Abstract

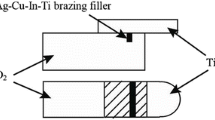

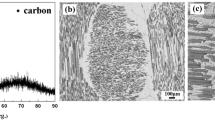

The real-time wetting behavior of the Si-10Zr (at. %) eutectic alloy over the SiCf/SiC composites was investigated for the first time. The brazing of C/C composites and SiCf/SiC composites using the Si-10Zr filler alloy under a range of time was studied. The interfacial microstructure between the liquid alloy and the SiCf/SiC composites was determined. The joint microstructure, mechanical performance, and fractures of the C/C and C/C-SiCf/SiC joints were analyzed. The Si-Zr melt showed a contact angle of only 10° at 1480 ℃, owing to good wettability and abundant infiltration into the porous SiCf/SiC composites. With the extension of holding time, the Si-10Zr alloy reacted with the two substrates and formed SiC interfacial layers. An optimal fracture mode combined the Si-ZrSi2 filler, composites, and the SiC reaction layers.

Similar content being viewed by others

References

Deng J, Zheng B, Hu K, Lu B, Fan S, Zhang L, Cheng L (2019) Microstructure and mechanical properties of SiCf/SiC joints brazed using CaO-MgO-Al2O3-SiO2 glass. Ceram Int 45(7):8890–8898

Fitriani P, Kwon H, Zhou X, Yoon DH (2020) Joining of SiCf/SiC using a layered Ti3SiC2-SiCw and TiC gradient filler. J Eur Ceram Soc 40(4):1043–1051

Giuranno D, Bruzda G, Polkowska A, Nowak R, Polkowski W, Kudyba A, Sobczak N, Mocellin F, Novakovic R (2020) Design of refractory SiC/ZrSi2 composites: wettability and spreading behavior of liquid Si-10Zr alloy in contact with SiC at high temperatures. J Eur Ceram Soc 40(4):953–960

Li M, Zhou X, Yang H, Du S, Huang Q (2018) The critical issues of SiC materials for future nuclear systems. Scripta Mater 143:149–153

Liu T, Fu Q, Liu B (2021) J Zhang (2021) Effect of temperature gradient on the ablation and flexural behavior of C/C-ZrC composites. Corros Sci 191:109736

He Z, Li C, Qi J, Huang Y, Feng J, Cao J (2018) Pre-infiltration and brazing behaviors of Cf/C composites with high temperature Ti Si eutectic alloy. Carbon 140(2018):57–67

Li S, Lu Q, Du D, Pei Y, Zhang L, Sun H, Long W (2021) Effect of C/C composite surface pretreatment on properties of brazed joint. Weld World 66(1):61–68

D Hu, Q Fu, M Tong, X Li (2022) Multiple cyclic ablation behaviors of multilayer ZrC-TaC coating with ZrC-SiC interface layer. Corros Sci: 110215.

Sun L, Fang J, Liu C, Guo S, Zhang J (2021) Crystallization kinetic of Li2O-MgO-Al2O3-SiO2 glass-ceramic and its application for joining of porous Si3N4 ceramic. Mater Char 172:110889

Ren X, Liu W, Ren H, Jing Y, Mao W, Xiong H (2020) Microstructures and joining characteristics of NbSS/Nb5Si3 composite joints by newly-developed Ti66-Ni22-Nb12 filler alloy. J Mater Sci Technol 58:95–99

Sun L, Fang J, Guo S, Wen Y, Liu C, Zhang J (2022) Joining dense Si3N4 to porous Si3N4 using a novel glass-ceramic interlayer with precipitated β-LiAlSi2O6/Mg2SiO4. J Eur Ceram Soc 42(1):87–95

Li WW, Chen B, Xiong HP, Zou WJ (2017) Brazing SiC matrix composites using Co-Ni-Nb-V alloy. Weld World 61(4):839–846

Sun L, Fang J, Guo S, Shan T, Wen Y, Liu C, Zhang J (2022) Effect of MgO/Al2O3 ratio on the crystallization behaviour of Li2O–MgO–Al2O3–SiO2 glass-ceramic and its wettability on Si3N4 ceramic. Ceram Int 48(14):20053–20061

