Abstract

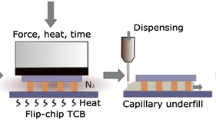

Cu pillar bump offers a number of advantages for flip chip packaging, compared to the conventional solder bump. However, due to its rigidity structure, Cu pillar bump introduces a lot of stress to the chip, which causes the failure of packaging structures, especially for the advanced node devices which typically have brittle low K dielectric material. In this paper, for the first time we propose two types of Cu pillar structures to reduce the stress. The first Cu pillar structure has bigger Cu dimensions at the base. The other one is designed to add an additional Cu pad under the Cu pillar bump. Finite element analysis is used to study the stress of the both structures, and it is found that with the increase in pillar bump contact area over the chip surface, the stress decreases in both structures. Results also indicate that the Cu pillar bump undercut induces higher stress, and thin Cu6Sn5 intermetallic compound has less impact on the stress during flip chip mount reflow. The study provides a novel way to improve the reliability by reducing the stress in the Cu pillar bump related packaging.

Similar content being viewed by others

References

W.J. Choi, E.C.C. Yeh, K.N. Tu, P. Elenius, H. Balkan, Electromigration of flip chip solder bump on Cu/Ni(V)/Al thin film under bump metallization, in Paper Presented at the 52nd Electronic Components and Technology Conference, San Diego, CA, USA (2002)

Y.H. Tian, C.Q. Wang, W.F. Zhou, Acta Metall. Sin. (Engl. Lett.) 19, 301 (2006)

S. Li, X.W. Hu, W.G. Zhang, Y.L. Li, X.X. Jiang, Acta Metall. Sin. (Engl. Lett.) 32, 629 (2019)

T. Wang, F. Tung, L. Foo, V. Dutta, Studies on a novel flip-chip interconnect structure—pillar bump, in Paper Presented at the 51st Electronic Components and Technology Conference, Orlando, FL, USA (2001)

N.M. Patel, V. Wakharkar, S. Agrahram, N. Deshpande, M. Pang, R. Tanikella, R. Manepalli, P. Stover, J. Jackson, R. Mahajan, P. Tiwari, Int. Technol. J. 12, 145 (2008)

B. Ebersberger, C. Lee, Cu pillar bumps as a lead-free drop-in replacement for solder-bumped, flip-chip interconnects, in Paper Presented at the 58th Electronic Components and Technology Conference, Lake Buena Viata, FL, USA (2008)

D. Gupta, H. Sato, Y. Nakadaira, Cu pillars on substrates—a low cost alternative for the next generation for flip chip packaging technology, in Paper Presented at the 60th Electronic Components and Technology Conference, Las Vegas, NV, USA (2010)

K.M. Chen, C.Y. Wu, H.L. Chou, P.C. Kuo, Cu pillar bump-on-trace (BoT) design for ultra low-k packaging, in Paper Presented at the 8th International Microsystems, Packaging, Assembly and Circuits Technology Conference, Taipei, Taiwan (2013)

B.K. Applet, H. Chung, C. Chen, R. Wang, M. Hung, Low cost fcCSP based on Cu pillar, in Paper Presented at the 13th Electronics Packaging Technology Conference, Singapore, Singapore (2011)

X.R. Zhang, W.H. Zhu, B.P. Liew, M. Gaurav, A. Yeo, K.C. Chan, Copper pillar bump structure optimization for flip chip packaging with Cu/low-K stack, in Paper Presented at the 11th International Thermal, Mechanical and Multi-Physics Simulation, and Experiments in Microelectronics and Microsystems, Bordeaux, France (2010)

M.W. Lee, J.Y. Kim, J.D. Kim, C.H. Lee, Below 45 nm low-k layer stress minimization guide for high-performance flip-chip packages with copper pillar bumping, Paper Presented at the 60th Electronic Components and Technology Conference, Las Vegas, NV, USA (2010)

