Abstract

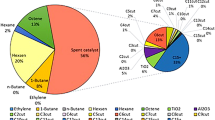

Spent caustic is a used industrial caustic whose chemical content puts it in the special waste category. The disposal of this waste and the production of value-added products from it has attracted the attention of researchers not only to solve environmental problems but also to take advantage of its byproducts. This research has experimentally proved the transferred thermal plasma technology as a practical method feasible for the disposal of spent caustic. In this study, the applied voltage, electrical current, and feed rate are variable parameters, and others are kept constant. GC analysis showed H2 as the main product, which is environmentally beneficial. The percentage of hydrogen production of approximately 74% is a promising result, considering the difficulty of achieving such a high percentage of hydrogen.

Similar content being viewed by others

Data availability

All data is available upon request.

References

Dou S, Tao L, Wang R, et al. Plasma-assisted synthesis and surface modification of electrode materials for renewable energy. Adv Mater. 2018;30:1705850. https://doi.org/10.1002/adma.201705850.

Bayatsarmadi B, Zheng Y, Vasileff A, Qiao S. Recent advances in atomic metal doping of carbon-based nanomaterials for energy conversion. Small. 2017;13:1700191. https://doi.org/10.1002/smll.201700191.

Lee DU, Xu P, Cano ZP, et al. Recent progress and perspectives on bi-functional oxygen electrocatalysts for advanced rechargeable metal-air batteries. J Mater Chem A. 2016;4:7107–34. https://doi.org/10.1039/c6ta00173d.

Li J, Liu K, Yan S, et al. Application of thermal plasma technology for the treatment of solid wastes in China: An overview. Waste Manag. 2016;58:260–9. https://doi.org/10.1016/j.wasman.2016.06.011.

Khani MR, Dejban Guy E, Khosravi A, Shokri B. Effect of microwave plasma torch on the pyrolysis fuel oil in the presence of methane and ethane to increase hydrogen production. Int J Hydrogen Energy. 2014;39:18812–9. https://doi.org/10.1016/j.ijhydene.2014.09.066.

Hawari A, Ramadan H, Abu-Reesh I, Ouederni M. A comparative study of the treatment of ethylene plant spent caustic by neutralization and classical and advanced oxidation. J Environ Manage. 2015;151:105–12. https://doi.org/10.1016/j.jenvman.2014.12.038.

Reich MC. Economic assessment of municipal waste management systems—case studies using a combination of life cycle assessment (LCA) and life cycle costing (LCC). J Clean Prod. 2005;13:253–63. https://doi.org/10.1016/j.jclepro.2004.02.015.

Kohlhase JE. The impact of toxic waste sites on housing values. J Urban Econ. 1991;30:1–26. https://doi.org/10.1016/0094-1190(91)90042-6.

Xu Y, Xue X, Dong L, et al. Long-term dynamics of leachate production, leakage from hazardous waste landfill sites and the impact on groundwater quality and human health. Waste Manag. 2018;82:156–66. https://doi.org/10.1016/j.wasman.2018.10.009.

Heberlein J, Murphy AB. Thermal plasma waste treatment. J Phys D Appl Phys. 2008;41:53001. https://doi.org/10.1088/0022-3727/41/5/053001.

Ferronato N, Torretta V, Ragazzi M, Rada EC. Waste mismanagement in developing countries: A case study of environmental contamination. UPB Sci Bull. 2017;79:185–96.

Dijkgraaf E, Vollebergh HRJ. Burn or bury? A social cost comparison of final waste disposal methods. Ecol Econ. 2004;50:233–47. https://doi.org/10.1016/j.ecolecon.2004.03.029.

Sharma RR, Sharma M, Sharma RR, Sharma V. The impact of incinerators on human health and environment. Rev Environ Health. 2013;28:67–72. https://doi.org/10.1515/reveh-2012-0035.

Zimmermann K. Microwave as an emerging technology for the treatment of biohazardous waste: A mini-review. Waste Manag Res. 2017;35:471–9. https://doi.org/10.1177/0734242X16684385.

Kollu VKR, Kumar P, Gautam K. Comparison of microwave and autoclave treatment for biomedical waste disinfection. Syst Microbiol Biomanufacturing. 2022;2:732–42. https://doi.org/10.1007/s43393-022-00101-y.

