Abstract

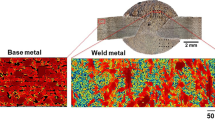

Effects of Al and N on the transformation of austenite to acicular ferrite during continuous cooling in Ti–B steel weld metals have been investigated using a dilatometric technique combined with (scanning) transmission electron microscopy (STEM/TEM) equipped with energy-dispersive X-ray (EDX) facilities. Results showed that addition of 160 ppm Al to a Ti–B–N weld metal with a low or ‘normal’ N content (designated as N) accelerated the transformation kinetics resulting in acicular ferrite as the dominant microstructure. As the amount of Al was increased to 560 ppm, the transformation was retarded as indicated by its lower transformation start temperature, hence favouring upper bainite. It is interesting to note that N could give a beneficial effect in Ti–B–N weld metals with 560 ppm Al when the amount of N was increased to an intermediate level (N1), i.e. 120 ppm, marked by an increase in the transformation start temperature with upper bainite being replaced by intragranular acicular ferrite. A reversal effect was observed as the N level was increased up to 240 ppm (N2) where the growth of acicular ferrite had to compete with that of intragranular polygonal ferrite, and the mechanism in which acicular ferrite develops in Ti–B–Al–N welds is discussed.

Similar content being viewed by others

References

Ito Y, Nakanishi M (1976) Study on Charphy impact properties of weld metals with submerged arc welding. Sumitomo Search 15:42–62

Lau TW, Sadowski MM, North TH, Weatherly GC (1988) Effect of nitrogen on properties of submerged arc weld metal. Mater Sci Technol 4:53–61

Croft NH, Hipley RL (1983) Microstructure and properties of heat treated weldments. International conference on: The effects of residual, impurity and microalloying elements on weldability and weld properties, London, Paper 26

Yamada T, Terasaki H, Komizo Y (2009) Relation between inclusion surface and acicular ferrite in low carbon low alloy steel weld. ISIJ Int 49(7):1059–1062

Yamanaka K, Ohmori Y (1977) Effect of boron on transformation of low carbon low alloy steels. Trans ISIJ 17:93–101

Babu SS (2004) The mechanism of acicular ferrite in weld deposits. Curr Opinion Solid State Mater Sci 8:267–278

Babu SS, David SA (2002) Inclusion formation and microstructure evolution in low alloy steel welds. ISIJ Int 42(12):1344–1353

Evans GM (1996) Microstructure and properties of ferritic steel welds containing Ti and B. Weld J 251 s-260s.

Evans GM (1998) Effect of nitrogen on C-Mn steel welds containing titanium and boron. Weld J 239s-248s.

Ilman MN, Cochrane RC, Evans GM (2012) Effect of nitrogen and boron on the development of acicular ferrite in reheated C-Mn-Ti steel weld metals. Weld World 56(11/12):41–50

Terashima H, Hart PHM (1983) Effect of flux TiO2 and wire Ti content on tolerance to high Al content of submerged-arc welds made with basic fluxes. Proc. Int. Conf. on: The effect of residual, impurity and microalloying elements on weldability and weld properties, The Welding Institute, London, paper 27.

Oldland RB (1985) The influence of aluminium and nitrogen on the microstructures and properties of single pass submerged arc welds. Australian Welding Research 44–56

Vanovsek W, Bernhard C, Fiedler M, Posch G (2013) Influence of aluminium content on the characterization of microstructure and inclusions in high-strength steel welds. Weld World 57(1):73–83

Grong O, Kluken AO, Hylund HK, Dons AL, Hjelen J (1988) Catalyst effect in heterogeneous nucleation of acicular ferrite. Metall Mater Trans 26A:525–534

Poulalion A, Botte R (1988) Proc. Int. Conf. on: High nitrogen steels, The Institute of Metals, Lille, France, 49–52.

Achar DRG, Kocak M, Evans GM (1998) Effect of nitrogen on toughness and strain age embrittlement of ferritic steel weld metal. Sci Technol Weld Join 3(5):233–243

Bang KS, Kim WY, Park C (2007) Effects of nitrogen on weld metal microstructure and toughness in submerged arc welding. Mater Sci Forum 539–543:3906–3911

Evans GM (1997) Effect of aluminium and nitrogen on Ti-B containing steel welds. Weld J 76(10):249s–261s

Evans GM, Bailey N (1997) Metallurgy of basic weld metal. Abington Publishing, Cambridge

Thewlis G (1994) Transformation kinetics of ferrous weld metal. Mater Sci Technol 10:110–125

Thewlis G, Whiteman JA, Senogles D (1997) Dynamics of austenite to ferrite phase transformation in ferrous weld metals. Mater Sci Technol 13:257–274

Harrison PL, Farrar RA (1981) Influence of oxygen-rich inclusions on the γ → α phase transformation in high strength low alloy (HSLA) steel weld metals. J Mater Sci 16:2218–2226

Ilman MN, Cochrane RC, Evans GM (2014) Effect of titanium and nitrogen on the transformation characteristics of acicular ferrite in reheated C-Mn steel weld metals. Weld World 58:1–10

Dubé CA, Aaronson HI, Mehl RF (1958) Rev Metall 55(3):201–210

Homma H, Ohkita S, Matsuda S, Yamamoto K (1987) Improvement of HAZ toughness in HSLA steel by introducing finely dispersed Ti-oxide. Weld J 66:301s–309s

Cochrane RC, Senogles DJ (1997) The effect of Ti additions on the microstructure of autogenous laser welds. Proc. of conference on: Titanium technology in microalloyed steels, the University of Sheffield December 1994. Ed. Baker T.N. The Institute of Materials, Cambridge, 207–223.

Ohkita S, Horii Y (1995) Recent development in controlling the microstructure and properties of low alloy steel weld metals. ISIJ Int 35(10):1170–1182

Takada A, Terasaki H, Komizo Y (2013) Effect of aluminium content on acicular ferrite formation in low carbon steel weld metals. Sci Technol Weld Join 18(2):91–97

Hilert M (1975) Diffusion and interface control of reactions in alloys. Metall Trans A 6:5–19

Mabuchi H, Nakao H (1983) The effects of excess aluminum on mechanical properties of Mn-Mo, Mn-Mo-Ni and Mn-Mo-Ni-Cr steels with regard to solute interactions. Trans ISIJ 23:504–512

Mori N, Homma H, Okita S, Wakabayashi M (1981) Mechanism of B and N of notch toughness improvement in Ti-B bearing weld metals. IIW Document, IX-1196-81, IIW 1981.

Lee SY, Oh YJ, Yi KW (2002) Effect of titanium and oxygen content on microstructure in low carbon steels. Mater Trans 43(3):518–522

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2543, recommended for publication by Commission II "Arc Welding and Filler Metals".

Rights and permissions

About this article

Cite this article

Ilman, M.N., Cochrane, R.C. & Evans, G.M. The development of acicular ferrite in reheated Ti–B–Al–N-type steel weld metals containing various levels of aluminium and nitrogen. Weld World 59, 565–575 (2015). https://doi.org/10.1007/s40194-015-0231-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-015-0231-6