Abstract

The current study aimed to determine alternative configurations of supply chain resilience strategies for managing supply chain performance (SCP) during a severe disruption. To do this, a multi-method and multi-study approach was adopted. Phase 1 of the study employed a qualitative approach to explore supply chain risk factors and their mitigation strategies during the COVID-19 pandemic. In Phase 2, the quality function deployment technique was used alongside quantitative case studies to determine the most critical risk factors and most crucial resilience strategies. The final phase, Phase 3, used fuzzy set qualitative comparative analysis to determine the alternative portfolio of strategies for SCP to create flexibility when employing resilience strategies. The results revealed that implementing resilience strategies alone is ineffective in improving SCP, while resilience strategies combined with the nullification of risk factors enhance SCP. The study also revealed two alternative configurations of resilience strategies to tackle the relevant risk factors. These findings can be used to guide managers toward identifying the most suitable configuration of resilience strategies to manage severe and unprecedented supply chain risk. The alternative configurations of resilience strategies can also provide flexibility to managers in deciding the best course of action for their firms.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Risks in supply chains are inevitable (Christopher et al., 2011) and have increased in recent years. In a recent survey conducted by Elliott et al. (2023), 11.5 percent of respondents reported facing over ten disruptions in 2022, a figure more than double the pre-pandemic level (4.8 percent). Additionally, over 65 percent of respondents reported that their organizations experienced one or more supply chain disruptions during this period. Moreover, supply chains have recently been exposed to many severe disruptions, such as epidemics and pandemics. For example, 1,438 epidemics were tracked by the World Health Organization (WHO) from 2011 to 2018 (Hudecheck et al., 2020). These disruptions in supply chains have severe negative impacts on operations and performance (Ivanov & Dolgui, 2020; Singh et al., 2021; Veselovská, 2020). Strategizing organizations and establishing robust resilience strategies can minimize the impact experienced and sustain performance (Chowdhury & Quaddus, 2017; Dwivedi et al., 2023; Sharma et al., 2023). As such, researchers have proposed many resilience strategies, including those pertaining to agility, robustness, flexibility, collaboration and redundancy (Chowdhury & Quaddus, 2017; Dhillon et al., 2023; Faisal et al, 2024; Kamalahmadi & Parast, 2016). However, the impacts of some recent disruptions, such as COVID-19, have shown that supply chains are still vulnerable to severe disruptions (Ishak et al., 2023; Linton & Vakil, 2020; Majumdar et al., 2020; Zaoui et al., 2023). Thus, investigating supply chain resilience (SCRES) capabilities to manage severe disruptions is important (Han et al., 2020).

An appropriate decision model that can identify and evaluate risk factors and related SCRES strategies simultaneously is vital in designing the most suitable strategies to minimize the impacts of disruption and improve SCP. However, there is a lack of decision models to identify risk factors caused by severe disruptions and corresponding resilience strategies (Chowdhury et al., 2021). Moreover, research in this area has mostly considered one stage (e.g., either risk identification and risk assessment or risk treatment) of supply chain risk and disruption management frameworks or processes, with most attention given to developing risk treatment strategies (Fan & Stevenson, 2018). While focusing on only one stage may enable an in-depth investigation, a holistic investigation of all stages ensures the most suitable SCRES strategies for disruption. For example, identifying and assessing risk factors is essential for understanding the critical risk factors for developing a risk treatment plan and resilience strategies (Fan & Stevenson, 2018). Hence, this study aimed to develop a holistic decision model that enables an exploration of alternative combinations of SCRES strategies to tackle the impact of various risk factors, thereby improving SCP. Exploring alternative configurations of resilience strategies will bring decision-makers flexibility to decide which configurations are most suitable for their supply chains.

In general, to overcome the impacts of risks, supply chain members need to set resilience strategies such as readiness, response and recovery strategies, which are interdependent and become more effective when they have a combined effect (Chowdhury & Quaddus, 2016). Moreover, risk and resilience strategies are also interdependent (Chowdhury & Quaddus, 2015). Therefore, it is essential to investigate the combined effects of risk and resilience on SCP. However, the literature thus far has largely failed to explain such combined effects of risks and resilience strategies on performance. Instead, attention has been given to investigating the net effect of risk and resilience strategies on SCP (Chowdhury et al., 2024). Such an investigation of the net effect may fail to explain the complexity of the phenomenon. In addition, assessing the net independent effect instead of the combined influence of causal factors may lead to flawed decision-making (Olya & Akhshik, 2019). Hence, this study investigated the combined effect of risk factors and SCRES strategies on SCP. Considering all these gaps, the study aimed to investigate the following research questions:

-

(i)

What are the appropriate SCRES strategies to tackle the risks caused by a severe disruption?

-

(ii)

What are the most important SCRES strategies for managing the prioritized risks?

-

(iii)

What are the alternative causal configurations of risks and SCRES strategies to improve SCP during a severe disruption?

The following specific research objectives were developed for the study to address the above-mentioned research questions:

-

(i)

To identify risks caused by a severe disruption and corresponding SCRES strategies;

-

(ii)

To prioritize the risks and determine the set of most important SCRES strategies for managing the prioritized risks; and

-

(iii)

To explore the alternative causal configuration of risks and SCRES strategies to improve SCP.

To address the above-mentioned research objectives, the COVID-19 pandemic was used as an example of severe disruption. This pandemic has severely affected supply chains, reducing global domestic product (GDP) and hampering economic growth (Onyango, 2024; Singh et al., 2021). The impact of this pandemic on supply chains is higher than any other previous outbreak, such as the 2009 H1N1 and 2014 Ebola outbreaks, as supply chains have been exposed to multi-regional risks (Agca et al., 2023; Koonin, 2020). This study used the Bangladesh apparel industry as the context. This context is deemed relevant due to the global nature of Bangladesh’s apparel supply chains, making them susceptible to multi-regional risks on both the upstream and downstream sides (Sen, 2020). We adopted a multi-methodological approach for this study. To investigate research objective (i), we used a qualitative approach. We employed the quality function deployment (QFD) technique to address research objective (ii) (Akao, 1990). To address research objective (iii), we used fuzzy set qualitative comparative analysis (fsQCA; Ragin, 2008). It should be mentioned that Study 1 informed Study 2, which then informed Study 3. fsQCA, which is a set-theoretic approach, allows for the identification of configurations of conditions that are sufficient to produce high-level outcomes (in our case, SCP). Researchers in the business/management domain argue that the configurational approach is a better way of understanding organizational performance outcomes than the isolated net effects of various antecedents (Misangyi & Acharya, 2014). In the current study, we deductively drove the causal conditions (supply chain risk and SCRES strategies) from Study 2 (QFD approach) and then inductively combined them to explore which configurations would lead to a high level of SCP. Therefore, the methodological approach used in this study is unique.

This study contributes substantially to the literature. First, relying on multi-methodological approaches, the study offers a decision model for modeling resilience strategies to better manage supply chain risks and performance. The findings provide alternative configurations of resilience strategies for managing the risk factors associated with severe disruption. The findings will contribute to our knowledge of flexible resilience strategies. Second, using fsQCA, a set-theoretic and configurational approach, the study also opens up a new methodological avenue for supply chain risk management. Finally, we demonstrate that improving SCP requires the implementation of a recipe of resilience strategies along with a recipe of risk negation. Managing risks and implementing resilience strategies in isolation is insufficient to create a high level of SCP. Thus, our study addresses the gaps in the risk management and resilience literature by providing a decision model that considers the combined effects of risks and resilience strategies on SCP.

The remainder of the paper is organized as follows. Section “Literature Review” presents a review of the existing literature, followed by a discussion on the methodology employed in the study. Next, information on the data analysis and the results are presented, followed by a discussion on the findings and their implications. Finally, the last section outlines the limitations of the current study and discusses the potential scope of further research.

Literature Review

This section reviews the extant literature on supply chain risk factors raised by the COVID-19 pandemic. It then reviews the potential resilience strategies to overcome the risk factors. Finally, the concept of SCP and the theoretical foundation of this study are provided.

