Abstract

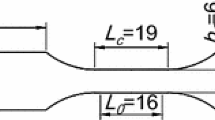

Specimen dimensions have significant effect on the tensile shear strength (TSS) of resistance spot welds (RSW) in the commonly employed tensile shear testing. Minimum required dimensions specified in different industrial test standards vary somewhat however. In this paper, the most influential dimension, the tensile shear test specimen width, is investigated for a low-strength steel (galvanized steel Q235), a high-strength steel (TRIP980), and aluminum alloy 5052. The relationships between the specimen width and weld properties, such as TSS, energy absorption, and failure modes, were investigated experimentally. The results show that there is a critical width of the specimen beyond which the TSS of the RSW maintains a constant value and the failure is at the spot weld. This constant TSS is a saturated value. The perceived TSS from the tensile shear testing is lower than the saturated TSS when the width is smaller than the critical value. The displacement at the TSS and the energy up to failure from the tensile shear testing, however, shows opposite trend due to the large plastic deformation from the base sheet metal in narrower specimens. From the results, a minimum width of tensile shear test specimen for determining saturated TSS is recommended.

Similar content being viewed by others

References

Brauser S, Pepke LA, Weber G, Rethmeier M (2010) Deformation behavior of spot-welded high strength steels for automotive applications. Mater Sci Eng A 527(26):7099–7108

Pouranvari M, Marashi SPH (2013) Critical review of automotive steels spot welding: process, structure and properties. Sci Technol Weld Join 18(5):361–403

Kahraman N (2007) The influence of welding parameters on the joint strength of resistance spot-welded titanium sheets. Mater Des 28(2):420–427

Aslanlar S (2006) The effect of nucleus size on mechanical properties in electrical resistance spot welding of sheets used in automotive industry. Mater Des 27(2):125–131

Tang H, Hou W, Hu SJ (2002) Forging force in resistance spot welding. Proc Inst Mech Eng B Eng Manuf 216(7):957–968

Zhou M, Zhang H, Hu SJ (2003) Relationship between quality and attributes of spot welds. Weld J 82(4):72–77

Bourges PH, Jubin L, Bocquet P (1995) Prediction of mechanical properties of weld metal based on some metallurgical assumptions. In: Cerjak H (ed) Mathematical modelling of weld phenomena. Institute of Materials, London, pp 201–212

Luo Z, Ao SS, Chao YJ, Cui XT, Li Y, Lin Y (2015) Application of pre-heating to improve the consistency and quality in AA5052 resistance spot welding. J Mater Eng Perform 24(10):3881–3891

AWS D8.9M (2012) Test methods for evaluating the resistance spot welding behavior of automotive sheet steel materials, American Welding Society

AWS C1.4M/C1.4 (2009) Specification for resistance welding of carbon and low-alloy steels, American Welding Society

ISO 14273 (2000) Specimen dimensions and procedure for shear testing resistance spot, seam and embossed projection welds. International standard

GB 2651 (1989) Method of tensile test for welded joint, General Administration of Quality Supervision, Inspection and Quarantine of People’s Republic of China, China National Standardization Management Committee

GB 2651 (2008) Method of tensile test for welded joint, General Administration of Quality Supervision, Inspection and Quarantine of People’s Republic of China. China National Standardization Management Committee

AWS D17.2/D17.2M 2nd Edition (2013) Specification for resistance welding for aerospace applications

BS EN ISO 14323 (2006) Resistance spot welding and projection welds-destructive testing of welds-specimen dimensions and procedure for impact shear test and cross-tension testing, International standard

Zhou M, Hu SJ, Zhang H (1999) Critical specimen sizes for tensile-shear testing of steel sheets. Weld J 78(9):305–312

Yang HG, Zhang YS, Lai XM (2008) An experimental investigation on critical specimen sizes of high strength steels DP600 in resistance spot welding. Mater Des 29(9):1679–1684

Sparagen W, Cordovi MA (1944) Mechanical characteristics of resistance welds in plain carbon steels. Weld J 23(7):305–343

Chao YJ (2003) Failure mode of spot welds: interfacial versus pullout. Sci Technol Weld Join 8(2):133–137

Pouranvari M, Marashi SPH (2010) Key factors influencing mechanical performance of dual phase steel resistance spot welds. Sci Technol Weld Join 15(2):149–155

Heuschkel J (1952) The expression of spot-weld properties. Weld J 31(10):931–943

Chao YJ (2003) Ultimate strength and failure mechanism of resistance spot weld subjected to tensile, shear, or combined tensile/shear loads. Trans ASME J Eng Mater Technol 125(2):125–132

Pouranvari M, Mousavizadeh SM, Marashi SPH (2010) Influence of fusion zone size and failure mode on mechanical performance of dissimilar resistance spot welds of AISI 1008 low carbon steel and DP600 advanced high strength steel. Mater Des 32(3):1390–1398

BS EN ISO 14273 (2016) Resistance spot welding—destructive testing of welds—specimen dimensions and procedure for tensile shear testing resistance spot and embossed projection welds

Acknowledgments

This work is supported by Natural Science Foundation of China (Grant 51275342, Grant 51275338 and 51405335).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission III - Resistance welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Ao, S., Shan, H., Cui, X. et al. Effect of specimen width on the failure behavior in resistance spot weld tensile shear testing. Weld World 60, 1095–1107 (2016). https://doi.org/10.1007/s40194-016-0384-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0384-y