Abstract

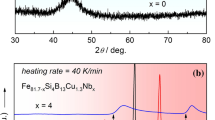

The effects of ribbon thickness (t) on the structure and magnetic properties of a Fe82.3B13Cu1.7Nb3 alloy in melt-spun and annealed states have been investigated. Increasing the t from 15 to 23 μm changes the structure of the melt-spun ribbons from a single amorphous phase to a composite with dense α-Fe nanograins embedded in the amorphous matrix. The grain size (Dα-Fe) of the α-Fe near the free surface of the ribbon is about 6.7 nm, and it gradually decreases along the cross section toward the wheel-contacted surface. Further increasing the t to 32 μm coarsens the Dα-Fe near the free surface to 15.2 nm and aggravates the Dα-Fe ramp along the cross section. After annealing, the ribbon with t = 15 μm has relatively large α-Fe grains with Dα-Fe > 30 nm, while the thicker ribbons possessing the pre-existing nanograins form a finer nanostructure with Dα-Fe < 16 nm. The structural uniformity of the ribbon with t = 23 μm is better than that of the ribbon with t = 32 μm. The annealed ribbons with t = 23 and 32 μm possess superior soft magnetic properties to the ribbon with t = 15 μm. The ribbon with t = 23 μm exhibits a high saturation magnetic flux density of 1.68 T, low coercivity of 9.6 A/m, and high effective permeability at 1 kHz of 15,000. The ribbon with t = 32 μm has a slightly larger coercivity due to the lower structural uniformity. The formation mechanism of the fine nanostructure for the ribbons with suitable t has been discussed in terms of the competitive growth effect among the pre-existing α-Fe nanograins.

Similar content being viewed by others

References

Y. Yoshizawa, S. Oguma, K. Yamauchi, J. Appl. Phys. 64, 6044 (1988)

Y. Yoshizawa, Mater. Sci. Forum 307, 51 (1999)

Y.H. Ding, X. Liu, S.S. Zhao, Y. Long, R.C. Ye, Y.Q. Chang, F.R. Wan, Acta Metall. Sin. -Engl. Lett. 20, 327 (2007)

Y.X. Geng, H.Y. Ding, D.P. Wang, Z.J. Zhang, H.B. Ju, L.H. Yu, J.H. Xu, Acta Metall. Sin. -Engl. Lett. 33, 313 (2020)

M. Ohta, Y. Yoshizawa, Mater. Trans. 48, 2378 (2007)

B. Zang, R. Parsons, K. Onodera, H. Kishimoto, A. Kato, A.C.Y. Liu, K. Suzuki, Scr. Mater. 132, 68 (2017)

M. Ohta, Y. Yoshizawa, J. Appl. Phys. 103, 07E722 (2008)

M. Ohta, Y. Yoshizawa, J. Phys. D: Appl. Phys. 44, 064004 (2011)

A. Makino, H. Men, T. Kubota, K. Yubuta, A. Inoue, Mater. Trans. 50, 204 (2009)

P. Sharma, X. Zhang, Y. Zhang, A. Makino, J. Appl. Phys. 115, 17A340 (2014)

T. Liu, F.C. Li, A.D. Wang, L. Xie, Q.F. He, J.H. Luan, A.N. He, X.M. Wang, C.T. Liu, Y. Yang, J. Alloys Compd. 776, 606 (2019)

X.D. Fan, M.F. Jiang, T. Zhang, L. Hou, C.X. Wang, B.L. Shen, J. Non-Cryst, Solids 533, 119941 (2020)

A. Makino, T. Kubota, K. Yubuta, A. Inoue, A. Urata, H. Matsumoto, S. Yoshida, J. Appl. Phys. 109, 07A302 (2011)

Y. Zhang, P. Sharma, A. Makino, IEEE Trans. Magn. 50, 1 (2014)

Y.L. Li, Z.X. Dou, X.M. Chen, K. Lv, F.S. Li, X.D. Hui, J. Alloys Compd. 844, 155767 (2020)