COVID-19 Pandemic and Supply Chain Risk Factors

Researchers have noted many risk factors that have arisen from the COVID-19 pandemic, all of which have moved through supply chains, from sourcing the materials to delivery of the final products to the customers. For example, a recent study by Paul et al. (2023) documented and analyzed various operational challenges raised by this pandemic in electronic supply chains. Another study by Ghadir et al. (2022) listed and evaluated supply chain risks under various categories such as demand, supply, logistical, political, manufacturing, financial and information risks caused by this pandemic in the context of the automotive industry in Iran. Similarly, Bastas and Garza-Reyes (2022) identified the influence of this pandemic on the operations of manufacturing firms across various industries.

In general, the COVID-19 pandemic has disrupted every area of the supply chain (Shafi et al., 2022). On the sourcing side, there is a substantial shortage of the raw materials required to produce the products (Ghadir et al., 2022; van Hoek & Dobrzykowski, 2021). This material crisis has been ongoing since the outbreak began in China, as China is the primary source of raw materials for many manufacturing firms in different industries worldwide (Koonin, 2020; Lalon, 2020). This material crisis has forced many apparel firms across the globe to shut their operations in production facilities. For example, a study by Sen (2020) reported that 20 percent of apparel factories in Myanmar have closed due to the material crisis. Moreover, reductions in manufacturing capacity due to limited hours of operation (Mollenkopf et al., 2020) and employee shortages due to a need for employees to maintain social distance in the workplace have been reported in prior studies (Mollenkopf et al., 2020).

Transportation has also been disrupted, including delays/longer lead times and shutdown of one or more modes of transportation. Significant delays in local transportation systems have been reported due to restrictions on vehicle movement (Singh et al., 2021). On the other hand, cross-border trade has been disrupted due to restrictions on international transportation and the movement of cross-border goods (Nikolopoulos et al., 2021). Moreover, traditional physical distribution networks have been unable to distribute products in line with government policies (Ketchen & Craighead, 2020). Similar to other supply chain areas, demand has also been severely disrupted. Fluctuations in demand for products are commonly reported in studies on the COVID-19 pandemic (Ketchen & Craighead, 2020; Singh et al., 2021). Comparing 23 different risk factors, including the pandemic, natural calamities, financial risk and institutional risk in the context of the Indian apparel industry, Dohale et al. (2023) found that demand uncertainty is the second most critical risk factor. Further, order cancellations from buyers, including big international brands, have been reported for apparel products not deemed critical during the COVID-19 pandemic (Sen, 2020). As a result of fluctuations in demand, prices of products and their associated materials have also changed. For example, the price of high-demand goods and their materials has increased (Gupta et al., 2020), and that of low-demand goods has decreased (Arezki & Nguyen, 2020). In addition to the functional areas of supply chains, this pandemic has disrupted supply chain relationships and collaborations (Ketchen & Craighead, 2020).

Due to the above-mentioned risk factors, the financial stability of supply chains, especially apparel supply chains, has decreased considerably. Many small- and medium-sized apparel manufacturers have been struggling to manage working capital (Lalon, 2020). Moreover, many apparel producers have been struggling to receive payments from their buyers, as buyers have also been hit hard by the pandemic (Sen, 2020). All such risk factors could lead to a total collapse of supply chain systems (Ivanov & Dolgui, 2020; Mollenkopf et al., 2020). Due to a lack of preparedness, many supply chains were not equipped with appropriate defenses against such risk factors and could not respond to this extraordinary disruption. Based on the extensive literature review conducted for this study, a summary of risk factors arising from the COVID-19 pandemic is presented in Table 1.

Supply chain Resilience Strategies

Supply chain resilience has been defined in various ways (Hosseini et al., 2016). For example, Kamalahmadi and Parast (2016) described the concept using the capabilities required in different phases of a disruption, such as anticipation, resistance and the recovery and response phases. On the other hand, Hosseini et al. (2022) and Hosseini et al. (2019) conceptualized SCRES using absorptive, adaptive and restorative capacities of a supply chain system. While many other forms of SCRES conceptualization exist in the literature, proactive and reactive measures are commonly used when explaining SCRES capabilities (Bastas & Garza-Reyes, 2022) since Rose (2004) summarized economic resilience to disaster under mitigation and recovery management strategies. Proactive measures are undertaken in the pre-disruption period to minimize the probability of failure by predicting the potential disruptions and analyzing their reasons (Ozdemir et al., 2022). On the other hand, reactive measures are taken to respond and recover from a disruption. These measures help to reduce the immediate impacts of disruption and return to the pre-disruption state, or even a better state, quickly (Chowdhury & Quaddus, 2017).

Proactive measures or supply chain readiness (Chowdhury & Quaddus, 2016, 2017) have proven to be indispensable for many global supply chains. The unpredictable nature of global supply chain disruptions necessitates a proactive approach toward achieving supply chain resilience for epidemic or pandemic disruptions (Ivanov & Das, 2020). In this regard, it is critical to have a disruption orientation that acknowledges the fact that disruption can occur at any time and can affect one or more functional areas of supply chains (Queiroz et al., 2022a, 2022b). As a result, creating supply chain disruption alertness to detect sudden changes in any areas of a supply chain can lead to reconfiguring the supply chain to respond to the changes (Queiroz et al., 2022a, 2022b).

Many organizations found themselves in a better position during the peak of the COVID-19 outbreak due to early situational assessment and coordinated planning with key stakeholders (Azadegan et al., 2020). Kilpatrick and Barter (2020) from Deloitte Consulting suggest organizations should develop a continuity plan to better prepare for disruption. As readiness strategies, reducing the number of suppliers from the same location (van Hoek, 2020) and including risk measures in supplier selection (Gebhardt et al., 2022) have been found to be effective in the management of product supply. Moreover, a detailed supply chain mapping with both suppliers and customers for greater visibility and transparency has been found effective for building proactive resiliency (Gebhardt et al., 2022). Such mapping also enables the designing of a robust and optimum supply chain network. Companies are also increasingly integrating advanced technology and data analytics into their building of proactive SCRES capabilities. For example, Spieske and Birkel (2021) found that Industry 4.0 implementation holistically enables effective proactive risk management.

Many low-cost manufacturers from developing countries have reported that, due to a lack of demand, major international apparel retailers have used “Forced Majeure” to cancel existing orders without any compensation, which has plunged the lives of impoverished factory workers from developing countries into uncertainty (Majumdar et al., 2020). As a remedy for such uncertain order cancellation, many manufacturers establish a flexible contractual agreement with retailers where both parties’ interests will be protected. Organizations can implement redundancy strategies, such as a backup stock for critical items to maintain operations (Ivaov & Das, 2020). Supply chain decision-makers should consider securing backup cash and finance to maintain operational costs. Finally, to overcome the crisis of employee shortage during a disruption, companies need to concentrate on building the capabilities of the staff and developing a multi-skilled workforce (Majumdar et al., 2020).

While companies are equipped with various proactive measures, several reactive strategies have also worked for many supply chains across industries. Many manufacturers focus on a leaner production system for optimum usage of resources (Handfield et al., 2020). Moreover, companies also realized that the reconfiguration of production systems or even entire logistics and supply chain networks is required to respond to this pandemic. For example, taking the Bangladesh garment industry as a context, Munim et al. (2022) and Mostafiz et al. (2022) revealed that a global value chain restructuring is necessary for producers to respond to this pandemic. The importance of developing reconfigurable production systems for supply chain resilience is also highlighted (Linton & Vakil, 2020). This pandemic has exposed incompetence within the physical flow of many global manufacturers’ and retailers’ products (Ketchen & Craighead, 2020). Thus, detecting and eliminating weak links within a supply chain network (Golan et al., 2020) and maintaining real-time visibility (Ivanov & Dolgui, 2021) are required in response.

Meanwhile, Ozdemir et al. (2022) found that supply chain innovation and empowerment are the keys to responding to a global crisis. Resilient companies come out of their comfort zone to practice new things and ideas during a disruption. These companies also collaborate and share knowledge and information with supply chain partners to enhance resilient capabilities, thereby minimizing the impacts of the disruption (Juan et al., 2022). Based on an analysis of sixteen different indicators, Badhotiya et al. (2022) found that information sharing has the largest driving power to increase resilience. Many researchers have found that global organizations can take advantage during a pandemic by collaborating with their respective governments to establish social-safety policies and maintain liaison within the industry (Bastas & Garza-Reyes, 2022; Majumdar et al., 2020). Taking a long-term perspective, Gebhardt et al. (2022) have projected that by 2025, companies will focus more on bridging than buffering strategies for improving SCRES.