Wittmaier M. A biomechanical process for the specific material-flow treatment of residual waste-perspectives for concepts of decentralised waste disposal in Germany. In: Sustainable waste management and recycling: construction demolition waste. Thomas Telford Publishing; 2004. pp. 71–83.

Molinaro DD, King AS, Young AJ. Biomechanical analysis of common solid waste collection throwing techniques using OpenSim and an EMG-assisted solver. J Biomech. 2020;104:109704. https://doi.org/10.1016/j.jbiomech.2020.109704.

Jouve A, Maubert H, Schulte E. Bio-mechanical removing of contaminated soils: a field experiment. CEA Centre d’Etudes de Fontenay-aux-Roses; 1992.

Rada EC, Ragazzi M, Panaitescu V, Apostol T. The role of bio-mechanical treatments of waste in the dioxin emission inventories. Chemosphere. 2006;62:404–10. https://doi.org/10.1016/j.chemosphere.2005.04.065.

Malviya R, Chaudhary R. Factors affecting hazardous waste solidification/stabilization: A review. J Hazard Mater. 2006;137:267–76.

Materazzi M, Lettieri P, Taylor R, Chapman C. Performance analysis of RDF gasification in a two stage fluidized bed–plasma process. Waste Manag. 2016;47:256–66. https://doi.org/10.1016/j.wasman.2015.06.016.

Bonizzoni G, Vassallo E. Plasma physics and technology; industrial applications. Vacuum. 2002;64:327–36. https://doi.org/10.1016/S0042-207X(01)00341-4.

Gomez E, Rani DA, Cheeseman CR, et al. Thermal plasma technology for the treatment of wastes: A critical review. J Hazard Mater. 2009;161:614–26. https://doi.org/10.1016/j.jhazmat.2008.04.017.

Gleizes A, Gonzalez J-J, Freton P. Thermal plasma modelling. J Phys D Appl Phys. 2005;38:R153.

Han QY, et al. Thermal plasma destruction of hazardous waste with simultaneous production of valuable coproducts. ACS Books; 1995. pp. 135–43.

Heberlein JVR. Generation of thermal and pseudo-thermal plasmas. Pure Appl Chem. 1992;64:629–36. https://doi.org/10.1351/pac199264050629.

Karimi H, Khani MR, Gharibi M, et al. Plasma pyrolysis feasibility study of spent petrochemical catalyst wastes to hydrogen production. J Mater Cycles Waste Manag. 2020;22:2059–70. https://doi.org/10.1007/s10163-020-01089-0.

Agon N, Hrabovský M, Chumak O, et al. Plasma gasification of refuse derived fuel in a single-stage system using different gasifying agents. Waste Manag. 2016;47:246–55. https://doi.org/10.1016/j.wasman.2015.07.014.

Materazzi M, Lettieri P, Mazzei L, et al. Thermodynamic modelling and evaluation of a two-stage thermal process for waste gasification. Fuel. 2013;108:356–69. https://doi.org/10.1016/j.fuel.2013.02.037.

Tang L, Huang H. An investigation of sulfur distribution during thermal plasma pyrolysis of used tires. J Anal Appl Pyrolysis. 2004;72:35–40. https://doi.org/10.1016/j.jaap.2004.02.001.

Wang Q, Yan JH, Chi Y, et al. Application of thermal plasma to vitrify fly ash from municipal solid waste incinerators. Chemosphere. 2010;78:626–30. https://doi.org/10.1016/j.chemosphere.2009.10.035.

Li Y, Huang Z, Xu Y, Sheng H. Plasma-arc technology for the thermal treatment of chemical wastes. Environ Eng Sci. 2009;26:731–7. https://doi.org/10.1089/ees.2008.0222.

Pfender E. Thermal plasma technology: Where do we stand and where are we going? Plasma Chem plasma Process. 1999;19:1–31. https://doi.org/10.1023/A:1021899731587.

Sears JW, Eschenbach RC, Hill RA. The plasma centrifugal furnace: A method for stabilization and decomposition of toxic and radioactive wastes. Waste Manag. 1990;10:165–75. https://doi.org/10.1016/0956-053X(90)90038-M.

