Abstract

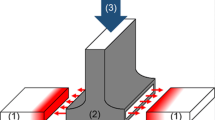

In welding of fiber-reinforced thermoplastics, the welding pressure initiates squeeze flow of melt into the weld bead. This leads to reorientation of fibers into the flow direction. Therefore, the fibers in the weld are mainly oriented perpendicular to the joining direction. Since this is mostly identical to the load direction, the reinforcing effect of fibers is not effective in the weld because fibers only have a reinforcing effect on the polymer when they are aligned along the load direction. Current investigations at the Kunststofftechnik Paderborn (KTP) aim at reaching an effective reinforcing effect of fibers in the weld of fiber-reinforced thermoplastics. The experiments are carried out on polypropylene and polyamide. Three different grades of PP are used: unreinforced, short glass fiber-reinforced, and long glass fiber-reinforced PP with 30% fiber content each. The used grades of PA differ in viscosity and shear thinning behavior. Experiments are being conducted on influences on the weld strength and the fiber orientation in the weld for hot plate welding. Common welding parameters are varied. One aim of the investigations is to find a correlation between the flow velocity during squeeze flow and weld strength or fiber orientation.

Similar content being viewed by others

Abbreviations

- a, b, c:

-

position of ROI’s in CT analysis

- a xx, a yy, a zz :

-

component of orientation tensor

- b :

-

width

- CT:

-

computed tomography

- d :

-

thickness

- DP:

-

design point

- DVS:

-

German Welding Association

- \( \frac{dp}{dx} \) :

-

pressure gradient in x-direction

- F :

-

joining force

- f z :

-

welding factor

- GF:

-

glass fiber-reinforced

- h :

-

melt layer height

- h 0 :

-

melt layer height at beginning of joining phase

- HP:

-

hot plate (welding)

- h residual :

-

melt layer height at end of joining phase

- K :

-

flow consistency index

- L 0 :

-

melt layer thickness after heating

- n :

-

flow behavior index

- P :

-

unit vector

- PA:

-

polyamide

- p F :

-

welding pressure

- PP:

-

polypropylene

- p x, p y, p z :

-

component of the unit vector P

- ROI:

-

region of interest

- s J :

-

joining displacement

- T HP :

-

hot plate temperature

- T M :

-

crystalline melt temperature

- v J :

-

joining velocity

- v x :

-

flow velocity in x-direction

- v y :

-

joining velocity

- x a, x b, x c :

-

position for calculation of flow velocity in squeeze flow

- \( \dot{\gamma} \) :

-

shear rate

- σW :

-

weld strength

References

Ehrenstein GW (2006) Faserverbund-Kunststoffe – Werkstoffe – Verarbeitung – Eigenschaften. Carl Hanser Verlag, München, 2., völlig überarbeitete Auflage

Menges G, Haberstroh E, Michaeli W, Schmachtenberg E (2002) Werkstoffkunde Kunststoffe. Carl Hanser Verlag, München

Schürmann H (2005) Konstruieren mit Faser-Kunststoff-Verbunden. Springer-Verlag, Berlin Heidelberg

Advani SG, Tucker CL (1987) The use of tensors to describe and predict fiber orientation in short fiber composites. J Rheol 31(8):751–784, John Wiley & Sons

Kamal, M. R.; Chung, Y.-M.; Gomez, R. (2008) Three-dimensional fiber orientation in vibration welded joints of glass fiber reinforced polyamide-6. Polym Compos, Vol. 20, No. 9, Wiley-VCH Verlag, Weinheim, pp. 954–963

Bay, R. S.; Tucker, C. L.: Fiber orientation in simple injection moldings. Part II: experimental results. Polymer Composites, August 1992, Vol. 13, No. 4, Wiley-VCH Verlag, Weinheim, pp. 332–341, 1992

Baudrit B (2014) Entwicklung innovativer Technologien zum Heizelementstumpf- und Infrarot-Schweißen von mineralgefüllten und faserverstärkten Kunststoffen. Forschungsbericht der SKZ - KFE gGmbH Kunststoff-Forschung und -Entwicklung zu dem AiF-geförderten Vorhaben 17303 N

Bruessel A (1999) Fertigungstechnische und werkstoffspezifische Aspekte zum Fügen von Thermoplasten mittels Heizelement. Dissertation, Universität-Gesamthochschule Paderborn

Kagan, V.: Optimized mechanical performance of welded and molded butt joints: part II – weld and knit lines integrity. J Reinf Plast Compos, Vol. 22, No. 09, Sage Publications, pp. 867–879, 2003

Bucknall CB, Drinkwater IC, Smith GR (1980) Hot plate welding of plastics: factors affecting weld strength. Polym Eng Sci 20(6):432–440, Wiley-VCH Verlag, Weinheim

Gehde M, Giese M, Ehrenstein GW (1997) Welding of thermoplastics reinforced with random glass mat. Polym Eng Sci 37(4):702–714, Wiley-VCH Verlag, Weinheim

Potente, H., Natrop, J., Pedersen, T. K., Uebbing, M. (1993) Comparative investigations into the welding of glass-fiber-reinforced PES. J Thermoplast Compos Mater, Vol. 6, Sage Publications, pp. 147–159

Kagan, V.; Bednarczyk, C.; Siu-Ching, L.; Smith, G. R. (1999) US-Patent 5.874.146: Performance of vibration welded thermoplastic joints

Kagan V, Lui S, Smith G, Patry J (1996) The optimized performance of linear vibration welded nylon 6 and nylon 66 butt joints. ANTEC 96, SPE Proceedings 1:1266–1274

Shih-Jung, L.; Hsin-Fu, C.: The influence of interface geometry on the joint strengths of hot plate welded composites. Journal of Reinforced Plastics and Composites, Vol. 29, No. 4, pp. 497–509, 2010, Sage Publications

Potente H (2004) Fügen von Kunststoffen – Grundlagen, Verfahren, Anwendung. Carl Hanser Verlag, München Wien

Kreiter J (1988) Optimierung der Schweißnahtfestigkeit von Heizelementstumpfschweißungen von Formteilen durch verbesserte Prozeßführung und Selbsteinstellung. Dissertation, Universität-Gesamthochschule Paderborn

DVS (2010) Heizelementschweißen von Formteilen aus thermoplastischen Kunststoffen in der Serienfertigung. Richtlinie DVS 2215–1

Dierig T, Becker B, Reinhart C, Günther T (2012) Fiber composite material analysis in aerospace using CT data. 4th International Symposium on NDT in Aerospace, 13.-15. Augsburg

Radtke A (2008) Steifigkeitsberechnung von diskontinuierlich faserverstärkten Thermoplasten auf der Basis von Faserorientierungs- und Faserlängenverteilungen. Dissertation, Universität Stuttgart

Potente H (1977) Zur Theorie de Heizelement-Stumfschweißens. Kunststoffe 67. Carl Hanser Verlag, München, pp 98–102

Acknowledgements

The IGF Project 18702N of the research association “Forschungsvereinigung Schweißen und verwandte Verfahren e. V. des DVS. Aachener Straße 172. 40223 Düsseldorf” was, on the basis of a resolution of the German Bundestag, promoted by the German Ministry of Economic Affairs and Energy via AiF within the framework of the program for the promotion of joint industrial research and development (IGF).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XVI - Polymer Joining and Adhesive Technology

Rights and permissions

About this article

Cite this article

Fiebig, I., Schoeppner, V. Factors influencing the fiber orientation in welding of fiber-reinforced thermoplastics. Weld World 62, 997–1012 (2018). https://doi.org/10.1007/s40194-018-0628-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-0628-0