Moreover, deployment of the reserve inventory and capacity is suggested to reduce vulnerability (Bastas & Garza-Reyes, 2022). Response measures such as hiring local drivers and local logistics firms are also needed to ensure the continuity of transport and logistics during a global crisis (Bastas & Garza-Reyes, 2022). In addition, effective health and safety measures for workers and regular communication with employees regarding wellbeing should be adopted during a pandemic period (Ivanov, 2020; Majumdar et al., 2020). Based on the literature outlined above, a summary of resilience strategies to mitigate various risk factors is presented in Table 2.

A combination of both proactive and reactive measures can be more effective in enhancing SCRES (Ozdemir et al., 2022). For example, Bastas and Garza-Reyes (2022) reported that several proactive measures (e.g., local and regional sourcing and technological integration) and reactive measures (e.g., supply chain collaboration, utilization of reserve inventory and capacity and continuity of transport and logistics) are effective for manufacturers to overcome the influence of this pandemic. Therefore, the major challenge for supply chain managers has always been to adopt the right set of strategies that can be implemented throughout the supply chain network. There is no doubt the future of the global economy will be highly influenced by the country-specific political policy (e.g., trade wars between countries) that shapes the dynamics of global supply chain risk management (Veselovska, 2020). Therefore, depending on global value chain linkages, companies need to undertake different configurations of context-specific SCRES strategies during a disruption (Shafi et al., 2022).

In measuring and offering SCRES strategies, quantitative methods are commonly used. For example, a recent review article by Chowdhury et al. (2021) reported that mathematical modeling is most commonly used in the supply chain disruption literature, including research on epidemic disruption. Hosseini et al. (2019) reviewed the quantitative methods used in SCRES research and found that mathematical and optimization modeling, Bayesian network modeling, structural equation modeling, Markov chain modeling and multi criterial decision-making approaches have been used thus far in this area. While mathematical modeling is extensively used in the literature, Bayesian networks, which are probabilistic graphical models, have been found to be powerful and effective in studies on risk and resilience (Hosseini & Ivanov, 2020). A substantial number of studies have also used simulation to assess the impact of this disruption and develop SCRES strategies (Ivanov, 2020; Moosavi & Hosseini, 2021; Singh et al., 2021). Readers are directed to Bier et al. (2020), Fahimnia et al. (2015), Hosseini and Ivanov (2020), Hosseini et al. (2019) and Snyder et al. (2016) to further explore the use of methods and models in supply chain disruption and resilience literature.

On the other hand, in general, there is a lack of qualitative research on supply chain risk management (Bier et al., 2020). Considering this, we first conducted interviews with practitioners in the apparel industry to understand the risk factors caused by the COVID-19 pandemic and how the firms deal with these risks. Moreover, considering the importance of implementing multiple resilience strategies simultaneously (Snyder et al., 2016), we employed fsQCA to determine the set of SCRES strategies and to understand the combined effects of risk and resilience strategies on SCP.

Supply chain Performance

The term SCP has been conceptualized in various ways in previous studies (Flynn et al., 2010). Some studies, such as Beamon (1999) and Chang et al. (2019), recommend multi-factor measurement to conceptualize and capture SCP. Accordingly, these studies offer a framework for measuring SCP, which includes three main elements: resources, output and flexibility. Resource indicator refers to a firm’s ability to achieve composite efficiency or do the job with minimum resource requirements, such as inventory, equipment, energy, personnel and cost. Output refers to a firm’s ability to meet the quality, quantity and time (on-time delivery, responsiveness and response time) requirements of customers to ensure their satisfaction. Finally, flexibility refers to how well firms accommodate volume and schedule fluctuations or other uncertainties in supply chains to satisfy customers. Additionally, flexibility includes two sub-elements: range flexibility and response flexibility. While range flexibility refers to the extent to which operations can be changed with uncertainties and disruptions, response flexibility denotes the ease with which such changes can be implemented (Beamon, 1999).

On the other hand, considering the challenge of capturing multiple factors, many other studies, such as Chowdhury and Quaddus (2016) and Mani et al. (2018), conceptualized SCP as a single factor. However, these studies utilized multiple indicators that effectively capture the evaluation of supply chain management in the performance. This conceptualization not only overcomes the challenge of capturing multiple factors but also maintains completeness by addressing various performance dimensions. For instance, in conceptualizing and developing a scale for various factors, Chowdhury and Quaddus (2017) proposed six indicators to measure SCP: sales, cost, profit, customer satisfaction, on-time delivery and quality. These indicators assess the abilities of supply chains to maintain efficiency (cost and profit performance), meet customer requirements (quality, on-time delivery and customer satisfaction performance) and compete in a competitive environment (sales performance). The current study adopted this conceptualization and uses the measures provided by Chowdhury and Quaddus (2017) to refer to SCP. A summary of the key SCP indicators is presented in Table 3.

Theoretical Foundation

Based on the literature review above, it is evident that developing suitable resilience strategies is essential to minimize or negate supply chain risks and improve performance. These causal associations can be explained through the lens of dynamic capability (Teece, 2007). Dynamic capabilities denote the ability of a firm to integrate, build and reconfigure resources and competencies to navigate the challenges of rapidly changing environments and minimize business environmental risks (Chowdhury & Quaddus, 2017; Teece, 2007). Supply chains must also orchestrate their resources in designing resilience strategies to tackle the impact of disruption. Hence, using the tenets of dynamic capability, this study argues that the ability to design the SCRES strategies is a dynamic capability of a firm and its supply chain, contributing to the mitigation of risk factors caused by severe disruption and improving performance.

Severe disruptions, such as the COVID-19 pandemic, bring substantial challenges and risks to supply chains. During such disruption, rapid responses are essential for the survival of supply chains. Such a quick response requires the dynamic capabilities of firms and their supply chains to orchestrate both internal and external resources efficiently. For example, supply chains must build their ability to sense disruptions and their impacts to develop readiness and response strategies. Similarly, they also need to develop their capabilities to seize opportunities and reconfigure resources and strategies to recover and potentially surpass the pre-disruption state (Teece, 2007). Hence, SCRES has been considered a dynamic capability of firms and their supply chains (Chowdhury & Quaddus, 2017). Prior studies such as Belhadi et al. (2022) and Chowdhury et al. (2024) used dynamic capability to argue that supply chains need to build capabilities of sensing, seizing and reconfiguring resources to manage the impacts of disruptions and improve performance effectively. In line with these studies, we also used the dynamic capability view in our study to assert that.

-

The ability to formulate and implement appropriate SCRES strategies is a dynamic capability of firms and their supply chains; and

-

This dynamic capability (the ability to build SCRES strategies) assists supply chains in addressing risks caused by severe disruptions and improving SCP.

Methodology

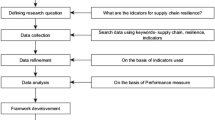

In the current study, we deployed a triangulated multi-method and multi-study research design, combining sequential qualitative and quantitative data collection strategies over three phases (Creswell & Poth, 2016) to ensure the reliability and validity of the research findings. In Phase 1 of the study, we adopted a qualitative approach to explore apparel supply chain risk factors and the corresponding resilience strategies implemented to mitigate those risks. More specifically, we used semi-structured interviews in this phase to identify risks caused by the COVID-19 pandemic and strategies to tackle such risks (Galletta, 2013). In Phase 2 of our study, we developed quantitative case studies to prioritize the risks and determine the most important strategies to mitigate apparel supply chain risks. In Phase 3 of our study, we adopted a configurational approach using fsQCA to determine the alternative portfolio of risk and SCRES strategies contributing to supply chain performance. As COVID-19—similar to any other severe disruption—has put global supply chains in a vulnerable position, managers need to design an idiosyncratic portfolio of risk and SCRES strategies to improve performance (Chowdhury et al., 2024). As a result, investigation of the appropriate configurations of risk and resilience strategies to improve performance is essential. Accordingly, we used fsQCA, a configurational approach, to analyze the configuration of strategies to explain SCP. We used primary data in all three phases of the study. However, the responses remain anonymous in all three phases.

Table 4 presents the systematic steps of the triangulated multi-method and multi-study research design, data collection and analysis process.