C.J. Zhai, U. Ozkan, A. Dubey, R.C. Blish, R.N. Master, Investigation of Cu/low-k film delamination in flip chip packages, in Paper Presented at the 56th Electronic Components and Technology Conference, San Diego, CA, USA (2006)

S.W. Lee, B.W. Jang, J.K. Kim, Y.H. Jung, Y.B. Kim, H.G. Song, S.Y. Kang, Y.M. Kang, S.M. Lee, K.C. Park, C.S. Ju, G.R. Kim, A Study on the chip-package-interaction for advanced devices with ultra low-k dielectric, in Paper Presented at the 62nd Electronic Components and Technology Conference, San Diego, CA, USA (2012)

M. Gonzalez, K. Vanstreels, V. Cherman, K. Croes, L. Kljucar, I. D. Wolf, Z. Tőkei, Mechanical stability of Cu/low-k BEOL interconnects, in Paper Presented at the IEEE International Reliability Physics Symposium, Waikoloa, HI, USA (2014)

W.C. Dong, D.B. Gao, S.P. Lu, Acta Metall. Sin. (Engl. Lett.) 32, 618 (2019)

N.Y. Ye, M. Cheng, S.H. Zhang, Acta Metall. Sin. (Engl. Lett.) 28, 1510 (2015)

L. Jiang, L. Zhang, Z. Q. Liu, Acta Metall. Sin. (Engl. Lett.) https://doi.org/10.1007/s40195-019-00875-6, (2019)

E. Suhir, J. Mater. Sci. Mater. Electronics 29, 2676 (2018)

L. Wang, C. Xu, W. Zhang, Investigation of thermal-mechanical stress and chip-packaging-interaction issues in low-k chips, in Paper Presented at the 16th International Conference on Electronic Packaging Technology, Changsha, Hunan, China (2015)

D.W. Wang, K.I. Papathomas, IEEE Trans. Compon. Hybrids Manuf. Technol. 16, 863 (1993)

Y. He, B.E. Moreira, A. Overson, S.H. Nakamura, Thermochim. Acta 357–358, 1 (2000)

Y. Pan, J.A. Zitz, D.L. Questad, K.K. Sikka, Chip package interaction: an experiment study on white bump mitigation using flat laminates, in Paper Presented at the 64th Electronic Components and Technology Conference, Orlando, FL, USA (2014)

S. Gallois-Garreignot, G. Hu, V. Fiori, M. Sorrieul, C. Moutin, C. Tavernier, Chip package interactions: package effects on copper pillar bump induced BEoL delaminations and associated numerical developments, in Paper Presented at the 65th Electronic Components and Technology Conference, San Diego, CA, USA (2015)

P. Lianto, H.Y. Li, R. Balamurugan, J. Wei, N. Binte Jaafar, L.C.E. Wai, A. Sundarrajan, IEEE Trans. Compon. Packag. Manuf. Technol. 6, 1120 (2016)

P.J. Cheng, C.M. Chung, T.M. Pai, D.Y. Chen, A challenge of 45 nm extreme low-k chip using Cu pillar bump as 1st interconnection, in Paper Presented at the 60th Electronic Components and Technology Conference, Las, Vegas, NV, USA (2010)

W. Wang, D. Zhang, Y. Sun, D. Rae, L. Zhao, J. Zheng, M. Schwarz, M. Shah, A. Syed, Study of polyimide in chip package interaction for flip-chip Cu pillar packages, in Paper Presented at the 68th Electronic Components and Technology Conference, San Diego, CA, USA (2018)

J. Han, H. Cen, M. Li, Acta Metall. Sin. (Engl. Lett.) 25, 214 (2012)

Acknowledgements

The technical support and discussion from Cheng Xu, Kim-Hwee Tan and Zhi-Quan Liu are acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Long, XJ., Shang, JT. & Zhang, L. Design Optimization of Pillar Bump Structure for Minimizing the Stress in Brittle Low K Dielectric Material Layer. Acta Metall. Sin. (Engl. Lett.) 33, 583–594 (2020). https://doi.org/10.1007/s40195-019-00948-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-019-00948-6