Liu K, Li Y, Wang J (2018) Vacuum diffusion bonding TC4 to Ni80Cr20: interfacial microstructure, segregation, cracking and properties. Vacuum 158:218–222

Ren X, Li W, Jing Y, Chen B, Huang S, Xiong H (2017) Dissimilar brazing of NbSS/Nb5Si3 composite to GH5188 superalloy using Ni-based filler alloys. Weld World 65(9):1767–1775

Guo W, Li K, Zhang H, Zhu Y, Shen X, Zhang L, Sun H, Zhong S, Long W (2022) Low residual stress C/C composite-titanium alloy joints brazed by foam interlayer. Ceram Int 48(4):5260–5266

Singh M, Smith CE, Asthana R, Gyekenyesi AL (2020) Active metal brazing of graphite foam-to-titanium joints made with SiC-Coated foam. J Eur Ceram Soc 40(7):2533–2541

Y Luo, X Song, S Hu, W Fu, X Chen, J Cao (2022) Evaluation of mechanical properties and vacuum brazing for TiAl/GH3536 hetero-honeycomb sandwich ultrathin-walled structure. Weld World (2022).

Wei J, Madeni JC, Liu S, Nelson S, Xu R (2019) Performance comparison of Al-Si-Ti and Co-Si-V-Ti braze alloys in the vacuum brazing of reaction-bonded silicon carbide. Weld World 63(6):1851–1860

Yeom H, Lockhart C, Mariani R, Xu P, Corradini M, Sridharan K (2018) Evaluation of steam corrosion and water quenching behavior of zirconium-silicide coated LWR fuel claddings. J Nucl Mater 499:256–267

Yeom H, He L, Mariani R, Sridharan K (2018) Structural evolution of oxidized surface of zirconium-silicide under ion irradiationm. Appl Surf Sci 455(2018):333–342

Zeng Y, Wang D, Xiong X, Zhang X, Withers PJ, Sun W, Smith M, Bai M, Xiao P (2017) Ablation-resistant carbide Zr0.8Ti0.2C0.74B0.26 for oxidizing environments up to 3,000 ℃. Nat commun 8:15836

He Z, Li C, Yang B, Zhang C, Qi J, Cao J (2021) Interfacial reaction and brazing behaviour of SiCf/SiC with Cf/C composites using Si-10Zr alloy at high temperatures. J Eur Ceram Soc 41(2):1142–1150

He Z, Sun L, Li C, Si X, Zhang C, Qi J, Feng J, Cao J (2020) Wetting and brazing of Cf/C composites with Si–Zr eutectic alloys: the formation of nano- and coarse-SiC reaction layers. Carbon 167(2020):92–103

He Z, Li C, Si X, Qi J, Cao J (2021) Wetting of Si–14Ti alloy on SiCf/SiC and C/C composites and their brazed joint at high temperatures. Ceram Int 47(10):13845–13852

Yang ZW, Wang CL, Han Y, Zhao YT, Wang Y, Wang DP (2019) Design of reinforced interfacial structure in brazed joints of C/C composites and Nb by pre-oxidation surface treatment combined with in situ growth of CNTs. Carbon 143:494–506

Wang ZY, Li MN, Ba J, Ma Q, Fan ZQ, Lin JH, Zhong ZX, Qi JL, Cao J, Feng JC (2018) In-Situ synthesized TiC nano-flakes reinforced C/C composite-Nb brazed joint. J Eur Ceram Soc 38(4):1059–1068

Acknowledgements

The financial support from the National Natural Science Foundation of China (No. 52205351) and the Project funded by the China Postdoctoral Science Foundation (No. 2022M710936) is highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, Z., Xu, H., Li, C. et al. The microstructure and mechanical performance of C/C-SiCf/SiC composite joints brazed by Si-10Zr eutectic alloy. Weld World 67, 525–531 (2023). https://doi.org/10.1007/s40194-022-01446-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01446-7