Study Phase 1 was aimed at identifying apparel supply chain risks arising from a severe disruption and the relevant strategies to mitigate those risks. In this regard, the COVID-19 pandemic was considered a severe risk incident. The qualitative data from semi-structured interviews were collected from 14 participants (consisting of apparel manufacturers and accessory suppliers) in Bangladesh. The demographic profiles of these respondents are provided in Appendix 1. A convenience sampling technique was used to select the interview participants. The rationale behind the use of convenience sampling is that key informants who are knowledgeable on the topic should be selected to ensure the reliability of the data (Zhu et al., 2008). The sample size for this study was not predetermined; however, after receiving interviews from 14 respondents, no further interviews were conducted, as no new themes emerged after the 14th interview. A comprehensive list of risks and mitigation strategies was developed by comparing the findings from the literature review and interviews.

Study Phase 2 was aimed at prioritizing risk factors and determining the most important strategies to overcome the relevant risk factors. In this regard, we conducted two case studies that comprised a case study involving an apparel manufacturer and an accessory producer in Bangladesh. Data were collected from supply chain decision-makers of the case companies using structured questionnaires. Case Study 1 was conducted on one of the leading manufacturers of jeans in Bangladesh. The firm started its manufacturing journey in 1984. It currently has six production units, employs over 33,000 employees, produces over 40 million jeans per year and exports to more than 25 countries in the world, including the USA, European countries and Japan. Given the volume of export and the geographically diverse market, this case company was selected to understand the impact of COVID-19 on medium- and large-scale apparel producers. Further, the case company was quite responsive and successful in withstanding the disruptions due to COVID-19. Case Study 2 was conducted on one of the largest accessory producers and suppliers in Bangladesh. It started its operation in the late 90 s with only 30 employees, and now it employs over 500 employees. The company produces various accessories such as fabric, thread, padding and buttons and supplies to more than 50 different apparel manufacturers. We selected this accessory supplier for our case study because of the volume and variety of supplies. Further, this supplying firm was successful in managing the disruptions associated with COVID-19.

We adopted QFD for the data analysis of the case studies because QFD is a popular tool for determining the most suitable strategies to be used to target relevant risk factors (Chowdhury & Quaddus, 2015). Figure 1 shows a QFD model where WHATs represent the apparel supply chain risks due to the COVID-19 pandemic and HOWs represent the strategies to mitigate those risks. The importance weights of WHATs (“Wi” in Fig. 1) were determined using the best–worst method (Rezaei, 2015).

Understanding the relationship between WHATs and HOWs (as shown by Rij values in Fig. 1) is a key step toward understanding to what extent given strategies (HOWs) are effective in mitigating risk (WHATs). To develop the WHAT-HOW relationship matrix, our respondents were asked on a scale of 1 to 9 (where 0 = no relation, 1 = very weak relation, 3 = weak relation, 5 moderate relation, 7 = strong relation and 9 = very strong relation) to what extent strategy “j” is effective in mitigating risk “i” (Chowdhury & Quaddus, 2015). In our case studies, we also determined the relationships among the strategies (shown by the roof matrix in Fig. 1) to understand how simultaneous implementation of two correlated strategies may save cost and time.

Study Phase 3 aimed to determine the suitable configuration/portfolio of risks and resilience strategies that can influence performance. In this regard, we adopted configurational analysis using fsQCA, as configurational analysis is highly suited to determining the best combination of strategies to achieve the desired goal (Roy et al., 2016). The literature reveals that fsQCA considers complex causal patterns among independent variables as well as addresses causal asymmetry (Roy et al., 2016; Woodside, 2014). Further, fsQCA is an effective tool for exploring the best causal conditions, which can alternatively be termed the combination of strategies leading to the outcome (Fiss, 2011). Thus, fsQCA addresses the complex causal patterns among the independent variables, which, in our research, are the risk factors and resilience strategies that determine the outcome/SCP.

Another key advantage of fsQCA is that it considers contrarian relationship cases between causal and outcome variables (Woodside, 2014). Therefore, it goes beyond traditional regression-type analysis and addresses the tenets of complexity theory (Woodside, 2014). The problem addressed in this research is complex, as many combinations of risks and resilience strategies may be formed to obtain the desired performance. Revealing such combinations is critical as this will bring flexibility to decision-makers to implement resilient strategies. Hence, fsQCA is an appropriate method for further analysis. For the fsQCA analysis, data were collected using a structured questionnaire (see Appendix 2), and 51 usable responses were obtained. It is worth mentioning that a fsQCA-based analysis is suitable for small- and medium-sized samples (Fiss, 2011). Therefore, the sample size used in this research is considered suitable for configurational analysis.

Analysis and Results

In this section, we present the results from the three study phases in three sub-sections, outlined below.

Study Phase 1: Identification of supply chain risk factors and resilience strategies From the semi-structured interviews, we identified 14 risk factors arising from a severe disruption (i.e., the COVID-19 pandemic) and 12 strategies to overcome those risk factors. The results from the interviews are presented in Table 5.

From the qualitative study, it was revealed that the risk factors and strategies derived from the literature review (Tables 1 and 2) were relevant to our contextual findings, which were derived from the interviews (see Table 5). However, some of the risk factors (e.g., R13 and R14) and strategies (e.g., St 9) in Table 5 appear new, as they were revealed in the context of the apparel supply chain in relation to the COVID-19 disruption.

Study Phase 2: Prioritization of supply chain risk factors and resilience strategies In this phase, we conducted two quantitative case studies using QFD to prioritize factors and SCRES. The findings of both case studies are provided below.

Case Study 1: Case Study 1 was conducted on an apparel manufacturing company in Bangladesh. A discussion was had with three decision-makers of the case company to complete the QFD matrix.Footnote 1 The findings from Case Study 1 are provided in Fig. 2. From Fig. 2, we can see that the most important risk factors were determined to be R3 (lack of purchase orders from buyers; weight = 0.1835), R4 (order cancellation; weight = 0.1260), R1 (lack of alternative sources of supply; weight = 0.0840), R9 (factory closure due to lockdown; weight = 0.0840) and R12 (border closure in supplier country; weight = 0.0840).

We also found that the most important strategies were St6 (alternative market), St8 (resource redundancy), St3 (sourcing flexibility) and St9 (fund for post-pandemic operations), with absolute importance (A.I) values of 7.155, 6.066, 5.729 and 5.044, as well as relative importance (R.I) values of 0.156, 0.132, 0.125 and 0.110, respectively.

Case Study 2: Case Study 2 was conducted on an accessory-producing company that supplies accessories to apparel manufacturers. We discussed with three decision-makers in the case company and collected the required data to complete the QFD matrix. The findings from Case Study 2 are provided in Fig. 3.

From Fig. 3, it is evident that the most important risk factors are R3 (lack of purchase orders from buyers; weight = 0.157), R10 (high price of raw materials; weight = 0.143, R4 (order cancellation; weight = 0.129), R9 (factory closure due to lockdown; weight = 0.101) and R6 (lower working capital; weight = 0.087). We also found that the most important strategies were St7 (business continuity planning; relative importance weight = 0.135), St8 (backup resource; relative importance weight = 0.134), St6 (alternative market; relative importance weight = 0.128), St3 (sourcing flexibility; relative importance weight = 0.124) and St5 (trust building; relative importance weight = 0.107).

Study Phase 3: Development of the alternative configuration of resilience strategies

In this section, we further analyze the data examined using the fsQCA method. Notably, the objective of this research was to explore the alternative configuration of resilience strategies to overcome the risks arising from a severe disruption to improve SCP. fsQCA is a configurational approach that explores the necessary and sufficient configurations of causal conditions leading to relevant outcomes (Fiss, 2011). Hence, fsQCA was used to determine the alternative configurations of resilience strategies that could be used to mitigate risks toward improving SCP. The findings will provide flexibility to managers as they can use a configuration that is best suited to their firms.

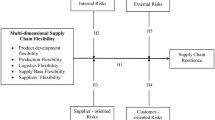

For the fsQCA analysis, we followed on from the important risks and SCRES strategies explored from case studies 1 and 2 through the use of QFD. It was found that an overlap existed between the resilience strategies and risks identified in both Study 1 (an apparel manufacturing company) and 2 (an apparel accessory production company). Taking a set-theoretic union approach, the combined list of risk factors is as follows: R1, R3, R4, R6, R9, R10 and R12. Accordingly, the combined list of SCRES strategies is as follows: St3, St5, St6, St7, St8 and St9. Taking a fsQCA approach, our objective was then to identify the configurations of SCRES strategies (Sts) that negate the necessary and sufficient configuration of risk (Rs) toward maximally improving SCP. Figure 4 shows the model that was used when the fsQCA approach was taken.

