Abstract

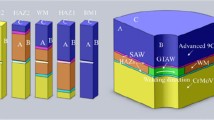

Fatigue crack growth (FCG) behavior of 9Cr/CrMoV dissimilar welded joint at elevated temperature and different stress ratios was investigated. Attention was paid to the region near the fusion line of 9Cr where carbon-enriched zone (CEZ) and carbon-depleted zone (CDZ) formed due to carbon migration during the welding process. Hard and brittle tempered martensite dominated the stress ratio-insensitive FCG behavior in the coarse grain zone (CGZ) of 9Cr-HAZ. For crack near the CGZ–CEZ interface, crack deflection through the CEZ and into the CDZ was observed, accompanied by an accelerating FCG rate. Compared with the severe plastic deformation near the secondary crack in 9Cr-CGZ, the electron back-scattered diffraction analysis showed less deformation and lower resistance in the direction toward the brittle CEZ, which resulted in the transverse deflection. In spite of the plastic feature in CDZ revealed by fracture morphology, the less carbides due to carbon migration led to lower strength and weaker FCG resistance property in this region. In conclusion, the plasticity deterioration in CEZ and strength loss in CDZ accounted for the FCG path deflection and FCG rate acceleration, respectively, which aggravated the worst FCG resistance property of 9Cr-HAZ in the dissimilar welded joint.

Similar content being viewed by others

References

J.J. Wu, H.J. Hou, Y.P. Yang, E. Hu, Appl. Energy 157, 123 (2015)

A. Rusin, G. Nowak, W. Piecha, Eng. Failure Anal. 34, 217 (2013)

S. Guan, C.Y. Cui, Acta Metall. Sin. Engl. Lett. 28, 1083 (2015)

A. Aghajani, C. Somsen, G. Eggeler, Acta Mater. 57, 5093 (2009)

O. Prat, J. Garcia, D. Rojas, G. Sauthoff, G. Inden, Intermetallics 32, 362 (2013)

X.P. Mao, H. Xu, G. Wang, Z.Y. Ma, Adv. Mater. Res. 33–37, 521 (2008)

W. Kosman, M. Roskosz, K. Nawrat, Appl. Therm. Eng. 29, 3386 (2009)

Y.Y. You, R.K. Shiue, R.H. Shiue, C. Chen, J. Mater. Sci. Lett. 20, 1429 (2001)

T. Helander, J. Agren, J.O. Nilsson, ISIJ Int. 37, 1139 (1997)

R.S. Vidyarthy, A. Kulkarni, D.K. Dwivedi, Mater. Sci. Eng. A 695, 249 (2017)

S.G. Nayee, V.J. Badheka, J. Manuf. Process. 16, 137 (2014)

R. Anand, C. Sudha, T. Karthikeyan, A.L.E. Terrance, S. Saroja, M. Vijayalakshmi, J. Mater. Sci. 44, 257 (2009)

S. Wang, Q. Ma, Y. Li, Mater. Des. 32, 831 (2011)

Y. Li, K. Li, Z. Cai, J. Pan, X. Liu, P. Wang, Weld. World 62, 1137 (2018)

A. Kulkarni, D.K. Dwivedi, M. Vasudevan, Mater. Sci. Eng. A 731, 309 (2018)

K. Laha, S. Latha, K.B. Sankara Rao, S.L. Mannan, D.H. Sastry, Mater Sci. Technol. 17, 1265 (2013)

K. Laha, K.S. Chandravathi, K.B.S. Rao, S.L. Mannan, D.H. Sastry, Metall. Mater. Trans. A 32, 115 (2001)

M.L. Huang, L. Wang, Metall. Mater. Trans. A 29, 3037 (1998)

M.L. Zhu, F.Z. Xuan, S.T. Tu, Int. J. Pressure Vessels Piping 110, 9 (2013)

Y.C. Su, X.M. Hua, Y.X. Wu, J. Mater. Process. Technol. 214, 750 (2014)

Q.J. Wu, F.G. Lu, H.C. Cui, X. Liu, P. Wang, Y.L. Gao, Mater. Lett. 141, 242 (2015)

P. Mayr, C. Schlacher, J.A. Siefert, J.D. Parker, Int. Mater. Rev. 64, 1 (2018)

R. Paventhan, P.R. Lakshminarayanan, V. Balasubramanian, Mater. Des. 32, 1888 (2011)

N. Arivazhagan, S. Singh, S. Prakash, G.M. Reddy, Int. J. Adv. Manuf. Technol. 39, 679 (2007)

L. Milović, T. Vuherer, M. Zrilić, A. Sedmak, S. Putić, Mater. Manuf. Processes 23, 597 (2008)

C.D. Lundin, K.K. Khan, D. Yang, Weld. Res. Counc. Bull. 407, 1 (1995)

X. Liu, Z.P. Cai, X.L. Deng, F.G. Lu, J. Mater. Res. 32, 3117 (2017)

V. Chaswal, G. Sasikala, S.K. Ray, S.L. Mannan, B. Raj, Mater. Sci. Eng. A 395, 251 (2005)

S. Kwofie, Int. J. Fatigue 26, 299 (2004)

M.L. Zhu, F.Z. Xuan, Mater. Sci. Eng. A 527, 4035 (2010)

S. Mannan, K. Laha, Trans. Indian Inst. Met. 49, 303 (1996)

K. Ding, H.J. Ji, X. Liu, P. Wang, Q.L. Zhang, X.H. Li, Y.L. Gao, J. Iron Steel Res. Int. 25, 847 (2018)

K. Ding, X.H. Li, B.G. Zhao, P. Wang, Y.M. Ding, F.G. Lu, Y.L. Gao, J. Mater. Res. Technol. 9, 6048 (2020)

J.G. Chen, Y.C. Liu, Y.T. Xiao, Y.H. Liu, C.X. Liu, H.J. Li, Acta Metall. Sin. Engl. Lett. 31, 706 (2018)

Acknowledgements

The authors gratefully acknowledge the financial support by the National Natural Science Foundation of China (No. 52001200) and the experimental support by Instrumental Analysis Center of SJTU.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose.

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Wang, Q., Shao, C., Cui, H. et al. Effect of Carbon Migration on Interface Fatigue Crack Growth Behavior in 9Cr/CrMoV Dissimilar Welded Joint. Acta Metall. Sin. (Engl. Lett.) 35, 714–726 (2022). https://doi.org/10.1007/s40195-021-01322-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01322-1