Abstract

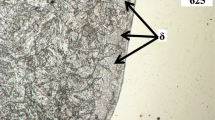

Although P91 steel welds should ideally exhibit a fully martensitic microstructure, delta ferrite is sometimes observed, which has detrimental effects on mechanical properties and performance during application. This research focused on the role of various alloying elements on the occurrence of delta ferrite in the final weld metal. In addition, a few welds were deposited using a preheating temperature of 250 °C to investigate the effect of slower cooling rates. Of 28 gas–metal arc welds with systematic variation in chemical composition, 21 welds fully complied with the AWS A5.28/A5.28 M:2020 composition specification, and 18 welds contained delta ferrite in their final microstructure. Of the 18 welds with delta ferrite, 13 complied with the composition specification. The results clearly demonstrate that compliance of weld metal chemical composition to the AWS A5.28/A5.28 M:2020 specification does not ensure a fully martensitic as-welded microstructure. A larger (Ae4 –Ae3) temperature range, which is the region where only austenite phase is stable, allows more time for delta ferrite to transform to austenite during cooling. The (Ae4–Ae3) value necessary to suppress delta ferrite in the as-welded microstructure decreased when preheating was applied. These results indicate that both the chemical composition, which determines the (Ae4–Ae3) value, and the cooling rate through this temperature range are important in suppressing delta ferrite in the final as-welded microstructure.

Similar content being viewed by others

References

Pandey C, Mahapatra MM, Kumar P, Saini N (2018) Some studies on P91 steel and their weldments. J Alloy Compd 743:332–364

Zhou X, Liu C, Yu L, Liu Y, Li H (2015) Phase transformation behavior and microstructural control of High-Cr martensitic/ferritic heat-resistant steels for power and nuclear plants: a review. J Mater Sci Technol 31(3):235–242

Mahlalela SS, Pistorius PGH (2022) Investigation of ẟ-ferrite content in weld metal of modified 9Cr–1Mo electrodes using thermodynamic modelling and quenching experiments. Weld World 66(6):1191–1198

Arivazhagan B, Kamaraj M (2013) A study on influence of D-ferrite phase on toughness of P91 steel welds. https://www.steel-grips.com/articles/2013/sg13004.pdf. Accessed 15 Jan 2022

Arivazhagan B, Kamaraj M (2013) Metal-cored arc welding process for joining of modified 9Cr-1Mo (P91) steel. J Manuf Process 15(4):542–548

Liu XY, Fujita T (1989) Effect of chromium content on creep rupture properties of a high chromium ferritic heat resisting steel. ISIJ Int 29(8):680–686

Arivazhagan B, Srinivasan G, Albert SK, Bhaduri AK (2011) A study on influence of heat input variation on microstructure of reduced activation ferritic martensitic steel weld metal produced by GTAW process. Fusion Eng Des 86(2):192–197

Arivazhagan B, Vasudevan M (2014) A comparative study on the effect of GTAW processes on the microstructure and mechanical properties of P91 steel weld joints. J Manuf Process 16(2):305–311

Zhang Z, Marshall AW, Farrar JCM (1998) Recent developments in welding consumables for P (T)-91 creep resisting steels. In Conference Proceedings, International Conference on Integrity of High-Temperature Welds, Nottingham, UK, pp 3–4

Klueh R (2005) Elevated temperature ferritic and martensitic steels and their application to future nuclear reactors. Int Mater Rev 50(5):287–310

Wang L (2010) Development of predictive formulae for the A1 temperature in creep strength enhanced ferritic steels (Doctoral dissertation, The Ohio State University)

Pandey C, Mahapatra MM, Kumar P, Saini N (2018) Homogenization of P91 weldments using varying normalizing and tempering treatment. Mater Sci Eng, A 710:86–101

Faulkner R, Williams J, Sanchez EG, Marshall A (2003) Influence of Co, Cu and W on microstructure of 9% Cr steel weld metals. Mater Sci Technol 19(3):347–354

Sireesha M, Albert S, Sundaresan S (2001) Importance of filler material chemistry for optimising weld metal mechanical properties in modified 9Cr–1Mo steel. Sci Technol Weld Joining 6(4):247–254

Barnes AM (1995) The effect of composition and heat treatment on the microstructure and mechanical properties of modified 9Cr 1Mo weld metal. TWI Members Report, p 534

Onoro J (2006) Martensite microstructure of 9–12% Cr steels weld metals. J Mater Process Technol 180(1–3):137–142

Swindeman RW, Santella ML, Maziasz PJ, Roberts BW, Coleman K (2004) Issues in replacing Cr-Mo steels and stainless steels with 9Cr-1Mo-V steel. Int J Press Vessels Pip 81(6):507–512

Olson D (1985) Prediction of austenitic weld metal microstructure and properties. Weld J 64(10):281s–295s

Sireesha M, Sundaresan S, Albert SK (2001) Microstructure and mechanical properties of weld fusion zones in modified 9Cr-1Mo steel. J Mater Eng Perform 10(3):320–330

Pandey C, Giri A, Mahapatra MM (2016) Evolution of phases in P91 steel in various heat treatment conditions and their effect on microstructure stability and mechanical properties. Mater Sci Eng, A 664:58–74

Sam S et al (2014) Delta ferrite in the weld metal of reduced activation ferritic martensitic steel. J Nucl Mater 455(1–3):343–348

Zhou X et al (2017) Effects of cooling rates on δ-ferrite/γ-austenite formation and martensitic transformation in modified ferritic heat resistant steel. Fusion Eng Des 125:354–360

Shanmugarajan B, Padmanabham G, Kumar H, Albert SK, Bhaduri AK (2011) Autogenous laser welding investigations on modified 9Cr-1Mo (P91) steel. Sci Technol Weld Joining 16(6):528–534

Abd El-Rahman Abd El-Salam M, El-Mahallawi I, El-Koussy M (2013) Influence of heat input and post-weld heat treatment on boiler steel P91 (9Cr–1Mo–V–Nb) weld joints Part 1–Microstructure. Int Heat Treat Surf Eng 7(1):23–31

Spiegel MR, Schiller JJ, Srinivasan RA (2013) Schaum’s outline of probability and statistics. McGraw-Hill Education (Book)

Acknowledgements

We acknowledge the following companies and people for assistance: SecMet for providing the P91 base material; Corney van Rooyen and Maritha Theron at the South African Council for Scientific and Industrial Research (CSIR) for assistance with the laser metal deposition and providing some of the alloying elements; Steinmüller Africa for donating the welding consumable; and Prof. Kathy Sole for English editing of this manuscript.

Funding

This study has been funded by the Southern African Institute of Welding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission IX - Behaviour of Metals Subjected to Welding

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mahlalela, S.S., Pistorius, P.G.H. Influence of alloying elements and cooling rate on the presence of delta ferrite in modified 9Cr–1Mo as-welded microstructure produced by gas–metal arc welding. Weld World 67, 1169–1180 (2023). https://doi.org/10.1007/s40194-022-01457-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01457-4