It is worth mentioning that the model can be executed by any regression-type approach (e.g., structural equation model); however, we chose to use fsQCA for the reasons discussed in the methodology section. Consistent with our objectives, Fig. 4 presents the three fsQCA models used. The corresponding equations are shown below. Notably, the bubble resilient strategy contains the combined list of resilient strategies obtained from Phase 2. In contrast, the bubble negation of risk comprises the combined list of negation of risks from Phase 2. The performance indicators are taken from Table 3.

Supply chain performance (SCP) = f (~ R).

SCP = f (St).

~ R = f (St).

Notably, the model SCP = f(~ R, St) could not be implemented, as “St” is an antecedent of ~ R; hence, the configuration of risk negation (~ R) and resilience strategy (St) to support SCP was not a meaningful one.

Before conducting the fsQCA analysis, we ran a series of cross-tabulations of the various risks and SCP items. Numerous studies support the notion that the negation of risks can improve SCP (see, e.g., Mishra et al., 2016; Wagner & Bode, 2008). However, our cross-tabulation revealed some contrarian cases. For example, the cross-tabulation result of R1 (lack of alternative sources of supply) and SCP 1 (delivery products within the desired lead time) revealed that 17.8 percent of the respondents agreed or strongly agreed that R1 is a significant issue. Despite this, they still agreed or strongly agreed that SCP 1 is very much achievable (contrarian case). Similarly, the cross-tabulation of the result of R9 (factory closure due to lockdown) and SCP 1 revealed that approximately 13.2 percent of respondents believed R9 was a significant issue. Despite this, however, they also believed that SCP 1 is very much achievable (contrarian case). Given that fsQCA can deal with the contrarian cases of relationship, it was considered an appropriate method for this study.

Configurations from the fsQCA

The results from the fsQCA analysis using the models as per Fig. 4 are outlined in Table 6.

The results of the FsQCA were evaluated for consistency and coverage. Regin (2008) states that consistency is equivalent to the concept of significance in the statistical sense of a configuration and, to be meaningful, should be > 0.8. On the other hand, coverage refers to the empirical relevance or importance of a configuration (Regin, 2008). It is believed that a configuration can be of a higher consistency with lower coverage and vice versa.

The model SCP = f (~ R) produced five risk configurations (the cr’s) and their negations to yield a high score for SCP. Two of the configurations had a perfect consistency score of 1. However, their unique coverages were found to be on the low side. The most promising configuration of this model was identified as cr12* ~ cr10*cr9* ~ cr6*cr4*cr3* ~ cr1, with a high consistency score of 0.945 and reasonable raw coverage of 0.22. This configuration can be interpreted as follows: accept cr12 (border closure in supplier country) as they are, negate cr10 (high price of raw materials—e.g., the source for low-cost raw materials), accept cr9 (factory closure due to lockdown), negate cr6 (low working capital—e.g., increase working capital), accept cr4 (order cancellation), accept cr3 (lack of purchase order) and negate cr1 (lack of alternative sources of supply—e.g., source from alternative/extra suppliers). Essentially, this configuration is ~ cr10* ~ cr6* ~ cr1—that is, strategies developed to counter risks 1, 6 and 10. Further examination of this configuration revealed that it had a consistency score of 0.95 and coverage of 0.5. Hence, configuration ~ cr10* ~ cr6* ~ cr1 was found to be the most effective configuration for improving SCP.

The model SCP = f (St) produced two strategy configurations (St’s) to produce a high SCP score. Both configurations were found to have high coverage (0.866 and 0.865) but low consistencies (0.638 and 0.603). Hence, these configurations were insufficiently significant to elevate SCP. From these results, it can be said that improving SCP through the use of mitigation strategies alone does not produce the desired results. Hence, the negation of risk needs to be achieved to improve SCP. The question now becomes, which configuration of strategies can reduce risk?

The model ~ R = f (St) produced two configuration strategies that were found to have high consistencies (0.898 and 0.9) and coverage (0.83 and 0.877). For example, one of the configurations was identified as cst9*cst7*cst6*cst5*cst3 (C = 0.9 RC = 0.877), which calls for implementing strategies 9 (funding post-pandemic businesses), 7 (business continuity planning), 6 (sourcing alternative market), 5 (trust building) and 3 (sourcing flexibility). This configuration can lead to a significant and strong negation of risk. In model SCP = f (~ R), we observed that the negation of risk resulted in significant improvement in SCP.

Discussion and Implications

Discussion of Findings

Using the apparel industry in Bangladesh, this study (a) Comprehensively identified supply chain risk factors arising from a severe disruption, as well as potential resilience strategies to deal with such risk factors; (b) Prioritized the risk factors and strategies; and (c) Identified the alternative configuration of strategies that reduced the risks associated with a severe disruption and improved SCP. By providing alternative configurations of a resilience portfolio, the findings bring flexibility to decision-makers when undertaking resilience strategies during severe disruptions.

The results of the semi-structured interviews in stage one revealed that (1) Apparel supply chains had been affected by numerous (14) risk factors during the severe disruption of the COVID-19 pandemic. This finding is consistent with other recent studies, such as Chowdhury et al. (2023), Mostafiz et al. (2022) and Sen (2020), who also documented the impacts of COVID-19 on the apparel sector of Bangladesh. The findings of all these studies suggest that the COVID-19 pandemic has had, and continues to have, multi-dimensional impacts on Bangladesh’s apparel supply chains. In other words, the Bangladeshi apparel sector is more susceptible to various risk factors during a severe disruption. This is likely because apparel supply chains are complex and involve partners from many countries across continents (Hira & Benson-Rea, 2017). In particular, both upstream and downstream networks of Bangladesh’s apparel industry include global partners. Such a supply chain configuration is prone to multi-regional risks (Sen, 2020).

Moreover, throughout the COVID-19 pandemic, lockdowns and restrictions have been imposed at various times in different countries. Consequently, apparel supply chains have been the most affected and have been exposed to several risk factors, as one or more of the relevant partners have been unable to function simultaneously. This finding is consistent with Ivanov (2020): the timing of facility closures and reopenings at different levels in the supply chain has determined the extent of losses in the system throughout the pandemic period. In documenting the risks caused by a severe disruption, our findings reveal two new risk factors: a lack of awareness of management and employees regarding health and safety (R13) and a lack of top management leadership in handling new risk factors (R14). This comprehensive investigation of risk factors will help in the formulation of SCRES strategies.

This study also identified 12 resilience strategies to combat the risk factors. This finding suggests that a single resilience strategy has been insufficient to combat the various risk factors throughout the pandemic period—instead, a combination of strategies is required. This observation is consistent with Ali et al. (2021), Chowdhury et al. (2023) and Su et al. (2022), who also suggest that apparel supply chains need a holistic resilience approach that combines several strategies to manage risks caused by a severe disruption. Our findings indicate that some strategies, such as backup resources (St8) and leaning capacity to minimize loss during low-demand periods (St10), help to overcome the immediate shock of severe disruption temporarily. On the other hand, other resilient strategies, such as alternative markets (St6) and sourcing flexibility (St3), strengthen resilience through structural changes in supply chains. Our results echo the findings of Mostafiz et al. (2022), who revealed that the COVID-19 disruption led to three dynamics in the restructuring of the global apparel value chain. The first dynamic is temporal changes for minimizing immediate shocks, while the other two are structural and spatial changes to build robust and resilient apparel supply chains. Similar to risk factors, our findings reveal the new resilience strategies (e.g., funds for post-pandemic business operations [St9)]) required to overcome the challenges of severe disruption.

