Abstract

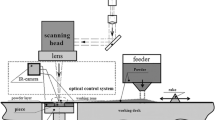

In material processing, heat input into parts is a major issue. To reduce heat impact, temperatures can be evaluated to optimize processes, i.e., for low distortion, low dilution, or small heat-affected zones. A new sensor, which combines ratio pyrometry with 2D-resolved measurement, is presented and compared to existing temperature sensors in the context of laser processing. The advantages of independence of emissivity and attenuation of the thermal radiation together with 2D temperature information are demonstrated on laser cladding. The temperature distribution at the parts’ surfaces becomes available quantitatively and with high precision. This information was successfully applied to determine melt pool diameters, latent heat, as well as to validate FEM-based temperature field simulations.

Similar content being viewed by others

References

Heuvelman CJ, König W, Tönshoff HK, Meijer J, Kirner PK, Rund M, Schneider MF, van Sprang I (1992) Surface Treatment Techniques by Laser Beam Machining. Annals CIRP 41(2):657–666

Wagner F, Welzenbach M, Buschhoff J, Gall S (2008) Forschung wird Wirtschaft oder Laser-Pulver-Auftragsschweißen im Schiffsreparaturbereich. In: Vollertsen F, Seefeld T (eds) 6. Laseranwenderforum (LAF'08), 36th edn. BIAS-Verlag, Bremen, Bd, pp 139–146

Mazumder J, Nutta D, Kikuchi N, Ghosh A (2000) Closed loop direct metal deposition: art to part; Optics and Lasers in Engineering Vol. 34. Issues 4–6:397–414

Toyserkani E, Khajepour A (2006) A mechatronics approach to laser powder deposition process. Mechatronics 16:631–641

Doubenskaia M, Bertrand P, Smurov I (2006) Pyrometry in laser surface treatment. Surf Coat Technol 201:1955–1961

Bonß S, Seifert M, Hannweber J, Karsunke U, Beyer E (2005) Low cost camera based sensor system for advanced laser heat treatment processes, Proc. ICALEO p. 851-855

Koehler H, Partes K, Seefeld T, Vollertsen F (2010) Laser reconditioning of crankshafts: From lab to application, Laser Assisted Net shape Engineering (LANE 2010), eds M. Schmidt, F. Vollertsen M. Geiger p. 387-397

Bi G, Schürmann B, Gasser A, Wissenbach K, Poprawe R (2007) Development and qualification of a novel laser-cladding head with integrated sensors. Int J Mach Tools Manuf 47:555–561

Hofman J (2009) Development of an observation and control system for industrial laser cladding, Ph.D.-thesis, M2i, published online under http://doc.utwente.nl/60627/

Craeghs T, Bechmann F, Berumen S, Kruth JP (2010) Feedback control of layerwise laser melting using optical sensors. Phys Procedia Part B 5:505–514

Hutter FX, Brosch D, Burghartz JN, Graf HG, Strobel M (2008) A new high speed thermal imaging concept based on alogarithmic CMOS imager technology; Photonics Europe 2008, Proc. of SPIE Vol. 7003, 70030H, Strasbourg, France, Lasers and Photonics Applications, ISBN: 978-0-8194-7203-8

Köhler H, Jayaraman V, Brosch D, Hutter FX, Seefeld T (2013) A Novel Thermal Sensor Applied for Laser Materials Processing. Phys Procedia 41:495–501

Goldak J, Chakravarti A, Bibby M (1984) A new finite element model for welding heat source. Metall Trans B 15B:299–305

Partes K (2008) Hochgeschwindigkeitsbeschichten mit dem Laserstrahl, Dissertation, BIAS Verlag Bremen Strahltechnik, Band 34

Grünenwald B et al. (1996) Laserbeschichten mit CO2- und Nd:YAG-Lasern, Hrsg. Dausinger, F. et al. Proceedings ECLAT p. 299–306

Koehler H, Schumacher J, Schuischel K, Partes K, Bomas H, Jablonski F, Vollertsen F, Kienzler R (2012) An approach to calculate fatigue properties of laser cladded components. Prod Eng R Dev 6(2):137–148, Springer Berlin/Heidelberg

Hutter FX, Brosch D, Graf HG, Klingler W, Strobel M, Burghartz JN (2009) A 0.25μm Logarithmic CMOS Imager for Emissivity Compensated Thermography; ISSCC Digest of Technical Papers, International Solid-State Circuits Conference 2009, San Francisco, CA, USA, February 8, 52 p. 354-355

Acknowledgments

The authors acknowledge funding by the Deutsche Forschungsgemeinschaft DFG for funding the project VO 530/31 “Laserstrahlbeschichten und Simulation der Temperatur- und Eigenspannungssituation” (Laser cladding and simulation of temperature and residual stress situation).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission IV --- Power Beam Processes

Rights and permissions

About this article

Cite this article

Köhler, H., Thomy, C. & Vollertsen, F. Contact-less temperature measurement and control with applications to laser cladding. Weld World 60, 1–9 (2016). https://doi.org/10.1007/s40194-015-0275-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-015-0275-7