Abstract

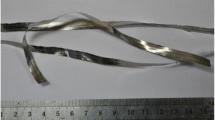

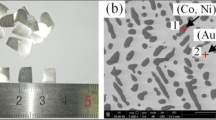

Eight kinds of PdNi(Co)-Cr alloys were designed, and their wettability on Si3N4 ceramic was studied with the sessile drop method. Under the vacuum heating condition of 1,523 K/30 min, Pd60-Ni40 alloy showed a contact angle of 28° on Si3N4 ceramic, and the reaction band between it and the Si3N4 consisted of the mixture of (Pd, Ni) solid solution and (Pd, Ni)-silicides. It was found that Cr addition into the Pd-Ni alloys further improved their wettability. Pd60-Co40 alloy gave a contact angle of 134°. When 8 wt.% Cr was added into Pd-Co alloy, its contact angle was remarkably decreased to 44°. The reaction products at the interfaces were examined by SEM equipped with an X-ray energy-dispersive spectrometer, and the corresponding interfacial reaction mechanism was also discussed. The formation of Pd2Si is evident at the interfaces. PdCo(Ni,Si,B)-(20∼25)Cr alloy was designed as a filler metal and was produced into filler foils by a rapidly-solidifying technique, and they were used for the brazing of Si3N4/Si3N4. The Si3N4/Si3N4 joints brazed at 1,523 K for 10 min exhibited an average three-point bend strength of 107.7 MPa at room temperature.

Similar content being viewed by others

References

Kang S, Kim HJ (1995) Design of high-temperature brazing alloys for ceramic-metal joints. Weld J 74:289s–295s

Peteves SD, Paulasto M, Ceccone G, Stamos V (1998) The reactive route to ceramic joining: fabrication, interfacial chemistry and joint properties. Acta Mater 46:2407–2414

Paulasto M, Ceccone G, Peteves SD, Voitovich R, Eustathopoulos N (1997) Brazing of Si3N4 with Au-Ni-V-Mo filler alloy. Ceram Trans 77:91–98

Loehman RE (1999) Recent progress in ceramic joining. Key Eng Mater 161–163:657–662

Hadian AM, Drew RAL (1996) Strength and microstructure of silicon nitride ceramics brazed with nickel-chromium-silicon alloys. J Am Ceram Soc 79:659–665

Ceccone G, Nicholas MG, Peteves SD, Tomsia AP, Dalgleish BJ, Glaesser AM (1996) An evaluation of the partial transient liquid phase bonding of Si3N4 using Au coated Ni-22Cr foils. Acta Mater 44(2):657–667

Nakamura M, Peteves SD (1990) Solid-state bonding of silicon nitride ceramics with nickel-chromium alloy interlayers. J Am Ceram Soc 73(5):1221–1227

Peteves SD, Suganuma K (1993) Solid state bonding of Si3N4 ceramics with Fe-Cr alloy interlayers. Ceramic Trans 35:229–238

Tillmann W, Lugscheider E, Schlimbach K, Manter C, Indacochea JE (1997) Heat-resistant active brazing of silicon nitride part 1: mechanical evaluation of braze joints. Weld J 76(8):300s–304s

Okamura H (1993) Brazing ceramics and metals. Weld Int 7(3):236–242

Gotman I, Gutmanas EY (1992) Microstructure and thermal stability of coated Si3N4 and SiC. Acta Metall Mater 40:S121–S126

Ceccone G, Nicholas MG, Peteves SD, Kodentsov AA, Kivilahti JK, van Loo FJJ (1995) The brazing of Si3N4 with Ni-Cr-Si alloys. J Eur Ceram Soc 15:563–572

Gulpen JH, Kodentsov AA, Loo FJJ (1995) Growth of Silicides in Ni-SiC bulk diffusion couples. Z Metallkd 86(8):530–535

Bhanumurthy K, Schmid-Fetzer R (2001) Interface reactions between silicon carbide and metals (Ni, Cr, Pd, Zr). Compos Part A 32:569–574

Park JS, Landry K, Perepezko JH (1999) Kinetic control of silicon carbide/metal reactions. Mater Sci Eng A 259:279–286

Barin I and Knacke O (1977) Thermochemical properties of inorganic substances, Springer, Berlin, FRG, 1977

Miedema AR, Boer FRDE, Boom R, Dorleijn JWF (1977) Calphad 1:353–359

Xiong HP, Chen B, Pan Y, Zhao HS, Guo WL (2014) Joining of Si3N4 to Si3N4 using a AuPd (CO, Ni)–V filler alloy and the interfacial reactions. Ceram Int 40(3):4141–4148

Xiong HP, Chen B, Pan Y, Guo WL, Mao W, Ma QS (2014) Joining of Si3N4 using PdCo (NiSiB)–V system brazing filler alloy and interfacial reactions. Prog Nat Sci–Mater Int 24:61–67

Xiong HP, Mao JY, Chen BQ, Wang Q, WU SB, Li XH (2013) Research advances on the welding and joining technologies of light-mass high-temperature structural materials in aerospace field. J Mater Eng 365:1–12 (in Chinese)

Acknowledgments

This research work is sponsored by National Natural Science Foundation of China (Contract Nos. 59905022 and 50475160). We also would like to thank Aeronautical Science Foundation of China (Grant 2008ZE21005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2490, recommended for publication by Commission XVII “Brazing, Soldering, and Diffusion Bonding.”

Rights and permissions

About this article

Cite this article

Xiong, HP., Chen, B., Guo, WL. et al. Wettability of PdNi(Co)-Cr alloys on Si3N4 ceramic and joining of Si3N4 to Si3N4 . Weld World 59, 33–44 (2015). https://doi.org/10.1007/s40194-014-0175-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-014-0175-2