The quantitative analysis in Stage 2 provides the ranking of the risk factors and potential strategies based on two case studies. The results of the first case study, Case Study 1, which was conducted with an apparel manufacturing firm, revealed that a lack of purchase orders from buyers, order cancellation, a lack of alternative sources of supply, factory closure due to lockdowns and border closures in the supplier country were the five most critical risk factors. On the other hand, the results of the second case study, Case Study 2, which was conducted on an apparel accessory-producing company, showed that among the top-five risk factors, only three overlapped with Case Study 1 and two were new—namely, the soaring prices of raw materials and lower working capital. Based on our knowledge, this is the first study that ranks the risk factors for both apparel manufacturers and accessory suppliers during a severe disruption. Differences in the ranking of risk factors for apparel manufacturers and suppliers suggest that all partners in a supply chain do not face the same challenges during a severe disruption. This understanding can help to guide the formulation of SCRES strategies. When comparing the findings with that of Paul et al. (2023), whose study was conducted in the context of the electronic industry, we noted that some of the five most critical risk factors of our study were not in their five most critical operational challenges. Paul et al. (2023) found that overstock of goods, low final consumer demand, order cancellation from dealers and retailers, high inventory holding cost and a lack of transportation were the five most critical challenges that the electronics industry faced during the COVID-19 pandemic. Only two challenges, the lack of purchase orders and order cancellation, were common in both studies [the current study and that of Paul et al. (2023)] in the five most critical risk factors. This result denotes that the COVID-19 pandemic poses different challenges across different industries.

Similarly, three strategies (alternative market, sourcing flexibility and business continuity planning) were found to be common among the top-five most effective strategies in the two case studies conducted in this research. These results are consistent with the findings of Sarkar and Kumar (2015): the benefit of a strategy is not the same as the different echelons of a supply chain. Unlike Chowdhury et al. (2023), who suggest that government support and policy constitute the most important strategy to manage the impacts of severe disruption, our results indicate that flexibility in the supply chain, specifically in the upstream supply chain, is vital for building a resilient supply chain. For example, our findings in Phase 2 revealed that sourcing flexibility is critical for apparel manufacturing and accessory manufacturing firms to remain resilient during a severe disruption.

The significant finding from the configurational analysis in Stage 3 using fsQCA was that resilience strategies alone do not ensure performance; rather, risk negation and the simultaneous implementation of resilience strategies generate the best outcomes for apparel manufacturers toward improving their performance. Based on our knowledge, this is the first empirical study investigating the configuration of risk and resilience strategies for improving SCP. The results suggest that while firms should accept some risks, they need appropriate strategies for reducing other risk factors. In terms of reducing risk, two alternative configurations offer strong consistency and coverage, meaning that they both could significantly reduce risks to enhance SCP. These findings enable firms to remain flexible in implementing SCRES strategies as they can decide which configuration is most suitable for them. Notably, the common strategies in these two configurations were strategy 9 (fund for post-pandemic business operations), 7 (business continuity planning), 6 (alternative market) and 3 (sourcing flexibility). Implementing these strategies enables apparel firms in developing nations, particularly those in Bangladesh, to overcome the challenges posed by resource constraints, order cancellations and material crises experienced in relation to COVID-19 (Ali et al., 2021; Su et al., 2022). Hence, managers should simultaneously implement these strategies to reduce pandemic-related risk.

On the other hand, they can be flexible in implementing strategy 5 (trust building) or 8 (backup resources). In line with the observations of Snyder et al. (2016), the findings of the current study indicate that the implementation of one strategy is not effective in improving performance—this, instead, requires a portfolio of strategies. As mentioned in the results and analysis section of this paper, the configuration of ~ cr10* ~ cr6* ~ cr1 (i.e., the negation of risks 10, 6 and 1 simultaneously) can significantly improve SCP, while other risks are accepted. Therefore, practitioners in supply chains should simultaneously negate risk and implement SCRES strategies to manage performance during a severe disruption.

Theoretical and Managerial Implications

The findings of the current study substantially contribute to knowledge in the area of supply chain resilience and risk management. Our contribution spans four areas. First, we synthesized the most recent literature on supply chain risk for the apparel supply chain arising from a severe disruption, namely COVID-19, and the strategies needed to enhance resilience. Second, we identified the main risk factors to which apparel supply chains have been exposed during the pandemic period. The findings suggest that apparel supply chains face diverse risk factors on both the upstream and downstream sides due to their complexity and the involvement of multiple partners across continents. Third, we determined the most important resilience strategies to mitigate risk factors. Fourth, this study proposed a decision model developed based on multiple studies and multiple methods to unveil a complex relationship between the most critical risk factors, resilience strategies and SCP during the pandemic period. Our model revealed that the combination of risk negation and resilience strategies could optimize SCP in the context of a pandemic, a novel finding in the literature on supply chains. This result indicates that apparel supply chains must accept some risk factors. For example, during a severe disruption, people focus more on emergencies than fashion products. As such, apparel supply chains must accept the lack of purchase orders from buyers (R3) and order cancellation (R4).

The configural principle adopted in this study also supports the complexity theory tenets that Woodside (2014) advocates. One such complexity is managing the existing contrarian cases via the configural principle. Our fsQCA results revealed that some risks can be accepted to enhance SCP if this is combined with negating other risks. For example, we found that the combination of cr12* ~ cr10*cr9* ~ cr6*cr4*cr3* ~ cr1 enhanced SCP with strong consistency and coverage. This combination accepts risks 12, 9, 4 and 3 but negates risks 10, 6 and 1 to achieve a high level of SCP. This is a unique contribution to the literature on supply chain management. The configural approach used in this study thus contributes significantly to the theory. Moreover, our study is one of the first that empirically shows alternative configurations of resilience strategies to minimize risks. These findings can contribute to the knowledge of flexible resilience strategies.

In terms of managerial implications, apparel supply chain managers can benefit by following the approach taken in the current study toward identifying and prioritizing risks by combining the configuration of resilience strategies to address those risks and improve performance. Our research approach and findings can assist managers in the apparel industry to prioritize risk factors and resilience strategies during a severe disruption. Further, our research approach enables supply chain managers to identify a context-specific configuration of risks and resilience strategies to improve performance during severe disruptions such as the COVID-19 pandemic. Therefore, apparel supply chain managers can determine the right combination of strategies to manage the risks associated with a severe disruption while also maintaining performance. Further, the approach enables managers to identify the complex causal relationship between risks, resilience strategies and performance to identify the most suitable combination of strategies.

Based on the study findings, managers also suggested there should be a focus on both risk negation and resilience strategy development toward improving SCP. For instance, our findings highlight the necessity for Bangladesh’s apparel firms to negate R1 (lack of alternative sources of supply). This underscores the industry’s heavy reliance on a single market, primarily China, for sourcing materials. In times of severe disruption, enhancing sourcing flexibility through local sourcing or diversifying the sourcing market becomes crucial. The two most suitable configurations of strategies provided in this study could assist them in determining the combination of strategies that would best safeguard their supply chain. These findings can help decision-makers remain flexible in building a resilient supply chain as they can decide from these two configurations. The findings can also help them use resources optimally as they can easily see which combination of strategies should be used to tackle a severe disruption.

Conclusion and Future Research

Using a multi-method and multi-study approach, this study determined a suitable configuration of risks and resilience strategies for managing the SCP of the apparel industry of Bangladesh based on the experiences associated with a severe disruption, namely COVID-19. Our study findings revealed that implementing resilience strategies alone was ineffective in improving performance. In contrast, a combination of resilience strategies and the nullification of risk factors was required to improve SCP. Our unique finding enriches the current body of supply chain risk management knowledge. Our results also offer significant value to supply chain managers, specifically apparel supply chain managers, by showing that they can be flexible in deciding a combination of resilience strategies for improving SCP. Moreover, the findings provide a systematic and holistic approach to managing resilience capability and improving performance during a global crisis.

While this study has many merits, it also has several limitations. First, the generalizability of the study’s findings is limited. The study was conducted in the context of the apparel supply chain in Bangladesh, which means the findings may not be generalizable to other supply chains or country contexts. Hence, future research in the context of the supply chains of other products could be conducted. Moreover, future research could be undertaken in the context of other countries where the institutional setting is different from that of Bangladesh. Second, the data for each phase of this study were gathered at a single point in time. Generally, severe disruptions, such as the COVID-19 pandemic, will continue for a prolonged period and pose different challenges in the response and recovery phases of resilience strategies. Hence, we suggest a longitudinal study during a severe disruption to explore resilience strategies and their impacts on SCP at different periods.

