Abstract

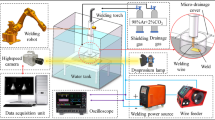

To explore the influence of calcium fluoride on underwater wet welding process stability, the relevance of calcium fluoride in the flux to metal transfer mode and arc stability was discussed in the process of underwater wet welding using a set of wires with various calcium fluoride contents. The metal transfer images were obtained using X-ray imaging system and the electric signal detection system was used to collect arc voltage and welding current signals synchronized with the film frames. Three metal transfer modes, i.e., repelled globular transfer, surface tension transfer, and spatter-like metal droplet transfer, were observed during the underwater wet welding process. The spatter-like metal droplet transfer mode was put forward firstly. Increasing the contents of calcium fluoride in the wire from 0 to 65%, the proportion of surface tension transfer mode steadily climbed from approximately 15 to 40% while that of spatter-like metal droplet mode declined from 53 to 35%. The arc stability of the welding process firstly deteriorated and then ameliorated with the increasing calcium fluoride content.

Similar content being viewed by others

References

Kralj S, Garašić I, Kožuh Z (2008) Diffusible hydrogen in underwater wet welding. Weld World 52:687–692

Guo N, Du Y, Maksimov S, Feng J, Yin Z, Krazhanovskyi D, Fu Y (2017) Study of metal transfer control in underwater wet FCAW using pulsed wire feed method. Weld World 1:1–8

Çam G, İpekoğlu G (2017) Recent developments in joining of aluminum alloys[J]. Int J Adv Manuf Technol 91(5–8):1851–1866

Çam G (2014) Friction stir welded structural materials: beyond Al-alloys. Int Mater Rev 56(1):1–48

Shi Y, Hu Y, Yi YY, Lin SQ, Li ZH (2017) Porosity and microstructure of underwater wet FCAW of duplex stainless steel. Metall Micro Analy 6(5):383–389

Matsushita M, Liu S (1999) Hydrogen control in steel weld metal by means of fluoride additions in welding flux: Dept. of Metallurgical and Metarials Engineering.Colorado School of Mines

Kuzmenko VG, Guzej VI (2005) Pore formation in weld metal in submerged arc welding with surface saturation of grains with fluorine. Paton Weld J 2:14–17

Liu F, Yang C, Lin S, Wu L, Su S (2003) Effect of weld microstructure on weld properties in A-TIG welding of titanium alloy. T Nonferr Metal Soc 13(4):876–880

SIS LB (1977) Welding flux cored electrodes in N2-CO2 and N2-Ar atmospheres. Weld J 53(7):211–216

Pessoa ECP, Bracarense AQ, Zica EM, Liu S, Perez-Guerrero F (2006) Porosity variation along multipass underwater wet welds and its influence on mechanical properties. J Mater Process Tech 179(1–3):239–243

Sun X, Wang HH, Zhang HQ (2006) Control of usability quality in flux-cored wire based on metal transfer theory. Electric Weld Mach 36(11):5–10

Matsuda F, Ushio M, Kuwayama N, Koyama K (1983) Metal transfer characteristics in self shielded flux cored arc welding for mild steel and 50kgf/mm2 class tensile steel (report I) : metal transfer mode and feasibility of welding (Welding Physics, Process & Instrument). Trans JWRI 12:19–25

Liu HY, Li ZX, Li H, Shi YW (2008) Study on metal transfer modes and welding spatter characteristics of self-shielded flux cored wire. Sci Technol Weld Join 13(8):777–780

Guo N, Fu Y, Feng J, Du Y, Deng Z, Wang M, Tang D (2016) Classification of metal transfer mode in underwater wet welding. Weld J 95(4):133–140

Jia CB, Zhang Y, Zhao B, Hu JK, Wu CS (2016) Visual sensing of the physical process during underwater wet FCAW. Weld J 95(6):202–209

Zhang Y, Jia CB, Zhao B, Hu JK, Wu CS (2016) Heat input and metal transfer influences on the weld geometry and microstructure during underwater wet FCAW. J Mater Process Tech 238:373–382

Meng QS, Wang B, Lu WX (1993) Effect of flux materials on surface tension of drops of electrodes. Trans China Weld Institut 02:63–68

Di L, Yonglun S, Feng Y (2000) Online monitoring of weld defects for short-circuit gas metal arc welding based on the self-organizing feature map neural networks [C]// Proceedings of the IEEE-INNS-ENNS International Joint Conference. 2000:239–244

Luksa K (2006) Influence of weld imperfection on short circuit GMA welding arc stability. J Mater Process Tech 175(1):285–290

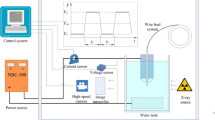

Guo N, Du YP, Feng JC, GuoW DZQ (2015) Study of underwater wet welding stability using an X-ray transmission method. J Mater Process Technol 225:133–138

Guo N, Guo W, Du YP, Fu YL, Feng JC (2015) Effect of boric acid on metal transfer mode of underwater flux-cored wire wet welding. J Mater Process Tech 223:124–128

Kim YS, Eager TW (1993) Analysis of metal transfer in gas metal arc welding. Weld J 72:6(3):1143–1152

Guo N, Guo W, Xu CS, Du YP, Feng JC (2015) Effect of boric acid concentration on viscosity of slag and property of weld metal obtained from underwater wet welding. J Mater Eng Perform 24(6):2563–2568

Zhuo LX, Huang FP, Chen BG, Jin LH (2001) Control on the droplet transfer of self-shielded flux-cored wire. J Mech Eng 37(7):108–112

Wang B, Song YL (2012) Welding arc phenomenon and the usability of welding consumables. China Machine Press, Beijing

Guo N, Xu C, Du Y, Wang M, Feng J, Deng Z, Tang D (2016) Effect of boric acid concentration on the arc stability in underwater wet welding. J Mater Process Tech 229:244–252

Acknowledgements

This study received financial support from the State Key Development Program for Basic Research of China (2013CB035502), the Shandong Provincial Key Research and Development Plan (2016ZDJS05A07, 2017CXGC0922), and Natural Science Foundation of Shandong Province (ZR2017QEE005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Guo, N., Xu, C., Du, Y. et al. Influence of calcium fluoride on underwater wet welding process stability. Weld World 63, 107–116 (2019). https://doi.org/10.1007/s40194-018-0642-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-0642-2