Abstract

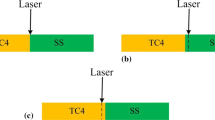

Laser welding-brazing of TC4 titanium (Ti) alloy to 304 stainless steel (SS) has been applied using 63Sn-37Pb alloy as filler metal. A new welding process for SS-Ti alloy joint was introduced on the basis of the controlling the formation of Ti–Fe intermetallics in the joint. One process was one pass welding involving creation of a joint with one fusion weld and one brazed weld separated by remaining unmelted SS. When laser beam on the SS side was 1.4 mm, SS would not be completely melted in joint. Through heat conduction of unmelted SS, the filler metal melted occurred at the SS-Ti alloy interface. A brazed weld was formed at the SS-Ti alloy interface with the main microstructure of Fe3Sn+Fe3Sn2, (βSn, Pb), (βSn)+Sn2Fe, and (βSn)+Sn3Ti2. The joint fractured at the brazed weld with the maximum tensile strength of 108 MPa.

Similar content being viewed by others

References

Boyzr RR (1996) An overview on the use of titanium in the aerospace industry. Mater Sci Eng A 213:103–114

Yang JL, Li Y, Wang F (2006) New application of stainless steel. Journal of Iron and Steel Research. International 13:62–66

Yuan XJ, Sheng GM, Qin B (2008) Impulse pressuring diffusion bonding of titanium alloy to stainless stecl. Mater Charact 59:930–936

Murray JL (1987) Phase diagrams of binary titanium alloys. ASM International:99–111

Sun Z, Karppi R (1996) The application of electron beam welding for the joining of dissimilar metals: an overview. J Mater Process Technol 59:257–267

Kundu S, Ghosh M (2005) Diffusion boning of commercially pure titanium to 304 stainless steel using copper interlayer. Mater Sci Eng A 407:154–160

Atasoy E, Kahraman N (2008) Diffusion bonding of commercially pure titanium to low carbon steel using a silver interlayer. Mater Charact 59:1481–1490

Kundu S, Chatterjee S (2008) Characterization of diffusion bonded joint between titanium and 304 stainless steel using a Ni interlayer. Mater Charact 59:631–637

Chen S, Huang J (2014) Microstructures and mechanical properties of laser penetration welding joint with/without Ni-foil in an overlap steel-on-aluminum configuration. Metall Mater Trans A 45:3064–3073

He P, Yue H, Zhan JH (2008) Hot pressing diffusion bonding of a titanium alloy to a stainless steel with an aluminum alloy interlayer. Mater Sci Eng A 486:171–176

Gao M, Mei SW (2012) Characterisation of laser welded dissimilar Ti/steel joint using Mg interlayer. Sci Technol Weld Join 17:269–276

Wang T, Zhang BG, Chen GQ (2010) Electron beam welding of Ti-15-3 titanium alloy to 304 stainless steel with copper interlayer sheet. Trans Nonferrous Met Soc China 20:1829–1834

Tomashchuk I, Sallamand P (2013) Evolution of microstructures and mechanical properties during dissimilar electron beam welding of titanium alloy to stainless steel via copper interlayer. Mater Sci Eng A 585:114–122

Tomashchuk I, Sallamand P, Andrzejewski H, Grevey D (2011) The formation of intermetallics in dissimilar Ti6Al4V/copper/AISI 316L electron beam and Nd:YAG laser joints. Intermetallics 19:1466–1473

Zhang BG, Wang T, Chen GQ, Feng JC (2012) Contact reactive joining of TA15 and 304 stainless steel via a copper interlayer heated by electron beam with a beam deflection. JMEPEG 21:2067–2073

Oliveira JP, Panton B, Zeng Z (2016) Laser joining of NiTi to Ti6Al4V using a Niobium interlayer. Acta Mater 105:9–15

Zhang Y, Sun DQ, Gu XY, HongMei L (2016) A hybrid joint based on two kinds of bonding mechanisms for titanium alloy and stainless steel by pulsed laser welding. Mater Lett 185:152–155

Kurta B, Orhan N, Evin E, Çalik A (2007) Diffusion bonding between Ti-6Al-4V alloy and ferritic stainless steel. Mater Lett 61:1747–1750

Lee WB, Jung SB (2004) Effect of microstructure on mechanical properties of friction welded joints between Ti and AISI 321 stainless steel. Mater Trans 5:2805–2811

Mousavi SAA, Sartangi P (2009) Farhadi. Experimental investigation of explosive welding of co-titanium/AISI 304 stainless steel. Mater Des 30:459–468

Honggang D, Zhonglin Y, Zengrui W, Dewei D, Chuang D (2014) Vacuum brazing TC4 titanium alloy to 304 stainless steel with Cu-Ti-Ni-Zr-V amorphous alloy foil. JMEPEG 23:3770–3777

Xiaohong H, Yuling W, Yang X (2016) Temperature field analysis of laser welding of titanium steel dissimilar material. Automobile Parts 1:1–6

Chen YB, Lei ZL, Li LQ, Wu L (2006) Experimental study on welding characteristics of CO2 laser TIG hybrid welding process. Sci Technol Weld Join 11:403–411

Karakaya I, Thompson WT (1988) The Pb-Sn (lead-tin) system. Bull Alloy Phase Diagrams 9:145–152

Singh M, Bhan S (1986) Contribution to the Fe-Sn system. J Mater Sci Lett 5:733–735

Okamoto H (2010) Sn-Ti (tin-titanium). J Phase Equilib Diffus 31:202–203

Kale GB, Patil RV, Gawade PS (1998) Interdiffusion studies in titanium-304 stainless steel system. J Nucl Mater 257:44–50

Torun O, Karabulut A, Baksan B, Çelikyürek I (2008) Diffusion bonding of AZ91 using a silver interlayer. Mater Des 29:2043–2046

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XVII - Brazing, Soldering and Diffusion Bonding.

Rights and permissions

About this article

Cite this article

Zhang, Y., Chen, Y., Zhou, J. et al. Microstructure and mechanical property in laser welding-brazing of stainless steel and titanium alloy using 63Sn-37Pb alloy as filler metal. Weld World 64, 257–266 (2020). https://doi.org/10.1007/s40194-019-00827-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00827-9