The other limitations of this study are related to the data collection and sampling process. For example, we used convenience sampling to select interviewees. We recommend future studies adopt a random sampling approach in selecting respondents. Moreover, for the fsQCA study, our usable sample size was 51 and, consequently, the subgroup sizes (i.e., apparel manufacturers and their suppliers) were somewhat inadequate for the multi-group fsQCA test. However, a subgroup analysis could explore a more specific portfolio of strategies for both manufacturers and their suppliers toward enhancing SCP. Hence, a fsQCA-based future study could be conducted with larger samples to provide a detailed subgroup analysis. In our decision model, the input for the fsQCA method was based on QFD. However, data collection and analysis in the QFD method are highly time-consuming and rigorous. As a result, conducting a large number of case studies is difficult with this method (Chowdhury & Quaddus, 2015). In addition, cooperation and consensus among the QFD team members (i.e., case company decision-makers who were involved in data collection) are also challenging (Wolniak, 2018). As such, this research analyzed the risk factors and resilience strategies in Study 2 based on limited case companies. Therefore, future research should focus on larger sample sizes to develop innovative decision models for effectively managing performance in highly uncertain crises.

Notes

For the sake of brevity, detail on the full data collection process for all QFD matrices is not presented in this paper. However, this information is available upon request.

References

Agca, S., Birge, J. R., Wang, Z., & Wu, J. (2023). The impact of COVID-19 on supply chain credit risk. Production and Operations Management, 32(12), 4088–4113. https://doi.org/10.2139/ssrn.3639735

Akao, Y. (1990). Quality function deployment (QFD): Integrating customer requirements into Product Design. Productivity Press.

Ali, M., Rahman, S. M., & Frederico, G. F. (2021). Capability components of supply chain resilience for readymade garments (RMG) sector in Bangladesh during COVID-19. Modern Supply Chain Research and Applications, 3(2), 127–144. https://doi.org/10.1108/mscra-06-2020-0015

Anner, M. S. (2020). Abandoned? The impact of Covid-19 on workers and businesses at the bottom of global garment supply chains. Pennstate Center forGlobal Workers’Rights (CGWR). https://www.researchgate.net/publication/340460592_Abandoned_The_Impact_of_Covid-19_on_Workers_and_Businesses_at_the_Bottom_of_Global_Garment_Supply_Chains

Ardolino, M., Bacchetti, A., & Ivanov, D. (2022). Analysis of the COVID-19 pandemic’s impacts on manufacturing: A systematic literature review and future research agenda. Operations Management Research, 15, 551–566.

Arezki, R., & Nguyen, H. (2020). Novel coronavirus hurts the Middle East and North Africa through many channels. In R. Baldwin & B. W. di Mauro (Eds.), Economics in the Time of COVID-19 (pp. 109–112). www.cepr.org.

Azadegan, A., Parast, M. M., Lucianetti, L., Nishant, R., & Blackhurst, J. (2020). Supply chain disruptions and business continuity: An empirical assessment. Decision Sciences, 51(1), 38–73.

Badhotiya, G. K., Soni, G., Jain, V., Joshi, R., & Mittal, S. (2022). Assessing supply chain resilience to the outbreak of COVID-19 in Indian manufacturing firms. Operations Management Research, 15, 1161–1180.

Bastas, A., & Garza-Reyes, J. A. (2022). Impact of the COVID-19 pandemic on manufacturing operations and supply chain resilience: Effects and response strategies. Journal of Manufacturing Technology Management, 33(5), 962–985.

Baveja, A., Kapoor, A., & Melamed, B. (2020). Stopping Covid-19: A pandemic-management service valuechain approach. Annals of Operations Research, 289(2), 173–184.

Beamon, B. M. (1999). Measuring supply chain performance. International Journal of Operations & Production Management, 19(3), 275–292.

Belhadi, A., Kamble, S., Jabbour, C. J. C., Gunasekaran, A., Ndubisi, N. O., & Venkatesh, M. (2021). Manufacturing and service supply chain resilience to the COVID-19 outbreak: Lessons learned from the automobile and airline industries. Technological Forecasting and Social Change, 163, 120447.

Belhadi, A., Kamble, S. S., Venkatesh, M., Jabbour, C. J. C., & Benkhati, I. (2022). Building supply chain resilience and efficiency through additive manufacturing: An ambidextrous perspective on the dynamic capability view. International Journal of Production Economics, 249, 108516.

Bier, T., Lange, A., & Glock, C. H. (2020). Methods for mitigating disruptions in complex supply chain structures: A systematic literature review. International Journal of Production Research, 58(6), 1835–1856.

Chang, H. H., Wong, K. H., & Chiu, W. S. (2019). The effects of business systems leveraging on supply chain performance: Process innovation and uncertainty as moderators. Information & Management, 56(6), 103140.

Choi, T.-M. (2020). Innovative “Bring-Service-Near-Your-Home” operations under Corona-Virus (COVID-19/SARS-CoV-2) outbreak: Can logistics become the Messiah? Transportation Research Part E: Logistics and Transportation Review, 140, 101961.

Choi, T. M., & Shi, X. (2022). Reducing supply risks by supply guarantee deposit payments in the fashion industry in the “new normal after COVID-19.” Omega, 109, 102605.

Chowdhury, M. M. H., Mahmud, A. K. M. S., Banik, S., Rabbanee, F. K., Quaddus, M., & Alamgir, M. (2024). Resilience strategies to mitigate “extreme” disruptions in sustainable tourism supply chain. Asia Pacific Journal of Marketing and Logistics, 36(2), 408–434.

Chowdhury, M. M. H., & Quaddus, M. A. (2015). A multiple objective optimization based QFD approach for efficient resilient strategies to mitigate supply chain vulnerabilities: The case of garment industry of Bangladesh. Omega, 57, 5–21.

Chowdhury, M. M. H., & Quaddus, M. (2016). Supply chain readiness, response and recovery for resilience. Supply Chain Management: An International Journal, 21(6), 709–731.

Chowdhury, M. M. H., & Quaddus, M. (2017). Supply chain resilience: Conceptualization and scale development using dynamic capability theory. International Journal of Production Economics, 188, 185–204.

Chowdhury, N. R., Janan, F., Mahmud, P., Liza, S. A., & Paul, S. K. (2023). Assessing strategies to mitigate the impacts of a pandemic in apparel supply chains. Operations Management Research, 23, 1–17.

Chowdhury, P., Paul, S. K., Kaisar, S., & Moktadir, M. A. (2021). COVID-19 pandemic related supply chain studies: A systematic review. Transportation Research Part E: Logistics and Transportation Review, 148, 102271.

Christopher, M., Mena, C., Khan, O., & Yurt, O. (2011). Approaches to managing global sourcing risk. Supply Chain Management: An International Journal, 16(2), 67–81.

Creswell, J. W., & Poth, C. N. (2016). Qualitative inquiry and research design: Choosing among five approaches (4th ed.). Sage publications.

Dhillon, M. K., Rafi-ul-Shan, P. M., Amar, H., Sher, F., & Ahmed, S. (2023). Flexible green supply chain management in emerging economies: a systematic literature review. Global Journal of Flexible Systems Management, 24(1), 1-28.

Dohale, V., Verma, P., Gunasekaran, A., & Ambilkar, P. (2023). COVID-19 and supply chain risk mitigation: A case study from India. International Journal of Logistics Management, 34(2), 417–442.

Dwivedi, A., Srivastava, S., Agrawal, D., Jha, A., & Paul, S. K. (2023). Analyzing the inter-relationships of business recovery challenges in the manufacturing industry: Implications for post-pandemic supply chain resilience. Global Journal of Flexible Systems Management, 24(Suppl 1), S31–S48.

Elliott, R., Garcia, M. F. L., & Riglietti, G. (2023). Supply chain resilience report 2023.

Fahimnia, B., Tang, C. S., Davarzani, H., & Sarkis, J. (2015). Quantitative models for managing supply chain risks: A review. European Journal of Operational Research, 247(1), 1–15.

Faisal, M. N., Sabir, L. B., AlNaimi, M. S., Sharif, K. J., & Uddin, S. F. (2024). Critical Role of Coopetition among Supply Chains for Blockchain Adoption: Review of Reviews and Mixed-Method Analysis. Global Journal of Flexible Systems Management, 25(1), 117–136.

Fan, Y., & Stevenson, M. (2018). A review of supply chain risk management: Definition, theory, and research agenda. International Journal of Physical Distribution & Logistics Management, 48(3), 205–230.

