Abstract

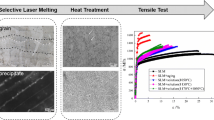

In this work, the microstructural evolution, micro-crack formation, and mechanical anisotropy of the selective laser melted (SLM) carbon-free Mar-M509 Co-based superalloy were systematically studied under different linear energy densities (LED). Observation shows that the SLM Mar-M509 superalloy possesses a fully dense structure, whereas some micro-cracks exist along the building direction. The electron backscatter diffraction results reveal that dominant columnar grains tend to elongate along the building direction parallel to the XZ plane. Meanwhile, both a < 001 > near fiber texture and a {100} < 001 > near sheet texture are observed in different specimens. For the specimen with fiber texture, a high misorientation angle exists among different columnar grains, which aggravated the generation of micro-cracks under thermal stress. Higher LED results in higher micro-crack density in the SLM specimen due to higher thermal stress. Mar-M509 specimen fabricated under lower LED exhibits higher tensile strength due to more significant grain refinement. More prominent anisotropy of tensile performance was found in the high LED specimen, which can be attributed to the higher density of micro-cracks and crystallographic texture. Furthermore, the SLM Mar-M509 superalloy exhibits better mechanical properties than the traditional cast technique. In summary, this work can contribute to the development and the future application of SLM-fabricated Co-based superalloy.

Similar content being viewed by others

References

A. Domashenkov, A. Plotnikova, I. Movchan, P. Bertrand, N. Peillon, B. Desplanques, S. Saunier, C. Desrayaud, Addit. Manuf. 15, 66 (2017)

W. Huang, H. Yu, J. Yin, Z. Wang, X. Zeng, Acta Metall. Sin. -Engl. Lett. 52, 1089 (2016)

M. Yan, S. Zhang, H. Wang, Acta Metall. Sin. -Engl. Lett. 43, 472 (2007)

M. Cartón-Cordero, M. Campos, L.P. Freund, M. Kolb, S. Neumeier, M. Göken, J.M. Torralba, Mater. Sci. Eng. A 734, 437 (2018)

N.C. Ferreri, S. Ghorbanpour, S. Bhowmik, R. Lussier, J. Bicknell, B.M. Patterson, M. Knezevic, Int. J. Plast. 121, 116 (2019)

X.A. Hu, G.L. Zhao, Y. Jiang, X.F. Ma, F.C. Liu, J. Huang, C.L. Dong, Acta Metall. Sin. -Engl. Lett. 33, 514 (2020)

H. Kovacı, Surf. Coat. Technol. 374, 987 (2019)

M. Cloots, K. Kunze, P.J. Uggowitzer, K. Wegener, Mater. Sci. Eng. A 658, 68 (2016)

X. Yan, S. Gao, C. Chang, J. Huang, M. Liu, J. Mater. Process. Technol. 288, 116878 (2020)

K.S. Kim, J.W. Hwang, K.A. Lee, J. Alloys Compd. 834, 155055 (2020)

E. Chauvet, P. Kontis, E.A. Jägle, B. Gault, D. Raabe, C. Tassin, J.J. Blandin, R. Dendievel, B. Vayre, S. Abed, G. Martin, Acta Mater. 142, 82 (2018)

W. Liu, C. Chen, S. Shuai, R. Zhao, Z. Ren, Mater. Sci. Eng. A 797, 139981 (2020)

H. Ali, H. Ghadbeigi, K. Mumtaz, J. Mater. Eng. Perform. 27, 4059 (2018)

D. Wang, Y.Q. Yang, X.B. Su, Y.H. Chen, Int. J. Adv. Des. Manuf. Technol. 58, 1189 (2012)

Y. Chen, F.G. Lu, K. Zhang, P.L. Nie, S.R. Hosseini, K. Feng, Z.G. Li, J. Alloys Compd. 670, 312 (2016)

N. Wang, S. Mokadem, M. Rappaz, W. Kurz, Acta Mater. 52, 3173 (2004)

M. Zhong, H. Sun, W. Liu, X. Zhu, J. He, Scr. Mater. 53, 159 (2005)

S. Kurosu, H. Matsumoto, A. Chiba, Metall. Mater. Trans. A 41, 2613 (2010)

F. Bachmann, R. Hielscher, H. Schaeben, Solid State Phenom. 160, 63 (2010)

F.M. Shang, S.Y. Chen, M.W. Wei, J. Liang, C.S. Liu, Mater. Res. Express. 6, 26566 (2018)

E. Vacchieri, A. Costa, G. Roncallo, G. Cacciamani, Mater. Sci. Technol. 1, 1100 (2017)

W. Jia, S. Chen, M. Wei, J. Liang, C. Liu, J. Li, Powder Metall. 62, 30 (2019)

J.R. Davis (ed.), Nickel, Cobalt, and Their Alloy (Materials Park, Ohio, 2000)

K. Rajan, J.B. Vander Sande, J. Mater. Sci. 17, 769 (1982)

Z. Wang, X. Lin, N. Kang, Y. Hu, J. Chen, W. Huang, Addit. Manuf. 34, 101260 (2020)

J.C. Zhao, M.R. Notis, Scr. Metall. Mater. 32, 1671 (1995)

S. Wen, A. Dong, Y. Lu, G. Zhu, D. Shu, B. Sun, Acta Metall. Sin. -Engl. Lett. 54, 393 (2018)

W.F. Smith, Structure and Properties of Engineering Alloys, 2nd. (McGraw-Hill, New York, 1993), pp. 14

E.O. Hall, Proc. Phys. Soc. Sect. B 64, 47 (1951)

J. Liu, Q. Peng, J. Xie, Acta Metall. Sin. -Engl. Lett. 57, 191 (2021)

T. Maitland, S. Sitzman, Electron Backscatter Diffraction (EBSD) Technique and Materials Characterization Examples, 14th (Springer, Berlin, 2007), p. 522

Q.L. Yuan, X.D. Feng, J.J. Cao, Z.J. Su, J. Henan Poly. Univ. (Nat. Sci.) 29, 245 (2010)

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (No. 2019YFA0705300), the Chinese National Science and Technology Major Project “Aeroengine and Gas Turbine” (No. 2017-VII-0008-0102), the Shanghai Science and Technology Committee (No. 19DZ1100704), Shanghai Shuguang Program (No. 20SG42), Shanghai Sailing Program (No. 19YF1415900), the National Natural Science Foundation of China (No. 52001191), the Shanghai Rising-Star Program (No. 20QA1403800).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose.

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Wang, X., Chen, C., Zhao, R. et al. Selective Laser Melting of Carbon-Free Mar-M509 Co-Based Superalloy: Microstructure, Micro-Cracks, and Mechanical Anisotropy. Acta Metall. Sin. (Engl. Lett.) 35, 501–516 (2022). https://doi.org/10.1007/s40195-021-01348-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01348-5