X.J. Jia, Y.H. Li, G.Q. Xie, T.L. Qi, W. Zhang, J. Non-Cryst, Solids 481, 590 (2018)

X.J. Jia, Y.H. Li, L.C. Wu, W. Zhang, AIP Adv. 8, 056110 (2018)

R. Parsons, B. Zang, K. Onodera, H. Kishimoto, A. Kato, K. Suzuki, J. Alloys Compd. 723, 408 (2017)

M. Ohta, Y. Yoshizawa, J. Magn. Magn. Mater. 321, 2220 (2009)

Z.X. Dou, Y.L. Li, K. Lv, T. Wang, F.S. Li, X.D. Hui, Mater. Sci. Eng. B 264, 114942 (2021)

Y.H. Li, X.J. Jia, Y.Q. Xu, C.T. Chang, G.Q. Xie, W. Zhang, J. Alloys Compd. 722, 859 (2017)

L.C. Wu, Y.H. Li, K. Yubuta, A.N. He, Y. Zhang, W. Zhang, J. Magn. Magn. Mater. 497, 166001 (2020)

Y.H. Li, X.J. Jia, W. Zhang, Y. Zhang, G.Q. Xie, Z.Y. Qiu, J.H. Luan, Z.B. Jiao, J. Mater. Sci. Technol. 65, 171 (2021)

F. Hosseini-Nasb, A. Beitollahi, M.K. Moravvej-Farshi, J. Magn. Magn. Mater. 373, 255 (2015)

F.P. Wan, T. Liu, F.Y. Kong, A.D. Wang, M.Q. Tian, J.C. Song, J.H. Zhang, C.T. Chang, X.M. Wang, Mater. Res. Bull. 96, 275 (2017)

D.A. Babu, B. Majumdar, R. Sarkar, D. Akhtar, V. Chandrasekaran, J. Phys. D: Appl. Phys. 41, 195002 (2008)

L.P. Duan, K. Wang, E.G. Wang, P. Jia, Acta Metall. Sin. -Engl. Lett. (2021). https://doi.org/10.1007/s40195-021-01206-4

Z. Xiang, A.D. Wang, C.L. Zhao, H. Men, X.M. Wang, C.T. Chang, D. Pan, J. Alloys Compd. 622, 1000 (2015)

P. Sharma, X. Zhang, Y. Zhang, A. Makino, Scr. Mater. 95, 3 (2015)

Y. Zhang, P. Sharma, A. Makino, J. Alloys Compd. 709, 663 (2017)

E. Lopatina, I. Soldatov, V. Budinsky, M. Marsilius, L. Schultz, G. Herzer, R. Schäfer, Acta Mater. 96, 10 (2015)

G. Herzer, IEEE Trans. Magn. 26, 1397 (1990)

A. Hernando, M. Vázquez, T. Kulik, C. Prados, Phys. Rev. B 51, 3581 (1995)

N. Murillo, J. González, J. Magn. Magn. Mater. 218, 53 (2000)

K. Suzuki, N. Ito, J.S. Garitaonandia, J.D. Cashion, G. Herzer, J. Non-Cryst, Solids 354, 5089 (2008)

T. Bitoh, A. Makino, A. Inoue, T. Masumoto, Mater. Trans. 44, 2011 (2003)

Acknowledgements

This research was financially supported by the National Natural Science Foundation of China (Grant Nos. 51871039, 51771039 and 51571047).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Wu, LC., Li, YH., Jia, XJ. et al. Effects of Ribbon Thickness on Structure and Soft Magnetic Properties of a High-Cu-Content FeBCuNb Nanocrystalline Alloy. Acta Metall. Sin. (Engl. Lett.) 35, 235–242 (2022). https://doi.org/10.1007/s40195-021-01244-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01244-y