Fiss, P. C. (2011). Building better causal theories: A fuzzy set approach to typologies in organization research. The Academy of Management Journal, 54(2), 393–420.

Flynn, B. B., Huo, B., & Zhao, X. (2010). The impact of supply chain integration on performance: A contingency and configuration approach. Journal of Operations Management, 28(1), 58–71.

Galletta, A. (2013). Mastering the semi-structured interview and beyond: From research design to analysis and publication. New York University Press.

Gebhardt, M., Spieske, A., Kopyto, M., & Birkel, H. (2022). Increasing global supply chains’ resilience after the COVID-19 pandemic: Empirical results from a Delphi study. Journal of Business Research, 150, 59–72.

Ghadir, A. H., Vandchali, H. R., Fallah, M., & Tirkolaee, E. B. (2022). Evaluating the impacts of COVID-19 outbreak on supply chain risks by modified failure mode and effects analysis: a case study in an automotive company. Annals of Operations Research. https://doi.org/10.1007/s10479-022-04651-1

Golan, M. S., Jernegan, L. H., & Linkov, I. (2020). Trends and applications of resilience analytics in supply chain modeling: Systematic literature review in the context of the COVID-19 pandemic. Environment Systems and Decisions, 40(2), 222–243.

Gunessee, S., & Subramanian, N. (2020). Ambiguity and its coping mechanisms in supply chains lessons from the Covid-19 pandemic and natural disasters. International Journal of Operations and Production Management, 40(7/8), 1201–1223.

Gupta, V., Ivanov, D., & Choi, T. M. (2020). Competitive pricing of substitute products under supply disruption. Omega, 101, 102279.

Han, Y., Chong, W. K., & Li, D. (2020). A systematic literature review of the capabilities and performance metrics of supply chain resilience. International Journal of Production Research, 58(15), 4541–4566.

Handfield, R. B., Graham, G., & Burns, L. (2020). Corona virus, tariffs, trade wars and supply chain evolutionary design. International Journal of Operations and Production Management, 40(10), 1649–1660.

Hira, A., & Benson-Rea, M. (2017). Governing corporate social responsibility in the apparel industry after Rana Plaza. New York: Palgrave Macmillan.

Hosseini, S., Barker, K., & Ramirez-marquez, J. E. (2016). A review of definitions and measures of system resilience. Reliability Engineering and System Safety, 145, 47–61.

Hosseini, S., & Ivanov, D. (2020). Bayesian networks for supply chain risk, resilience and ripple effect analysis: A literature review. Expert Systems with Applications, 161, 113649.

Hosseini, S., Ivanov, D., & Blackhurst, J. (2022). Conceptualization and measurement of supply chain resilience in an open-system context. IEEE Transactions on Engineering Management, 69(6), 3111–3126.

Hosseini, S., Ivanov, D., & Dolgui, A. (2019). Review of quantitative methods for supply chain resilience analysis. Transportation Research Part E: Logistics and Transportation Review, 125, 285–307.

Hudecheck, M., Siren, C., Grichnik, D., & Wincent, J. (2020). How companies can respond to the coronavirus. MIT Sloan Management Review. https://sloanreview.mit.edu/article/how-companies-can-respond-to-the-coronavirus/. Accessed 5 June 2020

Ishak, S., Shaharudin, M. R., Salim, N. A. M., Zainoddin, A. I., & Deng, Z. (2023). The effect of supply chain adaptive strategies during the COVID-19 pandemic on firm performance in Malaysia's semiconductor industries. Global Journal of Flexible Systems Management, 24(3), 439-458.

Ivanov, D. (2020). Predicting the impacts of epidemic outbreaks on global supply chains: A simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transportation Research Part E: Logistics and Transportation Review, 136, 101922.

Ivanov, D., & Das, A. (2020). Coronavirus (COVID-19/SARS-CoV-2) and supply chain resilience: A research note. International Journal of Integrated Supply Management, 13(1), 90–102.

Ivanov, D., & Dolgui, A. (2020). Viability of intertwined supply networks: extending the supply chain resilience angles towards survivability a position paper motivated by COVID-19 outbreak. International Journal of Production Research, 58(10), 2904–2915.

Ivanov, D., & Dolgui, A. (2021). OR-methods for coping with the ripple effect in supply chains during COVID-19 pandemic: Managerial insights and research implications. International Journal of Production Economics, 232, 107921.

Juan, S. J., Li, E. Y., & Hung, W. H. (2022). An integrated model of supply chain resilience and its impact on supply chain performance under disruption. International Journal of Logistics Management, 33(1), 339–364.

Kamalahmadi, M., & Parast, M. M. (2016). A review of the literature on the principles of enterprise and supply chain resilience: Major findings and directions for future research. International Journal of Production Economics, 171, 116–133.

Ketchen, D. J., & Craighead, C. W. (2020). Research at the intersection of entrepreneurship, supply chain management, and strategic management: Opportunities highlighted by COVID-19. Journal of Management, 46(8), 1330–1341.

Kilpatrick, J., & Barter, L. (2020). COVID-19: Managing supply chain risk and disruption. Deloitte.

Koonin, L. M. (2020). Novel coronavirus disease (COVID-19) outbreak: Now is the time to refresh pandemic plans. Journal of Business Continuity & Emergency Planning, 13(4), 1–15.

Lalon, R. M. (2020). COVID-19 vs Bangladesh: Is it possible to recover the impending economic distress amid this pandemic? Journal of Economics and Business, 3(2), 825–836.

Linton, T., & Vakil, B. (2020). Coronavirus is proving we need more resilient supply chains. Harvard Business Review, 5(5), 121–129.

Majumdar, A., Shaw, M., & Sinha, S. K. (2020). COVID-19 debunks the myth of socially sustainable supply chain: A case of the clothing industry in South Asian countries. Sustainable Production and Consumption, 24, 150–155.

Mani, V., Gunasekaran, A., & Delgado, C. (2018). Enhancing supply chain performance through supplier social sustainability: An emerging economy perspective. International Journal of Production Economics, 195, 259–272.

Misangyi, V. F., & Acharya, A. G. (2014). Substitutes or complements? A configurational examination of corporate governance mechanisms. The Academy of Management Journal, 57(6), 1681–1705.

Mishra, D., Sharma, R. R. K., Kumar, S., & Dubey, R. (2016). Bridging and buffering: Strategies for mitigating supply risk and improving supply chain performance. International Journal of Production Economics, 180, 183–197.

Mollenkopf, D. A., Ozanne, L. K., & Stolze, H. J. (2020). A transformative supply chain response to COVID-19. Journal of Service Management, 32(2), 190–202.

Moosavi, J., & Hosseini, S. (2021). Simulation-based assessment of supply chain resilience with consideration of recovery strategies in the COVID-19 pandemic context. Computers & Industrial Engineering, 160, 107593.

Mostafiz, M. I., Musteen, M., Saiyed, A., & Ahsan, M. (2022). COVID-19 and the global value chain: Immediate dynamics and long-term restructuring in the garment industry. Journal of Business Research, 139, 1588–1603.

Munim, Z. H., Mohammadi, M., Shakil, M. H., & Ali, S. M. (2022). Assessing measures implemented by export-oriented RMG firms in an emerging economy during COVID-19. Computers and Industrial Engineering, 165, 107963.

Nikolopoulos, K., Punia, S., Schäfers, A., Tsinopoulos, C., & Vasilakis, C. (2021). Forecasting and planning during a pandemic: COVID-19 growth rates, supply chain disruptions, and governmental decisions. European Journal of Operational Research, 290(1), 99–115.

Olya, H. G. T., & Akhshik, A. (2019). Tackling the complexity of the pro-environmental behavior intentions of visitors to turtle sites. Journal of Travel Research, 58(2), 313–332.

Onyango, J. O. (2024). Supply chain solutions for essential medicine availability during COVID-19 pandemic. Journal of Humanitarian Logistics and Supply Chain Management, 14(1), 118–133.

Ozdemir, D., Sharma, M., Dhir, A., & Daim, T. (2022). Supply chain resilience during the COVID-19 pandemic. Technology in Society, 68, 101847.

Paul, S. K., & Chowdhury, P. (2021). A production recovery plan in manufacturing supply chains for a high-demand item during COVID-19. International Journal of Physical Distribution and Logistics Management, 51(2), 104–125.