fatty acid esters on a diesel engine common rail system. Fuel 123:19–25

Tat M, Van Gerpen J (2003) Measurement of biodiesel speed of sound and its impact on injection timing. National Renewable Energy Laboratory, NREL/SR-510-31462

Han D, Duan Y, Wang C, Lin H, Huang Z, Wooldridge MS (2016) Experimental study of the two-stage injection process of fatty acid esters on a common rail injection system. Fuel 163:214–222

Acknowledgments

The authors would like to thanks Fuel Combustion and Emission center of Sharif University of Technology for financial support and Mr. Varzdar and Mr. Hosseinian for their assistance on experimental setup establishment.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Luis Fernando Figueira da Silva.

Rights and permissions

About this article

Cite this article

Mohebbi, M., Aziz, A.A., Hamidi, A. et al. Modeling of pressure line behavior of a common rail diesel engine due to injection and fuel variation. J Braz. Soc. Mech. Sci. Eng. 39, 661–669 (2017). https://doi.org/10.1007/s40430-016-0573-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40430-016-0573-z