Abstract

V-containing-active high-temperature brazing alloys were designed for ceramic joining, including PdCo–V, AuPdCoNi–V, AuCuPd–V, and CuPd–V system alloys. The joined ceramics or ceramic composites include Si3N4 ceramic, AlN ceramic, carbon fiber-reinforced silicon carbide composite (Cf/SiC), and C/C composite. The dynamic wettability of the V-containing brazes on ceramic or composite was studied with the sessile drop method. Based on the wetting experiment results, several alloys were chosen as the brazing filler metal. It was verified that during the brazing process, the reactions between the filler metal and the Si3N4 or AlN ceramic caused the formation of V–N layer at the interface close to the ceramic surface. The V–C compound was detected at the reaction interface between the V-containing-active filler metal and C/C composite or Cf/SiC composite. The formation of V–N or V–C layer played an important role in the joining of the ceramic or the ceramic composite. Both of the Si3N4–Si3N4 and Cf/SiC–Cf/SiC joints brazed with V-containing-active braze exhibited stable high-temperature property, and this should be attributed to the presence of refractory Pd2Si compounds within the joints. The newly developed V-containing-active brazes should have a potential to meet service temperatures of 973~1073 K, about 300 K higher than the AgCu–Ti brazing filler metals.

Similar content being viewed by others

References

Iseki TY, Matsuzaki H, Boadi JK (1985) Brazing of silicon carbide to stainless steel. Am Ceram Soc Bull 64(2):322–324

Martinelli AE, Hadian AM, Drew RAL (1997) A review on joining non-oxide ceramics to metals. J Can Ceram Soc 66(4):276–280

Kapoor RR, Eagar TW (1989) Oxidation behavior of silver- and copper-based brazing filler metals for silicon nitride/metal joints. J Am Ceram Soc 72(3):448–454

Peteves SD, Ceccone G, Paulasto M, Stamos V, Yvon P (1996) Joining silicon nitride to itself and to metals. JOM 48(1):48–52

Naka M, Okamoto I (1985) Wetting of silicon nitride by copper-titanium or copper-zirconium alloys. Trans JWRI 14(11):29–34

Nakao Y, Nishimoto K, Saida K (1989) Bonding of Si3N4 to metals with active filler metals. Trans Jpn Weld Soc 20(1):66–76

Xiong HP, Wan CG, Zhou ZF (1998) Development of a new CuNiTiB brazing alloy for joining Si3N4 to Si3N4. Metall Mater Trans 29A(10):2591–2596

Peteves SD, Paulasto M, Ceccone G, Stamos V (1998) The reactive route to ceramic joining: fabrication, interface chemistry and joint properties. Acta Mater 46(7):2407–2414

Chen JH, Wang GZ (1993) Segregation of chromium at the interface between Ni-Cr-Si-Ti brazing filler metal and Si3N4 ceramics. J Mater Sci Lett 12(1):87–89

Reichel U, Warlimont H (1999) Rapidly solidified CoTi alloys as brazing foils for high-temperature joining of silicon nitride ceramic. Z Met 90(9):699–703

Hadian AM, Drew RAL (1996) Strength and microstructure of silicon nitride ceramics brazed with nickel-chromium-silicon alloys. J Am Ceram Soc 9(3):659–665

Xian AP (1993) Precursor film of tin-based active solder wetting on ceramics. J Mater Sci 28:1019–1030

Sera T, Nitta A, Tsuchitori I, Hara N, Yoshino M, Watanabe T (1989) Joining of silicon nitride using copper alloy brazes. Proc. MRS Int. Meeting on Advanced Materials. Vol. 8, Metal-Ceramic Joints, 41–46, Materials Research Society

Paulasto M, Ceccone G, Peteves SD, Voitovich R, Eustathopoulos N (1997) Brazing of Si3N4 with Au-Ni-V-Mo filler alloy. Ceram Trans 77:91–98

Loehman RE (1999) Recent progress in ceramic joining. Key Eng Mater 161–163:657–662

Sun Y, Zhang J, Geng YP, Ikeuchi K, Shibayanagi T (2011) Microstructure and mechanical properties of an Si3N4/Si3N4 joint brazed with Au-Ni-Pd-V filler alloy. Scr Mater 64(5):414–417

Xiong J, Li J, Zhang F, Huang W (2006) Joining of 3D C/SiC composites to niobium alloy. Scr Mater 55:151–154

Jimenez C, Mergia K, Moutis NV, Azpiroz XA, Wilhelmi C, Speliotis T, Messoloras S (2012) Joining of Cf/SiC ceramics to nimonic alloys. J Mater Eng Perform 21:683–689

Lin G, Huang J, Zhang H (2007) Joints of carbon fiber-reinforced SiC composites to Ti-alloy brazed by Ag-Cu-Ti short carbon fibers. J Mater Process Technol 189(1–3):256–261

Tong Q, Cheng L (2006) Liquid infiltration joining of 2D C/SiC composite. Sci Eng Compos Mater 13:31–36

