Abstract

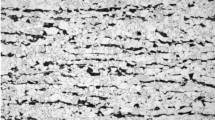

To identify the microstructural factors causing the local brittleness in electro-gas (EG) welded joint, this study investigated the EG welded joints produced by tandem EGW process using two different ship-grade steel plates: high-nitrogen type TiN steel and conventional EH36 steel. Experimental results revealed that, in contrast to conventional steel, the TiN steel shows a large scattering in impact values at FL attributing to the localized grain coarsening limited to a very narrow area following fusion line. In addition, at the center of EG weld metal, a bundle of parallel columnar grains are formed aligning in a vertical welding direction resulting in the formation of grain boundary ferrite veins lined up in the same direction. Brittle nature of grain boundary ferrite makes the cracks propagate easily through these veins, causing a sudden drop in impact toughness at the center of EG weld metal.

Similar content being viewed by others

References

Merk O (2018) Container ship size and port relocation, Discussion paper, International Transport Forum, Paris, France

Malchow U (2017) Growth in containership sizes to be stopped? Maritime Business Review 2(3):199–210

Helmy S, Shrabia A (2016) Mega container ships, pros, cons and its implication recession. J Shipp Ocean Eng 6(5):284–290

Hashiba Y., Kojima K., Kasuya T., Kumagai T. (2015) Development of welding consumables and welding process for newly developed steel plates, Nippon Steel & Sumitomo Metal Technical Report, No. 110, pp. 90–96

Jang T-W, Moon J-H, Yoon DR (2004) High speed welding present and future in shipbuilding assembly stage. J KWJS 22(6):500–504 (in Korean)

Lee J-S, Yun J-O, Jeong S-H, Park CG, An YH (2010) The study about characteristics of welding consumables and weld metal for EGW. Journal of KWJS 28(2):199–203 (in Korean)

Sasaki K., Suda K., Motomatsu R., Hashiba Y., Ohkita S., Imai S.: Development of two-electrode electrogas arc welding process, Nippon Steel Tech. Report, July 2004, No. 90, pp. 67–74

Jeong H-C, Park Y-H, An Y-H, Lee J-B (2007) Mechanical properties and microstructures of high heat input welded tandem EGW joint in EH36-TM steel. J KWJS 25(1):57–62 (in Korean)

Minagawa M, Ishida K, Funatsu Y, Imai S (2004) 390 MPa yield strength steel plate for large heat-input welding for large container ships, Nippon Steel Tech. Report, No. 90, pp.7–10

Kimura T, Sumi H, Kitani Y (2005) High strength steel plates and welding consumables for architectural construction with excellent toughness in welded joint-‘JFE EWEL” technology for excellent quality in HAZ of high heat input welded joints, JFE Technical Report, No 5, pp. 45–52

Jeong HC, An YH, Choo WY (2002) The effect of TiN particles on the HAZ microstructure and toughness in high nitrogen TiN steel. Int J KWS 2(1):25–28

Kanazawa S, Nakashima A, Okamoto K, Kanaya K (1975) Improved toughness of weld fusion zone by fine TiN particles and development of a steel for large heat input welding. Tetsu to Hagane 61(11):2589–2603

Nishio K, Tashima K, Katoh M, Mukae S (1984) Effects of Ti and N on notch toughness of synthetic weld heat affect zone: Transaction of JWS. J Jpn Weld Soc 15(2):120–128

Liu C, Bhole SD (2013) Challenges and developments in pipeline weldability and mechanical properties. Sci Technol Weld Join 18(2):169–181

Homma H, Ohkita S, Matsuda S, Yamamoto K (1987) Improvement of HAZ toughness in HSLA steel by introducing finely dispersed Ti-oxide. Weld J 66(10):301s–309s

Kojima A, Kiyose A, Uemori R, Minagawa M, Hoshino M, Nakashima T, Ishida K, Yasui H (2004) Super high HAZ toughness technology with fine microstructure imparted by fine particles, Nippon Technical Report, No. 90, pp 2–6

Terada Y, Kojima A, Kiyose A, Nakashima T, Doi N, Hara T, Morimoto H, Sugiyama M (2004) High-strength linepipes with excellent HAZ toughness, Nippon Technical Report, No. 90, pp 88–93

Suzuki S, Ichimiya K, Akita T (2005) High tensile strength steel plates with excellent HAZ toughness for shipbuilding —JFE EWEL technology for excellent quality in HAZ of high heat input welded joints, JFE Technical Report, No. 5, pp. 24–29

Welding handbook, Volume 2, 7th edition, 1978, p. 254, ed. W. H. Kearns, pub. AWS, USA

Choi W-H, Cho S-K, Choi W-K, Ko S-G, Han J-M (2012) Effects of microstructures on the toughness of high heat input EG welded joint of EH36-TM steel. J KWJS 30(1):64–71 (in Korean)

Norcross JE (1965) Electroslag/electrogas welding in the free world. Weld J 44(3):177–196

Norcross JE (1965) Properties of electroslag and electrogas welds. Weld J 44(3):135s–140s

Matsuda S, Okumura N (1978) Effect of TiN distribution of TiN precipitate particles on the austenite grain size. Trans ISIJ 18(4):198–205

Morikage Y, Oi K, Kawabata F, Amano K (1998) Effect of TiN size on ferrite nucleation on TiN in low-C steel. Tetsu to Hagane 84(7):510–515 (in Japanese)

Lee C, Nambu S, Inoue J, Koseki T (2011) Ferrite formation behavior from B1 compounds in steel. ISIJ Int 51(12):2036–2041

Jin H-H, Shin C, Lee H-C, Kim W-W (2008) Nucleation of intragranular ferrite on B1-type non-metallic inclusions. Solid State Phenom 135:115–118

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Seo, K., Ryoo, H., Kim, H.J. et al. Local variation of impact toughness in tandem electro-gas welded joint. Weld World 64, 457–465 (2020). https://doi.org/10.1007/s40194-019-00844-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00844-8