Safa S, Soucy G. Liquid and solution treatment by thermal plasma: a review. Int J Environ Sci Technol. 2014;11:1165–88. https://doi.org/10.1007/s13762-013-0356-3.

Snyder HR, Fleddermann CB, Gahl JM. Destruction of acetone using a small-scale arcjet plasma torch. Waste Manag. 1996;16:289–94. https://doi.org/10.1016/S0956-053X(96)00068-2.

Snyder HR, Fleddermann CB, Member S. Decomposition of dichloroethane in a plasma arcjet reactor: experiment and modeling. IEEE Trans plasma Sci. 1997;25:1017–22. https://doi.org/10.1109/27.649620.

Knak AN, Kalitko VA, Mosse AL, Fyodorov SA. Plasma-thermal processing of toxic halogen-containing organic waste. J Eng Phys Thermophys. 1997;70:593–7. https://doi.org/10.1007/BF02663578.

Kim S-W, Park H-S, Kim H-J. 100 kW steam plasma process for treatment of PCBs (polychlorinated biphenyls) waste. Vacuum. 2003;70:59–66. https://doi.org/10.1016/S0042-207X(02)00761-3.

Yuan M-H, Watanabe T, Chang C-Y. DC water plasma at atmospheric pressure for the treatment of aqueous phenol. Environ Sci Technol. 2010;44:4710–5. https://doi.org/10.1021/es9038598.

Rita AI, Rodrigues CSD, Santos M, et al. Comparison of different strategies to treat challenging refinery spent caustic effluents. Sep Purif Technol. 2020;253:117482. https://doi.org/10.1016/j.seppur.2020.117482.

Elmi R, Nejaei A, Farshi A, et al. Comparison of two methods of neutralization and wet air oxidation for treating wastewater spent caustic produced by oil refineries. Environ Monit Assess. 2021;193:1–24. https://doi.org/10.1007/s10661-021-09625-7.

Alnaizy R. Economic analysis for wet oxidation processes for the treatment of mixed refinery spent caustic. Environ Prog. 2008;27:295–301. https://doi.org/10.1002/ep.10261.

Wei Y, Zhao J, Liu Z, et al. Study on wet oxidation process and mechanism for ethylene spent caustic. Environ Technol. 2022;43:2637–46. https://doi.org/10.1080/09593330.2021.1892200.

Barge AS, Vaidya PD. Wet air oxidation of cresylic spent caustic–A model compound study over graphene oxide (GO) and ruthenium/GO catalysts. J Environ Manage. 2018;212:479–89. https://doi.org/10.1016/j.jenvman.2018.01.066.

Fabry F, Rehmet C, Rohani V, Fulcheri L. Waste gasification by thermal plasma: A review. Waste and Biomass Valorization. 2013;4:421–39. https://doi.org/10.1007/s12649-013-9201-7.

Kunze H-J. Introduction to plasma spectroscopy. Berlin: Springer Science & Business Media; 2009.

Cremers DA, Radziemski LJ. Handbook of laser-induced breakdown spectroscopy. John Wiley & Sons; 2013.

Radziemski L, Cremers D. A brief history of laser-induced breakdown spectroscopy: From the concept of atoms to LIBS 2012. Spectrochim Acta - Part B At Spectrosc. 2013;87:3–10. https://doi.org/10.1016/j.sab.2013.05.013.

McNair HM, Miller JM, Snow NH. Basic gas chromatography. John Wiley & Sons; 2019.

Littlewood AB. Gas chromatography: principles, techniques, and applications. Elsevier; 2013.

Fasihi M, Mohammadhosseini B, Ostovarpour F, et al. (Digital Presentation) Potential Application of Plasma Pyrolysis in Dairy Industries. ECS Meet Abstr. 2022;MA2022-02:2618. https://doi.org/10.1149/MA2022-02212618mtgabs.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aghayee, R., Khani, M., Ostovarpour, F. et al. Plasma pyrolysis feasibility study of Spent Caustic waste to hydrogen production. J Environ Health Sci Engineer (2023). https://doi.org/10.1007/s40201-023-00886-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40201-023-00886-7