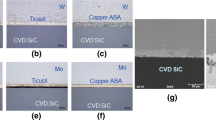

Xiong HP, Dong W, Chen B, Kang YS, Kawasaki A, Okamura H, Watanabe R (2008) Wettability of Ni-V, Co-V, and Ni-Cr-V system brazing alloys on Si3N4 ceramic and interfacial reactions. Mater Sci Eng A 474(1–2):376–381

Xiong HP, Chen B, Pan Y (2014) Joining of Si3N4 using PdCo(NiSiB)–V system brazing filler alloy and interfacial reactions. Prog Nat Sci:Mater Int 24:61–67

Du Z, Guo C, Yang X, Liu T (2006) A thermodynamic description of the Pd-Si-C system. Intermetallics 14:560–569

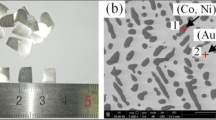

Xiong HP, Chen B, Pan Y, Zhao HS, Guo WL (2014) Joining of Si3N4 to Si3N4 using a AuPd(Co, Ni)–V filler alloy and the interfacial reactions. Ceram Int 40(3):4141–4148

Miedema AR, Boer FRDE, Boom R, Dorleijn JWF (1977) Tables for the heat of solution of liquid metals in liquid metal solvents. Calphad 1:353–359

Xiong HP, Chen B, Pan Y, Zhao HS, Mao W, Cheng YY (2014) A Cu-Pd-V system filler alloy for silicon nitride ceramic joining and the interfacial reactions. J Am Ceram Soc 97(8):2447–2454

Xiong HP, Chen B, Mao W, Li XH (2012) Joining of Cf/SiC composite with Pd-Co-V brazing filler. Weld World 56(1–2):76–80

Xiong HP, Chen B, Pan Y, Zhao HS, Ye L (2014) Joining of Cf/SiC composite with a Cu-Au-Pd–V brazing filler and interfacial reactions. J Eur Ceram Soc 34(6):1481–1486

Chen B, Xiong HP, Cheng YY, Mao W, Ye L, Li XH (2010) Microstructure and strength of Cf/SiC joints with Ag-Cu-Ti brazing fillers. J Mater Eng 329:27–31 (in Chinese)

Xiong HP, Chen B, Pan Y, Mao W, Cheng YY (2014) Interfacial reactions and joining characteristics of a Cu-Pd–V system filler alloy with Cf/SiC composite. Ceram Int 40(6):7857–7863

Lee HK, Lee JY (1996) A study of the wetting, microstructure and bond strength in brazing SiC by Cu-X (X = Ti, V, Nb, Cr) alloys. J Mater Sci 31:4133–4140

Park JS, Landry K, Perepezko JH (1999) Kinetic control of silicon carbide/metal reactions. Mater Sci Eng A 259:279–286

Bhanumurthy K, Schmid-Fetzer R (2001) Interface reactions between silicon carbide and metals (Ni, Cr, Pd, Zr). Compos A: Appl Sci Manuf 32:569–574

Xiong HP, Chen B, Kang YS, Mao W, Kawasaki A, Okamura H, Watanabe R (2007) Wettability of Co-V, and PdNi-Cr-V system brazing alloys on SiC ceramic and interfacial reactions. Scr Mater 56:173–176

Xiong HP, Mao W, Xie YH, Guo WL, Li XH, Cheng YY (2007) Brazing of SiC to a wrought nickel-based superalloy using CoFeNi(Si, B)CrTi filler metal. Mater Lett 61:4662–4665

Xiong HP, Mao JY, Chen BQ, Wang Q, Wu SB, Li XH (2013) Research advances on the welding and joining technologies of light-mass high-temperature structural materials in aerospace field. J Mater Eng 365:1–12 (in Chinese)

Xiong HP, Chen B (2014) High-temperature brazing filler metals for ceramic joining and interfacial metallurgy. National Defense Industry Press, Beijing (in Chinese)

Chen B, Xiong HP, Cheng YY, Mao W, Wu SB (2015) Microstructure and property of AlN joint brazed with Au-Pd-Co-Ni-V brazing filler. J Mater Sci Technol 31:1034–1038

Zhu S, Wlosinski W (2001) Joining of AlN ceramic to metals using sputtered Al or Ti film. J Mater Process Technol 109(3):277–282

Kara-slimane A, Juve D, Lebland E, Treheux D (2000) Joining of AlN with metals and alloys. J Eur Ceram Soc 20(11):1829–1836

Acknowledgments

This research work is sponsored by the National Natural Science Foundation of China (Contract Nos. 59905022, 50475160, 51275497, and 51410105004) and Aeronautical Science Foundation of China (Grant 2008ZE21005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XVII --- Brazing, Soldering, and Diffusion Bonding

Rights and permissions

About this article

Cite this article

Xiong, H., Chen, B., Zhao, H. et al. V-containing-active high-temperature brazes for ceramic joining. Weld World 60, 99–108 (2016). https://doi.org/10.1007/s40194-015-0276-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-015-0276-6